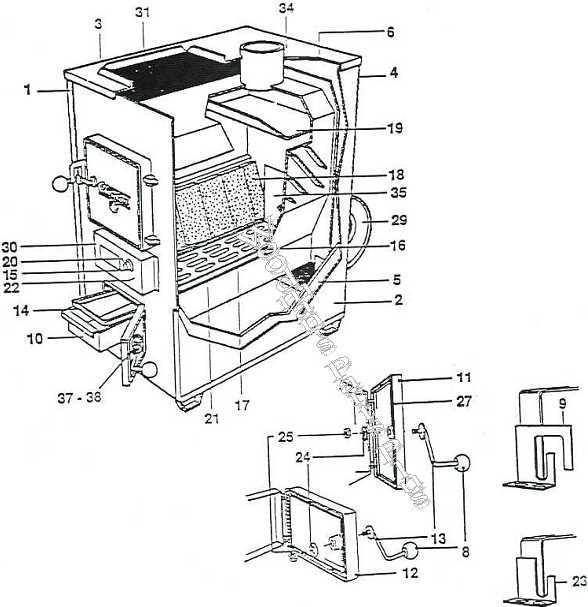

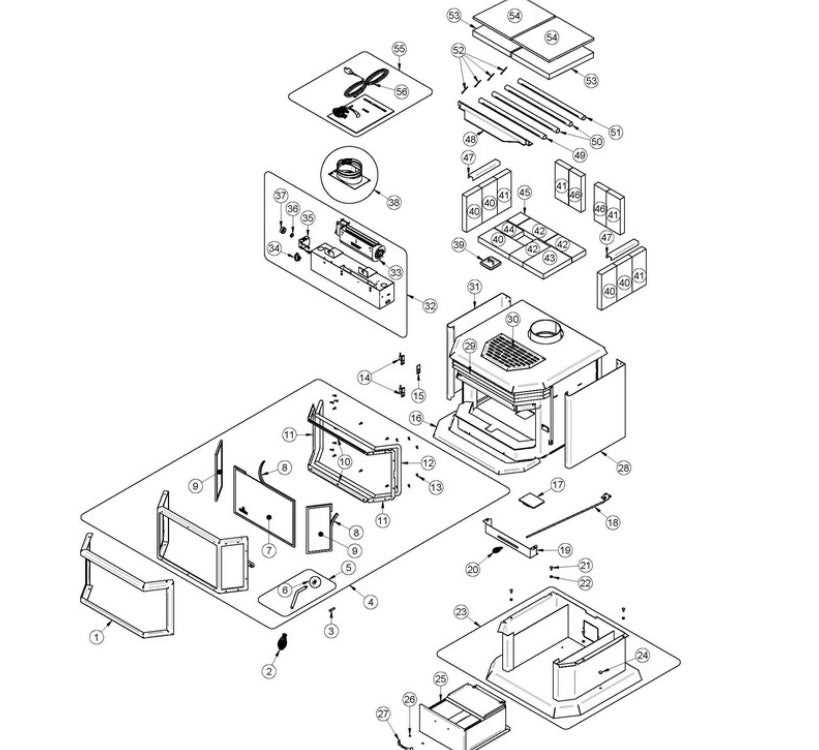

Exploring the intricate assembly of a heating device reveals a fascinating interplay of elements designed to efficiently generate warmth. Each section contributes to the overall functionality, ensuring optimal performance and user safety. Delving into these individual segments provides insight into how they work together harmoniously.

The construction of such an apparatus involves various integral elements, each serving a unique purpose. From the core mechanism that fuels combustion to the structural elements that ensure durability and efficiency, the synergy among these components is crucial for effective operation. Understanding their roles can enhance appreciation for the technology behind modern heating solutions.

Moreover, familiarizing oneself with the layout of these features can aid in troubleshooting common issues and performing maintenance tasks. An informed perspective allows users to optimize their experience and extend the lifespan of the unit, making it a valuable asset in any setting.

