The intricate workings of agricultural machinery are essential for efficient operation and maintenance. A thorough comprehension of how each element functions and its relationship to the overall system can significantly enhance productivity. This exploration delves into the specifics of a widely utilized model, emphasizing the importance of knowing each component.

By familiarizing oneself with the structure and layout of machinery, operators and technicians can effectively troubleshoot issues and perform necessary repairs. This knowledge not only streamlines maintenance processes but also prolongs the lifespan of the equipment. Detailed visual representations serve as invaluable resources in this endeavor.

In this section, we will examine a visual guide that illustrates the various components of a popular agricultural machine. Understanding these individual parts and their placements will empower users to optimize their maintenance practices and ensure their machinery operates at peak performance.

Overview of John Deere 5103 Series

The series in question represents a significant advancement in agricultural machinery, offering a robust and versatile solution for various farming needs. Designed for reliability and efficiency, this lineup caters to both small and large-scale operations, ensuring optimal performance in diverse environments.

Key features of this range include a powerful engine, excellent traction capabilities, and user-friendly controls that enhance overall productivity. The machines are engineered to handle a variety of implements, making them suitable for tasks such as tilling, mowing, and hauling.

In addition, durability and ease of maintenance are paramount, allowing operators to minimize downtime and maximize their investment. Overall, this series exemplifies a commitment to innovation and quality, providing a trustworthy option for modern agricultural demands.

Key Features of the 5103 Model

This model stands out for its robust design and reliable performance, making it a popular choice among professionals in various agricultural and industrial applications. Its features combine efficiency, durability, and ease of use, catering to the needs of operators seeking both power and precision.

| Feature | Description |

|---|---|

| Engine | Equipped with a powerful engine that ensures optimal performance in demanding tasks. |

| Transmission | Offers a smooth and efficient transmission system that enhances control and maneuverability. |

| Hydraulics | Features an advanced hydraulic system, providing superior lifting capacity and operational flexibility. |

| Operator Comfort | Designed with an ergonomic operator station that maximizes comfort during long working hours. |

| Versatility | Compatible with a wide range of attachments, allowing for diverse applications in different fields. |

