For those seeking to maintain or repair specific heating and cooling systems, familiarizing oneself with the layout of key components is essential. A clear overview of each part’s position and function helps in identifying issues and ensuring smooth operations. This knowledge empowers technicians and DIY enthusiasts alike to work with precision and confidence.

Every system is made up of interconnected elements, each playing a vital role in its overall efficiency. Understanding how these individual pieces fit together can simplify maintenance and troubleshooting. Whether you’re dealing with electrical units, mechanical components, or other essential parts, having a visual representation of their arrangement is invaluable.

In-depth knowledge of the inner workings of these systems allows for quicker problem-solving and more accurate repairs. It is crucial for anyone involved in the maintenance process to have access to reliable information, ensuring they can identify and replace damaged elements without unnecessary delays.

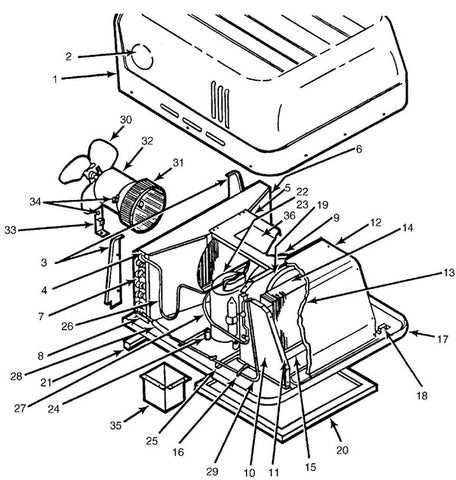

Overview of Duo Therm 57915 Components

This section provides a comprehensive look at the key elements that make up the system, offering insight into how these components interact to ensure optimal functionality. Understanding each component’s role is essential for proper maintenance and troubleshooting. These components come together to form a cohesive unit, each fulfilling a specific purpose that contributes to the overall performance.

Core Elements

The core assembly is designed to offer robust performance under varying conditions. It includes several critical units that regulate airflow, heating, and control. Each part has been engineered to meet precise standards, ensuring that the system operates smoothly and efficiently. Some of these units are responsible for electrical connectivity, while others control temperature and air distribution.

Supportive Mechanisms

In addition to the main components, the system incorporates various supportive mechanisms that assist in the smooth operation of the entire setup. These mechanisms play vital roles in enhancing safety, energy efficiency, and ease of use. From temperature sensors to mechanical linkages, every element works in harmony to provide a seamless experience for the user.

Key Features of the 57915 Model

The model under discussion is designed to offer high efficiency and exceptional durability, making it a popular choice for users seeking reliable performance. Its innovative design and robust construction make it suitable for various demanding environments, ensuring long-lasting operation. This model is built with attention to detail, which guarantees seamless functionality and ease of use.

One of the standout features is its compact size, which allows for easy installation in different setups without taking up too much space. Along with this, the advanced cooling system ensures that the device operates optimally even under high loads. Moreover, the system is engineered for minimal maintenance, providing users with hassle-free ownership.

Additionally, the unit boasts energy efficiency that reduces power consumption while maintaining optimal output. This is coupled with user-friendly controls that simplify operation, making it accessible even for those with limited technical expertise. All these aspects come together to deliver a product that is both efficient and cost-effective, making it a top choice for a variety of applications.

