The internal structure of all-terrain machines plays a crucial role in their performance and reliability. Familiarizing oneself with the intricate design and organization of different elements helps enthusiasts and mechanics ensure the smooth functioning of these vehicles. Knowing where each segment fits and how it interacts with others is key to both maintenance and potential upgrades.

For those diving into the mechanics of rugged vehicles, recognizing the arrangement of individual components is essential. This understanding aids in troubleshooting issues, performing replacements, and optimizing the vehicle’s capabilities for varied terrains. Mastering this knowledge can significantly extend the lifespan and enhance the resilience of your off-road machine.

Whether you’re a seasoned technician or a beginner learning the ropes, grasping the blueprint of these robust machines empowers you to make informed decisions. It opens the door to a deeper appreciation of the engineering behind the wheels, guiding you in tailoring your vehicle to meet your specific needs and preferences.

In this section, we will explore the various essential components that make up this iconic vehicle, highlighting their roles and functionalities. The focus will be on understanding how these elements contribute to the overall performance and reliability of the machine, providing insights into their placement and interaction.

Main Structural Elements

The primary framework and its supporting elements play a crucial role in the machine’s durability and stability. Let’s break down the core structures that maintain its shape and form:

- Chassis – Acts as the backbone, supporting all other assemblies and ensuring balance.

- Suspension System – Provides smooth handling over diverse terrains by absorbing shocks and impacts.

- Body Panels – Protects internal mechanisms from debris and external damage while enhancing its appearance.

Engine

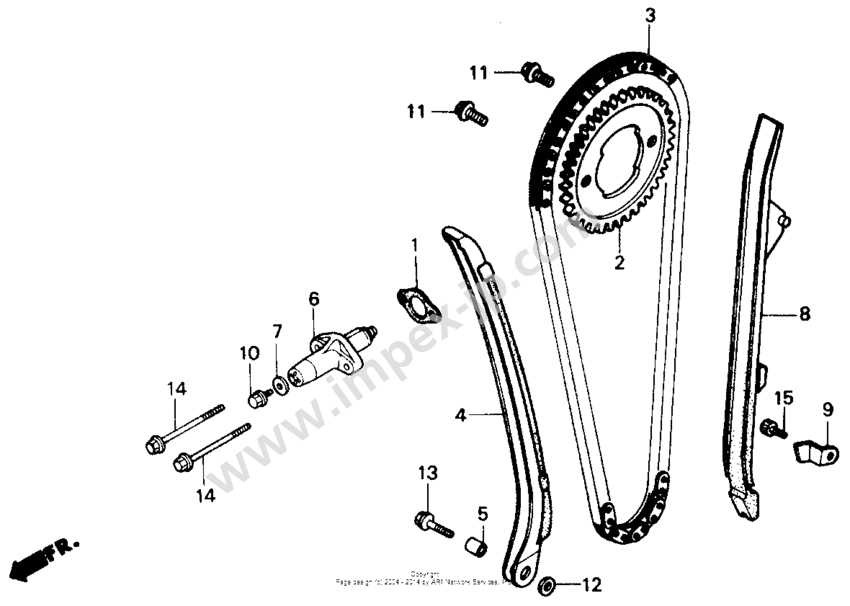

Engine Assembly Breakdown

Understanding the layout of the engine assembly is crucial for efficient maintenance and repairs. By examining the internal components and their connections, enthusiasts can gain insight into how each piece functions within the overall mechanism. This approach allows for a clearer view of how to diagnose issues and ensure the engine operates smoothly.

Core Components Overview

The engine consists of several essential parts that work together harmoniously. Key elements include the cylinder, crankshaft, piston, and connecting rod, each playing a significant role in power generation. Proper alignment and condition of these components are vital for optimal performance and longevity.

Linkages and Support Structures

The linkages and support structures hold the internal elements in place, ensuring stability during operation. This system includes bolts, brackets, and housings that secure everything firmly, preventing unnecessary movement or vibrations. Regular inspection of these parts can help maintain the assembly’s integrity and prevent potential malfunctions.

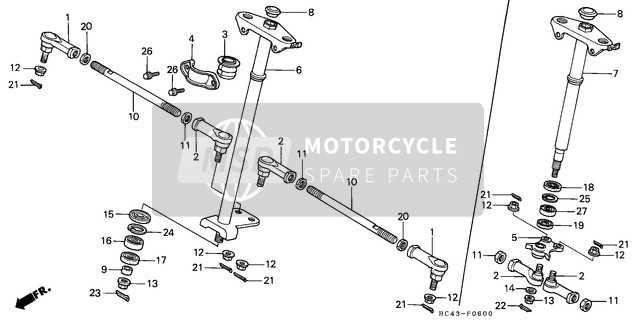

Suspension System Elements

The suspension system plays a crucial role in providing stability, comfort, and control during rides. It is designed to absorb shocks from uneven terrain, ensuring that the vehicle remains balanced and responsive. Understanding the different components within this setup can help enhance the overall performance and longevity of the system.

