In the realm of efficient cleaning technology, a thorough comprehension of the individual elements that contribute to optimal functionality is essential. Each component plays a significant role in enhancing the performance and longevity of these innovative devices. By exploring the intricate relationships between these elements, users can achieve the best results in their cleaning endeavors.

Identifying the main constituents not only aids in effective operation but also empowers users to troubleshoot and maintain their equipment. Familiarity with each section allows for a deeper understanding of how these machines harness power to deliver impressive cleaning capabilities.

As we delve into the specifics, it becomes clear that knowledge of the underlying structure ultimately leads to improved efficiency and satisfaction. By grasping the mechanics behind these cleaning tools, one can make informed decisions when it comes to repairs or upgrades.

Understanding Electric Pressure Washers

These powerful cleaning machines are designed to tackle tough grime and dirt, offering users an efficient way to maintain outdoor spaces and surfaces. With a combination of high-pressure water flow and various attachments, they make cleaning tasks easier and quicker. Their versatility allows for a range of applications, from washing vehicles to refreshing patios.

How They Operate

The mechanism relies on a motor that generates significant force, pushing water through a specialized nozzle. This results in a concentrated stream that can dislodge even the most stubborn debris. Various settings and nozzles can be adjusted to cater to different cleaning needs, enhancing the user experience and effectiveness.

Key Components

An understanding of the essential elements can greatly enhance the maintenance and longevity of these machines. Key components include the motor, water pump, hose, and nozzles, each playing a critical role in the overall functionality. Regular inspections and proper care of these elements ensure optimal performance and extend the lifespan of the equipment.

Key Components of Pressure Washers

Understanding the essential elements of a high-performance cleaning device can greatly enhance its effectiveness and longevity. Each component plays a crucial role in ensuring optimal operation, and familiarity with these parts allows users to troubleshoot issues and perform maintenance effectively.

Main Elements

The core features of these cleaning tools include various mechanical and electronic components that work in unison. Knowing how each element contributes to overall functionality is vital for both novice and experienced users.

| Component | Description |

|---|---|

| Motor | Drives the pump and powers the unit, providing necessary energy for operation. |

| Pump | Pressurizes water, enabling it to be expelled at high velocity for effective cleaning. |

| Nozzle | Controls the water flow and pressure, allowing for various spray patterns suited to different tasks. |

| Hose | Connects the device to the water source and carries the pressurized liquid to the nozzle. |

| Trigger Gun | Acts as the control mechanism, enabling users to start and stop the water flow. |

Additional Features

Many devices come equipped with extra functionalities that enhance user experience and cleaning efficiency. Features such as adjustable pressure settings, built-in detergent tanks, and mobility wheels can make tasks more manageable.

How Diagrams Enhance User Understanding

Visual representations play a crucial role in simplifying complex information, making it more accessible for users. By presenting intricate systems or components in an organized manner, these illustrations facilitate quicker comprehension and better retention of information. They serve as an effective tool for both novice and experienced individuals, enhancing their overall learning experience.

When users encounter detailed visuals, they can easily grasp relationships between various elements. This clarity helps to reduce confusion and allows for a more intuitive understanding of how everything fits together. Additionally, such representations can highlight critical features that might be overlooked in textual descriptions alone.

| Benefits of Visual Representations | Description |

|---|---|

| Enhanced Clarity | Visuals simplify complex ideas, making them easier to understand. |

| Improved Retention | People tend to remember visual information better than text. |

| Quick Reference | Illustrations provide an at-a-glance summary of essential components. |

| Engagement | Visual content can capture interest more effectively than written text. |

Overall, utilizing visuals not only aids in understanding but also enhances user engagement, making the learning process more enjoyable and effective. Through the combination of text and imagery, users can develop a holistic view of the subject matter, leading to better outcomes in their tasks and projects.

