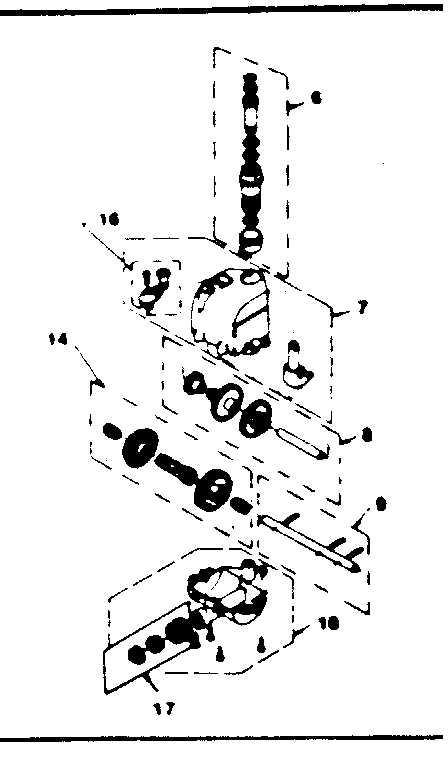

Maintaining an effective watering system for your garden can be made simple when you understand the structure and function of its key elements. These mechanical devices are designed to ensure uniform distribution of water across large areas, utilizing an efficient set of moving and stationary pieces. Each element plays a crucial role in regulating flow and movement, contributing to the system’s overall performance.

When examining the design, you’ll notice several distinctive parts that work in unison to control the water’s direction and rate of distribution. These include rotating mechanisms, connecting rods, and stabilizing features, all of which are carefully designed to handle outdoor conditions. A clear overview of these functional components can help ensure smooth operation and easy maintenance.

By becoming familiar with the layout and purpose of each component, you can quickly troubleshoot and replace any malfunctioning parts, leading to improved longevity of the entire irrigation setup. This guide provides a detailed

Understanding the Function of Rain Train Components

Each element of this type of watering equipment works together to ensure smooth and efficient water distribution across large areas. These systems rely on interconnected parts that guide, control, and maintain the flow of water, allowing the device to move steadily across your garden or lawn.

Water intake mechanisms ensure that a steady supply of water is delivered into the system. This step is crucial for the device to perform its irrigation task. Once water enters, flow regulators manage the pressure and volume to ensure consistency and avoid overwatering.

In addition to water control, movement control mechanisms play a key role in guiding the device across the surface. These parts determine the direction

How Each Part Contributes to Movement

The functionality of a system relies heavily on the intricate roles played by its components. Each element is meticulously designed to fulfill specific tasks that ensure smooth operation and efficiency. Understanding the relationship between these individual units and their collective contribution to the overall movement can enhance our appreciation of mechanical design.

The propulsion mechanism acts as the driving force, enabling the entire assembly to advance. This vital element generates the necessary energy to initiate motion, transforming potential energy into kinetic energy. Complementing this, the guiding framework provides stability and direction, allowing for controlled navigation through various terrains.

Support structures are equally crucial, as they bear the weight of the system and maintain balance. Their robust design prevents excessive wear and tear during operation, thereby extending the lifespan of the entire assembly. Additionally, the connecting elements facilitate seamless interaction between various units, ensuring coordinated movement and enhancing overall functionality.

Moreover, the engagement features allow for interaction with external factors, adjusting the system’s response to varying conditions. This adaptability is key to maintaining efficiency and effectiveness in diverse environments. Together, these components create a harmonious synergy that underscores the importance of each element in achieving desired outcomes.

Guide to Assembling Your Water Sprinkler System

Creating an effective irrigation setup is essential for maintaining a healthy and vibrant garden. This process involves understanding the components needed to distribute water evenly across your landscape. Proper assembly ensures that your system functions optimally, providing the right amount of moisture to your plants while minimizing waste.

To begin, gather the necessary components, which may include hoses, connectors, and sprinkler heads. Familiarize yourself with the different types of sprinklers available, as each serves a unique purpose based on the size and shape of the area being irrigated. For instance, stationary models are ideal for smaller spaces, while rotating versions are suitable for larger gardens.

