The intricacies of agricultural machinery play a pivotal role in enhancing productivity on farms. Each machine consists of various elements that contribute to its overall functionality. Familiarity with these components not only aids in effective maintenance but also ensures optimal performance during operations.

In this exploration, we will delve into the arrangement and function of crucial elements within a well-known tractor model. By examining the layout and relationships between these components, operators and enthusiasts alike can gain valuable insights into troubleshooting and repairs.

Furthermore, comprehending how these parts interact can lead to informed decisions regarding upgrades and replacements. This knowledge empowers users to extend the lifespan of their equipment and enhance its efficiency in the field.

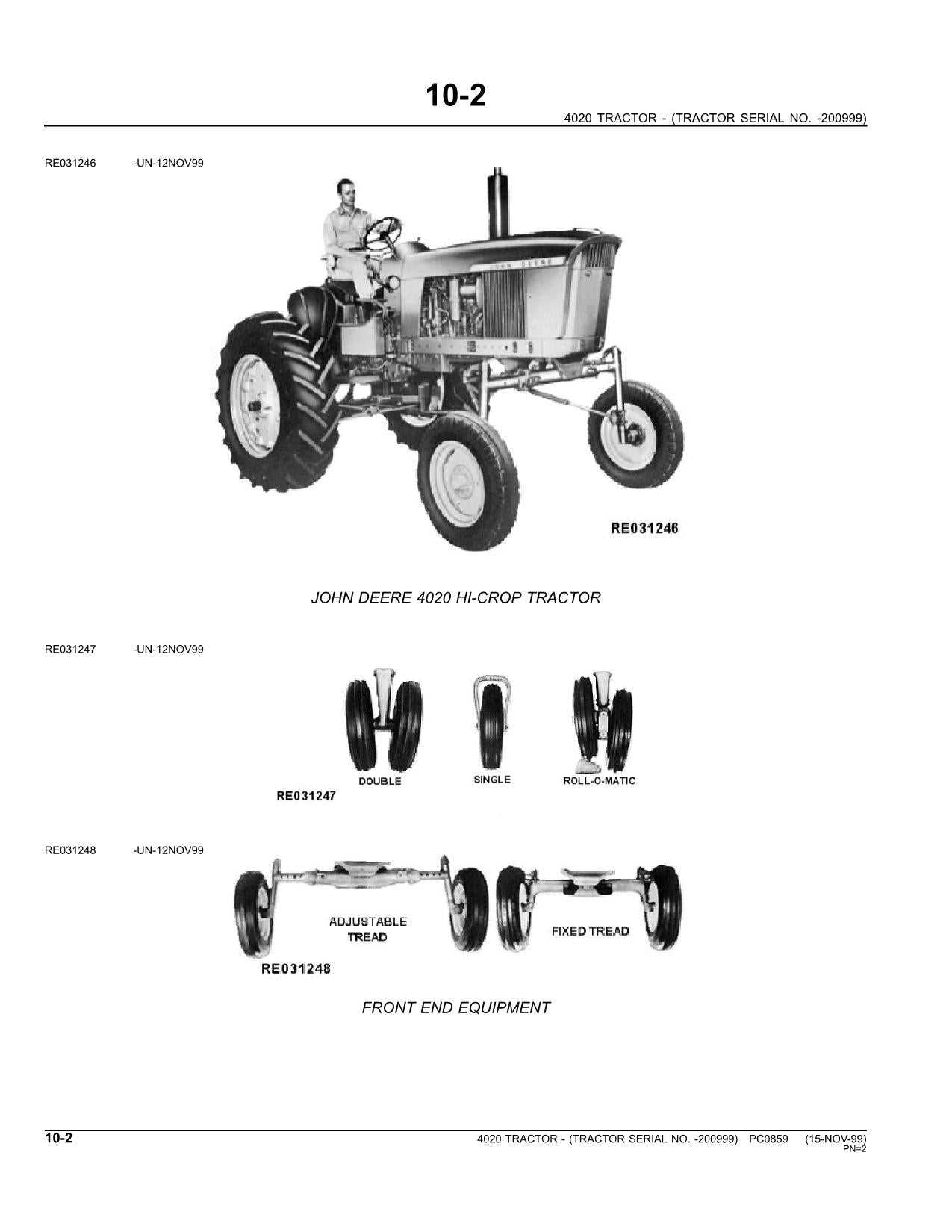

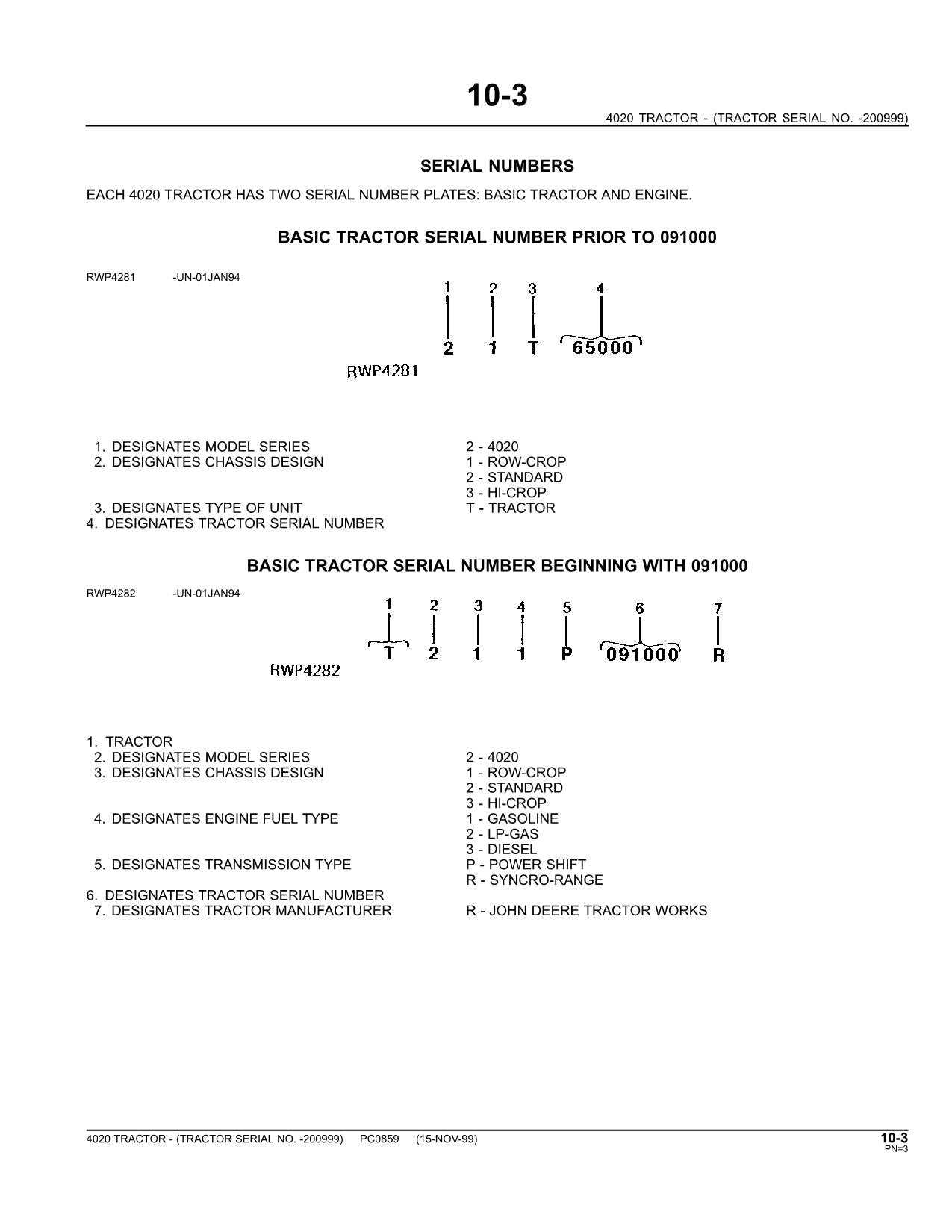

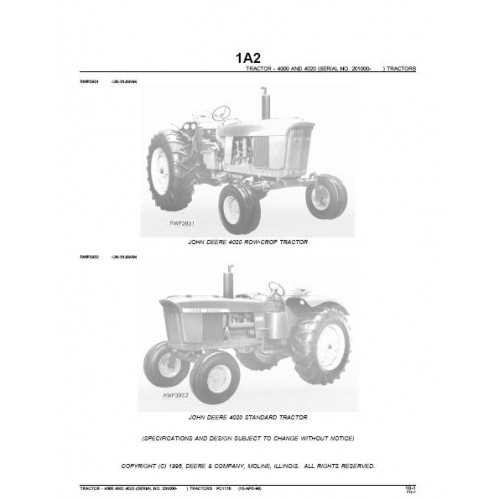

Overview of John Deere 4020 Parts

This section provides an essential understanding of the components that make up this classic agricultural machine. Each element plays a crucial role in ensuring optimal performance and reliability, contributing to the overall efficiency of operations. Familiarity with these components is vital for maintenance, repairs, and upgrades.

