In the realm of modern agriculture, efficiency and effectiveness are paramount. The functionality of various machines plays a crucial role in optimizing the processes involved in crop management. A thorough comprehension of the elements that make up these mechanical devices can significantly enhance their operation and maintenance.

Farm implements are composed of numerous individual elements, each serving a specific purpose in the overall machinery. Recognizing how these components interconnect allows operators to troubleshoot issues, perform routine maintenance, and ultimately improve productivity. By exploring the structure of these tools, one gains insights into their design and operational mechanisms.

Visual aids can be instrumental in grasping the complexities of agricultural machinery. Detailed illustrations not only clarify the arrangement of components but also highlight essential functions and potential areas for service. Such resources serve as invaluable references for both novice and seasoned users, fostering a deeper appreciation for the intricacies involved in agricultural practices.

Kuhn Hay Tedder Overview

This section provides a comprehensive look at a versatile agricultural implement designed for optimal forage management. Its engineering ensures efficient operation, making it a valuable asset for farmers seeking to enhance their productivity during the harvesting process.

Key Features

- Robust construction for durability and longevity.

- Advanced technology for improved efficiency.

- Adjustable settings to accommodate various crop types.

- User-friendly controls for ease of operation.

Benefits of Utilization

- Enhances the drying process of grass and other crops.

- Reduces labor time with streamlined functionality.

- Increases the quality of harvested material through effective handling.

- Promotes soil health by optimizing the use of organic matter.

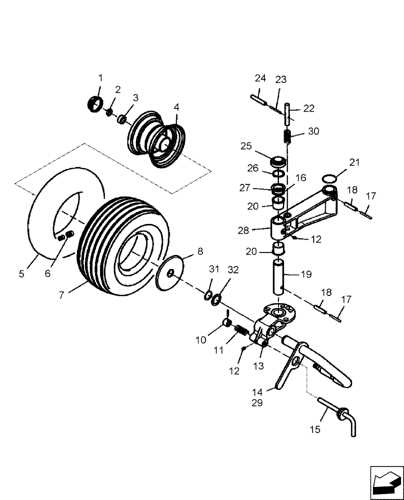

Key Components of Hay Tedders

Understanding the essential elements of these agricultural implements is crucial for optimal operation and maintenance. Each component plays a significant role in enhancing the efficiency and effectiveness of the machinery, contributing to better crop management and productivity.

| Component | Description |

|---|---|

| Frame | The structural backbone that supports all other elements, ensuring stability and durability during operation. |

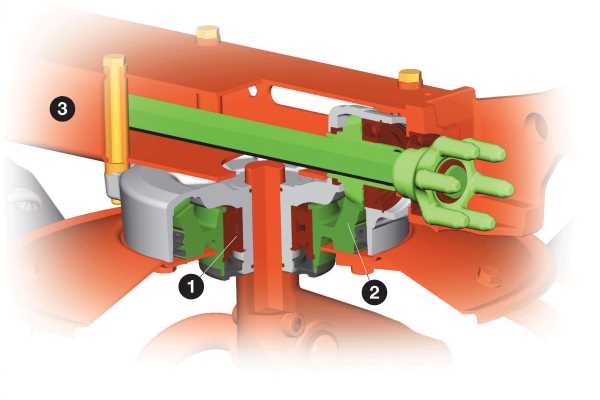

| Rotors | These rotating arms are responsible for spreading and aerating the crop, promoting even drying. |