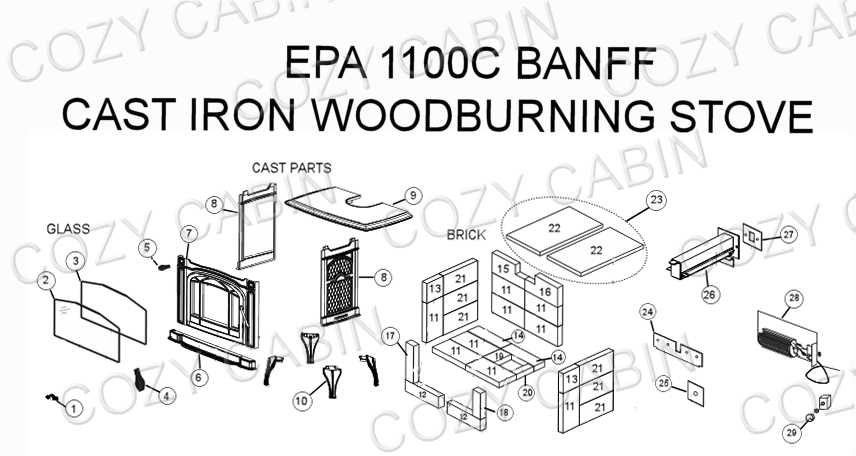

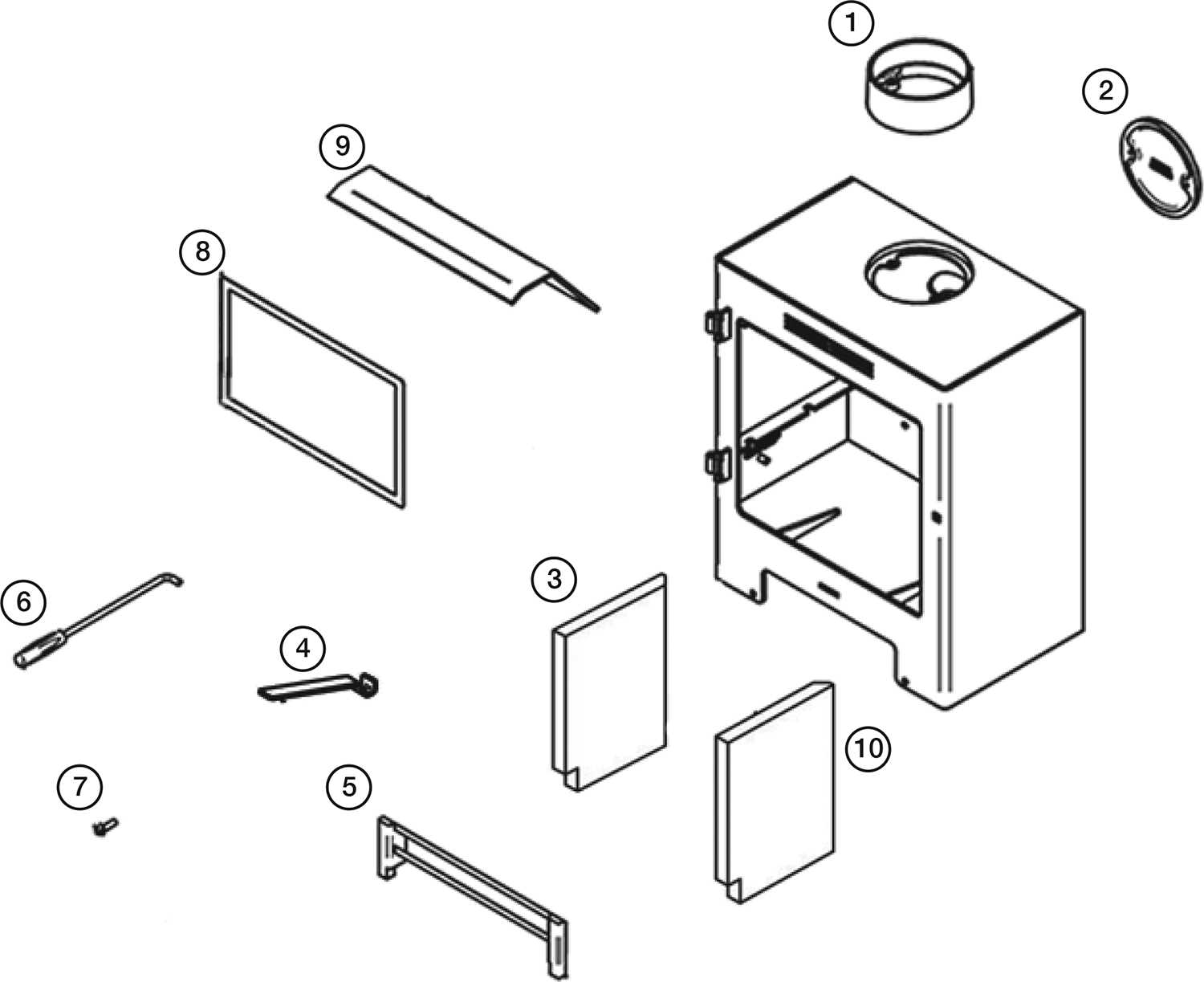

Understanding Wood Stove Components

In the realm of heating appliances, a thorough comprehension of the various elements involved is essential for optimal performance and safety. Each component plays a distinct role, contributing to the overall efficiency and functionality of the unit. Familiarizing oneself with these elements can enhance user experience and maintenance practices.

