In the realm of gardening and landscaping, mastering the machinery used for soil preparation can significantly enhance efficiency and results. A comprehensive exploration of these essential tools reveals the intricate relationships between their individual elements, which collectively contribute to their overall functionality.

By examining the various segments and their roles, one can gain valuable insights into how to optimize usage and maintenance. This knowledge empowers users to ensure that each piece operates in harmony, ultimately leading to a more productive gardening experience.

Whether you are a seasoned gardener or a newcomer, delving into the specifics of these implements will help you make informed decisions and address any issues that may arise. Understanding the construction and operation of each element is the ultimate key to mastering the art of cultivation.

Understanding Tiller Functionality

The operation of agricultural equipment designed for soil cultivation is essential for efficient land management. These machines are engineered to assist in breaking up, aerating, and preparing the earth for planting. By grasping the mechanics involved, users can enhance their agricultural practices and improve productivity.

Core components of this machinery work together seamlessly, enabling users to navigate various terrains and achieve desired soil conditions. Each element plays a crucial role, contributing to the overall effectiveness and ease of use.

Understanding the mechanical interactions within these systems allows operators to troubleshoot issues and maintain optimal performance. This knowledge is ultimately beneficial in maximizing yield and ensuring sustainable farming practices.

Key Components of a Tiller

Understanding the core elements of a cultivation machine is essential for optimal performance. These structural parts work together to ensure smooth operation and efficient soil preparation. Below are the most significant mechanical units that make up this equipment.

- Engine: The power source that drives the entire system, providing the necessary energy to rotate the blades and control movement.

- Blades: Sharp rotating pieces that dig into the soil, breaking it apart and making it easier for planting. These come in various configurations depending on the desired depth and coverage.

- Transmission: This mechanism transfers power from the motor to the wheels and blades, controlling the speed and ensuring smooth transitions between different modes.

- Handles: Designed for operator control, they allow for steering, speed regulation, and safety during use.

- Wheels: Essential for mobility, these help the machine move across the soil, especially on uneven terrain.