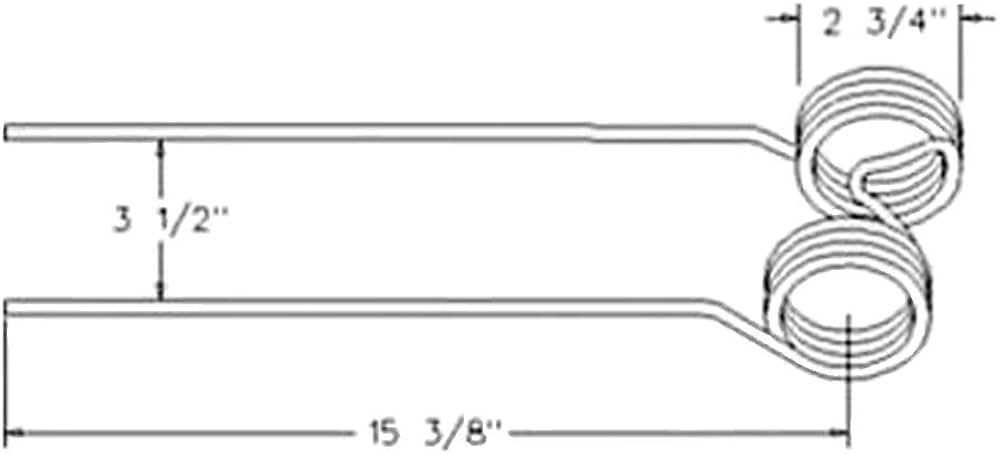

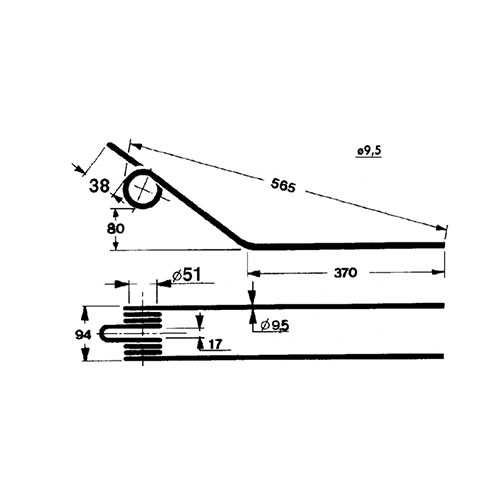

| Tines | Flexible prongs attached to the rotors that lift and separate the material, preventing matting. |

| Gearbox | Transmits power from the tractor to the implement, facilitating the rotational movement of the rotors. |

| Hitch | Connects the implement to the tractor, allowing for efficient maneuverability and transport. |

| Wheels | Support the entire assembly during transport and provide stability during operation on uneven terrain. |

By familiarizing oneself with these vital components, operators can enhance their understanding and ensure proper functionality, leading to improved performance and longevity of the equipment.

