When it comes to enhancing the performance and appearance of vehicles, the use of specialized components plays a crucial role. These elements are carefully selected to optimize various aspects of handling, stability, and aesthetic appeal, providing a tailored experience for both off-road enthusiasts and everyday drivers.

Each component serves a specific purpose, contributing to the overall balance and effectiveness of the vehicle’s modifications. By understanding how these elements work together, one can make informed decisions about upgrades, ensuring the vehicle operates smoothly and safely in diverse conditions.

In this article, we will explore the structure and function of key elements involved in vehicle enhancements, offering a clear view of how they interconnect. This insight is essential for anyone considering vehicle improvements, whether for performance or visual impact.

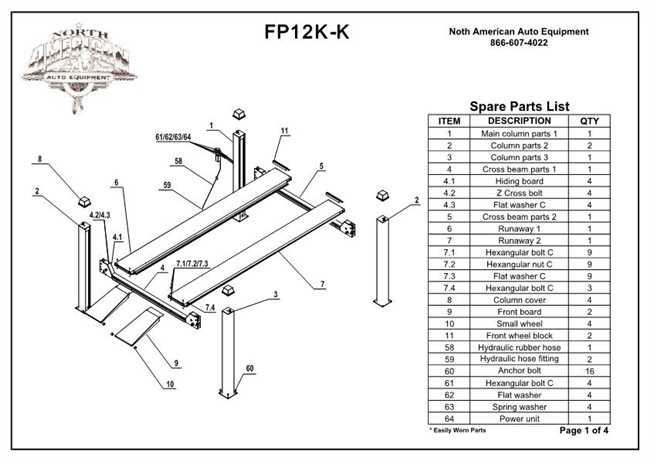

Understanding Lift Kit Components

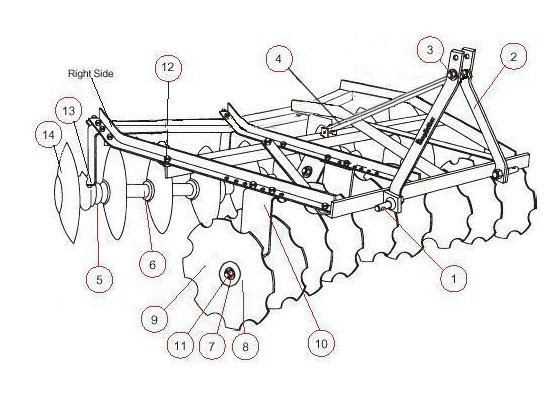

Suspension modifications are essential when adapting a vehicle for enhanced ground clearance or improved performance. These modifications consist of various mechanical elements that work together to change the height and stability of the vehicle, ensuring optimal function in off-road or customized settings.

Main Structural Elements

- Springs: The springs play a vital role in absorbing shocks and maintaining vehicle balance during motion. They can be replaced or adjusted to manage different load capacities.

- Shock absorbers: Designed to control the movement of the springs, these components reduce vibrations and keep the vehicle stable even on rough terrain.

- Control arms: These help to maintain the alignment and angle of the wheels, ensuring smooth maneuverability and steering.

