When maintaining efficient fluid circulation, comprehending the individual elements that contribute to the overall functionality is crucial. Each component plays a significant role in ensuring optimal performance and longevity of the system. A thorough exploration of these elements not only enhances operational knowledge but also aids in effective troubleshooting.

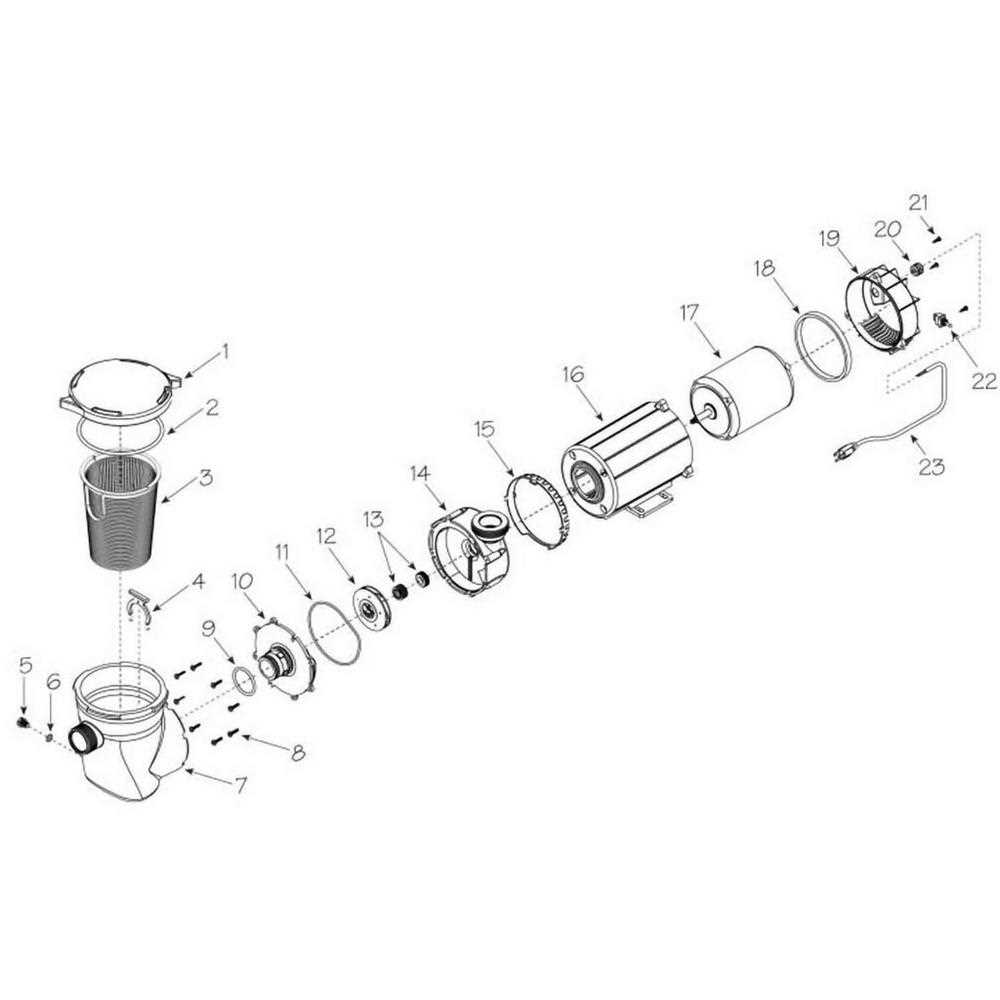

