When working with power tools, having a clear understanding of their individual components is crucial for optimal performance and maintenance. Each tool consists of various elements that play specific roles in ensuring efficiency and safety during operation. Grasping how these pieces fit together can enhance both the user experience and the longevity of the equipment.

Visual aids serve as invaluable resources for both novice and experienced users alike. They provide a comprehensive overview of the different sections of the device, making it easier to identify and troubleshoot issues as they arise. By familiarizing oneself with these illustrations, users can gain insights into the assembly and functionality of the tool.

In this article, we will explore the essential components of a widely used cutting instrument. We will delve into each element’s purpose, helping users make informed decisions about repairs, upgrades, or replacements. Whether for DIY projects or professional tasks, understanding the anatomy of your tools is key to achieving successful results.

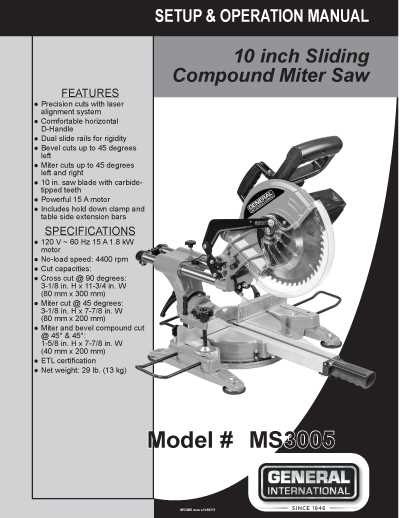

Understanding Miter Saw Components

To fully grasp the functionality of this cutting tool, it’s essential to explore its various elements and their roles. Each component works in harmony to achieve precise angles and clean cuts, making it an indispensable item in woodworking and construction.

Key Elements

The main features include the blade, which is responsible for the actual cutting, and the base, providing stability. Additional components such as the bevel adjustment and fence enhance versatility and accuracy, allowing users to execute a range of tasks effectively.

Importance of Maintenance

Essential Parts of Chicago Miter Saws

This section explores the critical components that contribute to the functionality and efficiency of cutting tools. Understanding these elements enhances maintenance and improves performance during various tasks.

| Component | Description |

|---|---|

| Base | The foundation that supports the entire unit and provides stability during operation. |

| Blade | The cutting edge that performs the actual slicing through materials. |

| Motor | The power source that drives the blade for cutting operations. |

| Fence | A guide that helps in achieving precise cuts by aligning the material properly. |

| Handle | Used to control the tool safely, ensuring user comfort and grip. |

Diagram Overview for Easy Assembly

This section provides a comprehensive overview of the visual representation that facilitates the assembly process. By breaking down components into an organized layout, users can efficiently navigate through the various elements needed for construction.

Understanding the Layout

The arrangement showcases each element clearly, allowing for quick identification and reference. Such clarity is essential for ensuring that every piece fits together seamlessly, leading to a successful build.

Key Benefits of Visual Guides

Visual aids significantly enhance the assembly experience by minimizing confusion and errors. They allow for an ultimate understanding of how individual parts interact, making the entire process smoother and more intuitive.

Common Issues and Solutions

When operating power tools, users often encounter various challenges that can affect performance and efficiency. Recognizing these common problems and knowing how to address them is essential for maintaining optimal functionality.

1. Inaccurate Cuts: One of the most frequent issues is achieving precise angles. This can stem from misalignment of the blade or an improperly set gauge. To resolve this, regularly check the calibration and ensure that the blade is securely fastened.

2. Blade Overheating: Excessive heat can lead to premature wear and tear. This may occur due to prolonged use or cutting through tough materials. To mitigate this, take breaks during operation and ensure the blade is appropriate for the material being cut.

3. Stalling Motor: A motor that frequently stalls can indicate a problem with the power supply or internal components. Inspect the cord for damage and check the electrical outlet. If the issue persists, professional maintenance may be required.

4. Difficulty in Raising or Lowering the Arm: If the arm is stiff or unresponsive, it may be due to debris accumulation or lack of lubrication. Clean the pivot points and apply a suitable lubricant to restore smooth movement.

5. Dust Accumulation: Excess dust can hinder performance and visibility. Regularly clear the work area and utilize dust collection features to maintain a clean workspace, which enhances safety and efficiency.

Tools Needed for Repairs

When it comes to maintaining and fixing your equipment, having the right tools is essential for effective and efficient repairs. The appropriate instruments not only make the process smoother but also help ensure that the job is done correctly. Whether you are a professional or a DIY enthusiast, being equipped with the right gear can significantly enhance your repair experience.