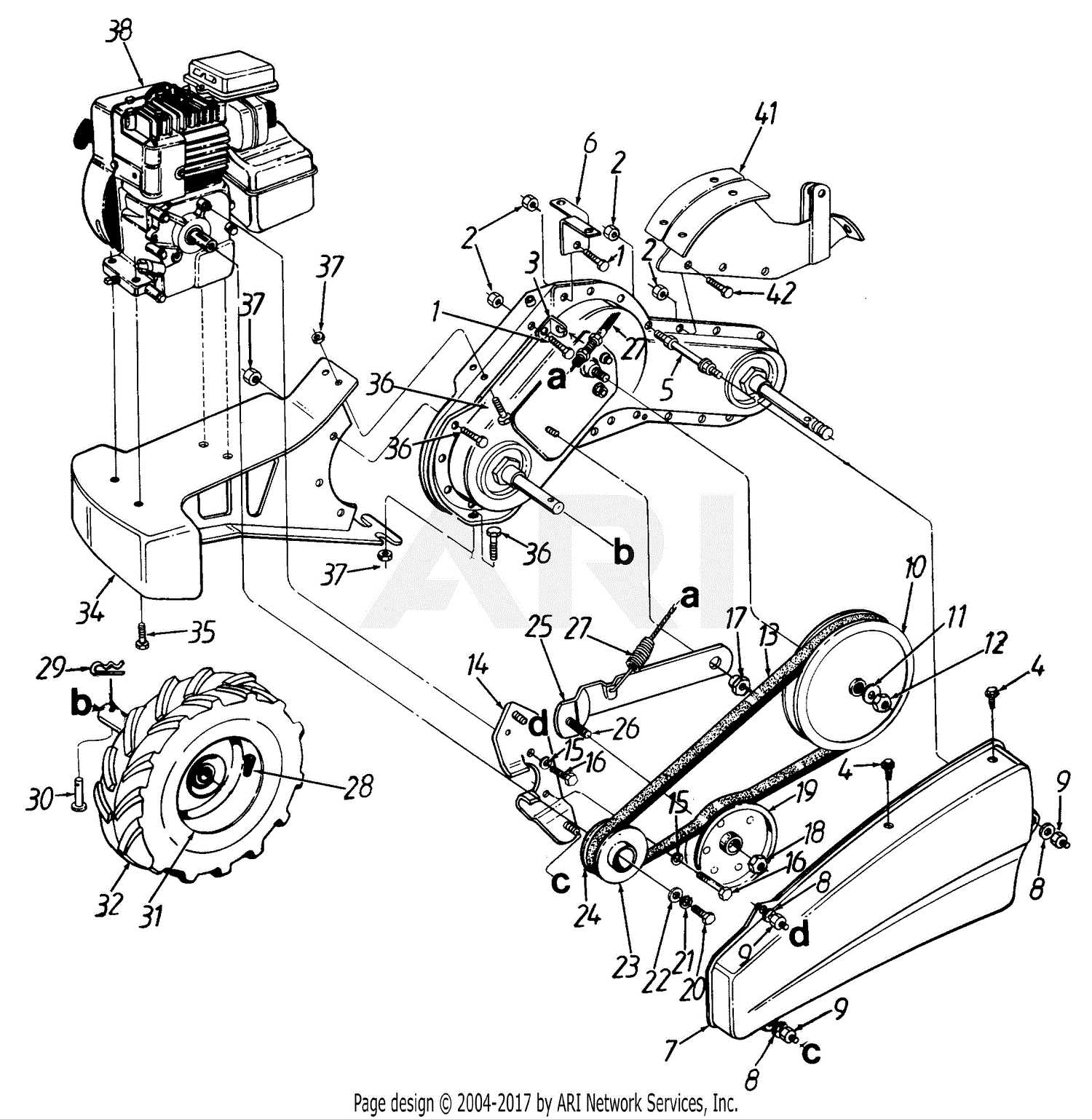

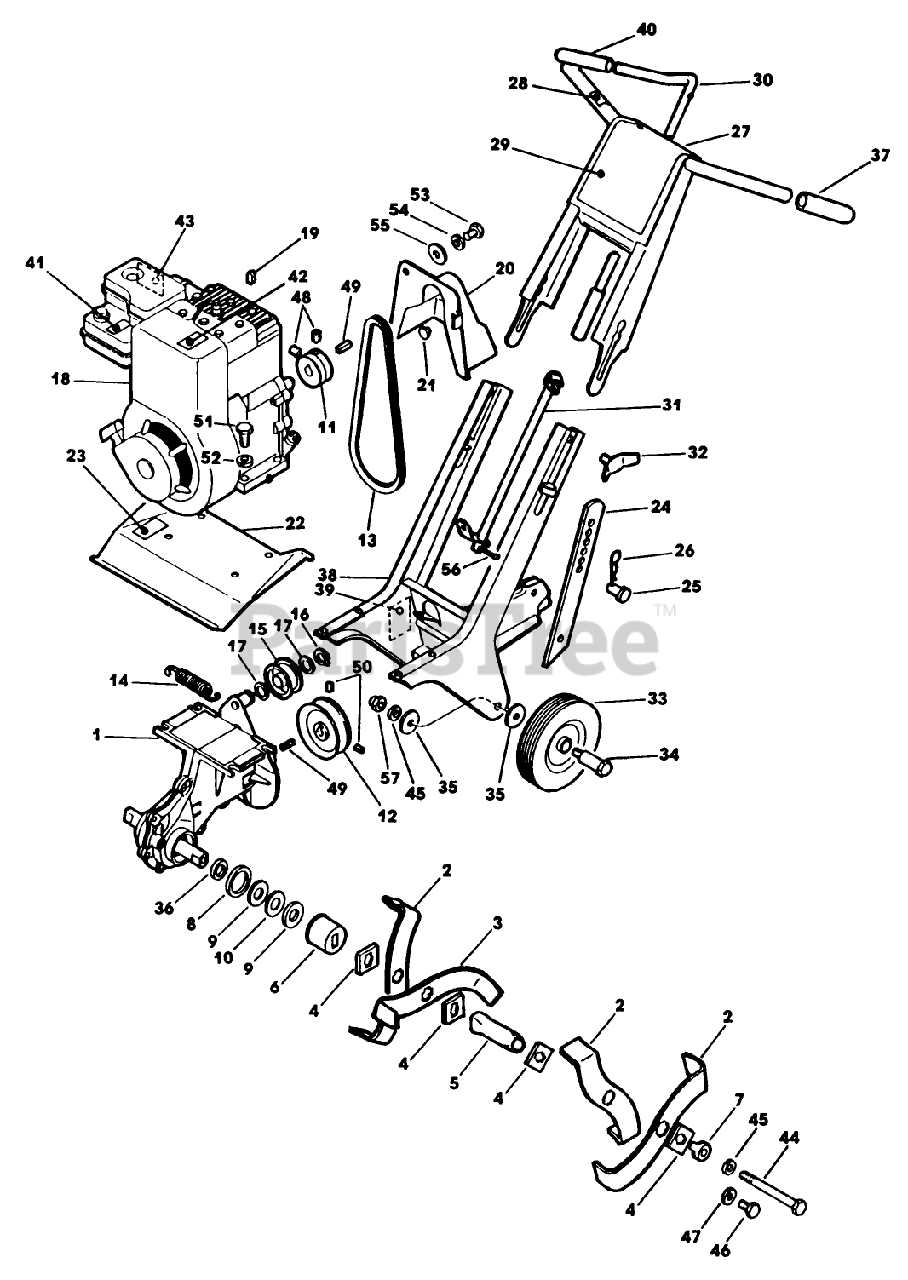

How to Read a Parts Diagram

Understanding how to interpret a schematic can be crucial for identifying various elements and their connections. Such diagrams often use visual representations to map out components, making it easier to determine their location, function, and how they fit together within a system. Being able to read these schematics helps ensure efficient repairs, replacements, and maintenance tasks.