Once you have your materials ready, sketch a layout of your garden, identifying areas that require more attention. This visual guide will help you determine the placement of each component to ensure comprehensive coverage. Next, assemble the main hose, attaching it securely to the water source, and lay it out according to your plan.

After establishing the primary line, connect the various sprinkler heads at designated points. Adjust their angles and distances to ensure that water reaches every part of your garden. It may be helpful to conduct a test run to observe the distribution and make any necessary adjustments.

Finally, consider incorporating timers or moisture sensors to automate your system. This addition will help regulate watering times and prevent over-saturation, promoting healthy growth while conserving water. By following these steps, you’ll create a reliable irrigation system that enhances your garden’s beauty and sustainability.

Steps for Proper Rain Train Installation

Installing an effective irrigation system requires careful attention to detail and adherence to specific guidelines. Ensuring that every component is correctly positioned and secured is vital for optimal performance. This section outlines the essential steps to achieve a successful setup, enhancing the efficiency of your watering system.

Preparation Before Installation

Before beginning the installation process, gather all necessary tools and components. It is crucial to review the assembly instructions and familiarize yourself with each element. Consider the layout of the area where the system will be set up, ensuring proper spacing and alignment for maximum coverage. Mark the locations where the components will be placed, taking note of any potential obstacles that could hinder functionality.

Step-by-Step Installation Process

Begin by connecting the main supply line to the designated fittings, ensuring a secure fit to prevent leaks. Next, install the distribution lines according to the marked layout, adjusting as needed to maintain consistent spacing. Ensure that each connection is tight and properly aligned. Finally, perform a test run of the system to verify that all components operate smoothly and make any necessary adjustments for optimal performance.

Maintaining Your Nelson Watering Device

Proper upkeep of your irrigation system is essential for ensuring optimal performance and longevity. Regular maintenance helps prevent clogs, leaks, and other issues that can impede the efficient distribution of water. Adopting a proactive approach can save time and resources while enhancing the overall functionality of your watering apparatus.

Routine Checks

Conducting regular inspections is crucial. Check for any signs of wear or damage, such as cracks or leaks. Ensure that all connections are secure and free from debris. Keeping the system clean will prevent blockages and ensure a steady flow of water.

Seasonal Maintenance

At the beginning and end of each season, it is important to perform a more thorough evaluation. Flush the system to remove any accumulated sediment and check the working condition of all components. Replacing worn parts promptly will ensure that the equipment operates effectively throughout its use.

Emphasizing upkeep is vital in maintaining an efficient watering system. By following these guidelines, you can enjoy a reliable and effective irrigation experience, allowing your garden or lawn to thrive.

Ensuring Longevity and Optimal Performance

Maintaining the durability and efficiency of your irrigation system is crucial for achieving desired results over time. By implementing proper care and proactive measures, you can enhance the functionality and lifespan of your equipment. This section outlines essential practices to ensure that your system operates at its best while minimizing potential issues.

Regular Maintenance Practices

Conducting routine inspections and maintenance is vital for identifying wear and tear before it escalates into more significant problems. Simple tasks such as cleaning filters, checking for leaks, and ensuring all components are functioning correctly contribute to a reliable system.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Inspect Components | Monthly | Check for signs of wear, damage, or clogs that may affect performance. |

| Clean Filters | Every 2 Months | Remove and clean filters to ensure optimal water flow and prevent blockages. |

| Check Connections | Quarterly | Examine all connections for leaks or loose fittings to maintain system integrity. |

Proper Usage and Adjustments

Adapting the system to fit the specific needs of your landscape can significantly improve its efficiency. Consider factors such as soil type, plant requirements, and weather conditions to optimize water distribution. Adjusting timers and nozzle settings can also prevent overwatering and promote healthier growth.

Troubleshooting Common Issues with Garden Sprinklers

Garden irrigation systems are essential for maintaining healthy landscapes, but they can occasionally encounter problems. Understanding how to identify and resolve these issues can save time and resources. Here are some common challenges and their solutions.

| Issue | Possible Causes | Solutions |

|---|---|---|

| Poor Water Coverage | Clogged nozzles, low pressure, incorrect positioning | Clean or replace nozzles, check pressure regulator, adjust sprinkler heads |

| Water Leaks | Damaged hoses, loose connections, faulty fittings | Inspect hoses for tears, tighten connections, replace defective fittings |

| Uneven Watering | Obstructed spray patterns, incorrect system design | Clear any obstructions, redesign layout for better coverage |

| Controller Malfunction | Faulty timer, programming errors | Reset timer, reprogram settings, replace timer if necessary |

By regularly inspecting your irrigation setup and addressing these common issues, you can ensure a more efficient and effective watering system for your garden.