| Component | Description |

|---|---|

| Engine | The powerhouse responsible for driving the vehicle, crucial for its operational capacity. |

| Transmission | Facilitates the transfer of power from the engine to the wheels, enabling smooth movement. |

| Hydraulic System | Allows for the operation of attachments and implements, providing versatility in tasks. |

| Chassis | The frame that supports all components, ensuring structural integrity and stability. |

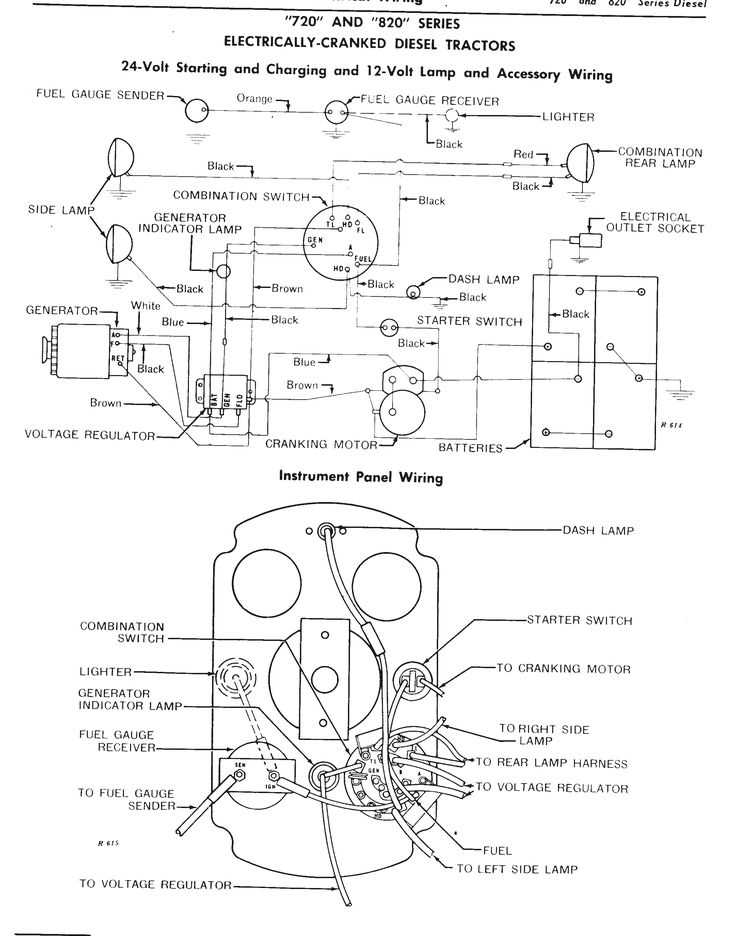

| Electrical System | Manages power distribution, controls, and lighting, essential for operation and safety. |

