In the realm of outdoor machinery, having a clear grasp of the various elements that make up your device is essential for optimal performance and maintenance. Each component plays a crucial role in ensuring the overall functionality and longevity of the system. By familiarizing yourself with these parts, you can enhance your operational efficiency and troubleshoot any issues that may arise.

Exploring the intricate relationships between different sections not only aids in proper assembly but also empowers users to make informed decisions regarding repairs and upgrades. Comprehensive visuals can serve as valuable guides, illustrating how each segment interacts with one another, thereby fostering a deeper understanding of the overall structure.

Ultimately, knowledge of these components equips operators with the confidence to address concerns and implement improvements. Whether you are a seasoned expert or a novice, embracing this information will enhance your experience and proficiency with the machinery.

Understanding the Snow Devil DB7651-26

This section aims to provide a comprehensive overview of a specific model of equipment, emphasizing its unique features and functionalities. A thorough understanding of its components can enhance user experience and maintenance practices.

Key Features

- Innovative design for efficiency

- Durable materials for longevity

- User-friendly controls

Maintenance Tips

- Regularly inspect moving parts for wear.

- Clean the exterior to prevent buildup.

- Follow the manufacturer’s guidelines for servicing.

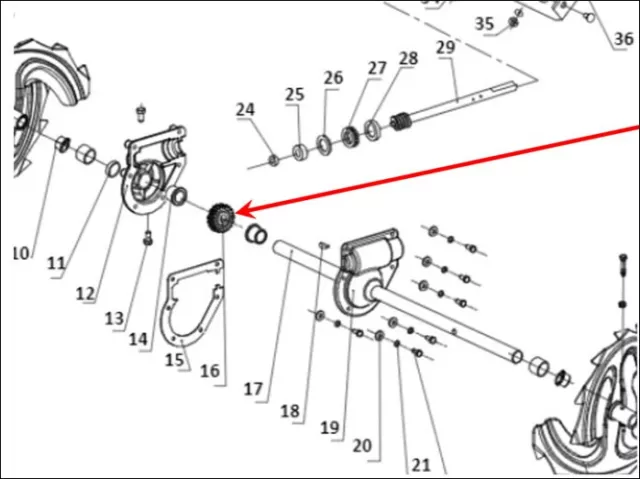

Overview of Parts Diagram Features

This section explores the essential characteristics of visual representations that enhance understanding and facilitate maintenance. These illustrations serve as invaluable tools for identifying components and their interrelations, promoting efficient troubleshooting and repair processes.

Key elements often included in these visuals are:

| Feature | Description |

|---|---|

| Clear Labels | Each element is marked with identifiers for easy reference. |

| Structural Layout | The arrangement showcases the organization and connectivity of components. |

| Color Coding | Different hues may indicate various categories or functions of elements. |

| Legend | A guide explaining symbols or abbreviations used within the representation. |

These attributes collectively empower users to delve deeper into their understanding of the system, ensuring they can effectively address any issues that arise.

Key Components of the Snow Devil

Understanding the essential elements of this machinery is crucial for optimal performance and maintenance. Each component plays a significant role in the overall functionality, ensuring efficiency and reliability during operation.

Essential Elements

Power System: The heart of the equipment, responsible for generating the necessary energy for operation. A robust power system ensures sustained performance.

Operational Mechanisms

Control Interface: This allows the user to manage settings and monitor performance. A user-friendly interface enhances the overall experience and effectiveness.

How to Read Parts Diagrams

Understanding visual schematics is crucial for anyone involved in maintenance or repair tasks. These illustrations provide a clear representation of components and their relationships, allowing users to identify individual elements and their functions within a system. Familiarity with these visuals can significantly enhance efficiency and accuracy in troubleshooting and assembly.

Start by identifying the key elements: Each illustration typically includes labeled sections that denote various components. Pay attention to these labels, as they guide you in recognizing what each part does and where it fits in the overall assembly.

Next, observe the connections: Lines or arrows often indicate how different elements interact. Understanding these connections helps in comprehending the flow of operation and can assist in pinpointing issues during repairs.

Utilize a legend: Many visuals feature a legend or key that explains symbols or color codes used throughout the schematic. Referencing this can clarify any confusion and ensure accurate interpretation of the information presented.

Practice makes perfect: Familiarity with reading these visuals improves over time. Regular exposure will enhance your ability to quickly decipher complex illustrations, making your repair or maintenance tasks more efficient.

Common Issues with Snow Devil Parts

When it comes to equipment maintenance, several recurring challenges can arise, affecting performance and reliability. Understanding these typical problems can help in addressing them effectively, ensuring smoother operation and longevity of your machinery.