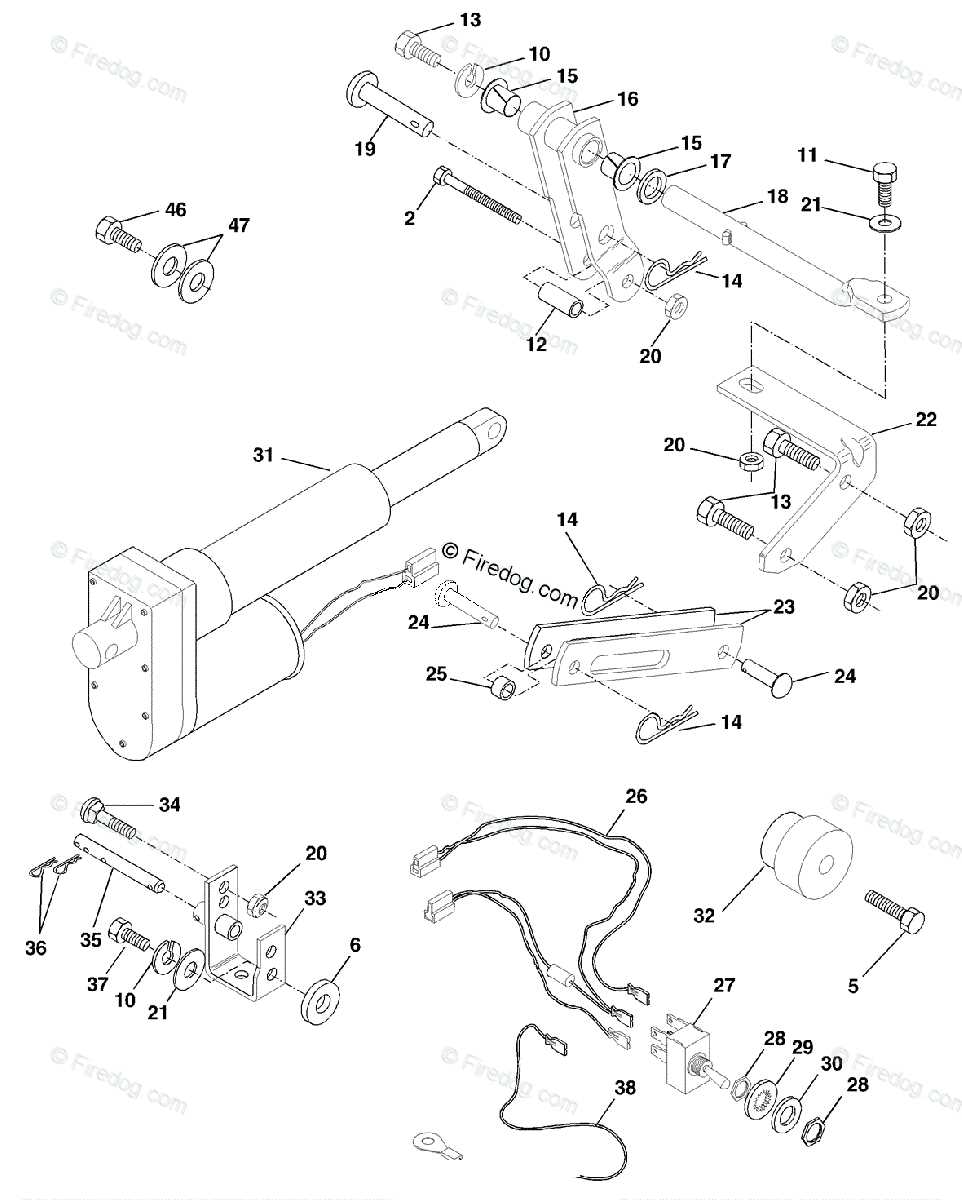

Supportive Hardware

- Brackets: Various brackets are used to secure the structural

Detailed Breakdown of Suspension Parts

Understanding the essential components of a vehicle’s suspension system is crucial for ensuring optimal performance and handling. This section provides an overview of the various elements that work together to support the vehicle, enhance stability, and absorb road shocks. Each component plays a specific role in maintaining balance and comfort during travel.

Key Elements of the Suspension System

- Springs: These are designed to absorb and distribute the force from bumps and irregularities in the road surface, providing a smoother ride.

- Shocks and Struts: These components help to control the motion of the springs, reducing excessive bounce and ensuring stability.

- Control Arms: These are pivoting links that connect the wheels to the frame, allowing for smooth vertical motion and maintaining alignment.

- Ball Joints: Ball joints act as a flexible connection point, enabling movement between the control arms and steering components.