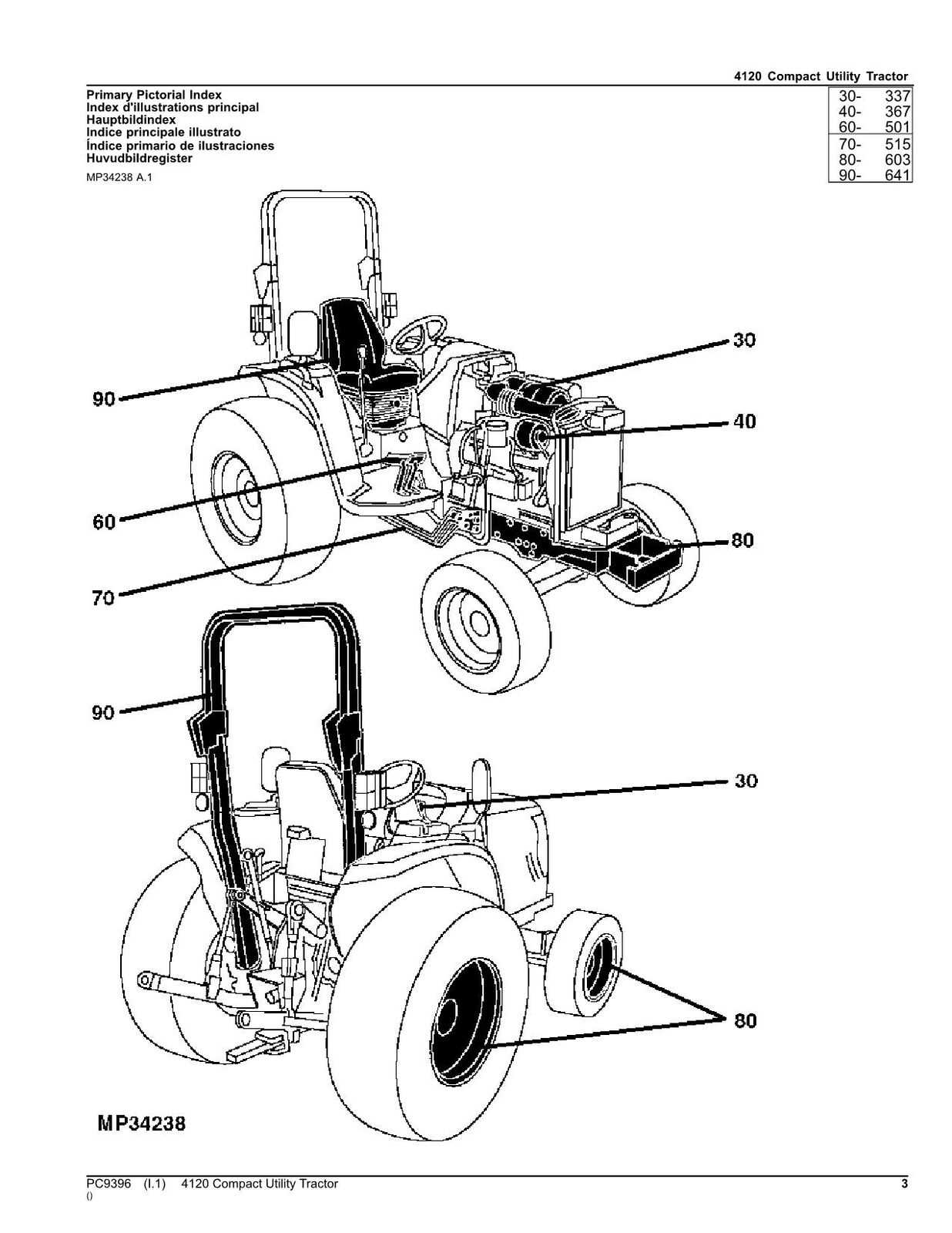

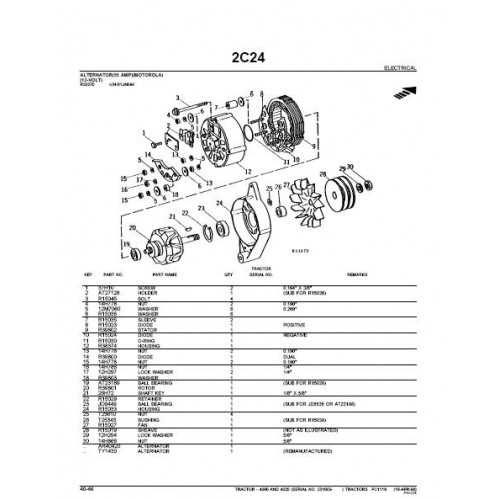

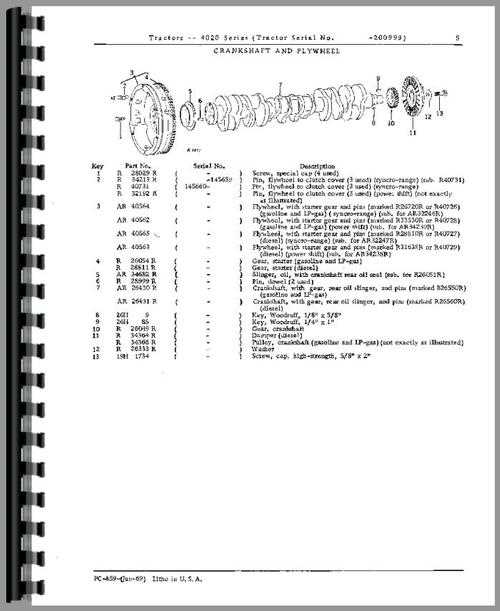

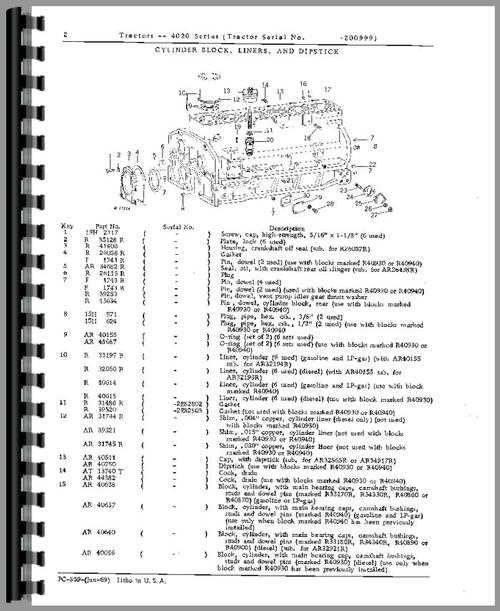

Understanding the Parts Diagram

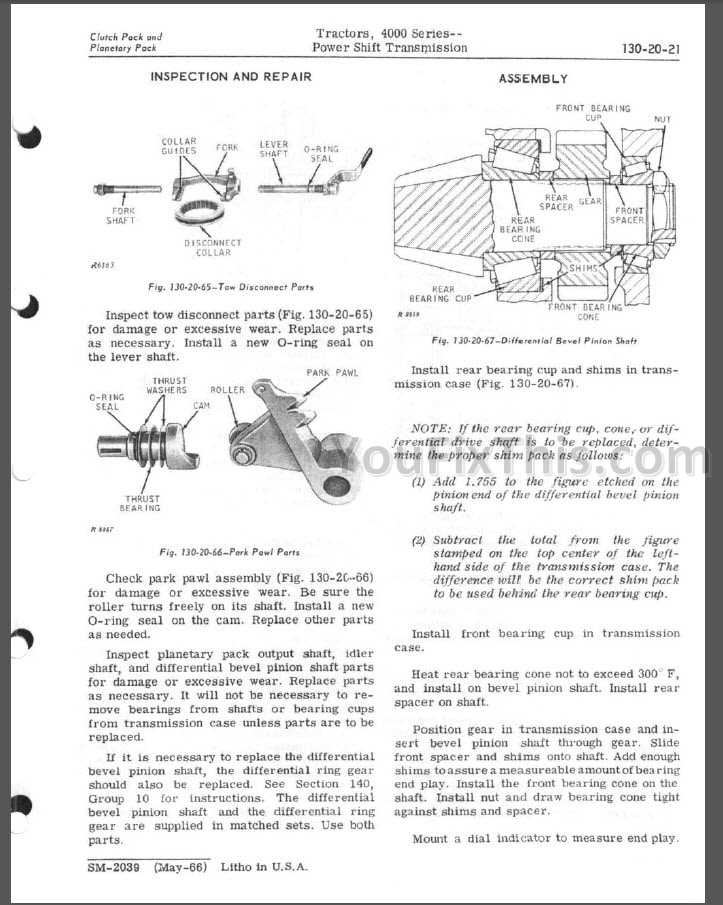

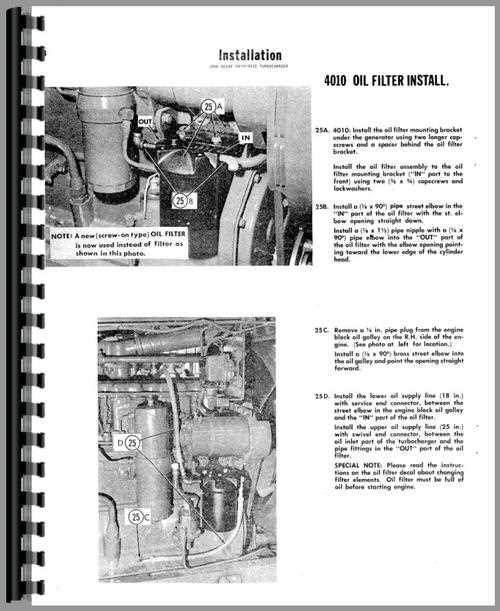

Comprehending the layout of components is essential for effective maintenance and repair of machinery. A well-structured visual representation can significantly aid in identifying various elements and their functions. This clarity not only facilitates troubleshooting but also enhances overall operational efficiency.

Importance of Component Identification

Recognizing individual parts within the schematic allows users to pinpoint issues quickly. Each segment plays a crucial role in the machinery’s performance, and understanding their interconnections can prevent costly downtime. A comprehensive grasp of these elements ensures that maintenance tasks are executed with precision.

Navigating the Visual Representation

