When maintaining outdoor machinery, a clear comprehension of the individual elements and their arrangement is crucial for optimal performance. This knowledge empowers operators to efficiently troubleshoot issues and ensure the longevity of their equipment.

By exploring the intricate network of parts, users can identify how each component interacts within the system. Recognizing these connections not only aids in repairs but also enhances the overall functionality of the machinery.

In this guide, we will delve into the essential features and configurations, providing valuable insights for anyone looking to achieve the ultimate efficiency in their operations. Understanding these specifics can transform the maintenance experience, making it more intuitive and effective.

Understanding the John Deere 14SB

This section aims to explore the essential components and functionality of a well-known piece of outdoor equipment. Recognizing its design and operational mechanics can enhance user experience and maintenance practices.

Key Features

- Powerful engine for efficient operation

- Durable construction ensuring longevity

- Ergonomic design for user comfort

- Versatile applications for various tasks

Maintenance Tips

- Regularly check oil levels for optimal performance.

- Inspect blades and replace them when dull.

- Clean air filters to ensure proper airflow.

- Store equipment in a dry place to prevent rust.

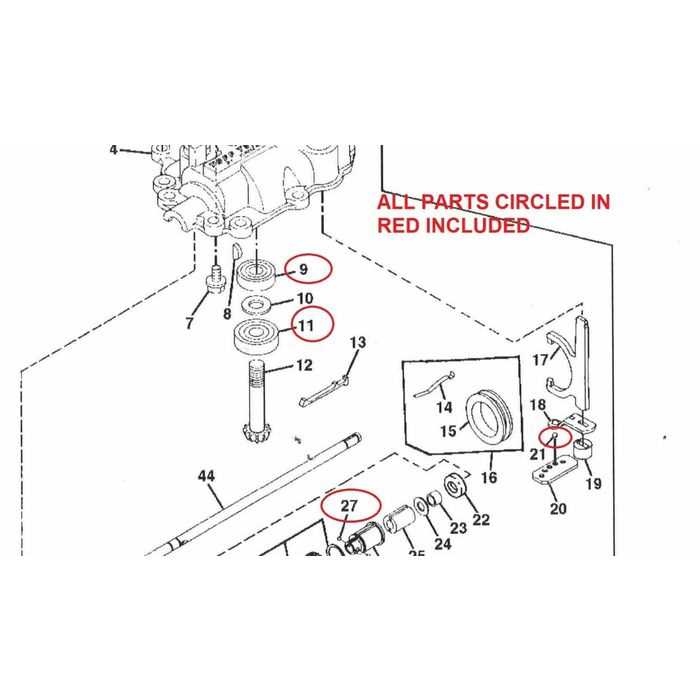

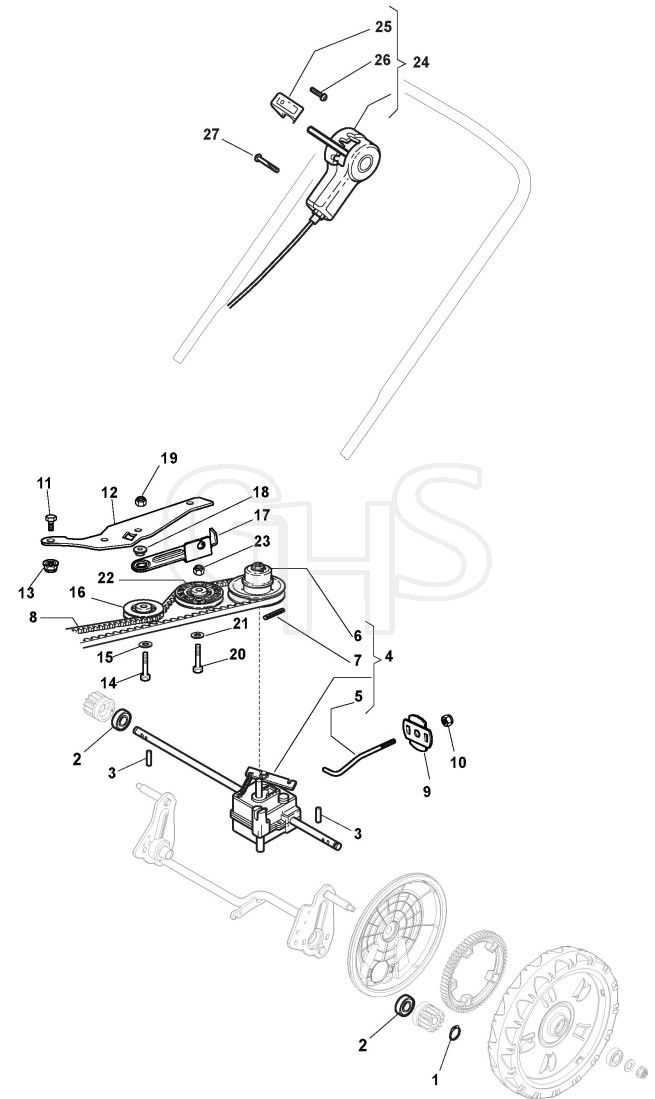

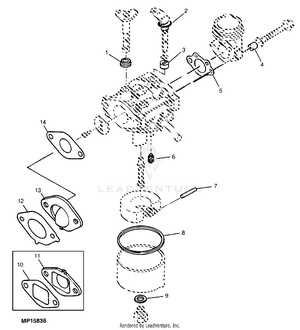

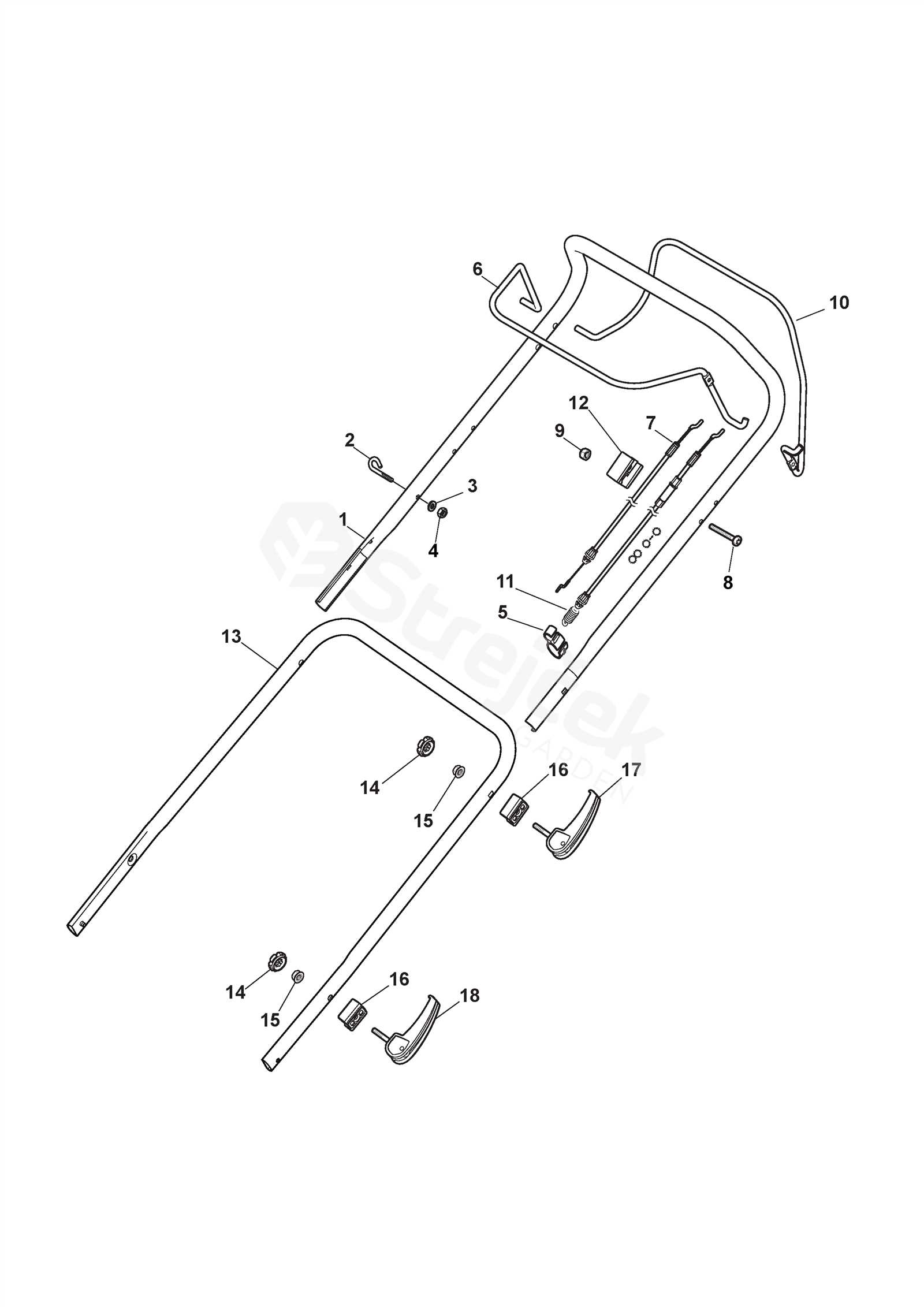

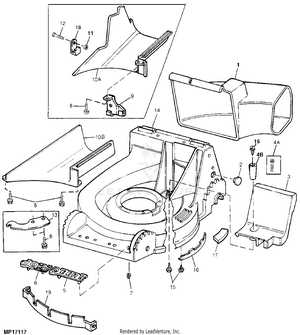

Importance of Parts Diagrams

