In the realm of agricultural machinery, comprehending the intricate layouts of various components is essential for efficient maintenance and repair. These visual representations serve as vital tools, enabling operators and technicians to identify parts and their relationships within complex systems. By delving into these schematics, one can streamline the process of troubleshooting and ensure optimal performance.

The value of these illustrations extends beyond mere identification; they foster a deeper understanding of how each element interacts with others. This interconnectedness is crucial for achieving seamless operation and longevity of equipment. With a clear grasp of these designs, users can make informed decisions regarding repairs and replacements, ultimately enhancing productivity.

Whether you are a seasoned professional or a newcomer to the field, familiarizing yourself with these visual aids will significantly benefit your ability to work effectively. In the following sections, we will explore specific examples and insights that highlight the importance of these informative resources.

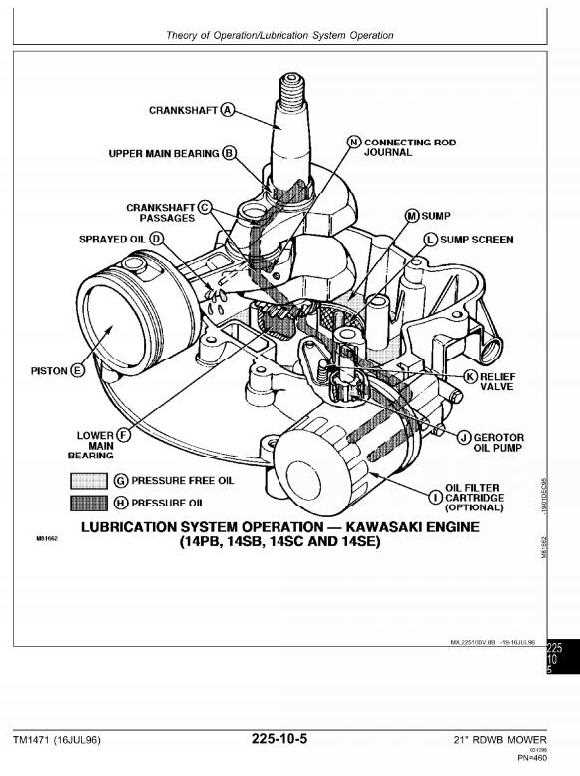

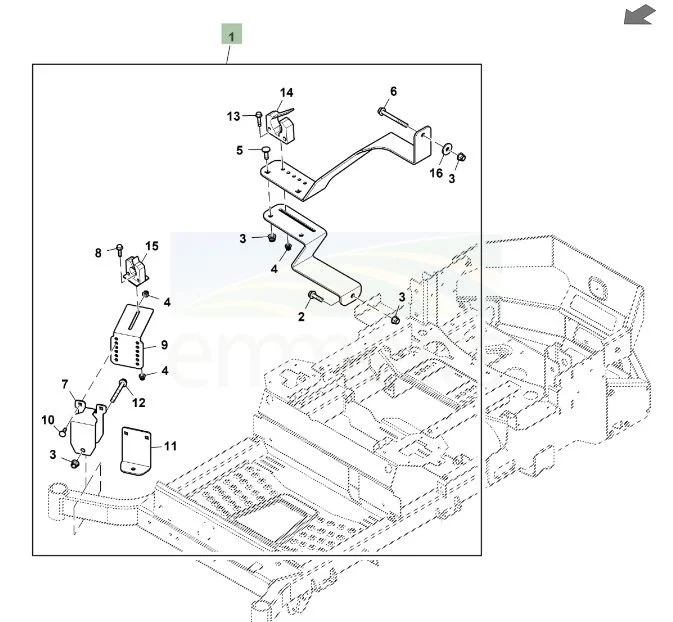

Understanding John Deere 14PZ Components

This section delves into the essential elements that make up a well-known agricultural machine. Each component plays a crucial role in the overall functionality and efficiency of the equipment. By grasping how these parts interact, operators can ensure optimal performance and longevity.

Key components typically include:

- Engine assembly – Provides the necessary power for operation.

- Transmission system – Facilitates smooth movement and control.

- Chassis – Serves as the frame, supporting all other components.

- Hydraulic system – Enables the operation of various attachments and tools.

- Electrical system – Powers lights and other electronic features.

Understanding the function of each part is vital for maintenance and troubleshooting. Here are some common elements to consider:

- Filters: Essential for maintaining fluid cleanliness and system integrity.

- Belt drives: Critical for transferring power from the engine to other components.

- Bearings: Support rotating parts, reducing friction and wear.

- Seals: Prevent leaks and protect against contaminants.