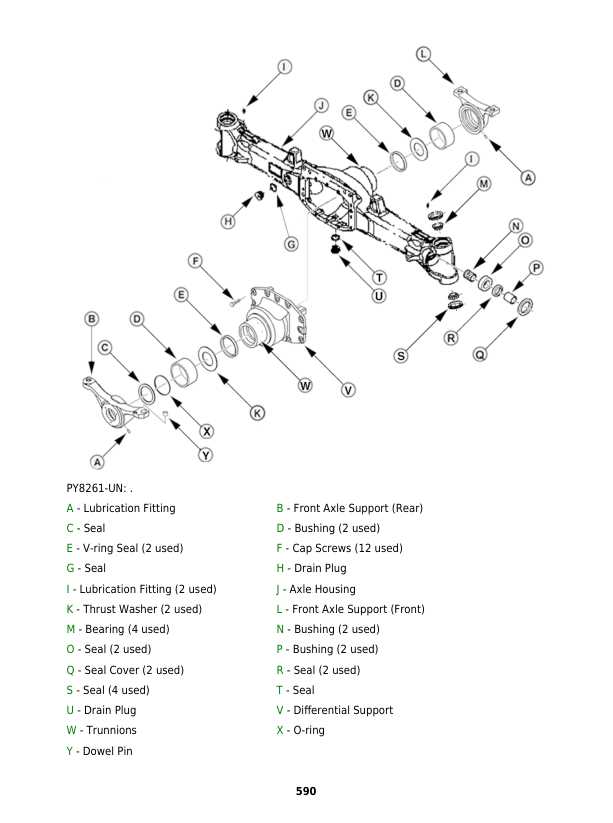

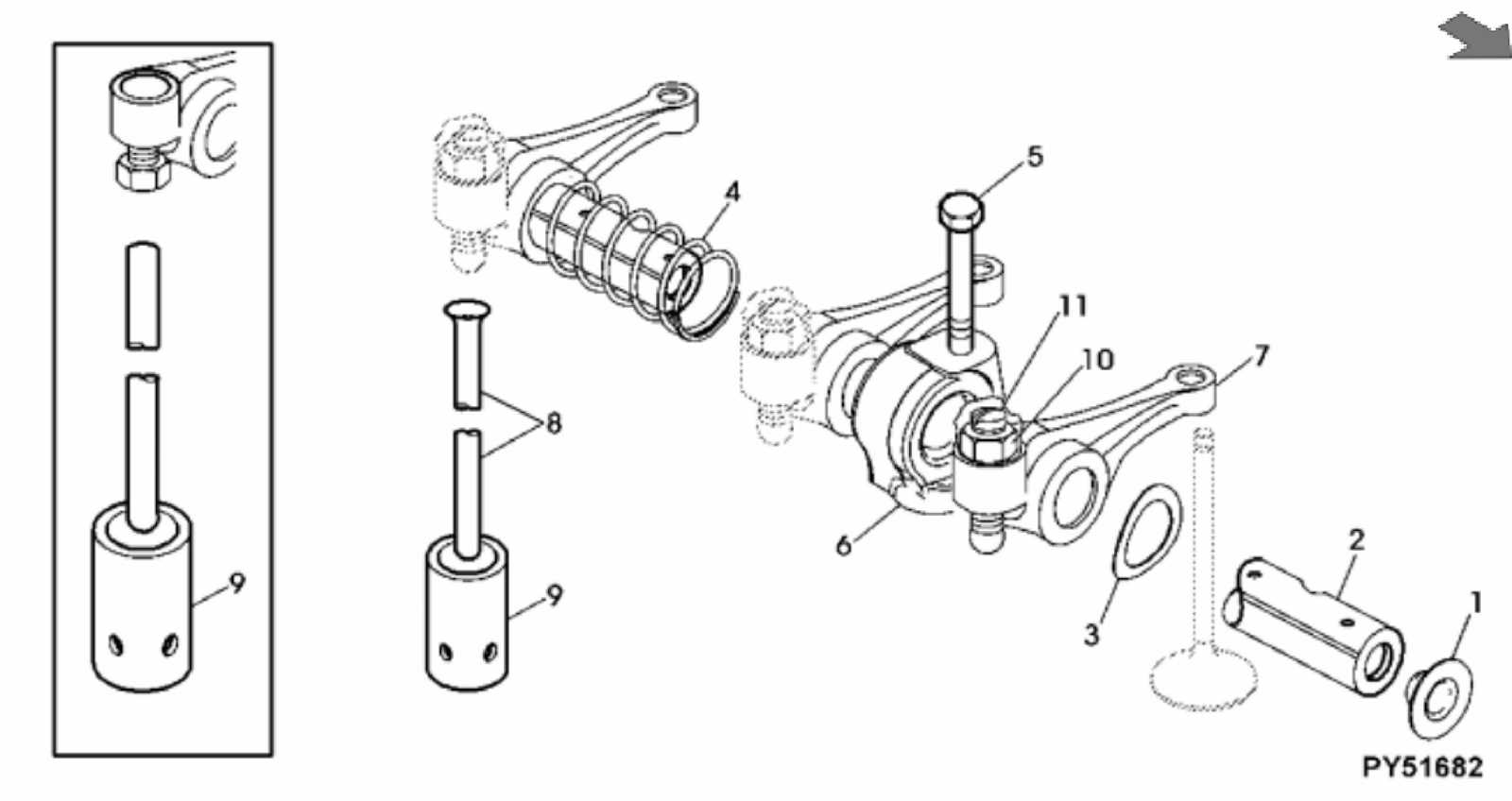

Importance of Parts Diagrams

Understanding the intricate components of machinery is crucial for maintenance and repairs. Visual representations serve as essential tools for both professionals and enthusiasts, ensuring clarity in identifying elements and their relationships within complex systems.

Facilitating Repairs

These visual guides streamline the repair process by providing clear instructions. They help users pinpoint specific elements that require attention, reducing time spent troubleshooting.

Enhancing Knowledge

Moreover, such representations enhance users’ understanding of the equipment, allowing them to grasp how various parts interact and function together, ultimately leading to better care and longevity.

| Benefit | Description |

|---|---|

| Time Efficiency | Reduces the time needed for repairs and maintenance. |

| Improved Understanding | Provides insights into how components work together. |

| Increased Accuracy | Minimizes errors during assembly or disassembly. |

Common Issues with 5103 Components

Understanding the typical challenges associated with agricultural machinery components can greatly enhance maintenance and operational efficiency. Various elements of such equipment may experience wear and tear over time, leading to potential failures or suboptimal performance. Identifying these issues early can save time and reduce costs associated with repairs.

Wear and Tear: Continuous use can lead to significant wear on critical components. This often manifests as reduced efficiency, unusual noises, or vibrations, indicating that parts may need inspection or replacement.