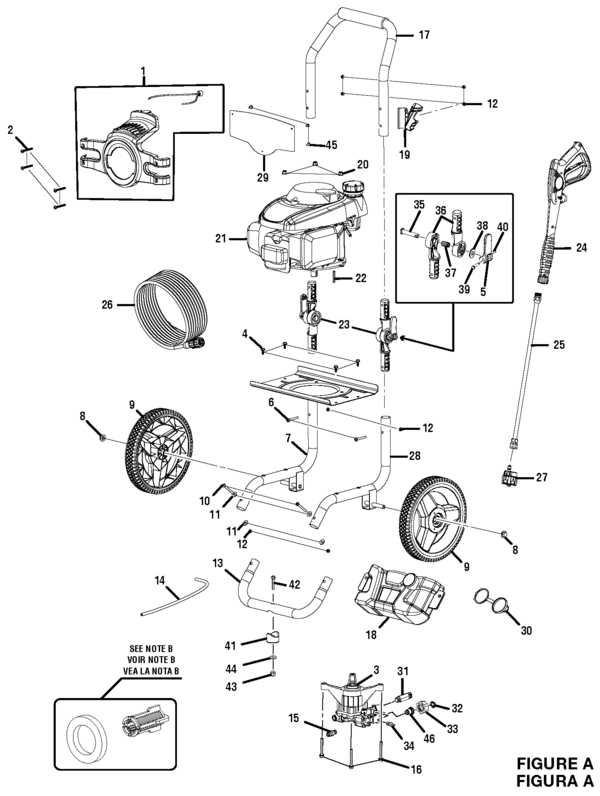

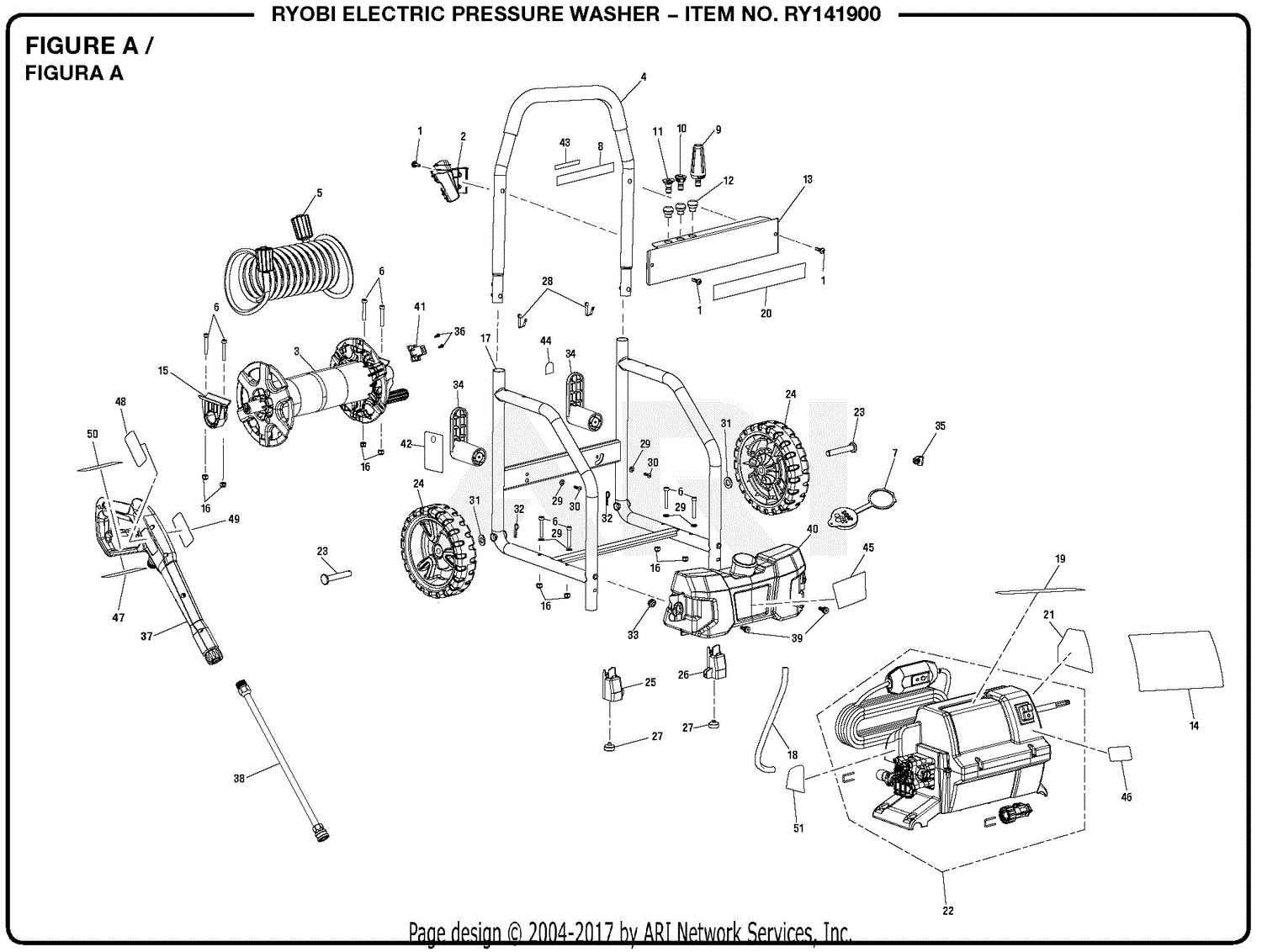

Common Parts and Their Functions

This section explores the essential components of a cleaning device and their specific roles in its operation. Understanding these elements is crucial for effective use and maintenance.

- Motor: Powers the entire system, providing the necessary energy to generate high flow and pressure.

- Pump: Converts the motor’s energy into hydraulic power, facilitating the movement of water through the system.

- Nozzle: Directs and modifies the water stream, allowing for adjustments in pressure and spray pattern to suit different cleaning tasks.

- Hose: Connects the nozzle to the pump, enabling the flow of water while withstanding high pressure.

- Trigger: Controls the release of water, allowing the user to start and stop the flow as needed.

- Water inlet: Serves as the entry point for water, ensuring a consistent supply for the cleaning process.

- Filter: Prevents debris from entering the system, protecting the internal components from damage.

- Wheels: Facilitate easy mobility of the device, making it convenient to transport to various locations.

- Frame: Provides structural support, housing all components securely for stability and durability.

Each component plays a vital role in ensuring the device operates efficiently, contributing to its overall performance and effectiveness in cleaning tasks.

Importance of Regular Maintenance

Consistent upkeep of equipment is vital for ensuring optimal performance and longevity. By adhering to a maintenance schedule, users can prevent minor issues from escalating into significant problems, thus safeguarding their investment.

Benefits of Regular Upkeep

Routine care not only enhances efficiency but also reduces the likelihood of unexpected breakdowns. Timely inspections can identify wear and tear, allowing for prompt repairs and replacements. This proactive approach ultimately saves time and money.

Best Practices for Maintenance

Incorporating simple cleaning routines and checks into regular use can make a substantial difference. Ensuring that components are functioning correctly and free from debris helps maintain peak performance and extends the lifespan of the equipment.