When examining the illustration, it’s vital to familiarize oneself with the symbols and numbering used. These indicators serve as guides for locating specific components, making it easier to follow assembly or disassembly procedures. Emphasizing attention to detail in this process can lead to more efficient repairs and a better understanding of the overall system.

Common Issues with 4020 Components

The machinery known for its reliability may still encounter a variety of challenges over time. Understanding these common issues can help in maintaining optimal performance and extending the lifespan of the equipment. Regular inspection and timely intervention are key to addressing these concerns effectively.

Frequent Challenges

- Hydraulic System Failures: Leaks or insufficient pressure can lead to poor performance.

- Electrical Malfunctions: Wiring issues or faulty connections often disrupt operation.

- Engine Overheating: Blockages or coolant problems can result in excessive temperatures.

Preventive Measures

- Regularly check fluid levels and top them off as necessary.

- Inspect wiring for wear and replace any damaged components.

- Maintain proper air circulation around the engine to prevent overheating.

Where to Find Replacement Parts

Locating suitable components for your machinery can greatly enhance its performance and longevity. Whether you are engaged in routine maintenance or facing a breakdown, knowing where to source high-quality replacements is essential for effective repairs. Here are some reliable avenues to explore.

Online Retailers

The internet provides a vast array of options for purchasing components. Consider the following:

- Specialized agricultural equipment websites

- General e-commerce platforms

- Manufacturer’s official websites

- Online auction sites for used components

Local Suppliers

Visiting nearby stores can be advantageous for immediate needs. Look into:

- Local machinery dealerships

- Hardware stores with agricultural sections

- Independent repair shops

- Farm supply stores

Utilizing these resources will help ensure that you find the components necessary to keep your equipment running smoothly.

Maintenance Tips for 4020 Equipment

Proper upkeep of agricultural machinery is essential for ensuring optimal performance and longevity. Regular maintenance not only prevents unexpected breakdowns but also enhances efficiency during operation. Here are some practical recommendations for maintaining your equipment effectively.

