When it comes to maintaining and optimizing the efficiency of machinery, having a comprehensive understanding of its individual elements is crucial. This section delves into the intricate relationships and arrangements of the various components that make up a specific model. By exploring the layout and functionality of each element, users can enhance their operational knowledge and ensure their equipment runs smoothly.

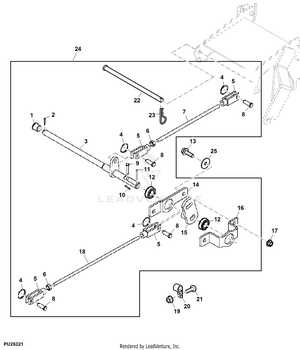

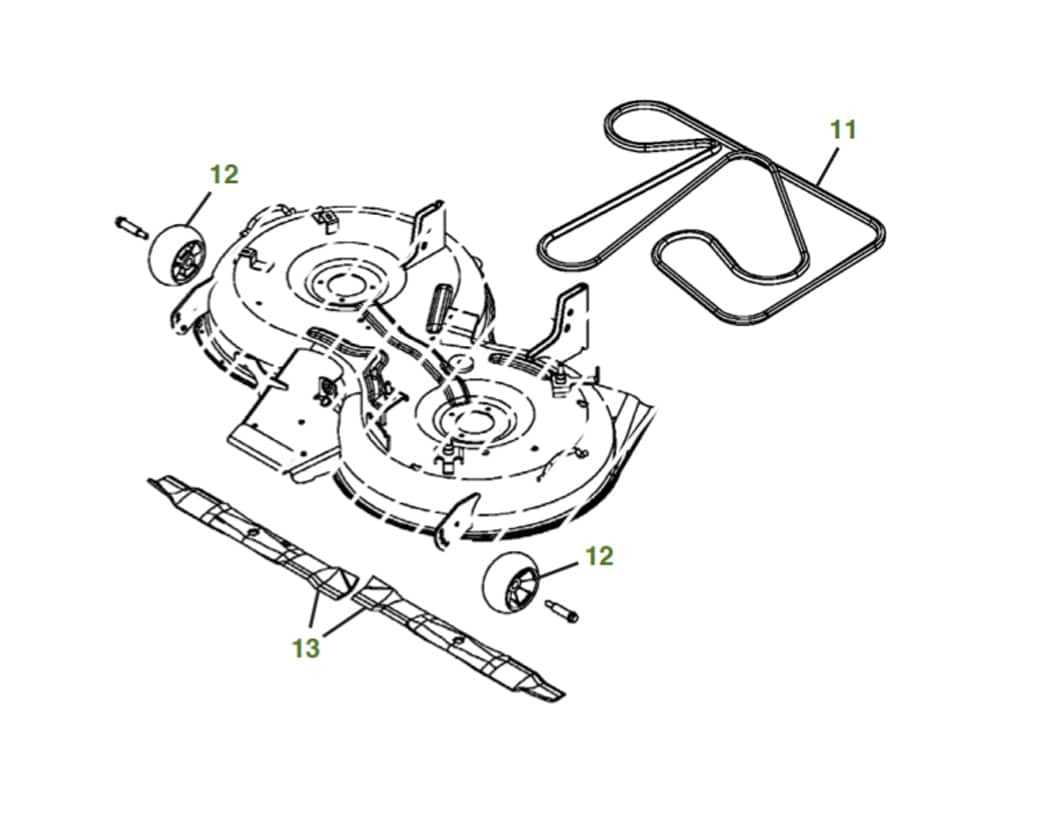

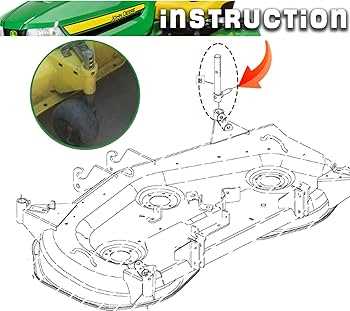

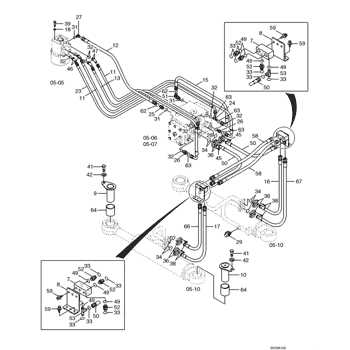

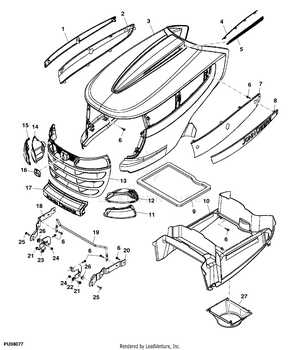

Detailed visual representations serve as invaluable tools for identifying and understanding the various elements involved. These illustrations not only clarify the assembly but also highlight the connections and interactions between different parts. A clear depiction of these components aids in troubleshooting, repairs, and upgrades, ultimately contributing to the longevity and performance of the machinery.

Moreover, familiarity with these representations empowers users to make informed decisions regarding maintenance and replacement. Recognizing the significance of each element within the broader system allows for proactive care and timely interventions. With this knowledge, operators can enhance their machinery’s performance and extend its service life.

Understanding John Deere X520 Components

In the realm of lawn care machinery, comprehending the various elements that comprise a machine is crucial for effective maintenance and operation. Each component plays a significant role in ensuring optimal performance, and recognizing their functions can aid in troubleshooting and repairs. This overview provides insight into the fundamental components of a popular model, focusing on their significance and interconnections.

Main Elements Overview

This section highlights the key components that contribute to the functionality of the machine, allowing users to appreciate the intricate design that facilitates seamless operation. Understanding these elements enhances the user’s ability to maintain and troubleshoot their equipment effectively.

| Component | Description |

|---|---|

| Engine | Powers the entire system, providing the necessary energy for operation. |

| Transmission | Facilitates speed and direction control, allowing for smooth maneuverability. |

| Deck | Houses the cutting blades, designed for efficient grass trimming and mowing. |

| Wheels | Support the machine, ensuring stability and traction on various terrains. |

| Controls | Enables the operator to manage speed, direction, and other functionalities. |

Significance of Component Knowledge

Familiarity with each component empowers users to perform routine inspections and timely maintenance, prolonging the lifespan of the machinery. By understanding how these parts work together, operators can optimize performance and address issues proactively, leading to a more efficient and enjoyable user experience.