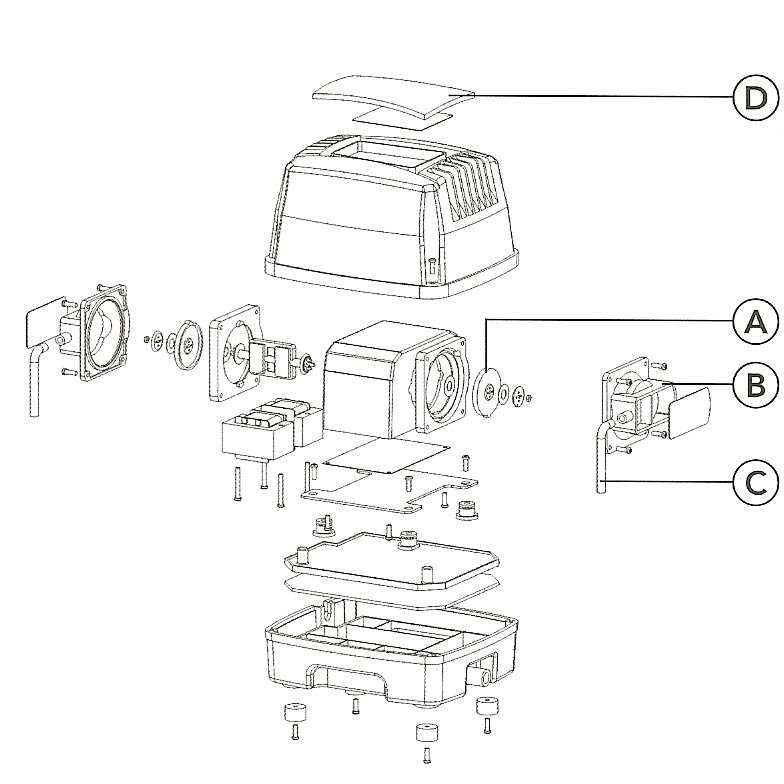

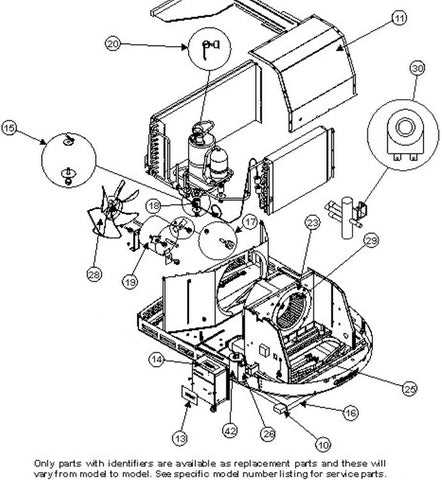

How to Identify Parts on the Diagram

Understanding how to recognize various components in a technical drawing can be crucial for assembly or maintenance tasks. The key to accurate identification lies in learning to read the visual cues and labels that highlight each item. By familiarizing yourself with the representation method, you can efficiently match real-world components with their corresponding images or symbols on the schematic.

First, examine the general layout of the drawing. Each symbol or outline represents a specific object or assembly. Look for unique identifiers such as numbers, letters, or specific shapes that are associated with the component. These are often included next to each item to provide additional context. Pay attention to connections and orientation, which can give hints about how each piece fits into the larger structure.

Next, refer to the accompanying key or legend, if available, which typically provides detailed explanations of the symbols and their meanings. This guide is invaluable for anyone unfamiliar with the technical language of such representations. Finally, practicing the identification process will improve your ability to quickly and accurately recognize the elements in future references.

Common Issues with Duo Therm 57915

When working with heating and cooling systems, it’s common to encounter a few challenges that can affect performance and efficiency. These units, designed to provide comfort in various environments, can face difficulties due to wear and tear or improper maintenance. Understanding the most frequent problems can help you address them effectively and avoid costly repairs in the future.