Frequent Challenges

Users often encounter issues such as wear and tear, improper assembly, and compatibility concerns. Regular inspections and maintenance are crucial in mitigating these problems.

Maintenance Tips

To enhance functionality, consider the following recommendations:

| Issue | Solution |

|---|---|

| Excessive wear | Regularly inspect and replace worn components. |

| Loose connections | Tighten and secure all fasteners periodically. |

| Incompatible components | Always verify compatibility before installation. |

Maintenance Tips for Optimal Performance

Regular upkeep is essential for ensuring that your equipment runs smoothly and lasts as long as possible. Proper care can prevent many common issues, improve efficiency, and extend the life of your machine. Whether you’re working with a power tool, an engine, or any other mechanical system, following maintenance guidelines will keep it in top condition.

Key Maintenance Practices

- Check and clean filters regularly to maintain airflow and prevent overheating.

- Lubricate moving parts to reduce friction and minimize wear.

- Inspect belts and hoses for any signs of wear or damage, replacing them as necessary.

- Ensure that all screws and bolts are tightened to avoid loose components causing further damage.

- Test electrical connections and clean any dirt or corrosion from connectors to prevent faulty wiring.

Seasonal Considerations

- Before storing your equipment for the off-season, clean it thoroughly to remove debris and moisture.

- Check fluid levels, such as oil and coolant, and replace them if they are low or contaminated.

- Inspect the spark plug for wear and replace it to ensure smooth operation during the next use.

- Test the battery before prolonged storage, ensuring it’s fully charged and disconnected if needed.

Where to Find Replacement Parts

When it comes to maintaining and repairing equipment, finding the right components is essential for ensuring optimal performance and longevity. There are several reliable sources where you can purchase the necessary items to replace damaged or worn-out elements of your machine. Whether you’re looking for individual components or a full set, knowing where to look can save both time and effort.

Here are some of the best places to consider for sourcing replacements:

- Official Manufacturer Websites – Many manufacturers offer a comprehensive catalog of spare parts directly on their websites. These platforms often provide exact matches for your equipment, ensuring compatibility and quality.

- Authorized Dealers – Visiting an authorized dealer is another good option. These dealerships are affiliated with the original brand and carry certified components, often offering expert advice on the best parts for your needs.

- Online Marketplaces – Websites such as Amazon, eBay, or specialized online retailers often feature a wide range of spare components, with the ability to compare prices and check user reviews.

- Local Repair Shops – Local service providers may have access to the necessary replacements or can order them on your behalf. They are also helpful for providing hands-on advice and assistance.

- Third-Party Suppliers – Many third-party suppliers offer quality replacements that are often more affordable than original brand options. However, it’s important to ensure that they are reliable and their parts meet safety standards.

By exploring these sources, you’ll be able to find the right pieces to restore your equipment to its full functionality with ease and confidence.

Comparing Snow Devil with Competitors

When evaluating performance and value, it is essential to compare various models within the same category. Each product in the market is designed with specific features aimed at different user needs. By understanding the strengths and weaknesses of each option, consumers can make informed decisions about which model suits their requirements the best.

Key Differences

- Performance: The power and efficiency of different models vary significantly. While some options are designed for heavy-duty tasks, others focus on providing convenience and ease of use for lighter applications.

- Durability: Some models are built to last longer with robust materials and components, while others may use lighter materials that compromise longevity in favor of lower weight.

- Price: Pricing strategies differ across the board. Some options are positioned as premium products with advanced features, while others aim to provide a more budget-friendly solution with fewer advanced functionalities.

Performance and Reliability

- Speed: Different models offer varying levels of speed, with some engineered for quick, efficient performance, while others prioritize steady, consistent operation.

- Ease of Maintenance: Ease of upkeep is a major factor in long-term reliability. Certain competitors offer simpler maintenance procedures, whereas others require more complex handling or professional servicing.

In conclusion, understanding these distinctions can help individuals select the ideal model based on their unique needs, whether they prioritize power, ease of use, or overall cost-effectiveness.

FAQs About Snow Devil DB7651-26

This section addresses common inquiries regarding a specific model of a winter equipment. Whether you’re looking for maintenance tips or operational guidance, these questions cover essential aspects.

- What is the recommended maintenance schedule?

Regular checks should be performed after every use, with a detailed inspection every season.

- How do I troubleshoot common issues?

Check for clogs, ensure all components are securely attached, and verify power connections.

- Where can I find replacement components?

Authorized dealers and online retailers typically stock various parts for this model.

- What safety precautions should I take?

Always wear protective gear and ensure the area is clear of obstacles before operation.

- Can I operate it on all surfaces?

It’s designed for use on snowy terrain; avoid hard surfaces to prevent damage.