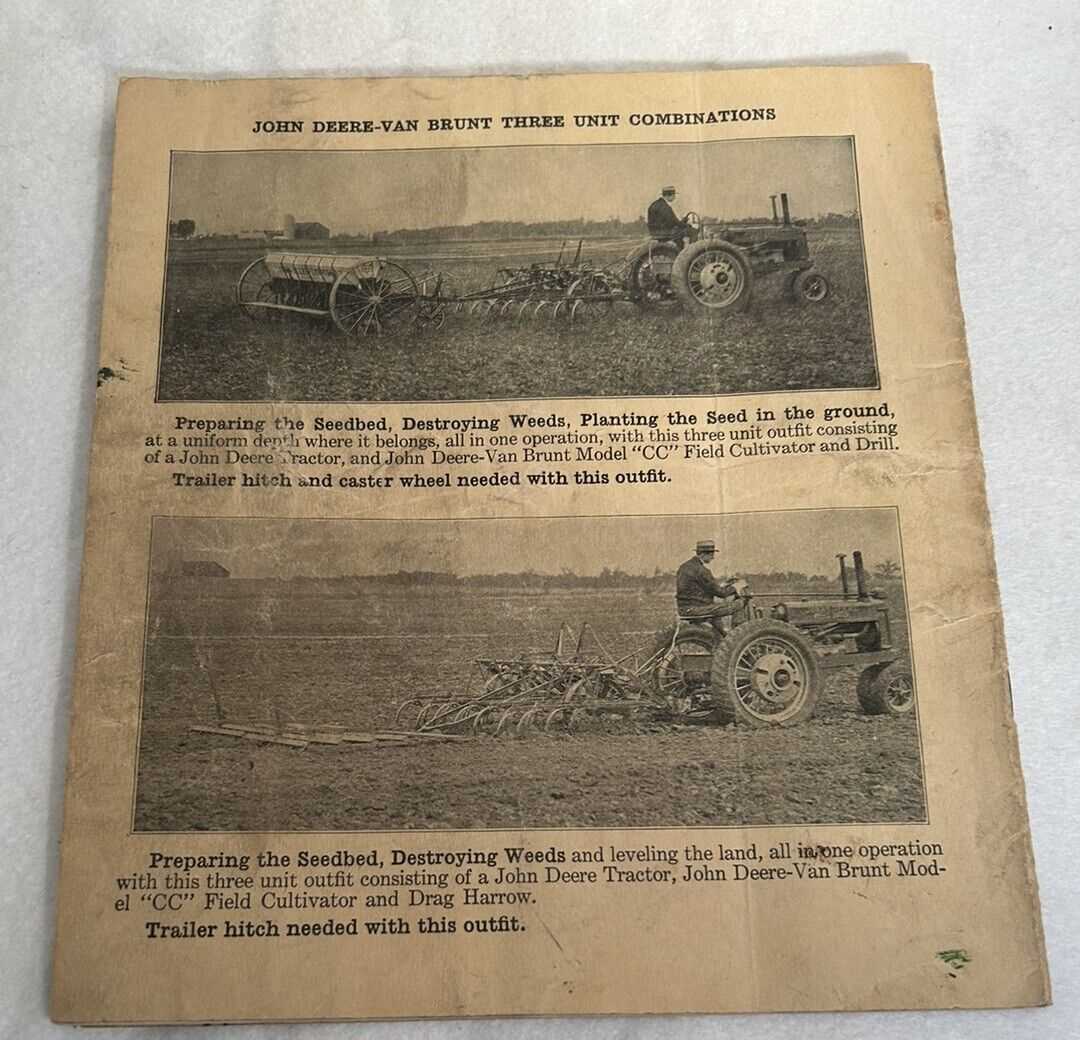

Understanding the intricacies of agricultural machinery requires a deep dive into the specific components that ensure efficient operation. Every element plays a crucial role in maintaining optimal performance, and knowing how these parts interconnect is essential for both maintenance and upgrades. This section provides a clear overview of how different elements work together to ensure smooth and reliable functionality.

The focus here is on the configuration of various elements, highlighting their importance in the overall system. Identifying and familiarizing oneself with the layout of these components allows for easier troubleshooting and enhances the user’s ability to keep the equipment in top shape. This knowledge is invaluable for anyone looking to maintain longevity and efficiency in their machinery.

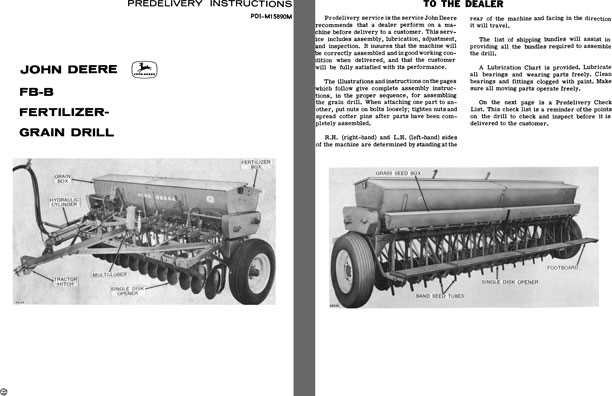

Understanding the Key Components of John Deere Van Brunt Grain Drill

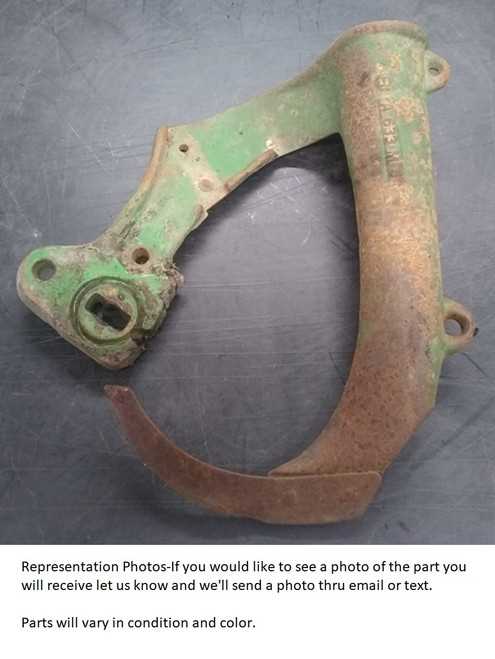

Exploring the essential elements of an agricultural implement reveals its functionality and effectiveness in field operations. Each component plays a critical role in ensuring optimal performance during planting. Familiarity with these elements can enhance operational efficiency and maintenance practices.