Understanding the various components of machinery is crucial for effective maintenance and repair. Visual representations serve as essential tools, enabling users to identify individual elements and comprehend their relationships within the larger assembly. These illustrations facilitate a streamlined approach to troubleshooting, ensuring that users can quickly locate issues and implement solutions.

Enhanced Maintenance Efficiency

Clear illustrations promote better organization during maintenance tasks. Technicians can refer to these visuals to ascertain the correct positioning and functionality of each component, significantly reducing the time spent on repairs. By minimizing guesswork, these resources lead to quicker resolutions and improved operational efficiency.

Improved User Understanding

Visual aids empower users by enhancing their understanding of complex machinery. Whether for novice operators or seasoned professionals, having a visual guide simplifies the learning process, making it easier to grasp intricate mechanisms. This clarity fosters confidence in handling equipment, ultimately contributing to better performance and longevity.

Key Components of the 14SB Model

This section focuses on the essential elements that make up the mentioned equipment, highlighting their functions and significance in the overall performance. Understanding these key components is crucial for maintenance and effective operation.

Core Elements

- Engine: The powerhouse that drives the entire unit, ensuring optimal performance and efficiency.

- Transmission: This system is responsible for transferring power from the engine to the wheels, enabling smooth movement.

- Chassis: The structural frame that supports various components, providing stability and durability.

- Cutting Mechanism: Essential for achieving precise results, this element is designed for effective grass management.