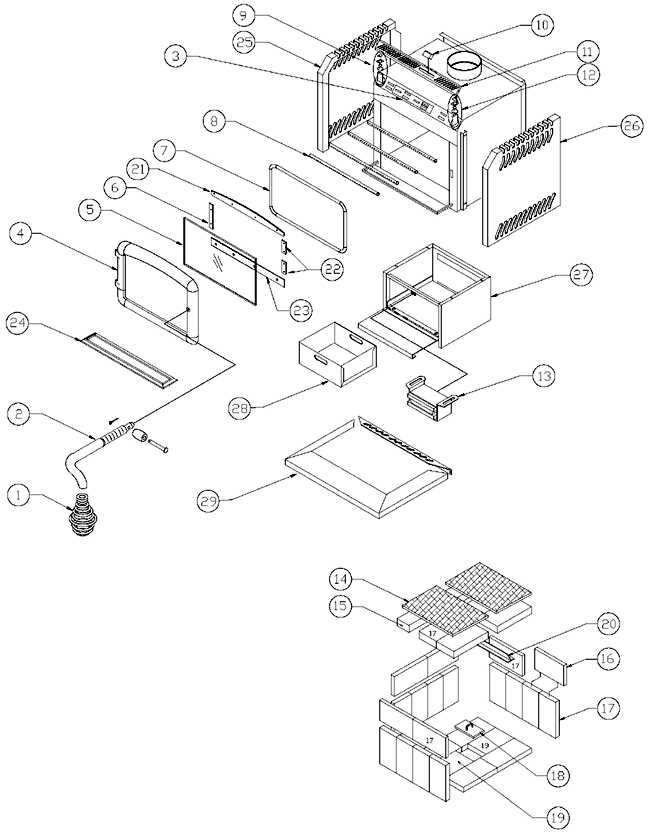

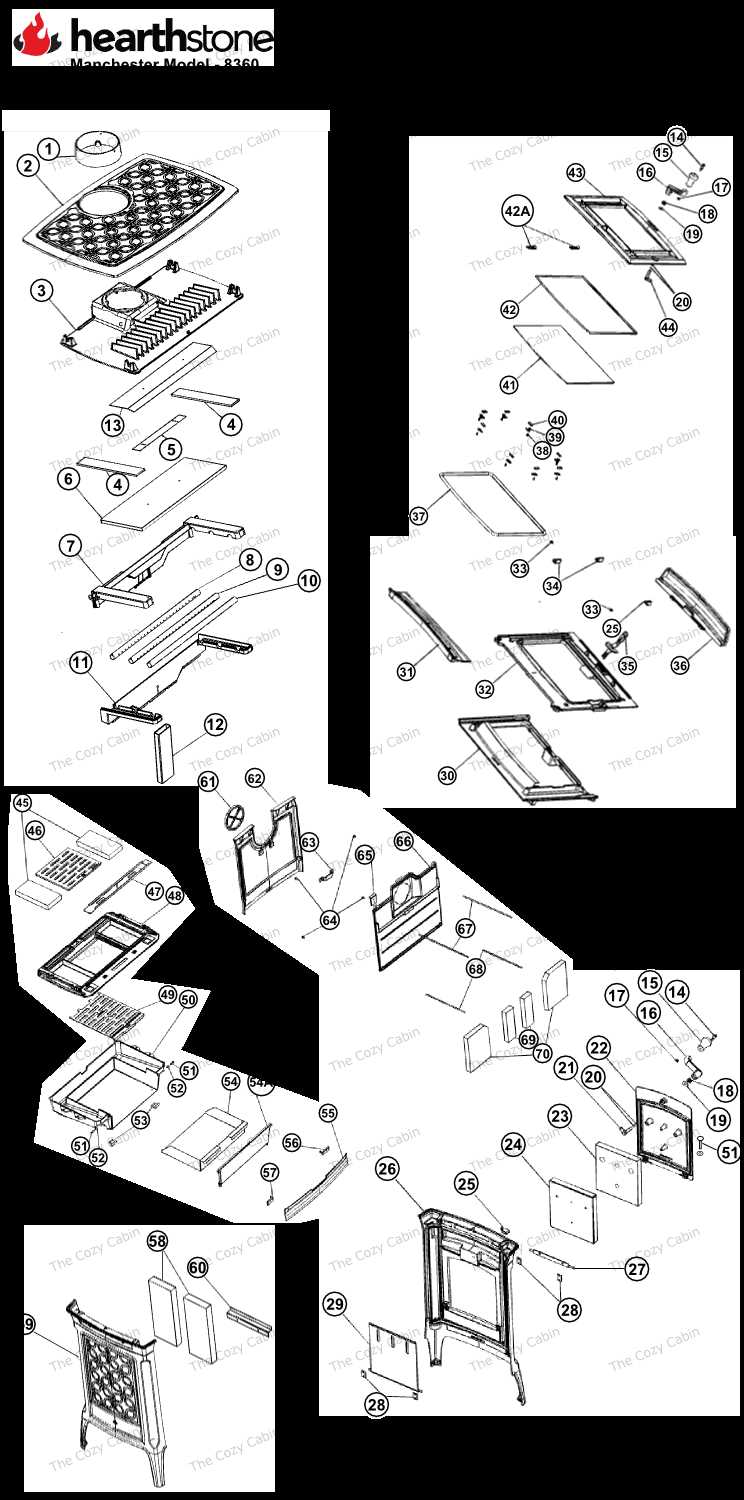

Key elements include:

- Burn Chamber: The area where combustion occurs, designed to withstand high temperatures.

- Flue: A passage that directs smoke and gases outside, essential for ventilation.

- Grate: A support structure that holds fuel while allowing air circulation underneath.

- Ash Pan: A container for collecting residue, facilitating easy cleanup.

- Door: An access point for loading fuel and monitoring the fire, often equipped with glass for visibility.

Understanding these elements helps users to maximize heat output, minimize emissions, and ensure safe operation. Proper knowledge leads to better maintenance and longevity of the appliance.

Function of the Firebox

The firebox serves as the central chamber where combustion takes place, playing a crucial role in the efficiency and effectiveness of heating appliances. Its design and materials are optimized to withstand high temperatures while facilitating proper airflow, which is essential for maintaining a steady flame and maximizing heat output.