Key Features of X520 Parts Diagram

This section highlights the essential attributes of the component layout, offering valuable insights for maintenance and repair tasks. Understanding these features can significantly enhance the efficiency of troubleshooting and replacement efforts.

- Detailed Representation: The schematic provides a clear and comprehensive visual of each element, making it easier to identify specific components.

- Numbering System: Each part is systematically numbered, facilitating straightforward reference and enhancing the clarity of communication during repairs.

- Interconnectivity: The layout illustrates how components interact with each other, allowing users to grasp the overall functionality of the assembly.

- Exploded View: This perspective helps to visualize the arrangement of parts in relation to one another, aiding in understanding the assembly process.

- Compatibility Information: The schematic often includes notes on compatible replacements, ensuring that users select the right alternatives.

Utilizing these features effectively can streamline maintenance operations and extend the longevity of the machinery.

Importance of Accurate Parts Identification

Correctly identifying components is essential for maintaining the efficiency and functionality of machinery. Precision in recognizing the right elements not only enhances performance but also extends the lifespan of equipment. Misidentification can lead to improper replacements, resulting in operational failures and increased maintenance costs.

Moreover, understanding the specific characteristics and compatibility of each component facilitates smoother repairs and replacements. This knowledge is critical for technicians and operators alike, ensuring that they can execute their tasks effectively and minimize downtime.

In addition, accurate identification contributes to improved safety standards. Using inappropriate or incorrect components can lead to hazardous situations, potentially endangering operators and damaging the machinery. Therefore, it is imperative to have a systematic approach to identifying components.

| Benefit | Description |

|---|---|

| Efficiency | Ensures optimal performance and reduces downtime. |

| Cost-effectiveness | Prevents unnecessary expenditures on incorrect components. |

| Safety | Reduces risks associated with improper parts usage. |

| Longevity | Extends the lifespan of machinery through proper maintenance. |

How to Read the Parts Diagram

Understanding an assembly illustration is crucial for effective maintenance and repair of equipment. These visual guides provide detailed representations of components, allowing users to identify individual pieces and their respective functions. By familiarizing oneself with the layout and notation used in these illustrations, one can streamline the repair process and ensure that every part is accounted for.