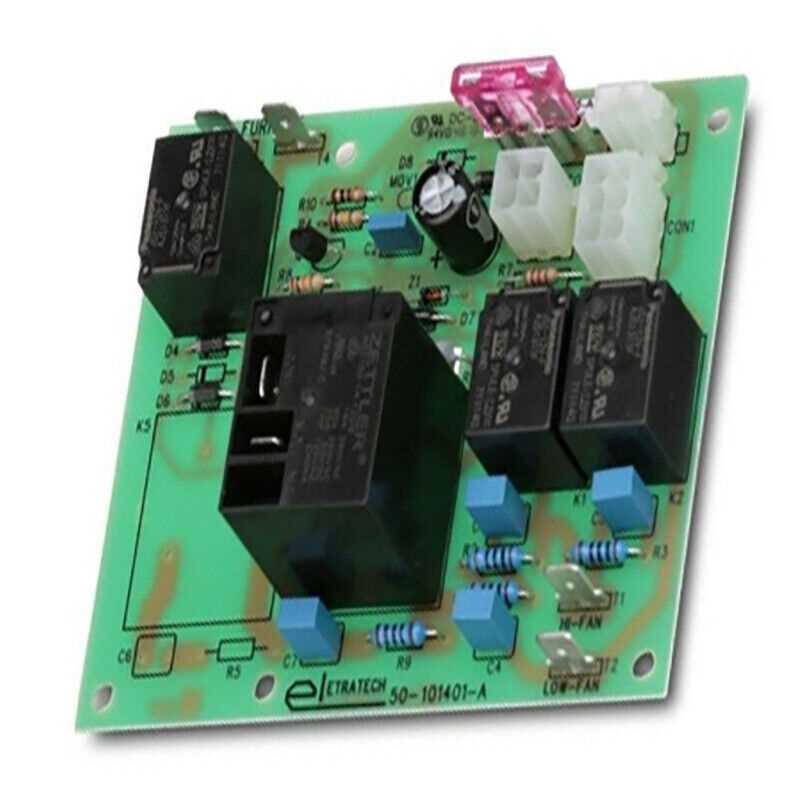

Electrical Failures: One of the primary issues experienced with such systems is electrical malfunctions. Whether it’s a blown fuse, faulty wiring, or a malfunctioning thermostat, electrical failures can interrupt the system’s operation. Inspecting connections and ensuring proper functionality of circuit components is essential.

Overheating: Overheating is another common concern. This can happen due to poor ventilation, a clogged filter, or an issue with the cooling fan. Over time, the unit may struggle to maintain proper temperatures, leading to reduced efficiency and potential damage to internal components.

Strange Noises: Unusual sounds, such as rattling or buzzing, may indicate that internal mechanisms are misaligned or loose. These noises should be investigated quickly to prevent further damage, as they often point to a mechanical fault that can worsen over time.

Inconsistent Temperature Regulation: In some cases, users report difficulty in maintaining a consistent temperature. This could be due to an issue with the sensor, poor insulation, or problems within the control system. Ensuring that all components are calibrated correctly is crucial for stable operation.

Water Leaks: Finally, leaks may develop, often caused by blocked drainage lines or damaged seals. Persistent leaks not only affect system performance but can also cause water damage to surrounding structures. Regular checks and maintenance can prevent this issue from escalating.

Where to Find Replacement Parts

When it comes to maintaining your equipment, knowing where to source the necessary components can make all the difference. Finding reliable suppliers for the specific pieces you need ensures smooth operation and longevity of your unit. In this section, we will explore the various avenues available for obtaining the right replacements for your system.

Authorized Dealers

One of the most trustworthy options is to visit authorized dealers. These providers are directly connected to the manufacturer, ensuring that the items they supply are genuine and tailored to your model. Not only do they stock original components, but they often offer customer support to help you identify the correct pieces for your needs. Always check for an official partnership with the manufacturer when considering a dealer.

Online Retailers

In today’s digital age, numerous online platforms offer a vast selection of replacement pieces. Websites specializing in home appliances and mechanical systems often carry a wide range of items suitable for various models. While convenient, it’s essential to read reviews and verify the authenticity of the seller before making a purchase to avoid counterfeit products or mismatches.

