Understanding the intricate details of machinery maintenance is crucial for ensuring optimal performance and longevity. A thorough examination of the various elements involved can significantly enhance one’s ability to troubleshoot and make informed decisions during repairs. This section aims to provide clarity on essential components, illustrating their relationships and functions.

By delving into the structure of these vital pieces, users can gain insight into how each component interacts within the overall system. This knowledge serves as a foundation for effective maintenance strategies and can ultimately lead to improved operational efficiency. Whether you are a seasoned technician or a novice, grasping these concepts is invaluable.

Furthermore, having access to a detailed reference can simplify the identification of specific elements and facilitate smoother repair processes. A well-organized overview not only aids in comprehension but also empowers users to address potential issues proactively, ensuring their equipment remains in top condition.

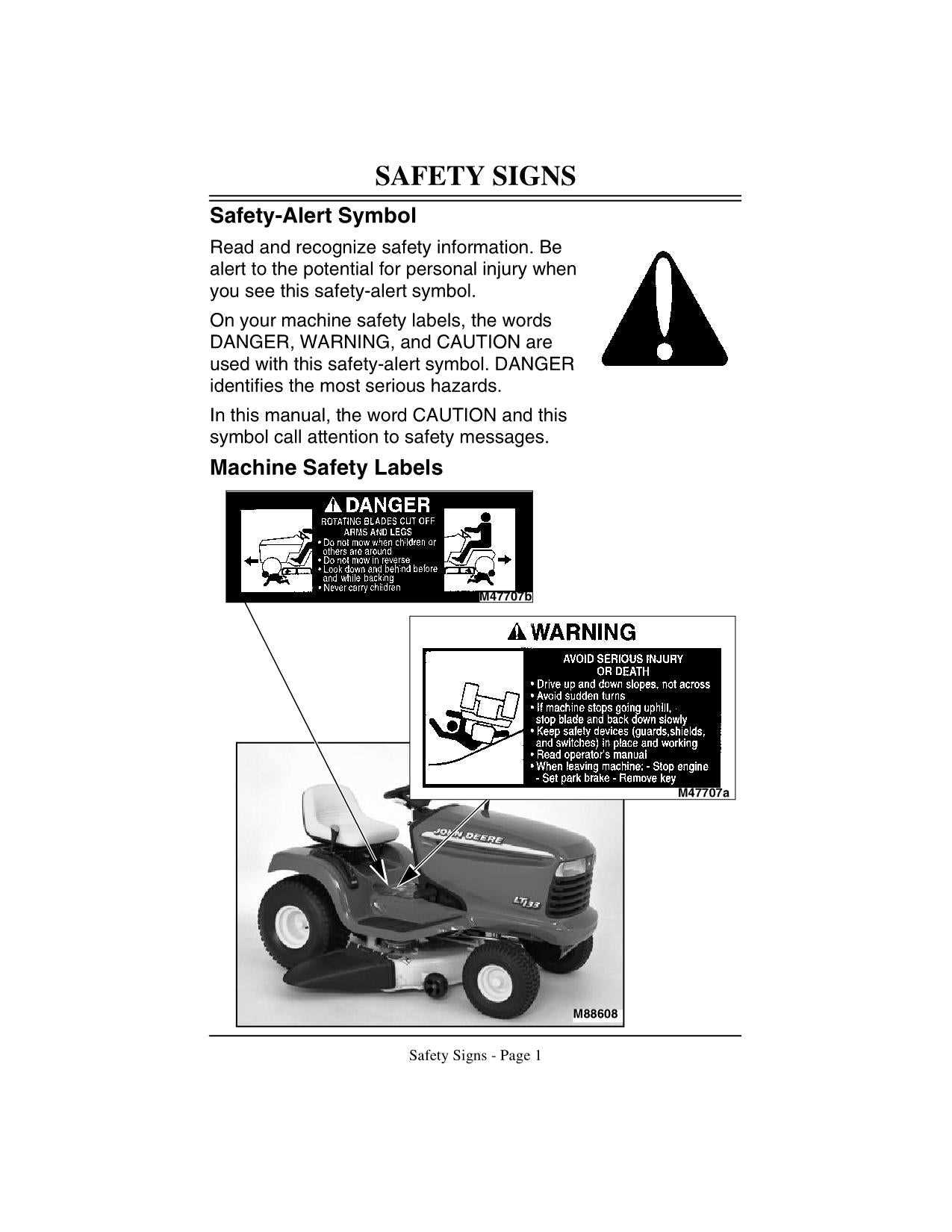

Understanding the John Deere LT166

This section explores a popular model of riding lawn equipment, known for its durability and efficiency. It combines innovative technology with user-friendly features, making it a favored choice among homeowners and landscapers alike. Understanding its components and functions can enhance maintenance and operation.