Key Components of the Illustration

Typically, the illustration will feature various sections that represent different assemblies within the equipment. Each section is often labeled with numbers or letters corresponding to a list of components, making it easier to locate specific items. Pay close attention to the orientation and arrangement of the components, as this will aid in understanding how they fit together.

Understanding Symbols and Notations

Different symbols and notations may be employed in the illustration to convey specific information. For instance, arrows might indicate the direction of movement or assembly, while lines can show connections between components. Familiarizing yourself with these symbols is essential for accurate interpretation. Additionally, take note of any accompanying notes or legends, as they can provide valuable context regarding the components depicted.

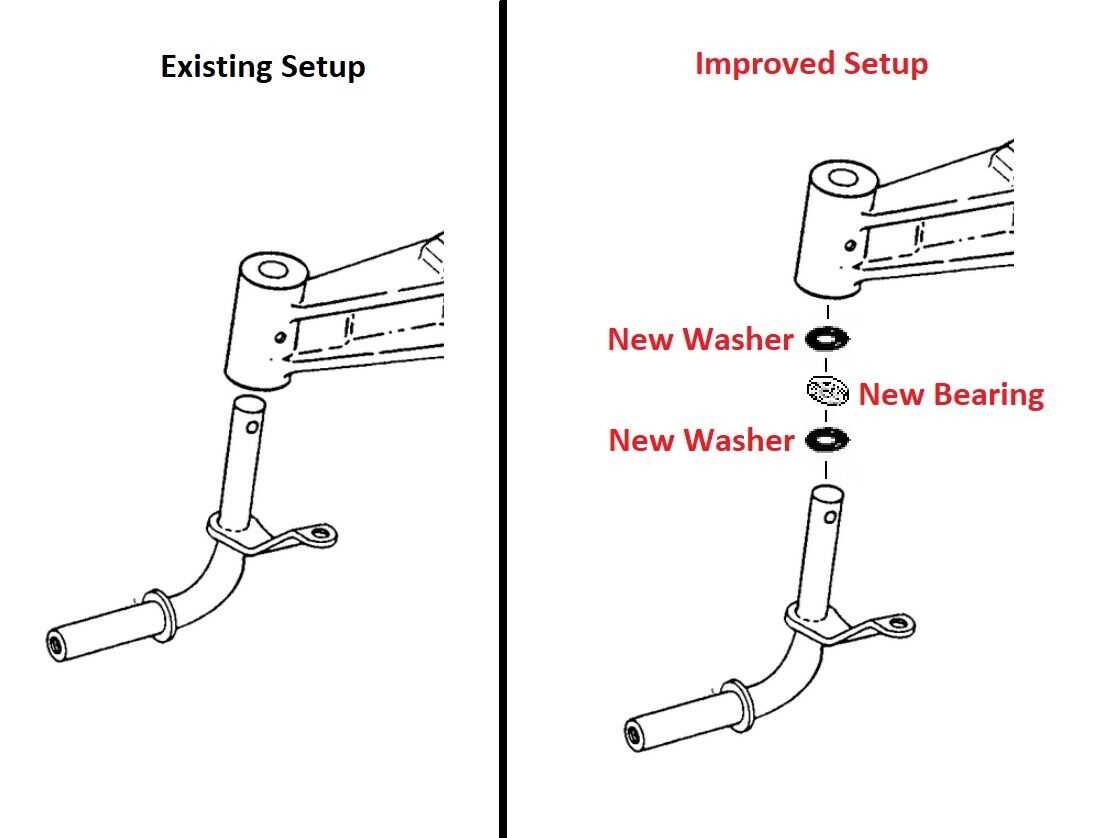

Common Issues with X520 Components

When operating any machinery, understanding the potential problems that may arise with its various elements is crucial for maintaining optimal performance. Certain components can develop issues over time due to wear, environmental factors, or improper maintenance. This section explores some of the frequently encountered complications related to these parts and offers insights on how to address them effectively.