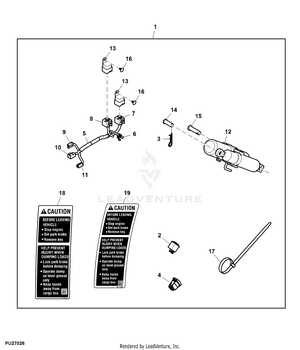

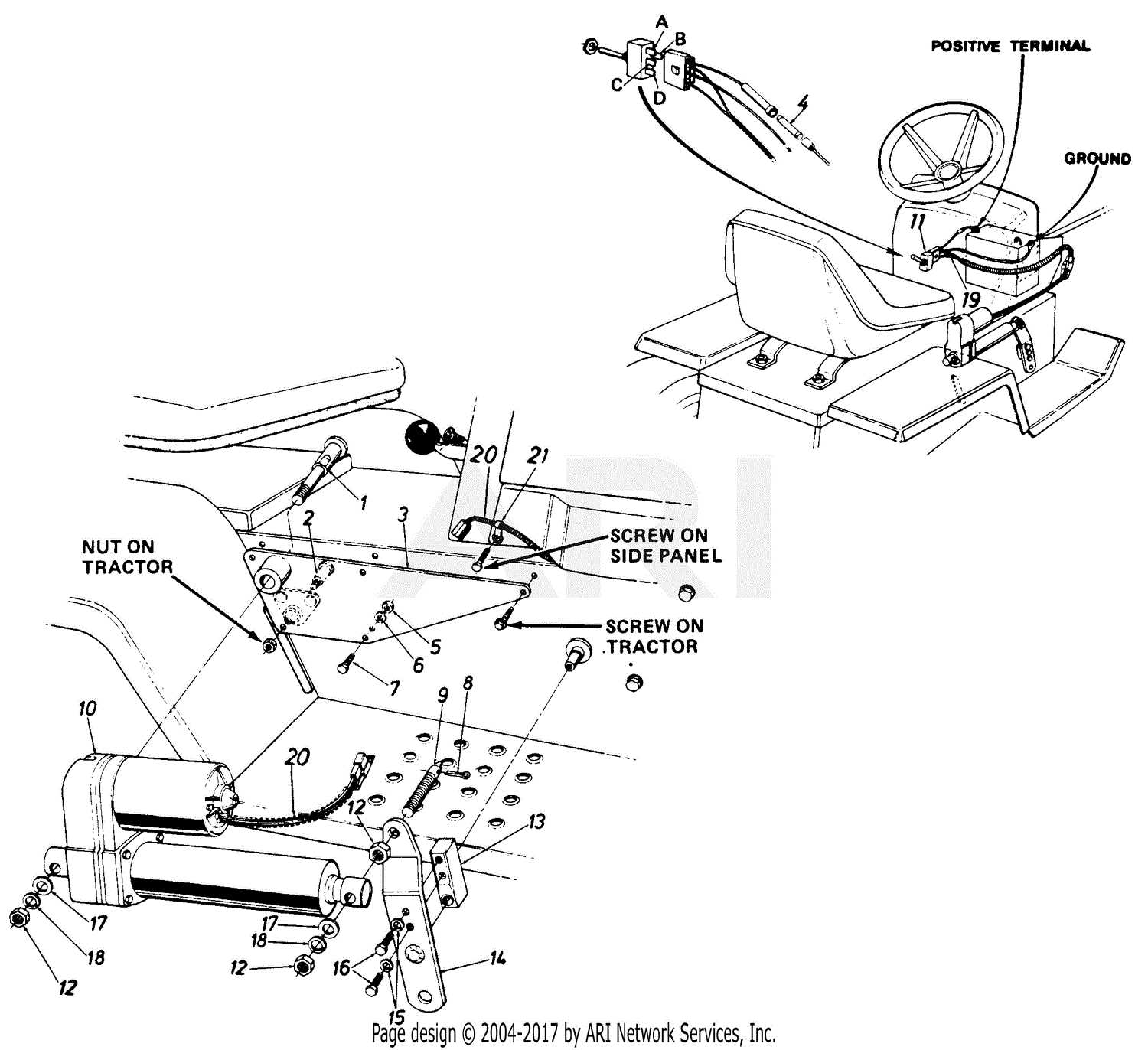

Steering Modifications for Lifted Vehicles

Altering the height of a vehicle often affects its steering components, which may require specific changes to maintain proper handling and safety. Modifications to the steering system ensure that the vehicle responds effectively to driver inputs, preventing excessive wear or instability during operation.

To address these challenges, several adjustments can be made, each designed to optimize performance and reduce stress on the steering assembly. Below is a summary of key adjustments commonly applied to vehicles with altered suspension systems:

Modification Purpose Steering Stabilizer Reduces vibration and provides smoother control. Drag Link Adjustment Corrects steering alignment and reduces uneven wear. Pitman Arm Replacement Pre Shock Absorbers and Their Role

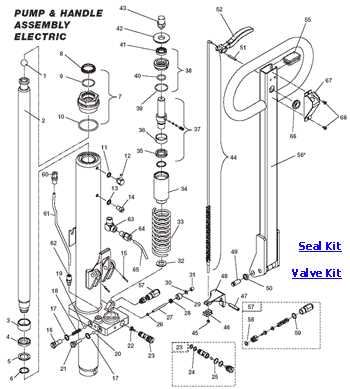

Shock absorbers play a critical role in maintaining vehicle stability and comfort. By controlling the movement of suspension components, they help ensure a smooth ride even on uneven terrains. The efficiency of these components directly affects both handling and safety, as they reduce the impact of road irregularities and prevent excessive bouncing.