Key Features

The machine boasts a powerful engine that ensures reliable performance. Its cutting system provides an even finish, while ergonomic controls enhance comfort during use. Regular maintenance is crucial for optimal operation, prolonging the lifespan of this equipment.

Maintenance Insights

Proper care involves routine checks of the engine, blades, and other essential elements. Delving into maintenance schedules and understanding each component’s role can lead to the ultimate efficiency and effectiveness of the machine, ensuring it meets your lawn care needs.

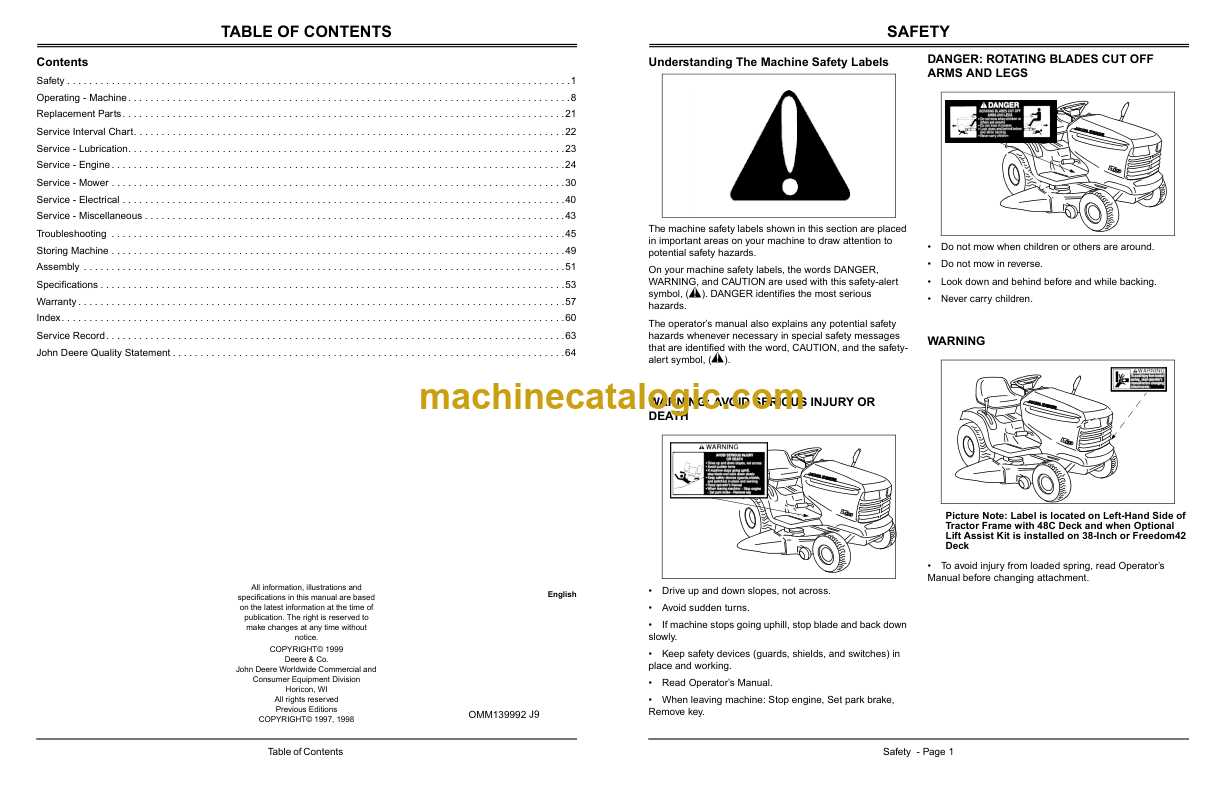

Key Components of the LT166

The understanding of essential elements in any machinery is crucial for effective operation and maintenance. This section highlights the primary parts that contribute to the functionality and efficiency of the model in question. By familiarizing yourself with these components, you can ensure optimal performance and address any issues that may arise.