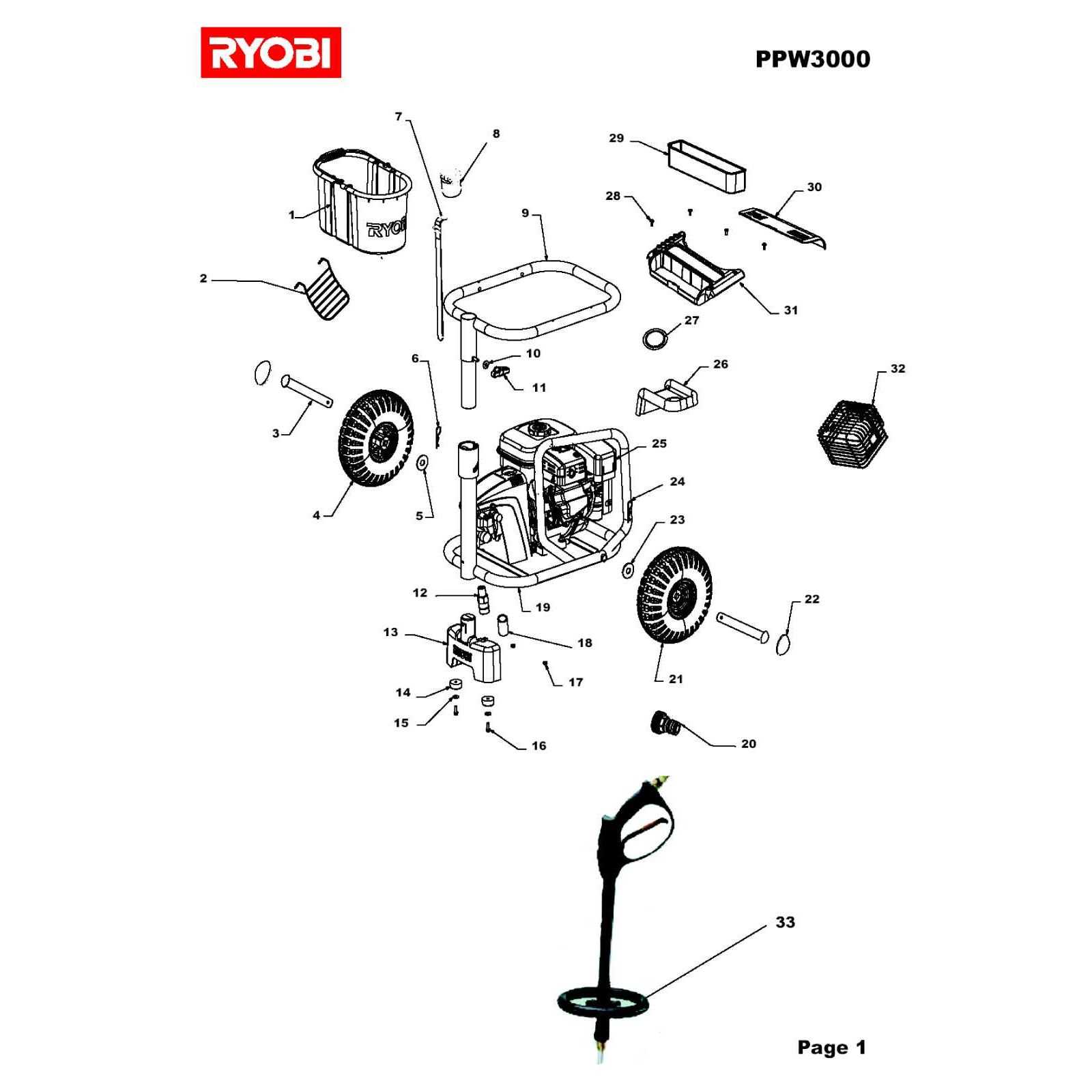

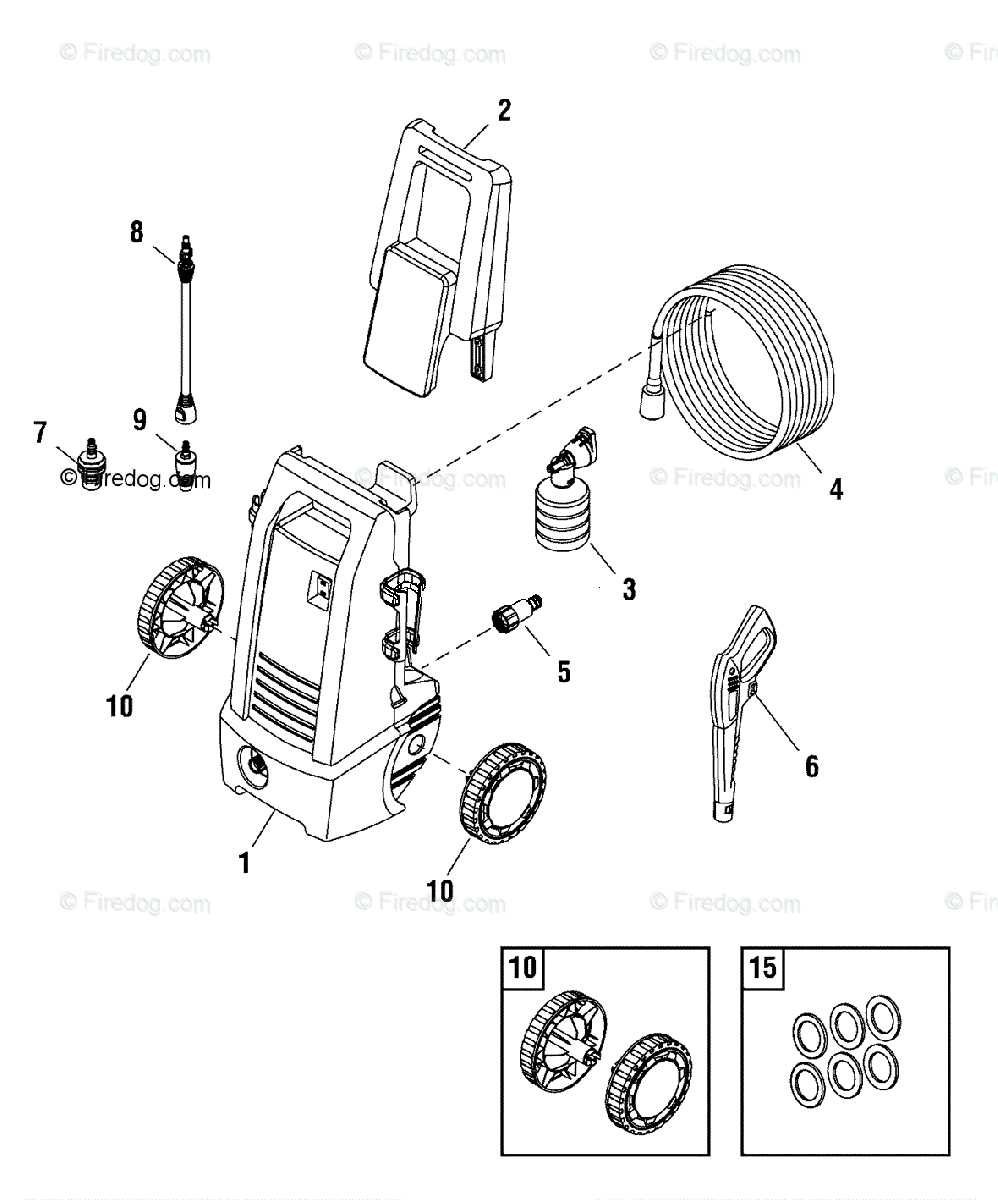

Identifying Replacement Parts Easily

Finding suitable components for your cleaning device can significantly enhance its performance and longevity. Understanding how to pinpoint these elements streamlines the replacement process and minimizes downtime.

- Refer to the user manual for specific information.

- Consult online resources for visual aids.

- Utilize manufacturer websites for original components.

- Seek forums or communities for shared experiences.

By leveraging these strategies, you can ensure you select the ultimate replacements tailored to your needs.