Functionality of Shock Absorbers

The primary function of shock absorbers is to dampen the oscillations caused by road imperfections. They work by converting kinetic energy into heat, which is then dissipated. This process reduces the amount of movement transferred to the vehicle’s body, allowing for better control and improved ride quality.

Types and Variations

There are several types of shock absorbers, each designed for specific driving conditions. These include hydraulic, gas-filled, and dual-tube variants, all of which provide varying levels of damping and performance based on vehicle design and usage.

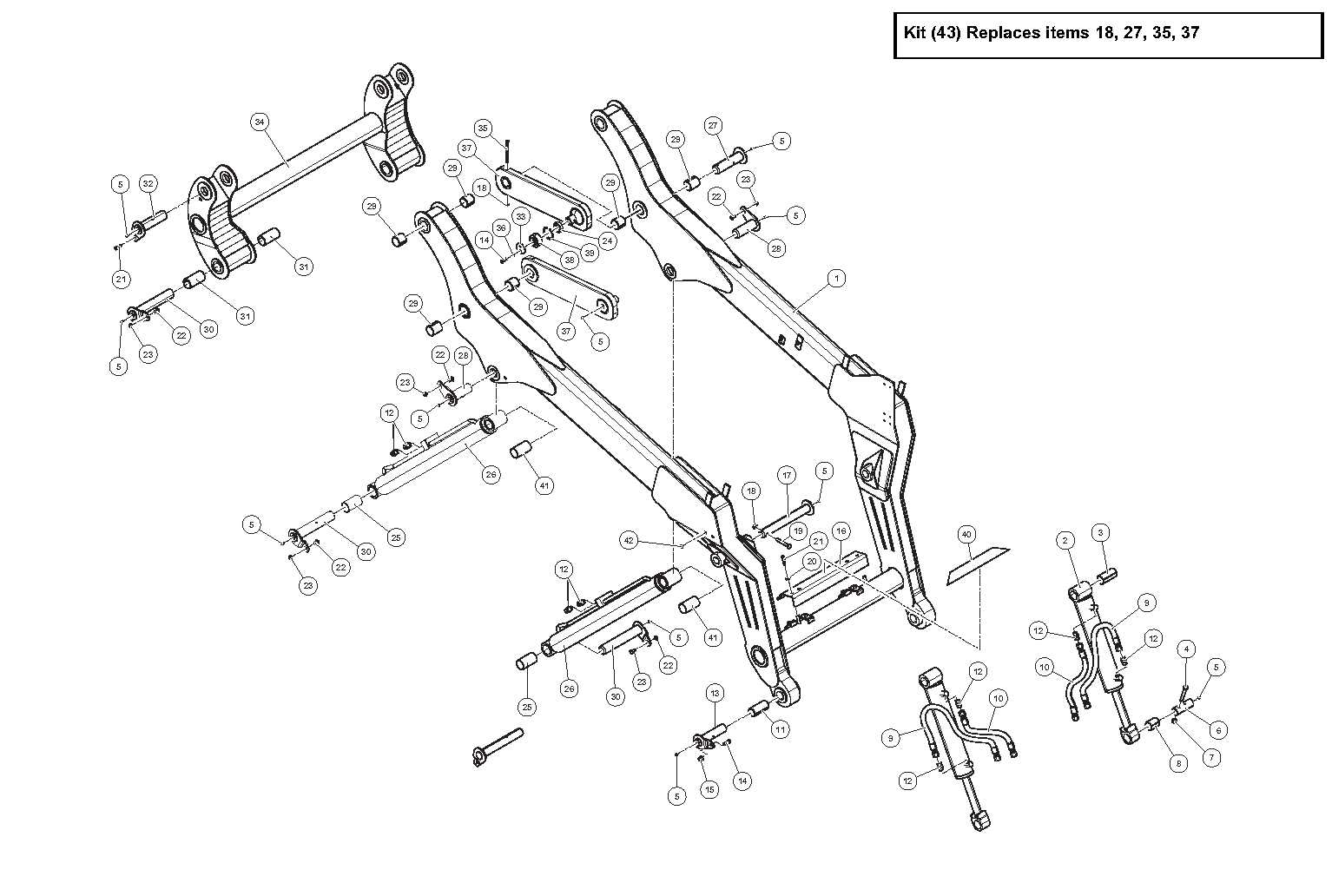

Type Drivetrain Adjustments in Lift Kits When making modifications to a vehicle’s height, it’s essential to ensure that the power transfer system remains aligned and efficient. Changes in the vehicle’s suspension can cause misalignment, which may lead to unwanted vibrations or strain on various components. Proper adjustments help maintain smooth operation and prolong the lifespan of the vehicle’s critical systems.