Key Symbols and Layout

Diagrams typically employ specific symbols to denote various elements. These symbols may include lines, shapes, and other markings that represent different objects and their connections. Familiarizing yourself with these conventions can greatly enhance your ability to quickly and accurately interpret the schematic.

Component Identification

Each part in the schematic is labeled with a unique identifier or number. These labels allow you to match components with corresponding descriptions or listings. By following these markers, you can easily locate the necessary item and verify its place in the system.

Common Tiller Issues Explained

There are several frequent problems that occur during the use of soil preparation equipment. These challenges may affect performance, efficiency, and even safety if not addressed in time. Below is a breakdown of common issues, their causes, and how to resolve them.

Engine Starting Problems

One of the most common challenges users face is difficulty in getting the machine started. This issue can be caused by a variety of factors, such as fuel system blockages, spark plug failures, or low oil levels.

- Ensure the fuel tank is full and check for blockages in the fuel lines.

- Inspect and clean the spark plug regularly to prevent ignition issues.

- Maintain proper oil levels to ensure smooth engine function.

Unstable Operation

Another common concern is unstable operation, where the machine may not function consistently. This can lead to poor soil preparation and uneven performance.

- Check the blades for dullness or damage, as this can affect performance.

- Verify that all fasteners and bolts are tightly secured to avoid instability.

- Inspect the drive belts for wear and replace them if necessary.

Benefits of Using Quality Parts

Choosing high-grade components for your equipment can significantly improve its overall performance and extend its lifespan. When machines rely on durable and reliable elements, they operate more smoothly and efficiently, reducing the risk of breakdowns and costly repairs.

Enhanced Durability

Opting for superior materials ensures that the elements can withstand regular use and harsh conditions. High-quality replacements are designed to resist wear and tear, ensuring that your machinery remains functional for a longer period.

Cost Efficiency

Though premium options might come with a higher upfront cost, they can save you money in the long run. Reliable components reduce the frequency of maintenance and replacements, making them a smart investment for anyone looking to maximize the efficiency of their equipment.

Maintenance Tips for Tiller Longevity

To ensure the optimal performance and durability of your equipment, regular care and attention are essential. Following a few basic maintenance steps can significantly extend its lifespan, allowing it to operate smoothly over time. This section provides practical guidance on keeping your machine in top condition through simple, consistent practices.

Regular Cleaning and Inspection

One of the most important steps in maintaining your equipment is regular cleaning. After each use, make sure to remove dirt and debris, especially from moving parts. Over time, buildup can lead to wear and tear, reducing efficiency. Additionally, inspect all mechanisms for signs of damage or wear, such as loose bolts or dull edges.

Lubrication and Tightening

To avoid friction and potential breakdowns, ensure that all moving components are well-lubricated. Use appropriate oils or greases as recommended by the manufacturer. Moreover, regularly check and tighten screws, nuts, and other fasteners to prevent them from loosening during operation.

Identifying Parts by Diagram

Understanding how to recognize various components through a visual guide is essential for efficient maintenance and repair. A clear illustration allows users to pinpoint specific elements and understand their role within the larger system, ensuring proper handling and replacement when necessary.

Breaking Down the Visual Guide

The visual representation offers an organized view, making it easier to locate individual components and understand their arrangement. By following the structured layout, one can quickly identify key pieces and their connections.

Utilizing the Reference for Maintenance

A well-detailed visual guide simplifies regular upkeep. It provides a clear pathway for identifying which components need attention, helping prevent errors during replacement or repair processes.

Aftermarket vs. Original Equipment Parts

When it comes to maintaining or upgrading machines, consumers often face a choice between components made by the original manufacturer and alternatives produced by third-party suppliers. Understanding the differences between these two options can significantly affect performance and cost.

Below is a comparison of key factors to consider when choosing between original manufacturer products and third-party options:

| Factor | Original Manufacturer | Third-Party Supplier |

|---|---|---|

| Cost | Typically higher due to brand assurance | Generally more affordable |

| Quality | Designed to fit and perform exactly as intended | Varies, some can match or exceed original quality |

| Availability | May be limited to authorized distributors | Often widely available from various retailers |

| Warranty |