| Component | Description |

|---|---|

| Engine | The powerhouse that drives the entire system, providing the necessary energy for operation. |

| Transmission | Responsible for transferring power from the engine to the wheels, allowing for smooth movement. |

| Deck | The cutting platform that ensures efficient grass management and overall performance during operation. |

| Wheels | Provide mobility and stability, essential for navigating various terrains. |

| Control Panel | Interface that allows the operator to manage settings and monitor the machine’s performance. |

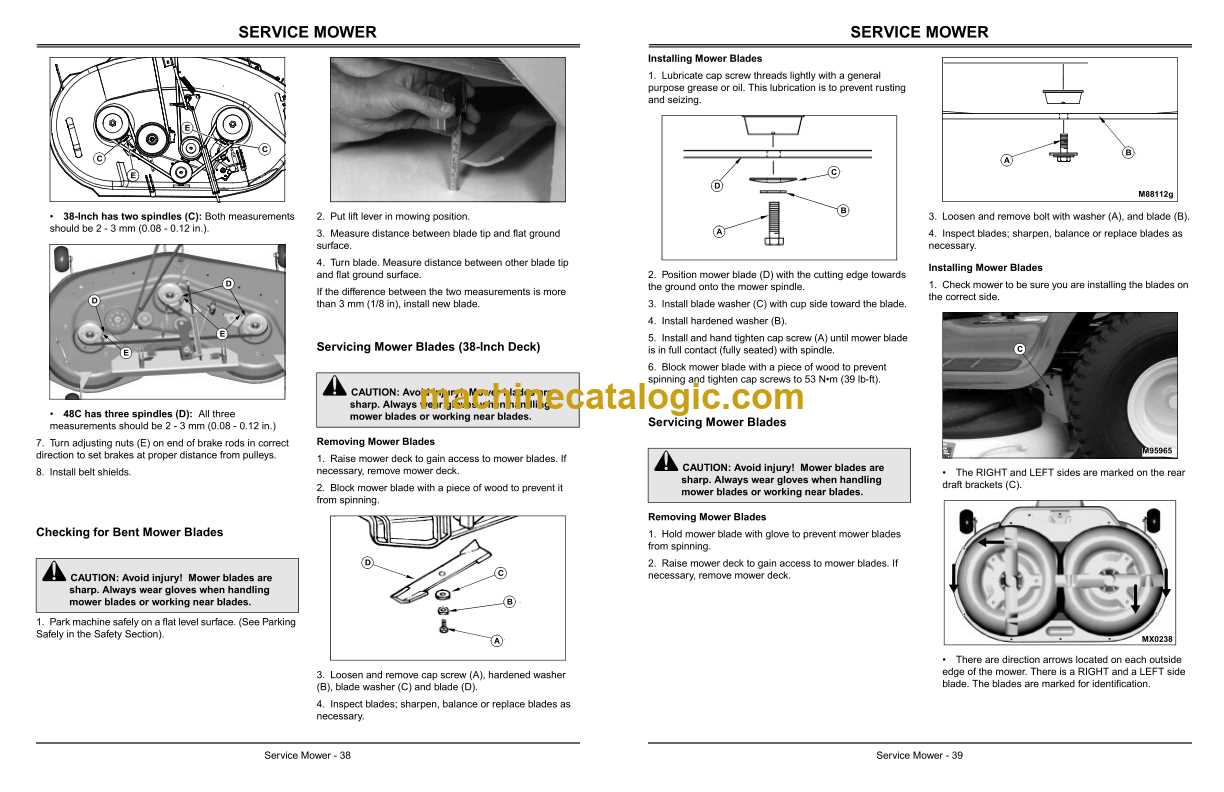

Importance of Parts Diagrams

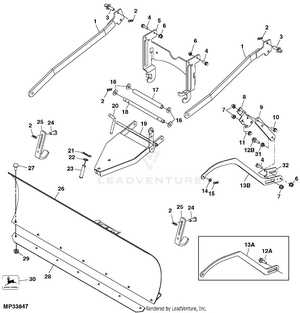

Understanding how various components work together is crucial for anyone involved in the maintenance or repair of machinery. Visual aids that outline the connections and interactions between elements provide clarity, making the process of identifying and replacing necessary components more efficient. These detailed illustrations help eliminate confusion, ensuring that the correct parts are used for any given task.