Within this chamber, fuel is ignited, and the resulting heat is generated. The structure is engineered to ensure that combustion is complete, minimizing smoke and harmful emissions. This not only enhances performance but also promotes a cleaner environment.

Moreover, the firebox’s configuration allows for easy loading and maintenance, making it convenient for users to manage their heating needs. The integration of insulation within its walls helps retain heat, ensuring that warmth is efficiently distributed throughout the living space.

In summary, the firebox is integral to the functionality of heating systems, providing a safe and effective means of producing heat while optimizing fuel consumption and reducing environmental impact.

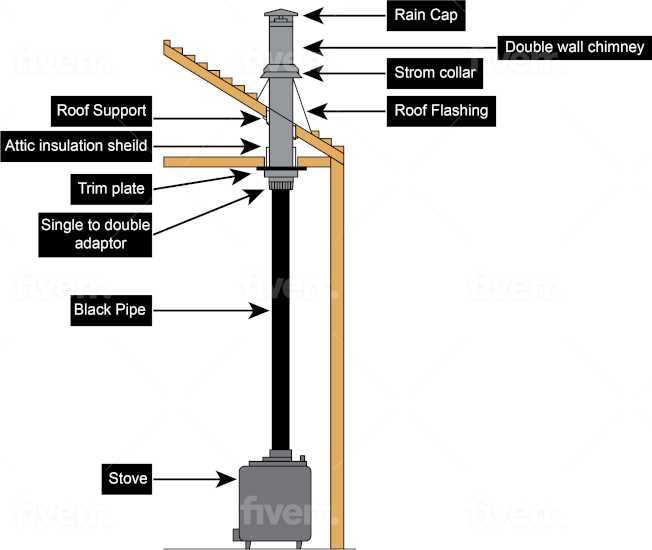

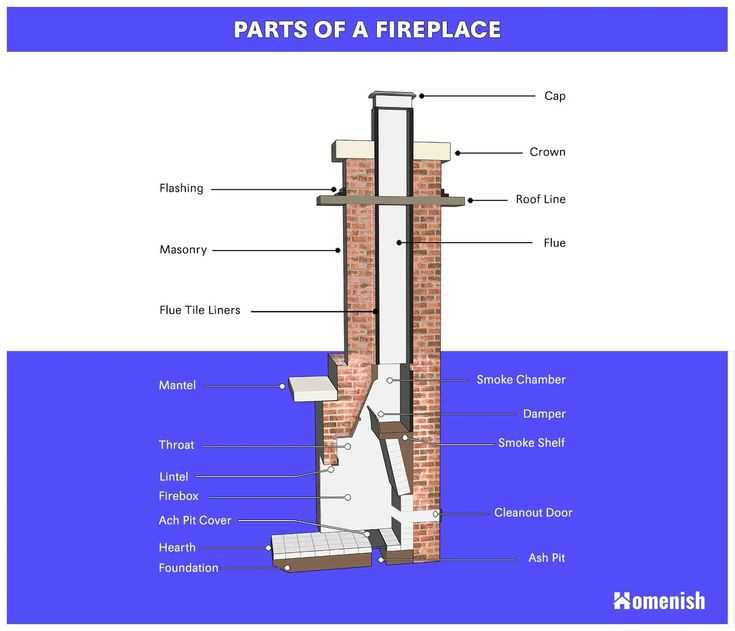

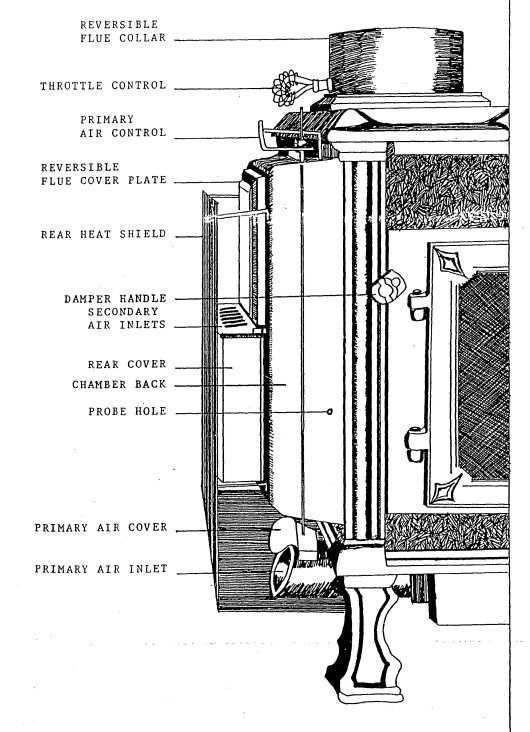

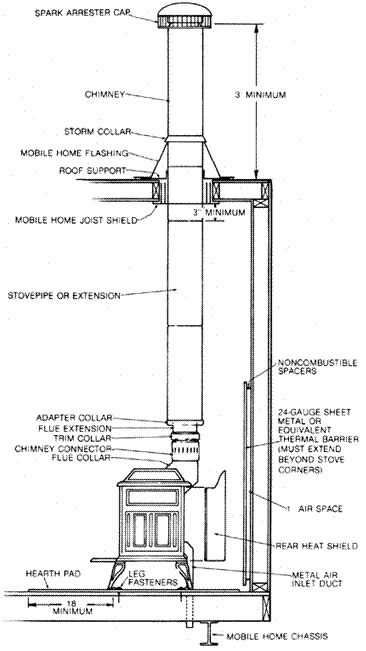

Role of the Flue System

The flue system serves a critical function in ensuring safe and efficient operation. It is designed to manage the movement of gases and smoke produced during combustion, directing them away from the living space and minimizing potential hazards. Proper functioning of this system is essential for maintaining indoor air quality and preventing the buildup of harmful substances.

Key Functions of the Flue System

- Ventilation: Facilitates the removal of combustion byproducts.

- Draft Control: Helps regulate airflow for optimal burning conditions.

- Temperature Regulation: Maintains safe temperatures to prevent overheating.

Importance of Proper Installation

Correct installation of the flue system is vital for achieving its intended benefits. Factors to consider include:

- Height and Size: Proper dimensions ensure effective draft.

- Material Selection: Durable materials withstand high temperatures.

- Clearances: Adequate space prevents heat transfer to combustible materials.

Investing in a well-designed flue system not only enhances safety but also improves overall efficiency, leading to a more enjoyable experience for users.

Importance of the Ash Pan

The component designed for collecting residual materials from combustion plays a crucial role in maintaining efficiency and safety during operation. Its proper management can significantly enhance the overall experience of using a heating appliance.

Here are several key reasons why this element is vital:

- Efficiency: Keeping the collection unit clean allows for optimal airflow, which enhances the burning process and increases heat output.

- Safety: Proper disposal of ash reduces the risk of fire hazards and ensures that flammable materials do not accumulate.

- Convenience: A dedicated space for residuals simplifies the cleaning process, making it easier to maintain the heating device.

- Longevity: Regularly removing ash helps prevent corrosion and damage to the appliance, extending its lifespan.

In conclusion, the importance of this collecting unit cannot be overstated. By ensuring its effective use and maintenance, users can enjoy a safer and more efficient heating experience.