Regular Inspections

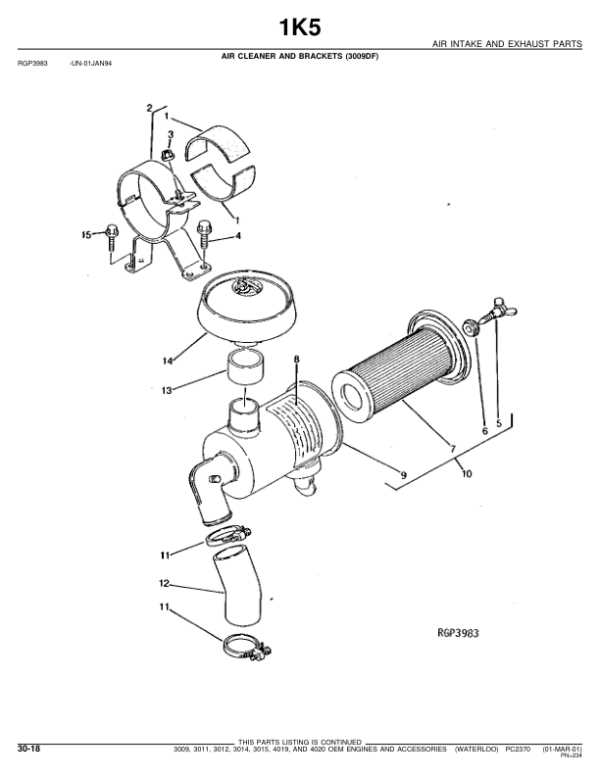

Conduct frequent evaluations of all components to identify wear and tear early. Focus on key areas such as the engine, hydraulic systems, and belts. Check fluid levels regularly, including oil, coolant, and hydraulic fluids. This proactive approach can save time and money in the long run.

Scheduled Lubrication

Ensure that all moving parts are adequately lubricated to minimize friction and prevent damage. Use high-quality lubricants as recommended in the equipment manual. Follow the manufacturer’s guidelines for lubrication intervals, as neglecting this can lead to increased wear and reduced efficiency.

Identifying Genuine John Deere Parts

Ensuring the quality and reliability of machinery components is crucial for optimal performance. Recognizing authentic elements is essential for maintaining equipment longevity and operational efficiency. This section explores key indicators to help users distinguish original components from imitations, ensuring proper functionality and durability.

Key Features of Authentic Components

Genuine components are designed with specific characteristics that set them apart. Familiarizing oneself with these traits can aid in making informed purchasing decisions. Below are some primary features to consider:

| Feature | Description |

|---|---|

| Manufacturer’s Logo | Look for clear, precise branding on the item, often embossed or printed. |

| Part Number | Authentic components have specific identification numbers that correspond to original specifications. |

| Packaging | Original items typically come in branded packaging, featuring quality seals and protective materials. |

| Weight and Material | Genuine components usually have a consistent weight and are made from high-quality materials. |

Benefits of Choosing Authentic Components

Opting for original elements not only enhances performance but also mitigates the risk of malfunctions. Using genuine replacements ensures compatibility and can contribute to the overall value of the machinery, providing peace of mind during operations.

Upgrades for Enhanced Performance

Enhancing the efficiency and capability of agricultural machinery can significantly improve productivity and reduce operational costs. Various modifications and improvements can be implemented to elevate performance, making equipment more reliable and effective for demanding tasks. These enhancements not only optimize functionality but also extend the lifespan of the machinery.

Engine Modifications: Upgrading the engine components can lead to increased power output and better fuel efficiency. Installing high-performance air filters and exhaust systems can facilitate better airflow, resulting in improved combustion and overall performance.

Hydraulic System Improvements: Enhancing the hydraulic system is crucial for better lifting and digging capabilities. Incorporating advanced hydraulic pumps and cylinders can boost lifting capacity and response times, making tasks more efficient.

Transmission Upgrades: Upgrading the transmission system can enhance torque distribution and speed control. Implementing advanced gear sets allows for smoother operation and can improve the overall driving experience, especially in challenging terrains.

Tires and Suspension: Selecting appropriate tires and upgrading the suspension system can significantly impact traction and comfort. High-traction tires and a robust suspension setup improve stability, allowing for more efficient operation in various conditions.

Electronic Enhancements: Modernizing electronic systems, including GPS and precision farming technology, can lead to more accurate navigation and resource management. These innovations assist in maximizing efficiency and reducing waste.

By considering these upgrades, operators can ensure their equipment meets the demands of modern agriculture, ultimately leading to greater productivity and profitability.

Comparing 4020 with Other Models

This section explores the differences and similarities between a specific agricultural machine and its contemporaries. Understanding these distinctions can assist potential buyers and enthusiasts in making informed decisions based on their needs and preferences.

Key Features

When evaluating various models, several features stand out:

- Engine performance and efficiency

- Transmission options and ease of use

- Durability and build quality

- Available attachments and compatibility

Performance Comparison

Analyzing the performance metrics of this machine against others reveals important insights:

- Power output and torque generation

- Fuel consumption rates

- Speed and maneuverability on different terrains

Such evaluations help users choose the right machine for their agricultural tasks, ensuring optimal productivity and efficiency.