Enhancing Efficiency and Accuracy

Using these visual tools improves the speed and precision of repairs or routine maintenance. Without a clear representation of how each element fits within the larger system, mistakes can occur, leading to potential delays or further complications. Diagrams help guide users through the process, saving time and reducing the likelihood of errors.

Supporting Long-Term Maintenance

Maintaining a machine over time requires a deep understanding of its structure and components. Visual aids allow for more effective troubleshooting and replacement strategies, ensuring that the machinery continues to operate smoothly and safely. This long-term view is essential for avoiding costly repairs and ensuring equipment longevity.

How to Read the Diagram

Understanding the layout and connections within a schematic can help ensure proper maintenance and assembly. This section will guide you on how to navigate a technical illustration, highlighting key components and their interactions.

- Identify Symbols: Most technical drawings use standardized symbols to represent various components. Familiarizing yourself with these will make interpretation easier.

- Follow the Flow: Look for directional markers or lines that show how different parts connect and work together. These pathways are crucial for troubleshooting and understanding functionality.

- Groupings: Components are often grouped by function or location. Pay attention to sections where items are clustered, as these areas typically represent systems working in unison.

- Labels and References: Diagrams often include labels or reference numbers that correspond to specific items or instructions. Use these identifiers to cross-check with any accompanying documentation.

- Color Coding: If the schematic uses colors, this is usually a visual aid to indicate different systems or types of connections. Be mindful of these distinctions as