Core Elements

- Frame: The structural backbone that supports various components.

- Hoppers: Containers for holding the seed, designed for efficient dispensing.

- Openers: Tools that create furrows in the soil, allowing for precise seed placement.

- Press Wheels: Components that ensure proper soil contact and coverage over the seeds.

Maintenance Considerations

- Regularly inspect all components for wear and tear.

- Ensure proper calibration of dispensing mechanisms.

- Keep the frame and wheels well-lubricated to prevent rust and ensure smooth operation.

Overview of the Grain Drill’s Operating Mechanism

The operating mechanism of this agricultural machine is designed to ensure precise and efficient sowing. Its intricate system works in harmony to control seed distribution, depth, and spacing, allowing for optimized crop growth. By using various components, the machine ensures that seeds are evenly placed in the soil, contributing to higher yield potential.

Seed Distribution System

This part of the mechanism is responsible for managing how seeds are dispensed. The system consists of several interconnected parts that regulate the flow and quantity of seeds to ensure consistent planting. Adjustments can be made to modify seed spacing, depending on the crop and soil conditions.

- Control levers for adjusting the rate of seed release

- Funnels to direct the seeds towards the soil

- Valves for regulating seed flow

Depth

Essential Maintenance Tips for Optimal Performance

Maintaining equipment properly is crucial to ensuring long-lasting and reliable operation. Regular upkeep helps prevent unexpected failures, improves efficiency, and extends the overall life of the machinery. To achieve optimal performance, it’s important to follow a consistent maintenance routine and address potential issues before they develop into costly problems.

Lubrication and Component Care

One of the key aspects of maintenance is ensuring all moving parts are adequately lubricated. This reduces friction, minimizes wear, and helps components move smoothly. Regularly inspect and grease joints, shafts, and other critical areas. Pay special attention to high-stress points that may require more frequent lubrication.

Inspection and Cleaning

Frequent inspection of key components is essential to catch early signs of

Detailed Breakdown of the Seed Delivery System

The seed delivery system plays a crucial role in ensuring that materials are evenly distributed across the soil surface. This mechanism allows for precise and consistent placement, which is essential for achieving optimal growth and yield. The system is composed of various interconnected components that work together to control the flow, speed, and depth of distribution.

Main Components and Their Functions

Several key elements are responsible for the effective operation of the seed placement system. These components regulate the release of materials and ensure even spacing throughout the planting area. Below is an overview of the primary components and their roles:

| Component | Function | |||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Metering Device | Controls the rate of distribution by regulating the amount released at a time. |

| Coulter Type | Function | Best Soil Type |

|---|---|---|

| Straight Coulters | Cut through soil and debris | Loamy and sandy soils |

| Disc Coulters | Improve soil mixing and seed placement | Clay and compacted soils |

| Notched Coulters | Enhance soil penetration and reduce drag | Various soil types |

Lubrication and Care for Moving Components

Maintaining optimal performance and longevity of machinery requires regular attention to the lubrication and upkeep of its mobile parts. Proper care not only enhances efficiency but also prevents premature wear and potential failures. This section will explore the essential practices for ensuring that all moving elements operate smoothly and effectively.

Routine inspection of components is crucial to identify any signs of wear or inadequate lubrication. Applying the right type of lubricant at appropriate intervals is vital in reducing friction and preventing damage. Below is a table outlining common moving parts, recommended lubricants, and suggested maintenance frequency.

| Component | Recommended Lubricant | Maintenance Frequency |

|---|---|---|

| Bearings | High-quality grease | Every 50 hours of operation |

| Shafts | Oil-based lubricant | Every 100 hours of operation |

| Gears | Gear oil | Every 200 hours of operation |

| Chains | Chain lubricant | After each use |

Adhering to a consistent lubrication schedule and utilizing the appropriate products will significantly extend the life of your machinery and maintain its operational efficiency. Regular maintenance is not just a recommendation; it is a necessity for ensuring that all moving parts function harmoniously.

Upgrading Older Models for Modern Efficiency

Improving older agricultural machinery is essential for enhancing productivity and performance in contemporary farming. By integrating modern technology and innovative components, operators can significantly boost efficiency while ensuring that legacy equipment continues to serve its purpose effectively. This approach not only extends the lifespan of the machinery but also maximizes its operational capabilities.

Key Areas for Enhancement

- Precision Tools: Incorporating advanced measuring and monitoring devices can provide real-time data, improving accuracy during operation.

- Energy Efficiency: Upgrading to more efficient engines or drive systems can reduce fuel consumption and minimize environmental impact.

- Automation Features: Implementing automated controls can streamline processes, reducing labor costs and increasing overall efficiency.

Benefits of Modern Upgrades

- Increased Productivity: Enhanced functionality can lead to faster operation times and higher yield rates.

- Cost Savings: Improved fuel efficiency and reduced maintenance needs can result in significant financial savings over time.

- Compatibility with Modern Techniques: Older models can be adapted to work with the latest farming practices, ensuring they remain relevant in a rapidly evolving industry.