One of the key factors to consider is the angle of the driveshaft. Altering the suspension height can affect this angle, potentially leading to increased wear on universal joints or causing vibrations. To counteract these issues, it is common to install specialized brackets or adjust linkages to realign the system. These adaptations ensure that torque is transmitted efficiently, reducing the risk of premature failure in the drivetrain.

Another important adjustment involves the differential. Raising the vehicle can change the geometry between the wheels and the power distribution system, requiring adjustments to the differential positioning or the installation of drop brackets. These changes help maintain proper wheel rotation and traction, preventing excessive stress on the axle and improving overall driving performance.

Axle and Differential Upgrades

Enhancing the axle and differential components of your vehicle significantly improves its performance and durability. These modifications can provide better power distribution, increase traction, and allow for greater handling capabilities, especially in off-road conditions.

When considering upgrades, several aspects should be evaluated:

- Gear Ratios: Altering the gear ratios can optimize torque delivery and enhance acceleration, particularly when larger tires are fitted.

- Differential Types: Switching to limited-slip or locking differentials can improve traction on slippery surfaces, providing better control in challenging terrains.

- Axle Strength: Upgrading to heavier-duty axles can withstand increased loads and resist bending or breaking under strain, especially during rigorous use.

Implementing these enhancements can transform your vehicle’s capabilities, making it more versatile and robust in diverse driving situations.

Brake System Enhancements for Lift Kits

Upgrading the braking system is essential when modifying a vehicle’s height. Enhanced braking components ensure optimal performance and safety, accommodating the increased demands placed on the braking system due to altered dynamics. This section explores various improvements that can be made to enhance braking efficiency in modified vehicles.

Key Upgrades to Consider

- High-Performance Brake Pads: Upgrading to premium pads can significantly enhance stopping power and reduce fade.

- Upgraded Rotors: Larger or ventilated rotors improve heat dissipation and overall braking performance.

- Stainless Steel Brake Lines: These lines provide better durability and improved pedal feel compared to standard rubber hoses.

- Brake Caliper Modifications: Adding caliper upgrades can increase clamping force, further enhancing stopping power.

Maintenance Tips for Enhanced Systems

- Regularly inspect all components for wear and tear.

- Bleed the brake system to remove any air bubbles, ensuring optimal hydraulic performance.

- Check fluid levels and replace brake fluid periodically to maintain effectiveness.

- Ensure that all modifications are installed correctly and securely.

Alignment Essentials After Lifting

Ensuring proper orientation of vehicle components following an elevation adjustment is crucial for optimal performance and safety. This process enhances stability and extends the lifespan of the suspension system. Ignoring alignment can lead to uneven tire wear and compromised handling.

Importance of Proper Alignment

Maintaining accurate alignment is essential for several reasons:

- Enhances vehicle control and handling.

- Reduces tire wear and prolongs lifespan.

- Improves fuel efficiency by minimizing resistance.

- Ensures even distribution of forces on suspension components.

Key Steps to Achieve Proper Alignment

- Check and adjust camber angles for optimal tire contact.

- Ensure toe settings are within manufacturer specifications.

- Inspect caster angles for stability during steering.

- Test drive the vehicle to verify handling and comfort.

Regular maintenance checks are advisable to preserve alignment integrity and prevent long-term issues. Prioritize professional assistance to guarantee accurate measurements and adjustments.

Tire and Wheel Compatibility

When modifying a vehicle’s suspension, understanding the relationship between tires and wheels is crucial. Proper selection ensures optimal performance, safety, and aesthetics. Compatibility influences factors like handling, ride quality, and overall stability.

Before choosing new tires and wheels, consider dimensions and specifications. Width and diameter are critical for fitment. Each vehicle has recommended sizes, and deviating from these can lead to issues such as rubbing against suspension components or fenders.

Additionally, offset and backspacing play significant roles in positioning the wheel correctly within the wheel well. Incorrect measurements can affect steering response and could lead to premature wear on tires. Always consult a compatibility chart or expert advice to ensure that selected combinations work harmoniously.

Lastly, keep in mind that different terrains and driving styles may require specific tire characteristics. All-terrain or mud-terrain tires, for instance, have unique features that affect their interaction with wheels. Matching these aspects with intended use will enhance the overall driving experience.