Identifying and Fixing Frequent Problems

Understanding common issues is essential for effective maintenance and operation. Many systems may exhibit recurring faults that can hinder performance and efficiency. By recognizing these challenges early on, users can implement timely solutions to ensure optimal functionality.

Here are some typical problems and their potential fixes:

-

Clogging:

Accumulation of debris can obstruct flow and reduce efficiency. Regular inspection and cleaning can help mitigate this issue.

-

Leakage:

Unwanted water escape can lead to waste and potential damage. Check seals and connections to identify and rectify leaks promptly.

-

Uneven Distribution:

Inconsistent output can affect overall performance. Inspect for blockages or misalignments in the delivery system.

-

Mechanical Wear:

Components may deteriorate over time, leading to inefficiencies. Regularly replace worn parts to maintain proper operation.

By addressing these common challenges proactively, users can enhance system reliability and longevity.

Essential Features of Nelson Rain Train Models

The various models designed for irrigation purposes offer a range of innovative attributes that enhance their functionality and efficiency. These mechanisms are engineered to optimize water distribution, ensuring plants receive the right amount of moisture for healthy growth. By understanding the core elements that define these models, users can make informed choices that align with their specific agricultural needs.

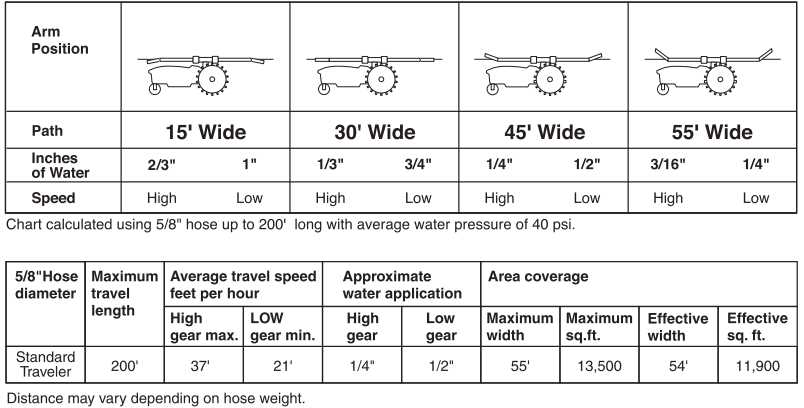

Precision Water Distribution

One of the standout characteristics of these systems is their ability to deliver water evenly across various terrains. Advanced technologies allow for adjustable settings that cater to different crop types and soil conditions. This precision minimizes water waste, promotes sustainability, and contributes to improved crop yields.

Durability and Versatility

Constructed with high-quality materials, these systems are built to withstand the rigors of outdoor use. Their robust design ensures longevity, while also being versatile enough to adapt to diverse environmental conditions. This adaptability is particularly beneficial for farmers looking to implement effective irrigation strategies across different seasons and crop varieties.

What to Know About Different Designs

When exploring various configurations in the realm of irrigation and fluid distribution, it is essential to consider the nuances that distinguish one model from another. These variations can significantly impact functionality, efficiency, and adaptability to specific environments.

- Material Composition: The choice of materials plays a crucial role in durability and performance. Options may include metals, plastics, and composites, each with unique benefits and drawbacks.

- Flow Mechanisms: Different systems may employ various methods for controlling the flow of liquids. Understanding these mechanisms can aid in selecting the right configuration for a particular application.

- Size and Scale: The dimensions of each design are tailored to fit specific needs. Evaluating the scale of operation is critical in determining the most effective option.

- Maintenance Requirements: Each variant may have different upkeep necessities, influencing long-term usability and costs. It is beneficial to consider how easy or challenging maintenance tasks will be.

In summary, understanding the distinctions among various configurations can enhance decision-making when selecting the most suitable solution for irrigation needs or fluid management. Each design offers unique attributes that cater to specific applications, making informed choices paramount for optimal performance.