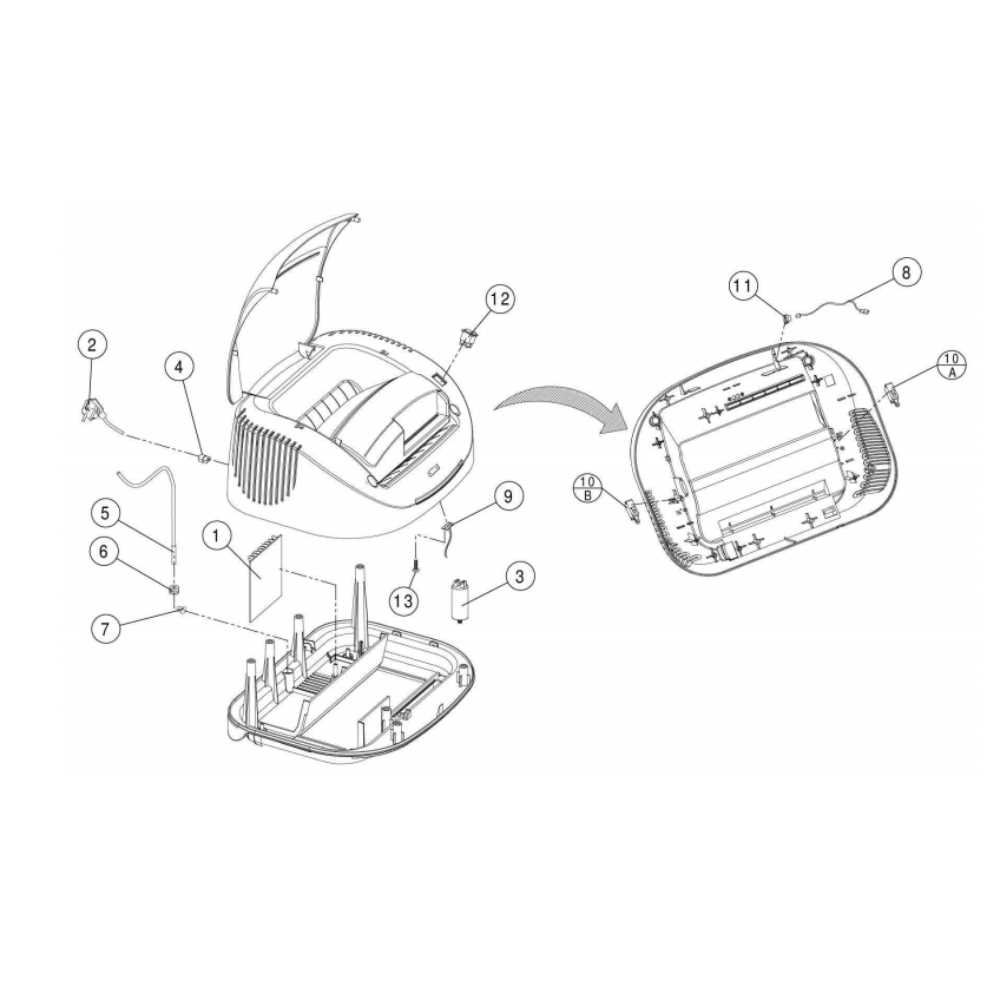

Step-by-Step Assembly of Duo Therm Parts

When assembling complex equipment, it is essential to follow an organized and methodical approach to ensure all components are correctly integrated. Understanding the structure of the system and recognizing how each component fits together can significantly reduce assembly time and minimize errors. This guide provides clear instructions for assembling the unit, allowing for an efficient and smooth process.

Preparation and Initial Setup

Before beginning the assembly process, gather all the necessary tools and components. Ensure each piece is free from defects and ready for installation. Having a clean workspace and organizing parts based on their functionality will help maintain focus throughout the process.

Assembly Steps

Start with the base assembly, aligning the foundational elements before moving on to the more intricate components. Begin by securing the main structure, followed by attaching smaller subassemblies. Pay attention to any locking mechanisms or fasteners that hold parts in place. Verify that all connections are secure, and test the fit of each piece before moving to the next stage.

| Step | Description |

|---|---|

| 1 | Align the main structural components. |

| 2 | Secure the subassemblies using appropriate fasteners. |

| 3 | Ensure all components are firmly locked in place. |

| 4 | Test the unit for proper functionality before finalizing the assembly. |

Maintenance Tips for Longevity

Proper care and regular maintenance are essential to extend the lifespan of your equipment. Keeping it in good working order ensures optimal performance and prevents costly repairs. By following a few simple practices, you can significantly increase the durability and efficiency of your device, allowing it to serve you for many years to come.