Supporting Features

- Fuel System: Supplies the engine with necessary energy, playing a vital role in overall efficiency.

- Electrical System: Powers various components and ensures proper functioning of lights and controls.

- Wheels and Tires: Designed for traction and stability, these elements are crucial for maneuverability.

- Control System: Provides operators with the necessary tools to manage the equipment effectively.

Understanding these components aids in recognizing the importance of regular maintenance, ensuring the equipment remains in peak condition for all tasks.

How to Access the Parts Diagram

Gaining insight into the components of machinery is essential for effective maintenance and repairs. Accessing a visual representation of these elements can simplify the process of identifying and replacing necessary items. This guide will provide you with straightforward methods to locate such resources, ensuring you have the information needed at your fingertips.

Online Resources

The internet offers a wealth of information, including official websites and forums dedicated to equipment enthusiasts. Searching for the specific model alongside terms related to visual breakdowns can yield useful results. Many manufacturers provide downloadable resources that can be easily printed or saved for reference.

User Manuals and Documentation

Common Issues with 14SB Parts

In the realm of outdoor equipment, various components may encounter problems over time, leading to decreased performance and efficiency. Understanding these common challenges can help users maintain their machinery effectively and ensure longevity.

- Wear and Tear: Frequent use can result in significant deterioration of essential elements, impacting overall functionality.

