In the realm of agricultural equipment, comprehending the intricate network of elements that ensure optimal functionality is essential. Each component plays a pivotal role in the overall performance and efficiency of the machinery, allowing operators to achieve their tasks with precision and ease. By familiarizing oneself with the various elements, users can enhance their maintenance practices and extend the lifespan of their equipment.

The exploration of these mechanical features encompasses an array of sections that detail the various functionalities and interconnections between the parts. Recognizing how each element contributes to the operational success is crucial for effective troubleshooting and repair. A thorough understanding fosters not only better performance but also empowers operators to make informed decisions regarding upgrades and modifications.

Ultimately, delving into the specifics of these mechanical structures provides valuable insights that can significantly impact productivity in agricultural operations. By investing time in learning about these components, individuals can cultivate a deeper appreciation for the machinery that supports their work, leading to improved outcomes and greater satisfaction in their agricultural pursuits.

Overview of HX15 Parts Diagram

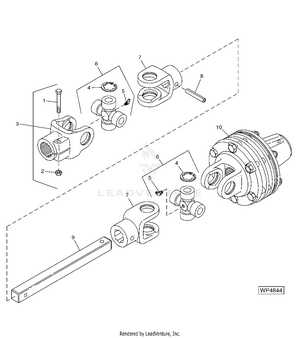

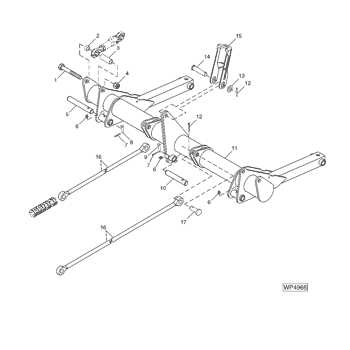

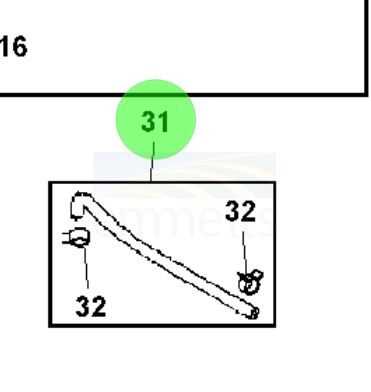

The illustration representing the various components of a specific agricultural implement serves as a crucial resource for understanding its structure and functionality. This visual representation aids in identifying individual elements, their arrangement, and interconnections, which is essential for maintenance and repair tasks. A comprehensive understanding of these elements enhances operational efficiency and ensures optimal performance.

Key Components

Within this visual representation, several significant elements stand out. Each component is meticulously labeled to provide clarity. Understanding the role of these parts is vital for anyone working with the implement, as it allows for informed decision-making regarding repairs and replacements.

Maintenance and Repair Insights

By referring to this illustration, users can gain insights into routine maintenance practices. Recognizing the location and function of each element simplifies troubleshooting processes and reduces downtime. The clarity offered by such an illustration empowers operators and technicians alike to address issues effectively and maintain the implement’s longevity.

Key Components of John Deere HX15

This section delves into the essential elements that comprise a well-functioning agricultural implement designed for efficient land management. Understanding these components is crucial for ensuring optimal performance and longevity of the equipment.

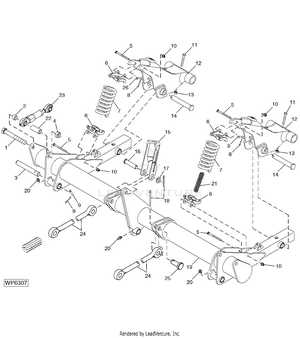

Structural Elements

The framework of the implement provides the necessary support and stability. Key structural elements include the chassis and the attachment points, which are designed to withstand the rigors of fieldwork.

Operational Mechanisms

Operational mechanisms include various systems that facilitate the functioning of the implement. These systems enable tasks such as cutting, leveling, and transport, ensuring versatility in different agricultural applications.

| Component | Description |

|---|---|

| Chassis | Supports all other components and provides stability during operation. |

| Cutting System | Includes blades and other cutting elements for effective vegetation management. |

| Hydraulic System | Powers various functions, allowing for adjustments and improved performance. |

| Transport Wheels | Facilitates mobility on and off the field, enhancing maneuverability. |

Understanding Hydraulic System Parts

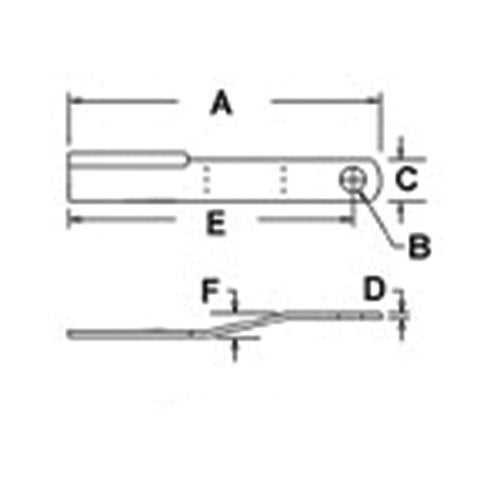

Hydraulic systems are essential components in various machinery, providing the necessary power for operation through the controlled movement of fluids. These systems rely on a combination of elements that work together to convert mechanical energy into hydraulic energy, enabling efficient functionality in heavy equipment.

Key components include pumps, which generate fluid flow; valves, which regulate this flow and direct it to specific areas; and cylinders, which transform hydraulic energy into mechanical force. Additionally, hoses and fittings are vital for connecting these elements, ensuring the proper transmission of hydraulic fluid. Understanding each component’s role is crucial for maintaining optimal performance and troubleshooting potential issues.