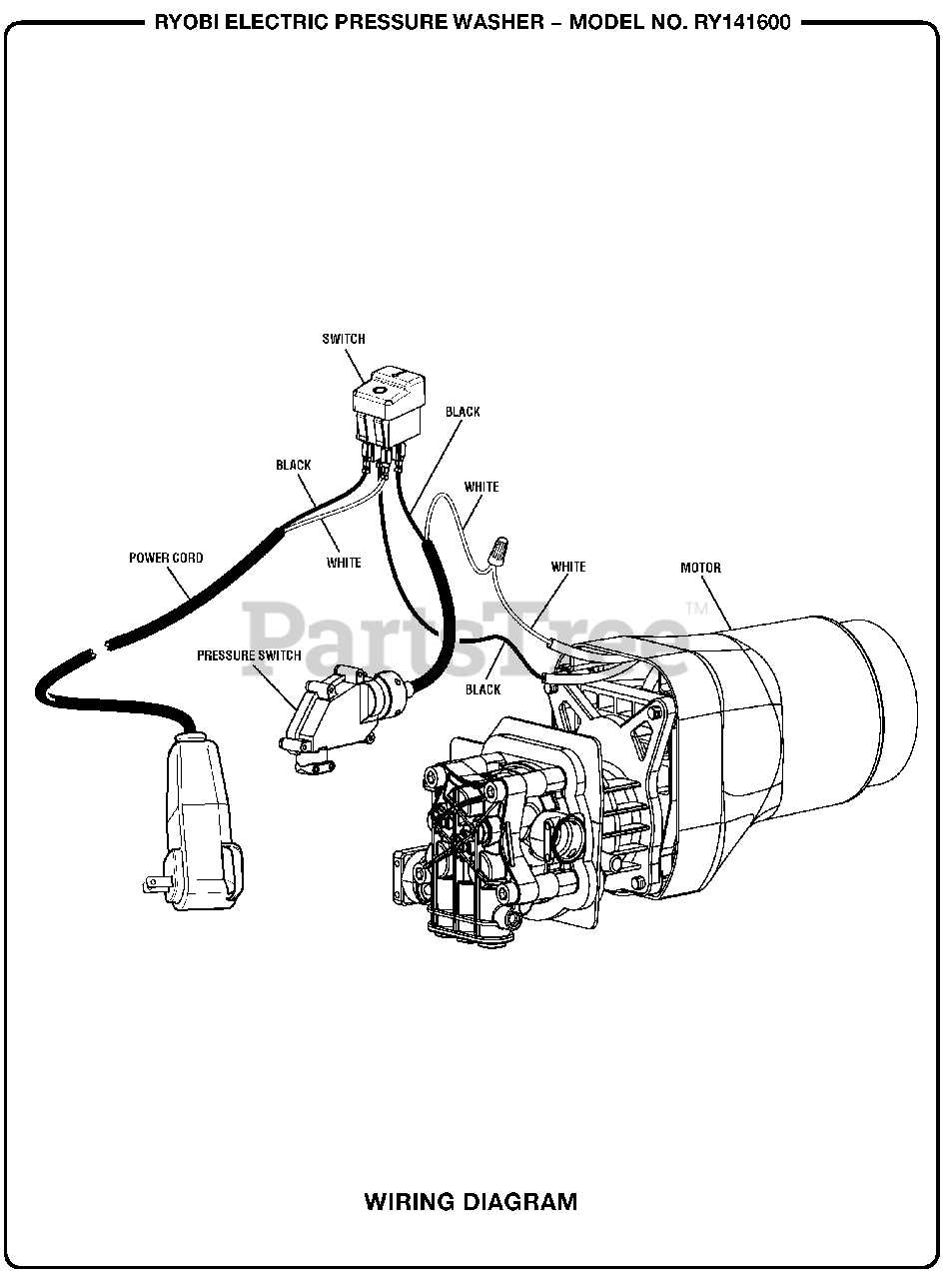

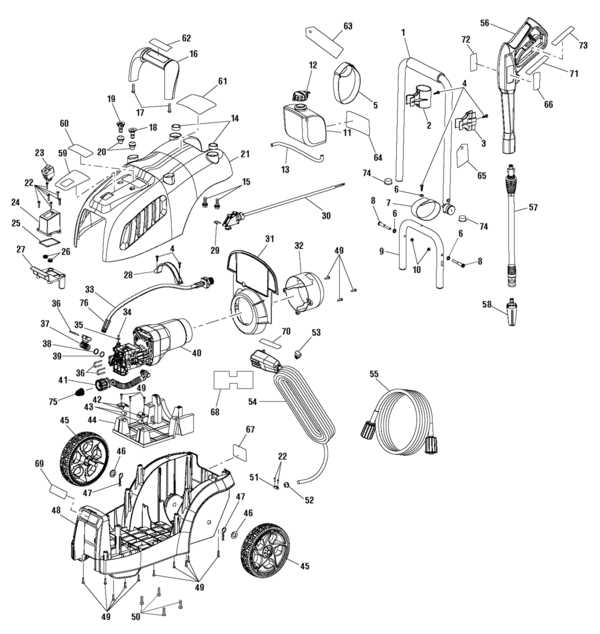

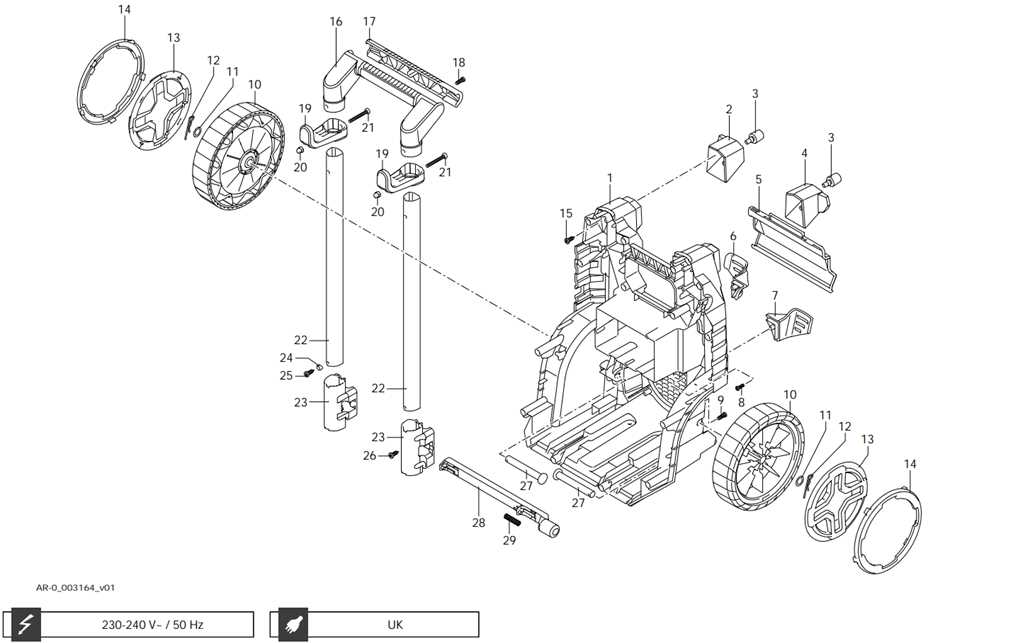

How to Read Pressure Washer Diagrams

Understanding the layout of a cleaning machine can greatly enhance your maintenance and repair skills. These illustrations serve as a visual guide, helping users identify various components and their relationships. By becoming familiar with these representations, you can effectively troubleshoot issues and perform necessary upkeep.

Begin with the Legend: Most diagrams include a legend or key that explains symbols used to represent different elements. Familiarize yourself with these symbols, as they are crucial for interpreting the information accurately.

Identify Main Components: Look for major sections, such as the motor, pump, and hose connections. Recognizing these parts allows you to navigate the illustration with ease, focusing on areas that require attention.

Follow Flow Arrows: Many schematics feature arrows indicating the flow of water or energy. Understanding this directionality is essential for diagnosing problems and ensuring everything operates smoothly.

Check for Annotations: Pay attention to any notes or labels provided within the diagram. These annotations often highlight important specifications, maintenance tips, or safety warnings that can prove invaluable.

Practice Makes Perfect: The more you engage with these illustrations, the easier it will become to interpret them. Take the time to review different schematics, which will deepen your understanding and boost your confidence in working with these machines.

Safety Features in Electric Models

Ensuring user safety is a crucial aspect of modern cleaning equipment. Advanced mechanisms are integrated into various models to protect operators and enhance their overall experience. These features not only minimize risks but also promote efficient and secure operation.