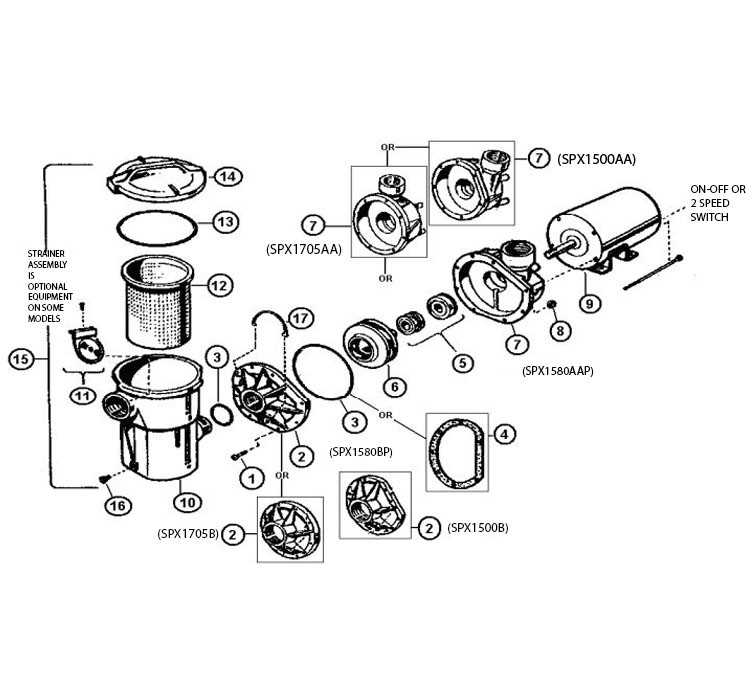

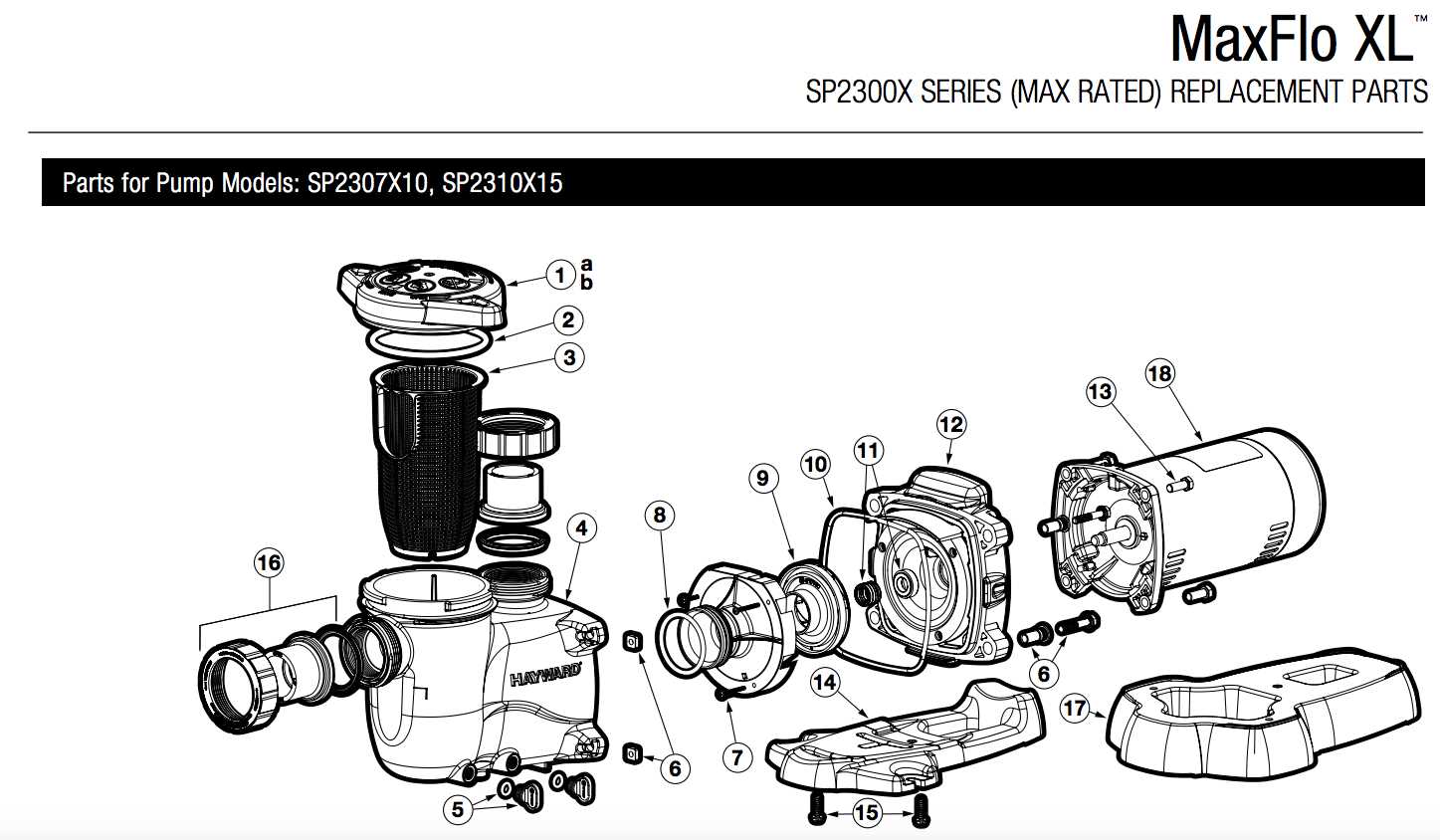

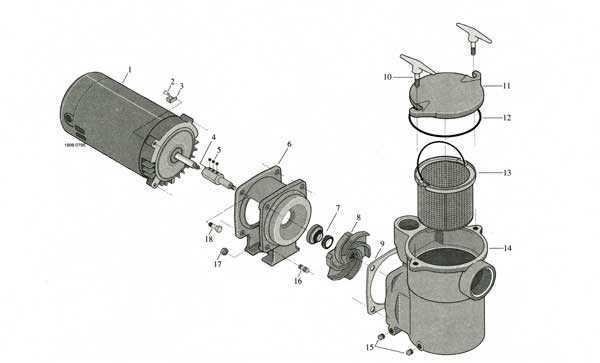

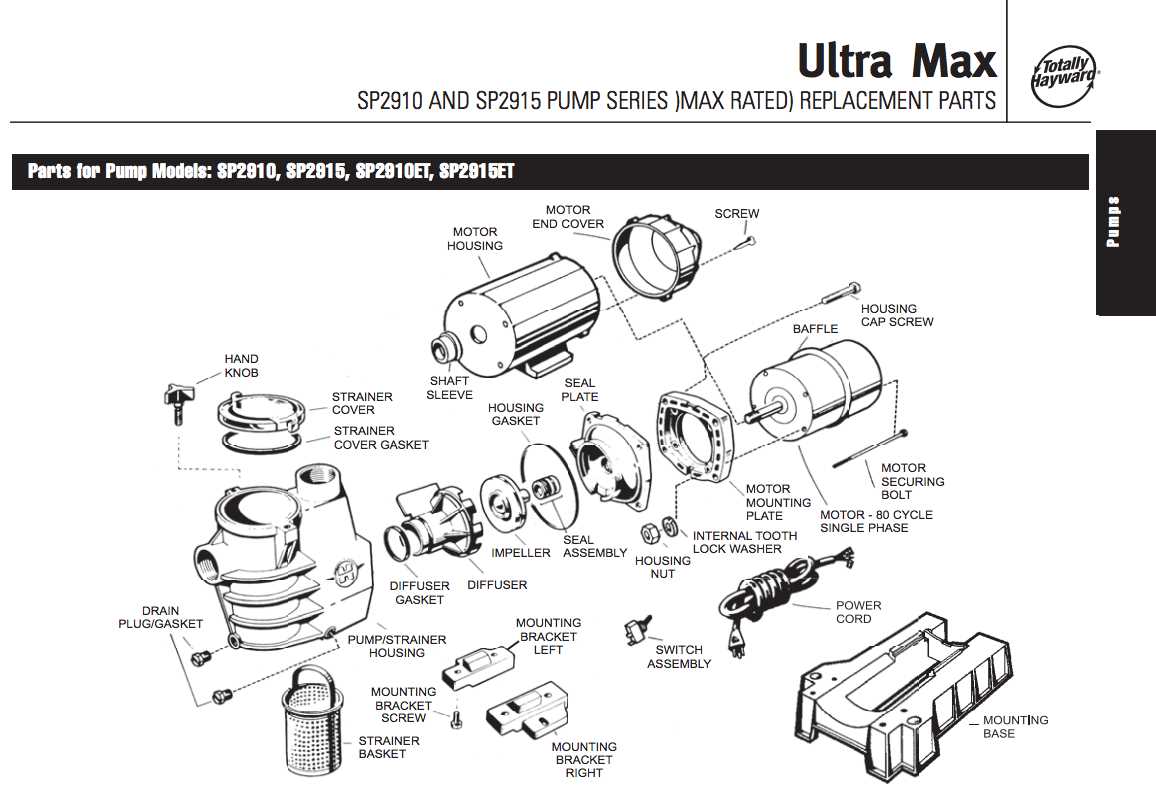

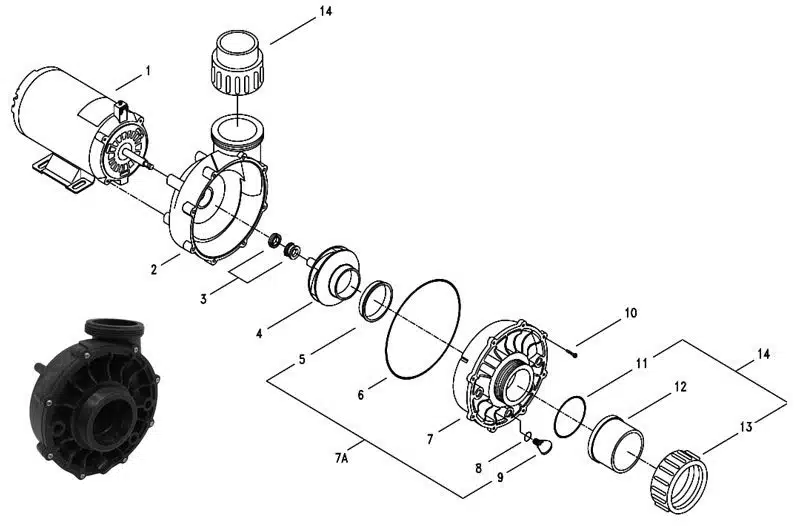

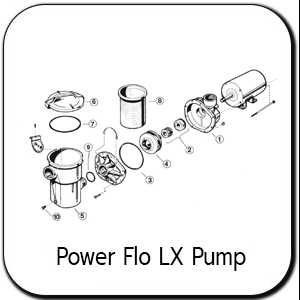

Visual aids can greatly assist in identifying and understanding the various components within the system. These illustrations serve as invaluable references, enabling users to pinpoint specific sections and their respective functions. By utilizing such resources, one can delve deeper into the mechanics at play.

Ultimately, recognizing how these pieces interconnect fosters a more informed approach to maintenance and repair. This understanding paves the way for improved efficiency and a longer lifespan for the entire circulation setup.

Understanding Hayward Power Flo LX Pump

This section explores the essential components and functions of a specific water circulation system widely used in residential settings. Knowing the intricacies of this equipment can enhance efficiency and maintenance, ensuring a smooth operation.

Key Components

- Motor

- Impeller

- Volute

- Strainer basket

- Seal plate

Functionality Overview

- Water intake from the pool or spa.

- Circulation through the filtration system.