Importance of Accurate Part Identification

Identifying components correctly is crucial for the efficient operation and maintenance of any machinery. Misidentification can lead to improper replacements, resulting in malfunctions and extended downtime. Understanding the precise specifications of each element ensures that repairs and upgrades are executed seamlessly, preserving the overall functionality of the equipment.

Moreover, accurate identification enhances the effectiveness of inventory management. When components are recognized accurately, it simplifies the ordering process and reduces the likelihood of errors during procurement. This not only saves time but also minimizes costs associated with returns or incorrect shipments. In essence, a thorough comprehension of each component plays a vital role in the longevity and reliability of the machine.

Finally, maintaining a clear record of all elements used within the system fosters better communication among technicians and operators. It ensures that everyone involved is on the same page regarding the status of the equipment, thereby facilitating more effective troubleshooting and maintenance strategies. Ultimately, the precision in component identification contributes significantly to the operational success of the machinery.

Common Issues with HX15 Components

In the realm of agricultural machinery, certain components may encounter frequent challenges that can hinder performance and efficiency. Understanding these common problems is essential for maintaining operational integrity and ensuring longevity. By identifying potential pitfalls, operators can take proactive measures to mitigate risks associated with wear and tear, thus enhancing the overall functionality of their equipment.

Wear and Tear on Key Components

Wear and tear is a prevalent issue that affects various mechanical parts over time. Critical elements such as blades, belts, and bearings are often subjected to significant stress during operation. This prolonged strain can lead to diminished effectiveness, resulting in suboptimal performance. Regular inspections and timely replacements are crucial to address these concerns and keep machinery running smoothly.

Hydraulic System Malfunctions

Another common challenge involves the hydraulic system, which is vital for the proper functioning of many agricultural implements. Issues such as leaks, pressure drops, or contaminated fluids can severely impact the efficiency of hydraulic components. Operators should routinely check for signs of hydraulic fluid leakage and ensure that the system is properly maintained to prevent costly repairs and ensure optimal operation.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your machinery involves a combination of regular upkeep, proper handling, and timely repairs. By following a systematic approach to maintenance, you can significantly enhance performance and reliability while minimizing downtime and costly replacements.

Key Maintenance Practices

Incorporating the following practices into your routine will help maintain optimal functionality:

| Practice | Description |

|---|---|

| Regular Inspection | Conduct routine checks to identify any signs of wear or damage that may affect performance. |

| Lubrication | Apply appropriate lubricants to moving parts to reduce friction and prevent premature wear. |

| Cleaning | Keep components free from dirt and debris, which can hinder operation and lead to malfunctions. |

| Timely Repairs | Address any issues as soon as they arise to prevent further damage and maintain efficiency. |

| Owner’s Manual | Refer to the manufacturer’s manual for specific guidelines on maintenance schedules and procedures. |

By adhering to these fundamental practices, you can significantly prolong the life of your equipment, ensuring it remains a reliable asset for years to come.

Replacement Procedures for HX15 Parts

Maintaining the functionality of machinery requires a thorough understanding of the components involved. This section provides guidance on the process of replacing essential elements, ensuring optimal performance and longevity. By following systematic steps, users can achieve a smooth transition when swapping out worn or damaged components.

Preparation for Replacement

- Gather necessary tools, including wrenches, screwdrivers, and safety gear.

- Consult the owner’s manual for specific details on the components and their locations.

- Ensure the machine is powered down and secured to prevent accidental operation.

Steps for Component Replacement

- Remove any coverings or shields that may obstruct access to the component.

- Carefully disconnect any attached wiring or hoses, noting their configuration for reassembly.

- Unfasten the component using appropriate tools, taking care to avoid damage to surrounding parts.

- Install the new component by reversing the removal steps, ensuring a secure fit.

- Reconnect any wiring or hoses, double-checking for proper alignment.

- Replace coverings or shields, ensuring all fasteners are tightened to specifications.

By adhering to these replacement procedures, users can ensure their machinery operates efficiently and effectively, minimizing downtime and enhancing productivity.

Where to Source Genuine Components

Finding authentic components for machinery is crucial for ensuring optimal performance and longevity. Whether for repairs or upgrades, sourcing high-quality elements can significantly impact the functionality and reliability of equipment. This section will guide you through effective avenues for obtaining reliable replacements, helping you make informed decisions.

One of the most dependable sources is the official manufacturer. They often provide a comprehensive catalog of genuine replacements that meet the required specifications. Purchasing directly from the manufacturer not only guarantees authenticity but also ensures that the components are designed to work seamlessly with your equipment.

Another excellent option is authorized dealers and distributors. These establishments typically stock a wide range of components and can offer expert advice on the right choices for your specific machinery. Their knowledge and experience can be invaluable, especially when navigating the complexities of different models and compatibility.

Online marketplaces and specialty websites dedicated to machinery parts can also be valuable resources. Many of these platforms feature user reviews and ratings, allowing you to assess the reliability of the sellers. However, it’s essential to verify that the components are indeed genuine before making a purchase, as counterfeit parts can lead to significant issues down the line.

Local repair shops and service centers may also have access to authentic components or can order them on your behalf. Establishing a relationship with a reputable service provider can lead to better deals and insights into the best components for your equipment.

In conclusion, whether through manufacturers, authorized dealers, online marketplaces, or local service providers, ensuring that you acquire genuine components is paramount for maintaining the efficiency and effectiveness of your machinery.