When maintaining outdoor machinery, having a clear understanding of its various components is essential for efficient operation and repair. Familiarizing oneself with the arrangement and functionality of different elements ensures optimal performance and longevity of the machine.

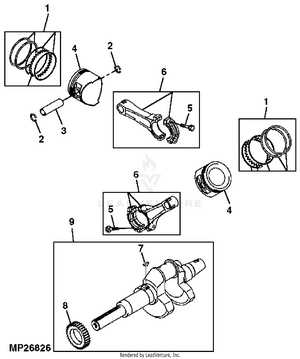

Detailed visual representations can significantly aid in grasping how each part fits together and interacts within the system. Such illustrations serve as valuable references, allowing users to quickly identify components, troubleshoot issues, and plan maintenance effectively.

In this section, we will explore a comprehensive overview of the various elements that constitute your machinery. By understanding the intricate layout and relationships among these components, you will be better equipped to handle repairs and enhance the overall efficiency of your equipment.

Understanding the layout and components of machinery is crucial for effective maintenance and repair. Visual representations serve as valuable tools that facilitate the identification and organization of various elements, ensuring that tasks are completed efficiently.

These illustrations provide numerous benefits, including:

- Enhanced Clarity: Visual aids simplify complex structures, making it easier for technicians to understand assembly and disassembly processes.

- Accurate Identification: They help users pinpoint specific components, reducing the risk of errors during repairs.

- Streamlined Repairs: Clear visuals can significantly expedite the troubleshooting process, allowing for faster resolution of issues.

- Improved Communication: Shared visuals foster better collaboration among team members, as everyone can reference the same illustration.

Incorporating these visual tools into maintenance practices not only boosts efficiency but also enhances overall safety by ensuring that all elements are accounted for during servicing.

Understanding Component Functions

The machinery consists of numerous interconnected elements that work together to perform essential tasks. Each individual unit plays a specific role, contributing to the overall efficiency and reliability of the equipment. By understanding how these elements operate, users can ensure optimal performance and address potential issues before they escalate.

Engine components are designed to manage energy conversion, ensuring that power is distributed effectively throughout the system. Proper maintenance of these elements is crucial for maintaining efficiency and preventing breakdowns. Transmission mechanisms handle the transfer of power, enabling the machine to function under varying conditions.

Other key elements include hydraulic systems, which provide the necessary force to perform heavy-duty operations, and cooling systems, which prevent overheating and ensure smooth operation over extended periods of time. Understanding these functions helps in identifying and resolving issues, ultimately extending the lifespan of the machinery.

Commonly Replaced Parts

Regular maintenance of outdoor machinery often involves the replacement of specific components that wear out over time. Understanding which elements are frequently substituted can help ensure the equipment operates efficiently and extends its lifespan.

Among the most commonly exchanged items are the belts, which can stretch or fray with consistent use. Additionally, filters play a crucial role in maintaining the system’s cleanliness and performance, making them essential for routine checks and replacements. Blades are also vital, as they can dull or become damaged, impacting cutting efficiency. Lastly, batteries often need attention due to their limited lifespan and the demands of starting the machinery.

Maintenance Tips for Longevity

To ensure the durability and optimal performance of your outdoor machinery, regular upkeep is essential. Implementing simple maintenance routines can significantly extend the lifespan of your equipment while enhancing its efficiency.

Regular Inspections

- Check for wear and tear on various components.

- Inspect belts and hoses for cracks or fraying.

- Ensure that all fasteners are secure to avoid loosening during operation.

Routine Cleaning

- Clean the exterior surfaces to prevent dirt buildup.

- Remove debris from the cooling system to maintain airflow.

- Flush the fuel system regularly to prevent clogging.

By following these simple tips, you can maintain your machinery’s reliability and enhance its operational life, making it a wise investment for years to come.

Where to Find Replacement Parts

Locating suitable components for your equipment is essential for maintaining its performance and longevity. There are several reliable avenues to explore when searching for the necessary items to keep your machinery in top condition.

- Authorized Dealers: Visiting a certified retailer can ensure that you receive genuine components designed specifically for your model. These dealers often have access to the latest inventory and expert advice.

- Online Marketplaces: Websites like eBay, Amazon, and specialized machinery parts retailers offer a wide range of options. Always check seller ratings and reviews to ensure reliability.

- Local Repair Shops: Local service centers often stock commonly needed components and can provide installation services. They may also offer refurbished items at a lower cost.

- Manufacturer’s Website: Many manufacturers maintain an online catalog of available items for various models. You can often order directly from their site or find links to authorized distributors.

By utilizing these resources, you can efficiently find the necessary components to ensure your equipment operates smoothly and effectively.

Resources for Parts Diagrams

Accessing reliable resources for component illustrations is essential for effective maintenance and repair. Numerous platforms provide detailed visuals and information that facilitate the identification and ordering of necessary elements for various machinery.

Manufacturer Websites: Official websites often feature comprehensive catalogs that include illustrations, making it easier for users to locate specific components. These sites are reliable sources of information as they provide accurate data directly from the manufacturer.

Online Retailers: E-commerce platforms specializing in machinery supplies frequently offer visual references for each item. These resources often include user reviews and ratings, helping customers make informed purchasing decisions.

Community Forums: Engaging with online communities can yield valuable insights. Experienced users frequently share their knowledge, including links to useful resources and personal recommendations for obtaining component illustrations.

Technical Manuals: Detailed manuals can be a goldmine of information, providing in-depth visuals alongside descriptions. These documents are often available for download from reputable sources or can be purchased directly from manufacturers.