Being familiar with these components will aid users in identifying potential issues and performing necessary repairs. Knowledge of the structure and function of these elements ensures that operators can maximize efficiency and reliability during use.

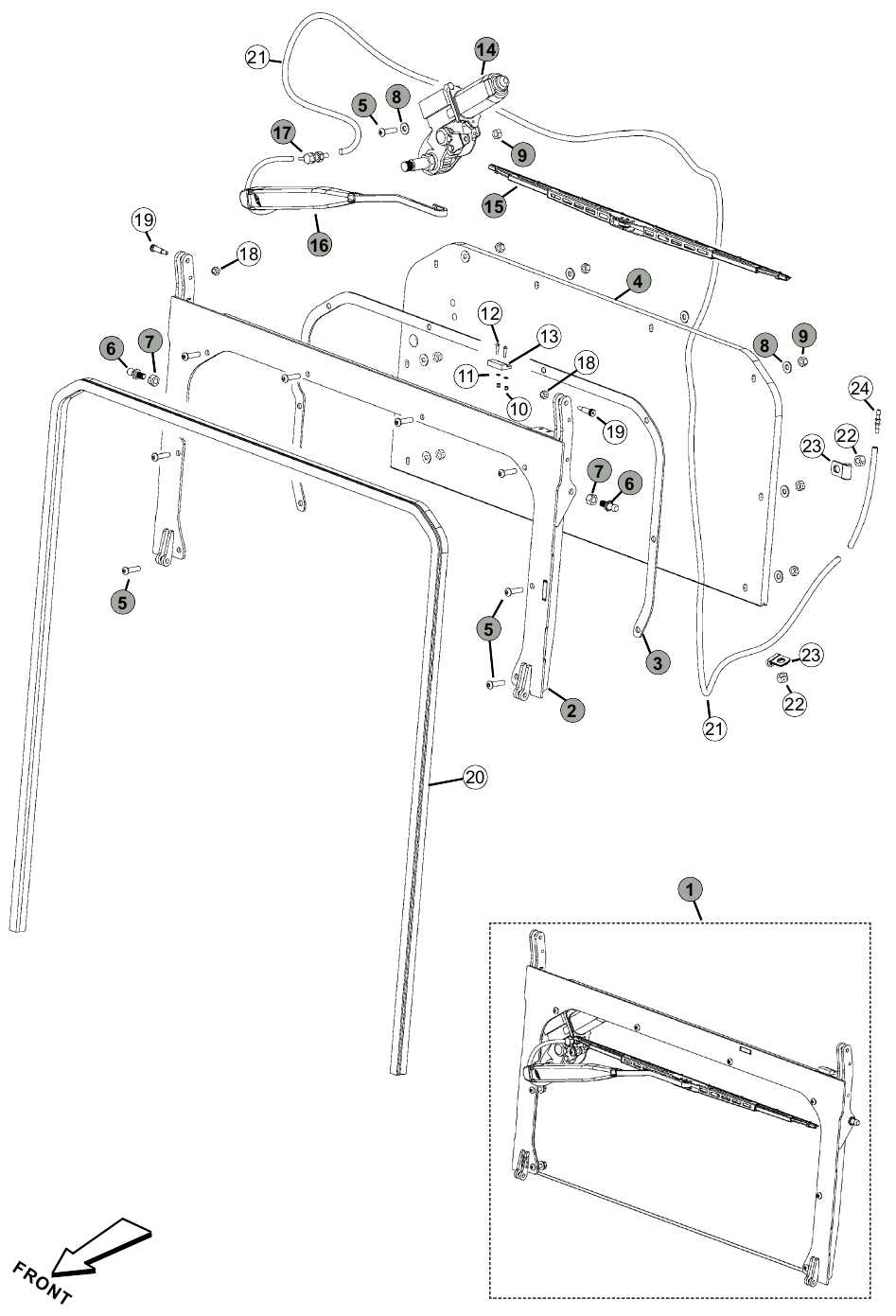

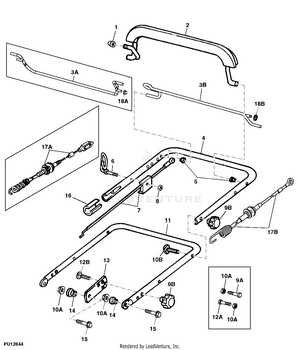

Importance of Parts Diagrams

Detailed illustrations are crucial in ensuring that every component of a machine is correctly identified and understood. These visual references allow users to locate individual elements, assess their functionality, and replace or repair them efficiently. Without such organized depictions, working on machinery becomes significantly more complex and prone to errors.