Hydraulic Problems: Hydraulic systems are essential for the effective functioning of many machinery types. Leaks or blockages in the hydraulic lines can result in inadequate power transmission, causing decreased performance during operation.

Electrical Failures: Electrical components can be prone to failures due to exposure to harsh environmental conditions. Issues such as faulty wiring or corroded connections can lead to operational interruptions, requiring immediate attention to restore functionality.

Engine Troubles: Common engine-related problems include overheating, starting difficulties, and unusual exhaust emissions. Regular checks and maintenance of engine components can help mitigate these issues and extend the machine’s lifespan.

Transmission Issues: Gear shifting difficulties or strange noises during operation may indicate transmission problems. Timely diagnosis and intervention are crucial to avoid more extensive damage and ensure smooth operation.

Addressing these common challenges proactively can significantly improve the reliability and efficiency of agricultural machinery, ultimately enhancing productivity in the field.

How to Read Parts Diagrams

Understanding visual schematics is essential for effective maintenance and repair of machinery. These illustrations provide a detailed representation of components and their relationships within a system, helping users identify necessary items and their configurations. By mastering the art of reading these visuals, one can enhance their efficiency in troubleshooting and ordering replacements.

To interpret these schematics effectively, it’s crucial to familiarize yourself with the symbols and numbering conventions used. Each element typically corresponds to a specific item, while accompanying annotations may offer additional context such as part numbers or descriptions. Here are some key aspects to consider:

| Aspect | Description |

|---|---|

| Legend | A guide that explains the symbols used in the illustration, often located in a corner of the page. |

| Callouts | Numbers or letters next to components that refer to specific items in a parts list. |

| Connections | Lines that indicate how different elements interact, showing their relationships and positions. |

| Views | Different angles or cross-sections that provide a comprehensive understanding of the assembly. |

By paying attention to these features, you can navigate the schematic with confidence, ensuring that you locate the correct items for your needs. This skill not only streamlines repair processes but also reduces the likelihood of errors during maintenance tasks.

Where to Find Replacement Parts

Locating suitable components for your agricultural machinery can be crucial for maintaining optimal performance. There are several reliable sources where you can discover the necessary items to keep your equipment running smoothly.

- Authorized Dealers: Visiting certified retailers ensures access to genuine components that meet quality standards.

- Online Marketplaces: Websites like eBay and Amazon offer a vast selection of aftermarket options, often at competitive prices.

- Specialty Stores: Local shops specializing in agricultural equipment frequently stock a variety of necessary supplies.

- Salvage Yards: Exploring used parts from salvage yards can be a cost-effective method for finding hard-to-source items.

- Manufacturer’s Website: Official websites typically provide detailed catalogs and ordering options for components.

By exploring these avenues, you can effectively source what you need for your machinery.

Maintenance Tips for 5103 Tractors

Regular upkeep of agricultural machinery is crucial for optimal performance and longevity. By adhering to a few key practices, operators can ensure their equipment remains in top condition, minimizing downtime and enhancing productivity.

Routine Inspections

Conducting frequent checks on various components is essential. Focus on the engine, hydraulic systems, and electrical parts to identify wear or damage early.

Fluid Levels

Maintaining appropriate fluid levels is vital for seamless operation. Regularly inspect and replenish oil, coolant, and hydraulic fluid to prevent potential issues.

| Component | Recommended Check Frequency |

|---|---|

| Engine Oil | Every 50 hours of operation |

| Hydraulic Fluid | Every 100 hours of operation |

| Coolant Level | Before each use |

Cost Considerations for Repairs

When planning for machinery repairs, understanding the financial implications is essential for effective budgeting. Various factors can influence the overall expense, and being informed can help in making strategic decisions.

Key aspects to consider include:

- Labor Costs: Skilled technicians may charge varying rates, depending on their expertise and the complexity of the work.

- Component Prices: The cost of individual elements can fluctuate significantly based on brand, quality, and availability.

- Service Fees: Some service providers may impose additional charges for diagnostics or emergency repairs.

It’s also important to factor in:

- Frequency of Repairs: Regular maintenance can prevent larger expenses in the long run.

- Warranty Coverage: Reviewing warranty terms can help determine if certain repairs are covered, reducing out-of-pocket costs.

- Downtime: Consider the potential revenue loss due to machinery being out of service during repairs.

By evaluating these elements, operators can better prepare for repair expenses and ensure their equipment remains in optimal working condition.