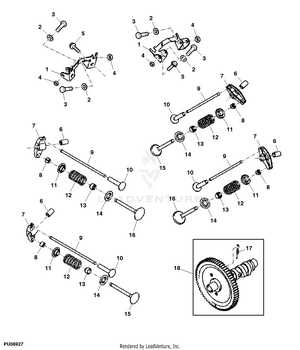

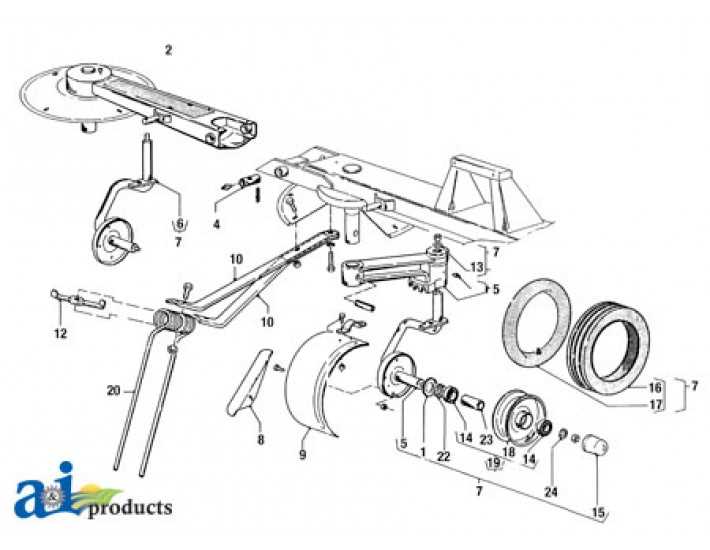

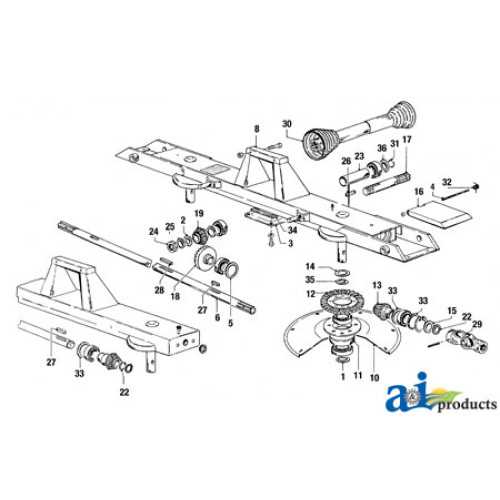

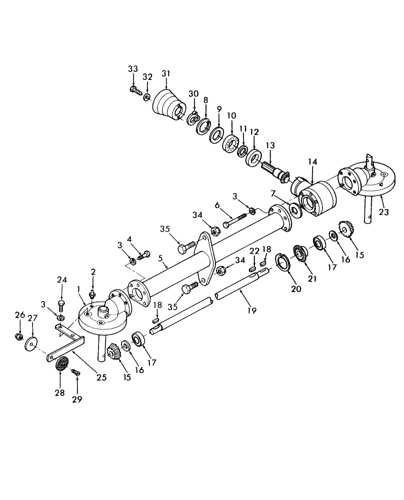

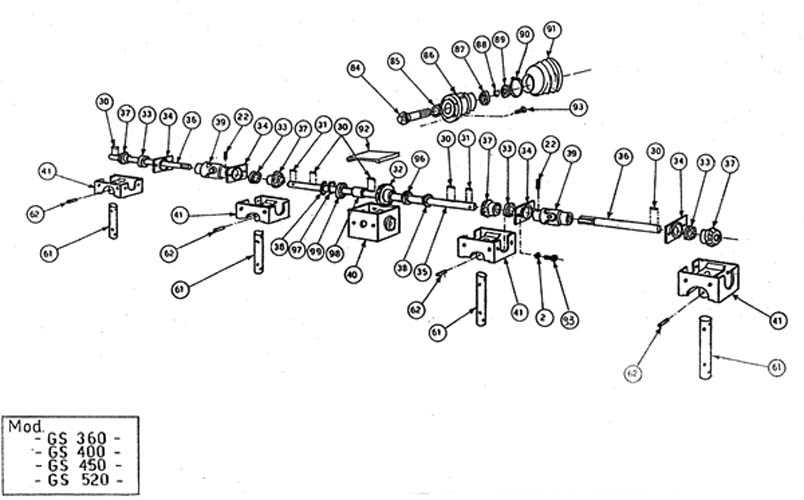

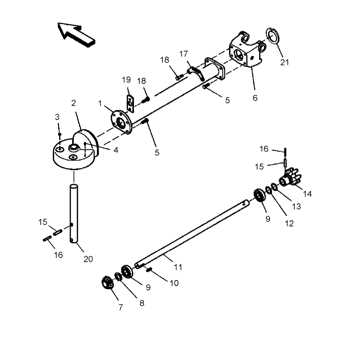

Understanding the Parts Diagram

In any machinery, a visual representation of components is essential for maintenance and repair. Such illustrations help users identify individual elements, ensuring efficient troubleshooting and servicing. Grasping the layout of these components can significantly enhance one’s familiarity with the equipment.

Importance of Component Familiarity

Recognizing the various sections and their functions allows operators to conduct routine checks more effectively. By understanding how each part interacts with others, users can anticipate potential issues before they escalate, ultimately prolonging the lifespan of the equipment.

Navigating the Visual Representation

These illustrations typically showcase labeled segments, which provide clarity on assembly and disassembly processes. A detailed look at the layout can guide users in accessing hard-to-reach areas, making repairs more straightforward. Mastering this skill not only empowers operators but also contributes to smoother operations overall.

Importance of Regular Maintenance

Regular upkeep of agricultural machinery is essential for optimal performance and longevity. By adhering to a consistent maintenance schedule, operators can prevent unexpected breakdowns and ensure that their equipment functions at peak efficiency. This proactive approach not only enhances productivity but also reduces overall repair costs.

| Benefit | Description |

|---|---|

| Increased Efficiency | Well-maintained equipment operates more smoothly, leading to improved operational speed and output. |

| Extended Lifespan | Regular checks and services can significantly prolong the usable life of machinery. |

| Cost Savings | Preventative maintenance helps avoid costly repairs and downtime by addressing issues early. |

| Safety Assurance | Ensuring that machines are in good working order minimizes the risk of accidents and injuries. |

Identifying Common Issues

Recognizing prevalent challenges in agricultural machinery is crucial for maintaining optimal performance and ensuring longevity. Operators often encounter various malfunctions that can hinder productivity. By understanding these typical problems, one can take proactive measures to address them effectively.