Ensuring Accuracy in Repairs

When performing maintenance or replacements, having a clear overview of each component’s placement and connection is essential. This prevents unnecessary downtime and costly mistakes, as well as ensures the longevity of the equipment. A well-structured illustration provides an easy-to-follow guide, making complex repairs much more manageable.

Enhancing Efficiency

By referencing well-organized visuals, technicians and users can easily find the specific elements they need to work on. This significantly reduces time spent searching for the correct components, allowing for quicker troubleshooting and more effective repairs. These tools help ensure that machinery is kept in optimal working condition.

Common Issues with John Deere 14PZ

Owners of this popular push mower often encounter a variety of challenges over time. These issues can range from mechanical wear to performance declines, which are common for equipment that is frequently used in demanding conditions. Understanding the typical problems helps in maintaining its efficiency and ensuring it operates smoothly for longer periods.

Engine Starting Problems

One of the most frequent complaints involves difficulty in starting the engine. This could be caused by several factors, such as a clogged air filter, faulty spark plug, or fuel system issues. Regular inspection and maintenance of these components can significantly reduce starting issues.

Blade Performance and Cutting Quality

Another common issue relates to inconsistent cutting performance. Blades may become dull or damaged, leading to uneven cuts or strain on the motor. Ensuring that the blades are sharp and properly balanced will not only improve cutting quality but also extend the lifespan of the machine.

Where to Find Replacement Parts

When it comes to maintaining or restoring older machinery, it’s important to know where to source the necessary components for repairs. Identifying reliable suppliers and outlets can save time and ensure the longevity of your equipment.

Authorized Dealers and Distributors

Authorized sellers are often the best place to start your search. These stores provide certified components, ensuring quality and compatibility with your machine. You can also benefit from expert advice regarding which components will best suit your needs.

Online Marketplaces

Online platforms offer a vast selection of components, sometimes at a lower cost. However, it’s essential to verify the credibility of the seller and check customer reviews before making a purchase.

- Look for sellers with high ratings and positive feedback.

- Compare prices to get the best deal without compromising on quality.

- Consider shipping times and costs, especially for urgent repairs.

By exploring these options, you can find what you need quickly and efficiently to keep your equipment in top shape.

Step-by-Step Repair Process

This guide provides a clear and systematic approach to repairing and maintaining mechanical equipment. Follow the outlined steps carefully to ensure a smooth and successful repair process.

Preparation

- Ensure that all necessary tools are gathered before starting.

- Disconnect any power sources to avoid accidents.

- Lay out the components in an organized manner for easy access.

Disassembly

- Remove the external casing by loosening the fasteners.

- Carefully label and set aside smaller parts to prevent confusion during reassembly.

- Inspect internal components for any signs of wear or damage.

Once disassembly is complete, replace any faulty components, ensuring compatibility. Reverse the steps to reassemble the equipment, testing functionality after each stage of the repair.

Maintenance Tips for Longevity

Regular upkeep is essential to ensure that your equipment functions smoothly for years. By following a few simple guidelines, you can prevent unnecessary wear and tear, keeping your machine in optimal working condition.

First, make it a habit to check all critical components regularly. This includes inspecting moving parts, ensuring that connections are secure, and replacing any worn-out items promptly. Proper lubrication of joints and gears will also significantly reduce friction and extend the life of the equipment.

Additionally, always clean the machinery after use. Removing dirt, debris, and buildup will prevent potential damage and ensure that all elements work as intended. Storing the machine in a dry and sheltered place is equally important to protect it from the elements.

Finally, following the manufacturer’s guidelines for regular servicing and using high-quality replacement items will help maintain peak performance over time. A proactive approach to maintenance is key to maximizing the lifespan of your equipment.

Comparing Parts with Other Models

When evaluating components from various models, it’s crucial to understand the subtle and significant differences that may affect performance and compatibility. This section delves into how specific elements from one equipment model can vary in design, durability, and functionality when compared to others. By understanding these distinctions, users can make informed decisions about maintenance and upgrades.

Key Differences in Engine Components

The internal mechanisms, especially those related to engine performance, often show notable variations. For example, the fuel systems in some models are designed with efficiency in mind, offering better fuel consumption. In contrast, other models might focus on enhanced power delivery but at the cost of fuel efficiency. The configuration of cooling systems also plays a role in how each model operates under prolonged use.

Frame and Build Structure Comparison

When comparing the overall structure, the frame and build quality between models may seem similar at first glance. However, differences in material choice, weight distribution, and structural reinforcements can greatly influence the longevity and usability of the equipment. Some designs might prioritize lightweight mobility, while others focus on strength and durability, especially in demanding environments.

| Component | Model A | Model B |

|---|