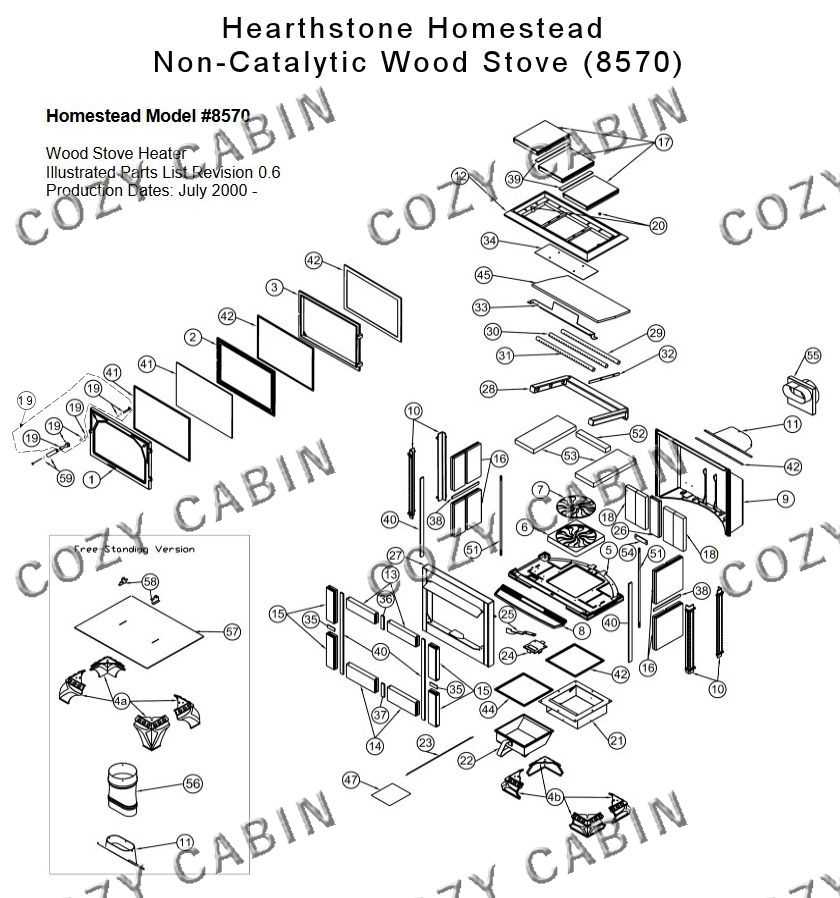

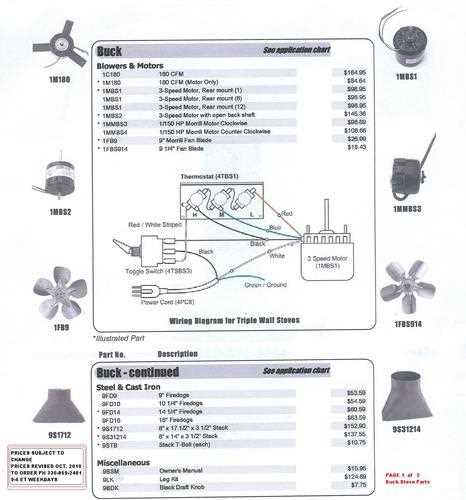

Heat Exchanger Mechanism Explained

The mechanism of heat exchange is a crucial aspect of optimizing thermal efficiency in various heating systems. This process facilitates the transfer of thermal energy from one medium to another, enhancing the overall performance of the system. Understanding how this mechanism operates is vital for maximizing heating capabilities and ensuring effective energy utilization.

How It Works

The heat exchange process typically involves several key elements that work together seamlessly:

- Heating Source: The initial energy source generates heat, which is crucial for the exchange process.

- Transfer Medium: This can be air, water, or other fluids that absorb the generated heat.

- Heat Exchanger Unit: This component facilitates the transfer of heat between the source and the medium without direct contact.

- Distribution System: Once the medium is heated, it is circulated to deliver warmth throughout the space.

Benefits of Effective Heat Exchange

Implementing an efficient heat exchange mechanism offers several advantages:

- Improved energy efficiency, reducing fuel consumption.

- Enhanced comfort through consistent temperature distribution.

- Lower environmental impact by minimizing emissions.

- Extended lifespan of the heating system due to reduced strain on components.

Insulation and Safety Features

Effective thermal management and safety considerations are crucial when it comes to efficient heating appliances. These elements not only enhance performance but also ensure a secure environment for users. Proper insulation helps to maintain optimal temperatures while minimizing heat loss, while safety features are designed to protect against potential hazards.