Shock Absorbers

Shock absorbers are essential for dampening the impact from rough surfaces, reducing vibrations and maintaining smooth handling. They work by converting kinetic energy into heat, which helps in minimizing sudden jolts and providing a more comfortable ride.

Springs and Linkages

Springs and linkages support the vehicle’s weight and contribute to its flexibility over various terrains. They distribute forces evenly, allowing the wheels to maintain contact with the ground while adapting to changing conditions, which is vital for stability and maneuverability.

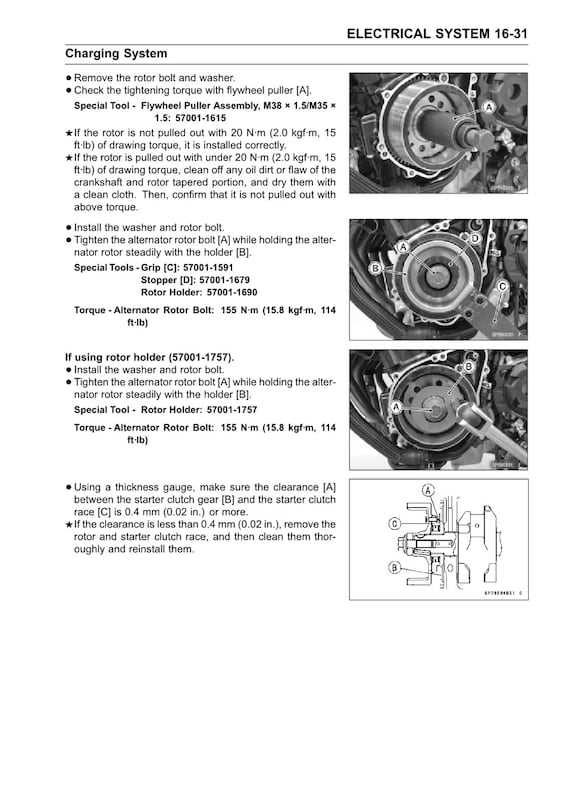

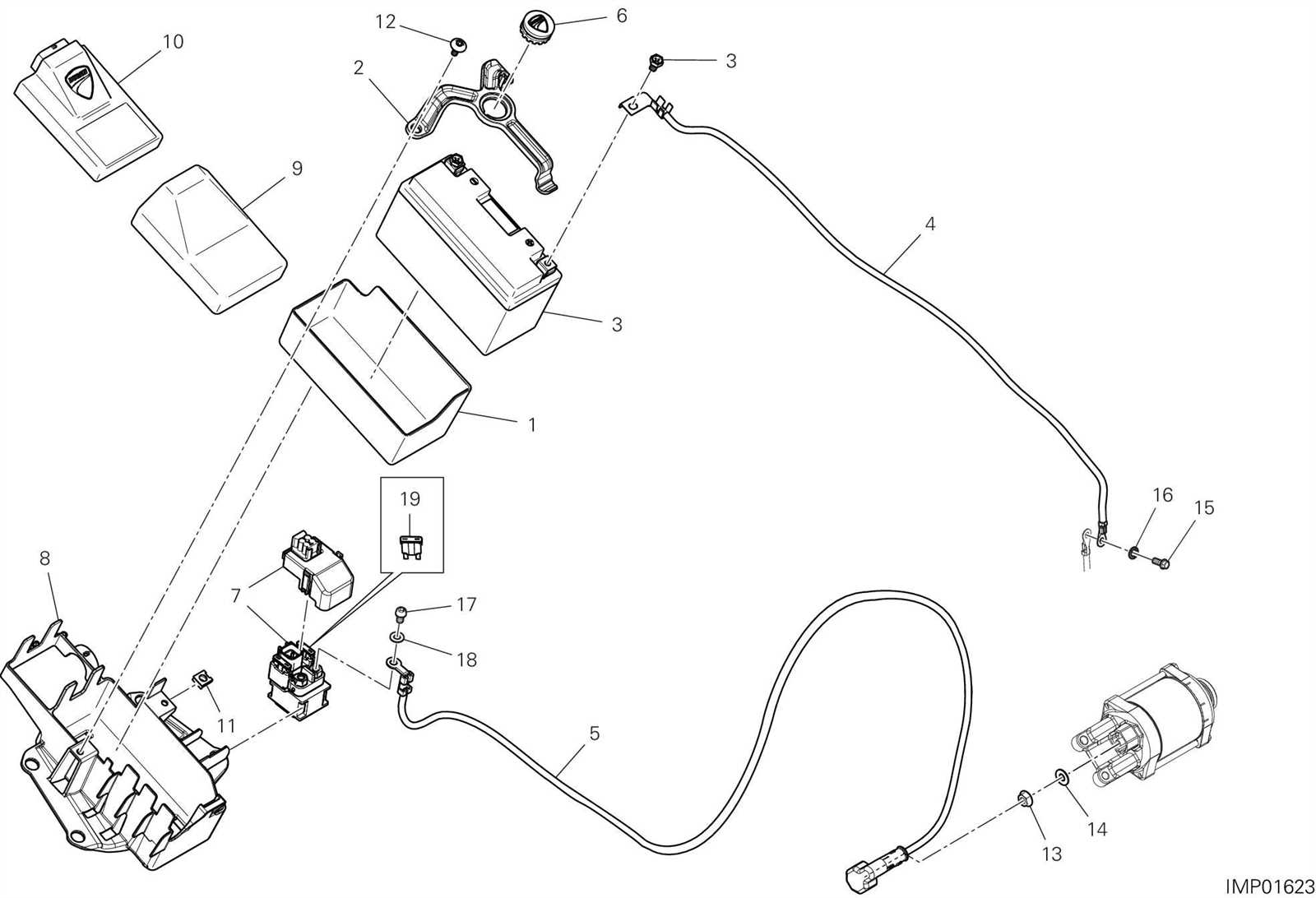

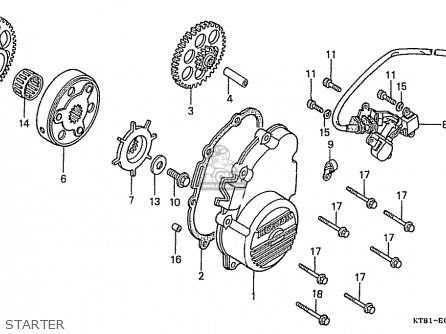

Electrical Wiring Layout

The electrical connections within the system are designed to ensure seamless functionality across various components. Understanding the arrangement of these connections is crucial for maintaining the system’s performance and addressing any technical issues. The layout illustrates how each conductor links different units, allowing for efficient power distribution and signal flow.

Each wire serves a specific purpose, interconnecting multiple circuits to facilitate communication between the system’s elements. Recognizing the placement and role of each connection helps in diagnosing potential malfunctions and ensuring smooth operation of the setup. Detailed knowledge of this structure enables effective troubleshooting and optimal system configuration.