- Return flow to maintain cleanliness and clarity.

- Energy efficiency and reduced noise levels.

Key Components of the Pump

Understanding the essential elements of a circulation system is crucial for effective maintenance and optimal performance. Each component plays a vital role in ensuring the system operates smoothly, contributing to the overall efficiency and longevity of the setup.

Impeller

The impeller is the heart of the system, responsible for generating the necessary flow of fluid. Its design and material directly influence the system’s capacity and efficiency, making it a critical part for optimal functionality.

Motor

The motor powers the impeller, converting electrical energy into mechanical energy. The selection of a high-quality motor not only ensures reliable operation but also enhances energy efficiency, which is essential for long-term savings and sustainability.

How to Read Pump Diagrams

Understanding schematics related to fluid circulation equipment is essential for effective maintenance and troubleshooting. These illustrations serve as visual guides, depicting the components and their interconnections, which ultimately aids in comprehending how the system operates.

Key Elements to Identify

- Symbols: Familiarize yourself with common representations for each component.

- Flow Direction: Look for arrows indicating the movement of fluids.

- Labels: Pay attention to annotations that clarify the function of each part.

Steps for Effective Interpretation

- Begin by identifying the main components illustrated.

- Trace the flow lines to understand the sequence of operations.

- Refer to the legend if available for clarification on symbols.

Common Issues and Solutions

Understanding the frequent challenges encountered with various filtration systems can enhance their longevity and efficiency. Many users face similar problems, which often stem from installation errors, regular wear, or environmental factors. By identifying these common issues, users can implement effective solutions to maintain optimal functionality.

1. Insufficient Water Flow

One of the most prevalent problems is inadequate water circulation. This can result from several factors, such as clogged filters or obstructed intake valves. Regularly inspecting and cleaning these components can restore proper flow. Additionally, ensuring that the system is free of debris will promote better performance.

2. Unusual Noises

Unexpected sounds can indicate mechanical issues or misalignment. If a humming or rattling noise occurs, it may be due to loose components or an imbalance. Tightening screws and checking the alignment of moving parts can often resolve this problem. In cases of persistent noise, consulting a professional may be necessary.

By proactively addressing these common issues, users can enhance the efficiency and lifespan of their filtration systems, ensuring a smooth operation throughout their use.

Maintenance Tips for Longevity

Ensuring the durability of your equipment requires regular care and attention. By implementing a few essential practices, you can enhance performance and extend the lifespan significantly. A proactive approach not only prevents issues but also saves on costly repairs.

Regular Inspections

Frequent checks can help identify wear and tear early. Inspect components for any signs of damage, leaks, or unusual noises. Addressing minor issues promptly can prevent major failures down the line.

Cleaning and Debris Removal

Maintaining cleanliness is crucial. Remove debris and dirt from the unit to ensure optimal operation. Regular cleaning helps avoid blockages and inefficiencies, contributing to overall effectiveness and longevity.