Essential Instruments

To tackle any maintenance task, you’ll need a selection of fundamental instruments. Screwdrivers, wrenches, and pliers are staples in any toolkit, allowing you to handle various screws and nuts with ease. Additionally, a good quality hammer can assist in adjusting components without causing damage. Don’t forget to include a measuring tape to ensure precision during any adjustments.

Specialized Tools

For more intricate repairs, specialized tools may be required. Socket sets are particularly useful for tightening and loosening fasteners, while a torque wrench can help ensure that everything is secured to the manufacturer’s specifications. Having a reliable multimeter is also beneficial for diagnosing electrical issues, enabling you to identify problems efficiently.

Maintenance Tips for Longevity

Ensuring the durability of your cutting tool requires consistent upkeep and attention to detail. By following a few essential guidelines, you can significantly extend the lifespan of your equipment and maintain its optimal performance.

Regular Cleaning: Keeping the tool free from dust and debris is crucial. After each use, wipe down the surfaces and remove any particles that may have accumulated. This prevents buildup that can affect functionality.

Inspect Components: Frequently check the various elements for wear and tear. Look for any signs of damage, such as cracks or misalignments. Addressing these issues promptly can prevent more significant problems in the future.

Lubrication: Applying the appropriate lubricant to moving parts is vital for smooth operation. Ensure you use the recommended type and amount to avoid overheating and unnecessary friction.

Proper Storage: When not in use, store your tool in a dry, protected location. Use a cover to shield it from dust and moisture, which can lead to rust and degradation.

Follow Manufacturer Guidelines: Always adhere to the maintenance recommendations provided by the manufacturer. These guidelines are tailored to your specific model and can help ensure optimal performance and longevity.

Upgrading Your Miter Saw Parts

Enhancing the functionality of your cutting tool can significantly improve your craftsmanship. By focusing on specific components, you can boost precision, efficiency, and overall performance. This not only elevates your project outcomes but also extends the lifespan of your equipment.

Consider upgrading the blade to achieve cleaner cuts and a smoother finish. A high-quality blade can make a substantial difference in material handling, reducing splintering and tear-out. Additionally, investing in a more advanced motor can enhance power and speed, enabling you to tackle tougher materials with ease.

Another important aspect is the base and fence system. A sturdy and well-aligned base ensures stability during operation, while a reliable fence provides accurate measurements. Upgrading these elements can lead to more precise cuts, reducing the need for rework.

Don’t overlook the importance of dust collection systems. A better dust management solution can keep your workspace clean and improve visibility, making your tasks safer and more enjoyable. By prioritizing these enhancements, you’ll not only improve your current tool’s capabilities but also enhance your overall woodworking experience.

Finding Replacement Components Online

When equipment malfunctions, sourcing the right components can be crucial for maintaining functionality and performance. The internet offers a plethora of options for locating these essential items, making the process more convenient and efficient.

Here are some effective strategies to help you find the right replacements:

- Manufacturer’s Website: Always start by visiting the official site of the manufacturer. They often provide detailed catalogs and the latest updates on available components.

- Online Retailers: Major e-commerce platforms specialize in tools and accessories. Search for the specific items you need using relevant keywords.

- Specialized Parts Websites: Some websites focus solely on providing components for specific types of machinery. These platforms can be invaluable for finding hard-to-locate items.

- Forums and Community Groups: Online forums dedicated to tool enthusiasts can offer insights and recommendations on where to find reliable components.

- Local Hardware Stores: While online options are plentiful, don’t overlook local shops. Many have online catalogs and can order specific items for you.

Before making a purchase, ensure that the components are compatible with your equipment. Checking reviews and ratings can also help you gauge the reliability of the seller and the quality of the items.

Safety Features in Miter Saw Design

Ensuring user protection is a crucial aspect of any cutting tool’s engineering. Modern designs incorporate various safety mechanisms to minimize risks associated with operation. These features are essential for both novice and experienced users, promoting safe handling and effective usage.

Key Safety Mechanisms

- Blade Guards: These shields protect users from accidental contact with the blade.

- Electric Brakes: Quickly stop the blade, reducing the potential for injury.

- Safety Switches: Prevent accidental activation when not in use.

- Anti-Kickback Systems: Reduce the risk of the material being pushed back towards the user.

Importance of User Training

While safety features play a vital role, proper training is equally important. Understanding the tool’s operation and inherent risks enhances safety. Regular maintenance and following manufacturer guidelines further contribute to a secure working environment.