One frequent issue is wear and tear on essential components, which can lead to reduced efficiency and increased fuel consumption. Regular inspection of moving parts helps in detecting early signs of damage. Additionally, misalignment can cause operational disruptions, resulting in uneven processing and potential equipment failure.

Another concern is the accumulation of debris and residue, which can obstruct functionality. Regular cleaning and maintenance are vital in preventing buildup that can lead to more serious complications. Furthermore, issues related to hydraulic systems, such as leaks or pressure inconsistencies, can significantly impact the overall operation. Monitoring hydraulic fluid levels and ensuring proper sealing can mitigate these risks.

Finally, electrical failures often manifest through intermittent functionality or complete inoperability. Ensuring that connections are secure and that wiring is intact can prevent these disruptions. By being aware of these common challenges and implementing routine checks, operators can enhance the reliability and efficiency of their equipment.

Replacement Parts Availability

Access to essential components is crucial for maintaining optimal performance and extending the lifespan of agricultural machinery. Ensuring that high-quality replacements are readily obtainable can significantly enhance operational efficiency and reduce downtime. The availability of these items often varies by supplier, location, and demand.

| Supplier | Location | Contact Information | Stock Status |

|---|---|---|---|

| AgriSupply | California | (555) 123-4567 | In Stock |

| FarmEquip | Texas | (555) 987-6543 | Limited Availability |

| PartsDirect | New York | (555) 456-7890 | Out of Stock |

| RuralTech | Florida | (555) 321-0987 | In Stock |

It is advisable to establish a relationship with reliable suppliers and to keep informed about their inventory levels. Additionally, many manufacturers offer online catalogs, making it easier to find the specific components required for repair or maintenance tasks.

Installation Tips for New Parts

When integrating new components into your machinery, it’s essential to follow best practices to ensure optimal performance and longevity. Proper installation not only enhances efficiency but also minimizes the risk of future complications.

1. Prepare Your Workspace: Ensure that your area is clean and organized. Gather all necessary tools and components beforehand to streamline the process.

2. Review the Manual: Always consult the manufacturer’s instructions. Understanding the specific requirements for each element can prevent common mistakes during assembly.

3. Check Compatibility: Verify that the new elements match the specifications of your equipment. Mismatched components can lead to inefficiencies or damage.

4. Take Your Time: Rushing through installation can lead to oversights. Carefully follow each step and double-check your work as you progress.

5. Test Thoroughly: After installation, conduct a thorough test of the machinery. Look for any irregularities and ensure everything operates smoothly before returning to regular use.

By following these guidelines, you can enhance the performance and durability of your equipment, ultimately achieving better results in your operations.

Enhancing Efficiency with Upgrades

Improving performance in agricultural machinery can significantly impact productivity and cost-effectiveness. By integrating advanced components and innovative technologies, users can optimize their operations, reduce downtime, and enhance overall functionality. Such enhancements not only streamline processes but also contribute to long-term sustainability.

| Upgrade Type | Benefits |

|---|---|

| Component Replacement | Increased durability and reliability |

| Technological Integration | Enhanced precision and control |

| Efficiency Improvements | Lower fuel consumption and operational costs |

| Maintenance Tools | Reduced downtime and easier repairs |

Best Practices for Operation

Efficient operation of agricultural machinery is essential for optimal performance and longevity. Adhering to best practices ensures not only smooth functionality but also enhances safety and productivity in the field.

Regular Maintenance

Implementing a routine maintenance schedule can significantly reduce downtime and repair costs. Consider the following:

- Check fluid levels and change them as recommended.

- Inspect belts and chains for wear and tear.

- Clean components regularly to prevent buildup.

- Sharpen or replace blades as needed to maintain efficiency.

Operational Techniques

Utilizing proper techniques during operation can maximize performance and minimize damage. Keep these tips in mind:

- Familiarize yourself with the operator’s manual for specific guidelines.

- Adjust settings according to field conditions and crop type.

- Monitor speed to prevent overloading the machine.

- Ensure safety gear is worn at all times to protect against hazards.

By following these best practices, operators can enhance the functionality and lifespan of their equipment, leading to improved agricultural outcomes.