Mechanical Failures

Mechanical components can face numerous challenges that affect the overall functionality of the equipment. Common mechanical failures include issues with the transmission system, steering mechanism, and cutting deck. These problems can lead to reduced efficiency and may require timely interventions to prevent further damage.

Electrical System Malfunctions

The electrical system is another area where problems frequently occur. Battery failures, wiring issues, and faulty sensors can disrupt the machine’s operation, resulting in performance inconsistencies. Identifying and rectifying these issues promptly is essential to ensure reliable operation.

| Component | Common Issues | Possible Solutions |

|---|---|---|

| Transmission | Slipping gears, abnormal noises | Check fluid levels, inspect for wear |

| Steering | Difficulty in maneuvering, loose components | Inspect joints and alignments, lubricate as needed |

| Battery | Failure to start, dim lights | Test battery voltage, replace if necessary |

| Sensors | False readings, intermittent failures | Check connections, clean terminals |

Where to Buy Replacement Parts

Finding quality components for your equipment can be a daunting task, but with the right approach, it becomes manageable. Numerous options are available, from authorized dealers to online platforms, each offering a range of items suitable for various models. The key is to identify reliable sources that ensure authenticity and compatibility with your machine.

Authorized Dealers

One of the most trustworthy options is to purchase through authorized dealers. These retailers specialize in genuine items, guaranteeing that you receive the right fit and quality for your equipment. Additionally, they often provide expert advice and support, helping you choose the appropriate components based on your specific needs.

Online Retailers

Online shopping has revolutionized the way consumers access components. Several e-commerce platforms offer a vast selection of items, often at competitive prices. Be sure to check customer reviews and ratings to ensure you are purchasing from a reputable seller. Look for sites that specialize in machinery supplies to enhance your chances of finding exactly what you need.

Maintenance Tips for X520 Models

Regular upkeep is essential for ensuring optimal performance and longevity of your machinery. Following a structured maintenance routine not only enhances efficiency but also prevents costly repairs in the long run. By adhering to a few straightforward practices, you can keep your equipment in peak condition and ready for any task.

1. Clean the Air Filter: Keeping the air filter clean is crucial for engine performance. A clogged filter can reduce efficiency and power. Regularly inspect and replace the air filter as needed to ensure optimal airflow.

2. Check Oil Levels: Monitoring the oil levels is vital for engine health. Ensure the oil is at the recommended level and replace it according to the manufacturer’s guidelines. Fresh oil helps in reducing friction and wear.

3. Inspect Belts and Hoses: Over time, belts and hoses can wear out or develop cracks. Regularly check for signs of wear and replace them as necessary to prevent breakdowns during operation.

4. Maintain the Battery: A well-maintained battery is essential for reliable starts. Clean the terminals and ensure the connections are secure. If the battery shows signs of corrosion or weakness, consider replacing it to avoid unexpected failures.

5. Sharpen Blades: For models equipped with cutting implements, keeping blades sharp is vital for effective performance. Dull blades can lead to poor cutting results and increased strain on the engine. Regularly sharpen or replace blades as needed.

6. Store Properly: When not in use, store your equipment in a dry, sheltered location to protect it from the elements. Consider using a cover to shield it from dust and moisture, ensuring it remains ready for use when needed.

By implementing these maintenance practices, you can significantly enhance the performance and lifespan of your equipment. A proactive approach to care will ensure that your machinery operates efficiently for years to come.

Benefits of Using Genuine Parts

Utilizing authentic components for machinery maintenance offers significant advantages that enhance performance and longevity. Choosing original elements ensures compatibility, reliability, and efficiency, ultimately safeguarding your investment and minimizing downtime.

Enhanced Performance

Original components are specifically designed to work seamlessly with your equipment, providing the following benefits:

- Optimized functionality tailored to your machine’s specifications.

- Increased efficiency, resulting in better fuel consumption and productivity.

- Consistent performance over time, reducing the likelihood of malfunctions.

Long-Term Savings

Investing in authentic components may lead to cost savings in the long run due to:

- Reduced maintenance and repair costs, as these elements are less prone to failure.

- Extended lifespan of your machinery, delaying the need for replacements.

- Improved resale value, as buyers often prefer equipment with genuine parts.