Automatic Shut-Off Mechanism

One of the most significant safety enhancements is the automatic shut-off feature. This mechanism activates when the device is not in use, preventing unnecessary energy consumption and reducing the likelihood of overheating. By automatically disabling the machine, it ensures that operators can work without constant monitoring, contributing to a safer environment.

Ground Fault Circuit Interrupter (GFCI)

Another vital component is the ground fault circuit interrupter, which helps protect users from electric shocks. This device detects imbalances in electrical current and promptly disconnects the power supply, minimizing the risk of injury. It is particularly important for use in damp or wet conditions, where the likelihood of accidents is higher. Incorporating such safety measures allows for greater peace of mind during operation.

Troubleshooting Common Issues Effectively

Addressing typical challenges requires a systematic approach that can lead to quick resolutions. Understanding potential pitfalls and their indicators is crucial for maintaining optimal functionality.

Start by identifying symptoms that signal malfunction. Unusual noises, reduced performance, or leaking fluid are common signs that something may be amiss. Pay close attention to these manifestations, as they often provide valuable clues.

Next, check the components for wear and tear. Inspect hoses, connections, and nozzles for blockages or damage. Regular maintenance can prevent minor issues from escalating into significant problems.

Finally, consult the user manual for guidance. These documents typically contain troubleshooting sections that offer step-by-step instructions tailored to common complications. By following these recommendations, you can ensure your equipment remains in peak condition.