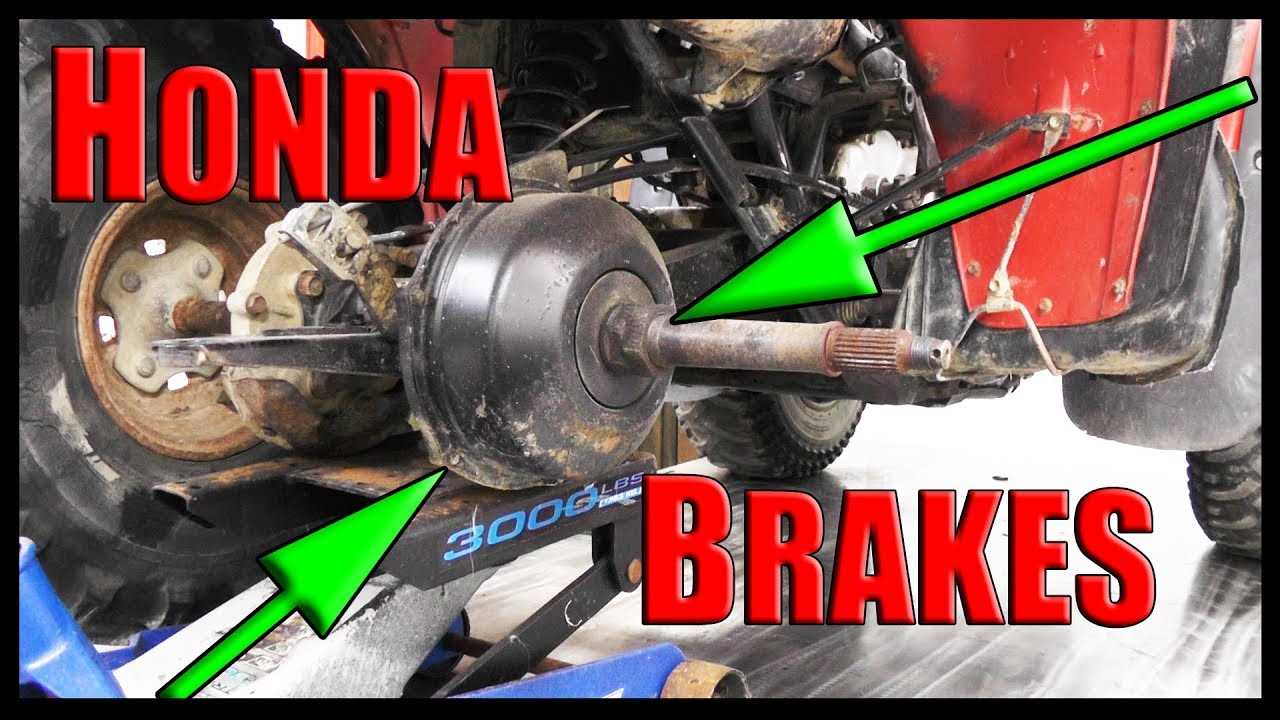

Brake System Components

The brake assembly is a crucial aspect of any off-road vehicle, designed to ensure safe and reliable stopping power. This section provides a detailed look at the individual elements that make up the braking mechanism, highlighting their functions and interactions within the overall setup.

| Component | Description |

|---|---|

| Master Cylinder | Acts as the primary control unit, converting the force from the lever or pedal into hydraulic pressure to engage the brake calipers. |

| Brake Calipers | Clamp onto the rotor using hydraulic pressure to slow down or stop the wheel’s rotation. |

| Brake Pads | Friction material attached to the calipers, making direct contact with the rotor to create the necessary braking force. |

| Rotors | Discs that rotate with the wheels, against which the brake pads press to slow down or stop the motion. |

Brake

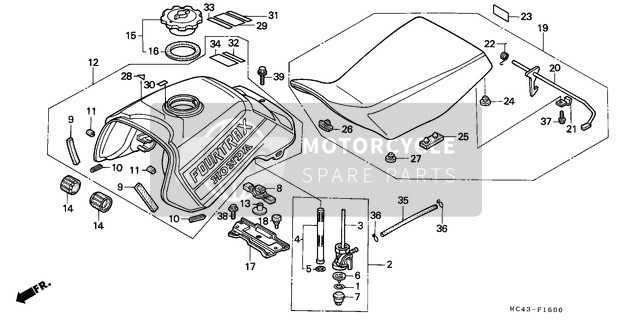

Fuel System Overview

The fuel system is a crucial component that ensures the efficient operation of the engine by delivering the appropriate mixture of fuel and air. This system encompasses several elements that work together to regulate fuel flow, maintain optimal pressure, and enhance combustion efficiency. Key Components

Essential parts of the fuel system include the fuel tank, pump, filter, and carburetor. Each element plays a vital role in storing, transporting, and mixing fuel with air. The tank holds the fuel, while the pump draws it into the system. The filter ensures that impurities are removed, and the carburetor precisely mixes the fuel with air for optimal performance. Functionality and MaintenanceProper functionality of the fuel system is essential for reliable engine performance. Regular maintenance, such as checking for leaks, replacing filters, and inspecting the pump, helps prevent issues that could lead to reduced efficiency or engine failure. Understanding these components and their roles can aid in troubleshooting and ensuring smooth operation. Chassis and Frame Components

The structural integrity and design of a vehicle significantly influence its performance and durability. Understanding the various elements that make up the frame is essential for maintenance and repairs. This section delves into the critical components that support the vehicle’s overall functionality.