Importance of Insulation

Insulation plays a vital role in enhancing the efficiency of heating systems. It reduces energy consumption and contributes to a comfortable indoor climate. Key benefits include:

- Minimizing heat escape, leading to lower energy bills.

- Maintaining consistent temperatures throughout the space.

- Reducing the risk of overheating and damage to surrounding materials.

Essential Safety Features

In addition to insulation, various safety features are integrated to prevent accidents and ensure user protection. These may include:

- Heat Shields: Protect surrounding surfaces from excessive heat.

- Temperature Sensors: Automatically shut down the system if temperatures exceed safe limits.

- Airflow Controls: Regulate ventilation to prevent harmful gas accumulation.

- Child Locks: Prevent unauthorized access and ensure safety in homes with young children.

By prioritizing these thermal management and safety features, users can enjoy the benefits of efficient heating while minimizing risks.

Types of Wood Stove Materials

When selecting a heating appliance, the choice of construction materials plays a crucial role in efficiency, durability, and performance. Different substances impart unique characteristics to the unit, influencing heat retention, distribution, and overall user experience.

Cast Iron is renowned for its ability to retain heat for extended periods, providing a steady warmth even after the fire has diminished. Its robust nature allows for intricate designs, making it both functional and aesthetically pleasing.

Steel, on the other hand, is lighter and heats up more quickly than cast iron. This material is often preferred for its modern look and ease of installation. However, it may require more frequent maintenance due to its tendency to warp over time.

Soapstone is another popular choice, celebrated for its exceptional heat retention properties. This natural stone can absorb heat and release it slowly, ensuring a consistent temperature in the surrounding area.

Brick or ceramic linings are often used to enhance insulation within the structure, improving safety and efficiency. These materials not only contribute to the appliance’s performance but also add an element of design sophistication.

Each material offers distinct advantages, making the selection process critical for achieving the desired heating outcome and overall satisfaction.

Air Control Systems Overview

Efficient combustion relies heavily on the management of airflow within a heating appliance. The ability to regulate the intake of air significantly impacts both performance and fuel efficiency. Understanding how these systems operate can enhance the overall functionality of heating units and contribute to a cleaner environment.

Airflow Management is crucial for optimizing combustion. By controlling the amount of oxygen available, users can influence the temperature and intensity of the fire. This balance not only maximizes heat output but also minimizes smoke emissions, promoting a more sustainable use of resources.

There are typically two main categories of airflow regulation: primary and secondary. Primary airflow is responsible for initiating combustion, while secondary airflow enhances the burn efficiency by promoting complete combustion of gases produced during the burning process. Together, these systems create a more controlled and efficient heating environment.

Advanced designs may also incorporate automatic control mechanisms, which adjust airflow based on real-time conditions, ensuring optimal performance without constant manual intervention. These innovations reflect a growing trend towards smart technology in heating solutions.

Maintenance Tips for Wood Stoves

Regular upkeep is essential for ensuring efficient and safe operation of your heating appliance. By following some simple practices, you can extend its lifespan and improve performance, ultimately providing a cozy atmosphere during colder months.

Here are some key maintenance tips to keep in mind:

- Inspect the chimney: Regularly check for blockages or creosote buildup to prevent hazardous situations.

- Clean the appliance: Remove ashes and residue after each use to maintain airflow and efficiency.

- Check seals and gaskets: Ensure that all connections are airtight to maximize heat retention and minimize smoke leakage.

In addition to these fundamental tasks, consider the following recommendations:

- Schedule an annual professional inspection to identify any potential issues early.

- Use seasoned fuel to reduce the amount of creosote produced and enhance combustion efficiency.

- Monitor the temperature during operation to avoid overheating, which can damage the unit.

By adhering to these guidelines, you can ensure that your heating appliance operates optimally, providing comfort and safety for you and your family.