- Corrosion: Exposure to moisture and harsh weather conditions can lead to rust, weakening metal components and causing failures.

- Misalignment: Improper assembly or prolonged use can cause components to become misaligned, resulting in inefficient operation.

Addressing these issues promptly can prevent further damage and enhance the performance of the equipment. Regular inspections and maintenance are crucial.

- Conduct routine checks for visible signs of damage.

- Replace worn-out components with quality replacements.

- Lubricate moving parts to reduce friction and wear.

By staying vigilant and proactive, operators can minimize disruptions and ensure their equipment runs smoothly for years to come.

Replacement Parts and Upgrades

Maintaining the efficiency and performance of your equipment often requires thoughtful consideration of components and enhancements. Upgrading certain elements can significantly improve functionality, longevity, and overall user experience. Understanding what options are available for replacements can help ensure that your machinery remains in optimal working condition.

When selecting new components, it’s crucial to focus on quality and compatibility. Investing in high-quality alternatives can lead to better performance and reduced wear over time. Original equipment manufacturers often provide a range of compatible items that fit seamlessly with your machine, ensuring reliability and performance.

In addition to replacements, consider implementing upgrades that enhance capabilities. Whether it’s improved cutting mechanisms or advanced technological features, modern enhancements can offer substantial benefits. Evaluating the specific needs of your equipment will guide you in choosing the most suitable upgrades that align with your operational goals.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your equipment requires regular attention and care. By following a few essential practices, you can significantly extend the lifespan of your machinery and keep it operating at peak performance. Regular maintenance not only prevents unexpected breakdowns but also enhances overall functionality, ensuring that your investment remains worthwhile.

Regular Inspection

Conducting routine checks is crucial for identifying potential issues before they escalate. Make it a habit to inspect key components such as belts, filters, and lubrication systems. Addressing wear and tear early can save you from costly repairs down the line.

Proper Cleaning

Keeping your equipment clean is vital for optimal operation. Dirt and debris can accumulate and affect performance. Regularly wash external surfaces and ensure that internal parts are free from dust and buildup to maintain efficiency.

| Maintenance Task | Frequency |

|---|---|

| Inspect belts and hoses | Monthly |

| Change oil and filters | Every 50 hours |

| Clean air filter | Every 25 hours |

| Check tire pressure | Weekly |

Implementing these straightforward maintenance tasks can significantly enhance the longevity of your machinery, ensuring that it serves you effectively for years to come.

Where to Find Genuine Parts

Finding authentic components for your machinery is crucial for ensuring optimal performance and longevity. Reliable sources offer not only quality items but also peace of mind knowing that you’re investing in the best for your equipment. Exploring authorized dealers, online retailers, and specialized shops can lead you to the right options.

Authorized dealerships typically provide a range of original components that meet manufacturer standards. They often have knowledgeable staff who can assist with any inquiries. Additionally, many online platforms focus on quality and authenticity, featuring reviews and detailed product descriptions to guide your choices.

Another effective approach is to connect with local equipment repair shops. They frequently have access to genuine items and can offer advice based on their expertise. Joining online forums or communities dedicated to machinery can also help you find recommendations and insights on where to source original components.

User Reviews and Experiences

This section explores feedback and stories from users regarding their experiences with a popular brand of lawn care equipment. Insights shared by owners highlight the effectiveness, durability, and maintenance challenges they have encountered. Personal accounts often provide valuable information for potential buyers, helping them make informed decisions based on real-life usage.

Performance Insights

Many users commend the efficiency of their machines, noting how easily they tackle various tasks. A common sentiment is the reliability during extended usage periods, allowing for smooth operation without frequent interruptions. However, some reviewers mention occasional issues that arise, emphasizing the importance of understanding maintenance requirements to prolong the lifespan of the equipment.

Customer Support Experiences

Customer service plays a crucial role in user satisfaction. Positive experiences often stem from responsive support teams that assist with troubleshooting and replacement queries. On the flip side, some users report delays or difficulties in obtaining parts, highlighting the need for improved logistics. Overall, the relationship between the manufacturer and its customers significantly influences user perceptions.