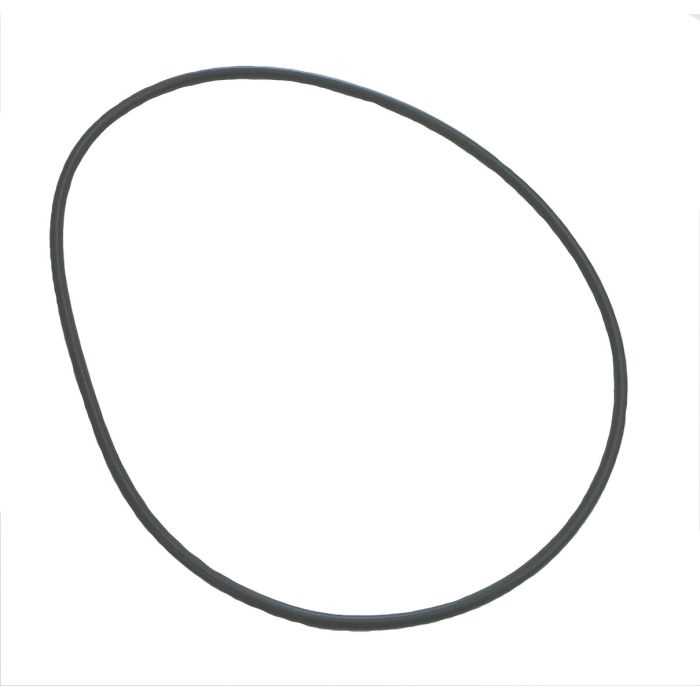

Replacing Parts Effectively

Ensuring optimal functionality of your equipment often requires timely replacements of worn-out components. Understanding how to efficiently identify and substitute these elements can significantly enhance performance and longevity.

Assessing Condition

Before initiating any replacement, thoroughly evaluate the current state of each element. Look for signs of wear, such as cracks, corrosion, or leaks. This assessment will guide you in determining which components need attention.

Steps for Replacement

Once you’ve identified the necessary elements, gather the appropriate tools and replacement items. Follow the manufacturer’s guidelines to ensure a correct fit and function. Take your time during the installation to avoid damaging surrounding structures, and always double-check your work before reassembling.

Benefits of Using Original Parts

Choosing authentic components for your equipment can significantly enhance performance and longevity. By investing in original items, users can experience a range of advantages that contribute to overall efficiency and reliability.

- Quality Assurance: Genuine components undergo rigorous testing to meet high standards.

- Compatibility: These items are specifically designed to fit seamlessly, minimizing the risk of malfunctions.

- Longevity: Original components typically last longer, reducing the frequency of replacements.

- Warranty Protection: Utilizing authentic items often ensures coverage under manufacturer warranties.

- Enhanced Performance: These components are engineered to optimize the overall functionality of the system.

In conclusion, selecting original components is an investment in quality and efficiency, ultimately benefiting both the user and the equipment.

Where to Find Replacement Parts

When it comes to maintaining your equipment, locating suitable components is crucial for optimal performance. A variety of sources are available for acquiring these necessary elements, ensuring your system operates efficiently.

Online Retailers: Numerous e-commerce platforms specialize in providing a wide array of components. These sites often feature detailed descriptions and customer reviews, making it easier to identify the right items.

Local Supply Stores: Visiting nearby hardware or specialty shops can also yield great results. Knowledgeable staff can assist in finding the exact components needed for your machinery.

Manufacturer Websites: Directly accessing the official sites of manufacturers can offer a comprehensive selection of original components, ensuring quality and compatibility with your system.

Forums and Community Groups: Engaging with online communities can provide insights into where others have found reliable components. Members often share their experiences and recommendations, which can be invaluable.

In summary, utilizing a combination of online and local resources can greatly enhance your ability to find the necessary components for your equipment.

Comparing Models and Specifications

When selecting a suitable fluid circulation device for your needs, understanding the various options and their specifications is crucial. Each model presents unique features tailored to specific applications, making it essential to compare them effectively.

Performance Metrics: Different units offer varying flow rates and energy efficiencies. Evaluating these metrics helps determine which model aligns best with your operational requirements. For instance, a higher flow rate may be necessary for larger installations, while smaller units can be more efficient for residential use.

Durability and Design: The construction materials and design elements can significantly influence longevity and maintenance needs. Some models are engineered with corrosion-resistant materials, ensuring reliability in diverse environments. Consideration of these factors can lead to better long-term performance and reduced maintenance costs.

Features and Compatibility: Various units come equipped with different functionalities, such as variable speed options or advanced control systems. Assessing compatibility with existing systems is also essential to ensure seamless integration. Taking time to explore these aspects can prevent future operational challenges.

Ultimately, a thorough comparison of available models and their specifications is vital for making an informed decision that meets both immediate and long-term needs.