Regular Cleaning

One of the most important aspects of maintenance is keeping the unit clean. Dust and debris can accumulate over time, leading to reduced efficiency or even damage to internal components. Make sure to clean the exterior and interior parts according to the manufacturer’s recommendations. This includes removing dust from vents, fans, and other sensitive areas where dirt may accumulate. A clean system runs more efficiently and experiences less wear and tear.

Routine Inspections

Scheduling regular inspections is crucial to ensure all moving parts are functioning as they should. Check for any signs of wear, such as loose connections or damaged components, and address them before they become major issues. Staying proactive can help prevent unexpected breakdowns and extend the device’s operational life. Additionally, make sure all lubricants and fluids are at appropriate levels to keep everything running smoothly.

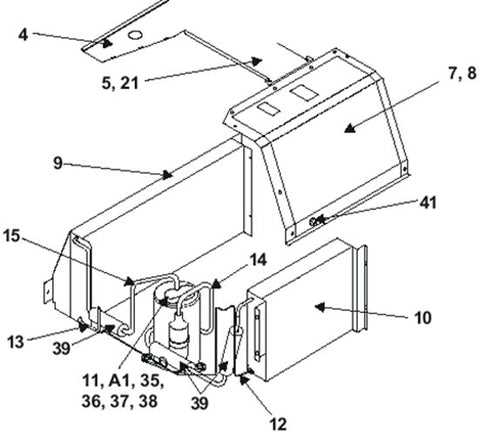

Upgrading Your Duo Therm System

Improving the functionality of your climate control unit can significantly enhance your comfort and efficiency. Whether you’re looking to modernize your system for better performance or replace outdated components, there are several upgrades worth considering. These adjustments can offer greater energy savings, improved air circulation, and increased reliability.

Enhanced Efficiency with New Components

When upgrading, focus on the key areas that directly impact energy consumption. Replacing older parts with more efficient models can result in lower operational costs and improved system longevity. Upgrading components like the control unit or heating elements can also reduce maintenance needs and prevent common malfunctions.

Improved Comfort with Advanced Features

For those seeking enhanced comfort, consider installing units with advanced temperature control features. Smart thermostats, for example, allow you to manage climate settings remotely, optimizing the environment even when you’re away. Additionally, adding extra vents or updating the air distribution system can help ensure consistent airflow and temperature throughout your space.

FAQs on Duo Therm 57915 Parts

This section provides answers to common questions regarding the components of a specific air conditioning unit and its assembly. If you are looking to understand how the system operates or how to maintain it properly, you will find helpful insights here. The following questions and answers cover various aspects of the product’s internal mechanisms and their functionalities.

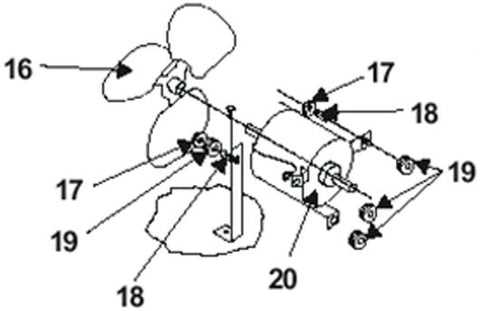

- What is the purpose of the cooling unit’s fan assembly?

The fan assembly is responsible for circulating air within the system, ensuring efficient cooling and maintaining the overall temperature balance.

- How often should filters be replaced or cleaned?

It is recommended to clean or replace the filters every 3 to 6 months depending on usage, ensuring optimal air quality and airflow.

- Can I replace the compressor myself?

While it is possible to replace the compressor, it is advised to seek professional help for this complex task to avoid damage or safety issues.

- What are the signs that indicate a malfunctioning capacitor?

Signs of capacitor failure include unusual noises, the system not starting, or the compressor running inefficiently.

- Are there any specific tools required for servicing the unit?

Basic tools such as screwdrivers, wrenches, and a multimeter are typically needed for minor repairs. For more advanced repairs, specialized tools may be required.

- How can I identify if the condenser coil needs to be replaced?

If you notice reduced cooling efficiency or the presence of visible damage on the coil, it may be time to consider a replacement.