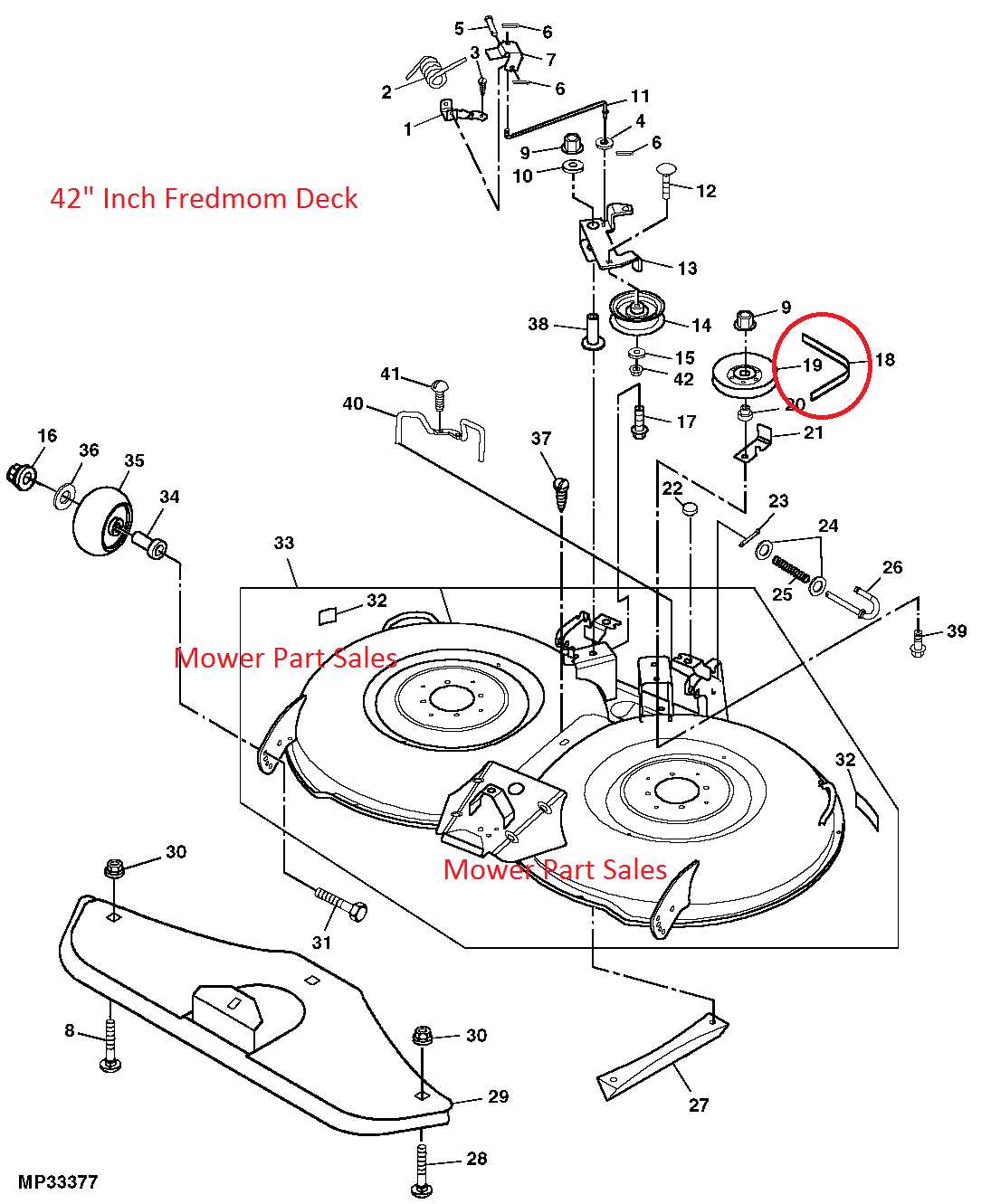

Common Replacement Parts for LT166

When maintaining a garden machine, it’s important to understand which components typically need replacement over time. Regular upkeep ensures the longevity of your equipment and helps avoid unexpected breakdowns. In this section, we’ll outline some of the most frequently swapped elements to keep your machine running smoothly.

Essential Mechanical Components

The mechanical structure of the machine includes several key items that may wear out with prolonged use. These include the drive belt, which transmits power to the wheels and blades, as well as various pulleys that ensure smooth operation. Bearings and bushings are also subject to deterioration due to friction and should be checked regularly.

Electrical and Engine-Related Elements

Key electrical components such as the ignition switch, spark plugs, and battery may also need replacement. Regularly inspecting these elements will help maintain consistent engine performance. Filters, including air and fuel filters, play a critical role in protecting the engine and ensuring efficient fuel consumption.

Component Function Where to Find OEM Parts

For those looking to maintain or repair their equipment, sourcing original components is essential for ensuring compatibility and performance. Finding authentic items can sometimes be challenging, but there are several reliable places where you can find what you need without compromising on quality.

- Authorized Dealers: Many manufacturers have a network of certified retailers who specialize in distributing genuine replacement pieces. These vendors offer trusted advice and access to a wide range of items designed specifically for your model.

- Online Stores: Numerous official e-commerce platforms provide easy access to original components. These websites often allow you to search by model number, making it convenient to locate the exact part needed.

- Service Centers: Certified repair centers not only handle fixes but also stock various original components. Visiting such centers ensures that you receive expert guidance on the correct item to use.

- Local Distributors: Depending on your location, you might find smaller local stores

Troubleshooting with the Diagram

Understanding how to diagnose and resolve issues is much simpler when you have a clear visual reference. A schematic layout provides a roadmap to identify potential problem areas quickly, guiding users step-by-step through the intricacies of the system. This approach minimizes guesswork and ensures a more efficient repair process.

Here are some key steps to follow when troubleshooting:

- Identify the malfunction: Start by observing any irregularities in performance or operation. This helps narrow down the components or connections that may be involved.

- Compare with the layout: Use the schematic as a guide to locate the relevant sections and confirm their proper functioning or possible failure.

- Check connections: Loose or damaged wiring can often cause issues. Ensure all connections are secure and in their correct positions.

- Test individual components: Once potential issues are identified, test each component to ensure it’s working within the expected parameters.

Maintenance Tips for Longevity

Regular upkeep of your equipment is essential to ensure smooth operation and extend its service life. By following simple care routines, you can prevent wear and tear, enhance performance, and reduce the likelihood of costly repairs. Routine checks and proactive maintenance play a vital role in maximizing the lifespan of any machine.

Lubrication is a key factor in preventing friction and maintaining the efficient function of moving components. Make sure to regularly apply the appropriate oils and greases to all joints, axles, and other mechanisms to reduce the risk of damage.

It’s also crucial to inspect belts and hoses for any signs of wear, such as cracks or fraying. Replacing these elements before they fail can help avoid breakdowns during operation, keeping your equipment in optimal condition.

Lastly, always clean and store your equipment properly. Removing debris and dirt, especially from areas prone to buildup, will keep the machine running efficiently. Storing it in