Regular inspection and maintenance of these elements are vital for optimal performance and safety. Ensuring that each component is in good condition contributes to a more reliable and enjoyable riding experience. Transmission Assembly DetailsThe transmission assembly plays a crucial role in the overall functionality of the vehicle, facilitating the transfer of power from the engine to the wheels. Understanding its components and layout is essential for efficient maintenance and repairs. Key Components: The main elements include gears, shafts, and various linkage systems that work together to achieve smooth operation. Each component contributes to the effective management of torque and speed, ensuring optimal performance during different riding conditions. Assembly Overview: The assembly process typically involves aligning the components accurately to prevent misalignment, which can lead to mechanical failures. Proper lubrication is vital to minimize friction and wear, prolonging the lifespan of the assembly. Maintenance Tips: Regular inspections of the transmission assembly are recommended to identify signs of wear or damage early. Keeping the system clean and properly lubricated can significantly enhance the performance and reliability of the entire drivetrain. Exhaust System Configuration

The exhaust system plays a crucial role in the overall performance and efficiency of an all-terrain vehicle. It is designed to effectively channel exhaust gases away from the engine, minimizing back pressure and optimizing power output. Proper configuration ensures that harmful emissions are directed safely while enhancing the vehicle’s sound and aesthetic appeal. This assembly typically consists of several key components, including the exhaust manifold, muffler, and tailpipe. Each element must work in harmony to facilitate smooth gas flow and reduce noise levels. The layout of these parts can vary, affecting the performance characteristics and emissions of the vehicle. Regular maintenance of the exhaust system is essential to prevent rust and damage that can lead to leaks or decreased performance. Inspections should include checking for cracks, loose connections, and signs of corrosion. Replacing worn-out components promptly can help maintain optimal functionality and extend the lifespan of the vehicle. |