The intricate structure of a traditional energy generator reveals a fascinating interplay of elements that work harmoniously to harness natural forces. Each element plays a crucial role in converting kinetic energy into usable power, showcasing the ingenuity of design and engineering.

By examining these essential elements, one can truly appreciate the functionality and efficiency inherent in such systems. From the rotating blades to the supporting framework, each component is meticulously crafted to withstand environmental challenges while maximizing energy output.

Furthermore, exploring these mechanisms allows enthusiasts and professionals alike to delve into the ultimate purpose of renewable energy solutions. Understanding how each section contributes to overall performance can inspire innovations and improvements in sustainable practices.

Understanding Windmill Components

Exploring the essential elements of a traditional energy harnessing structure reveals the intricate design and functionality that contribute to its efficiency. Each component plays a crucial role in converting natural forces into usable energy, reflecting a blend of engineering and natural principles.

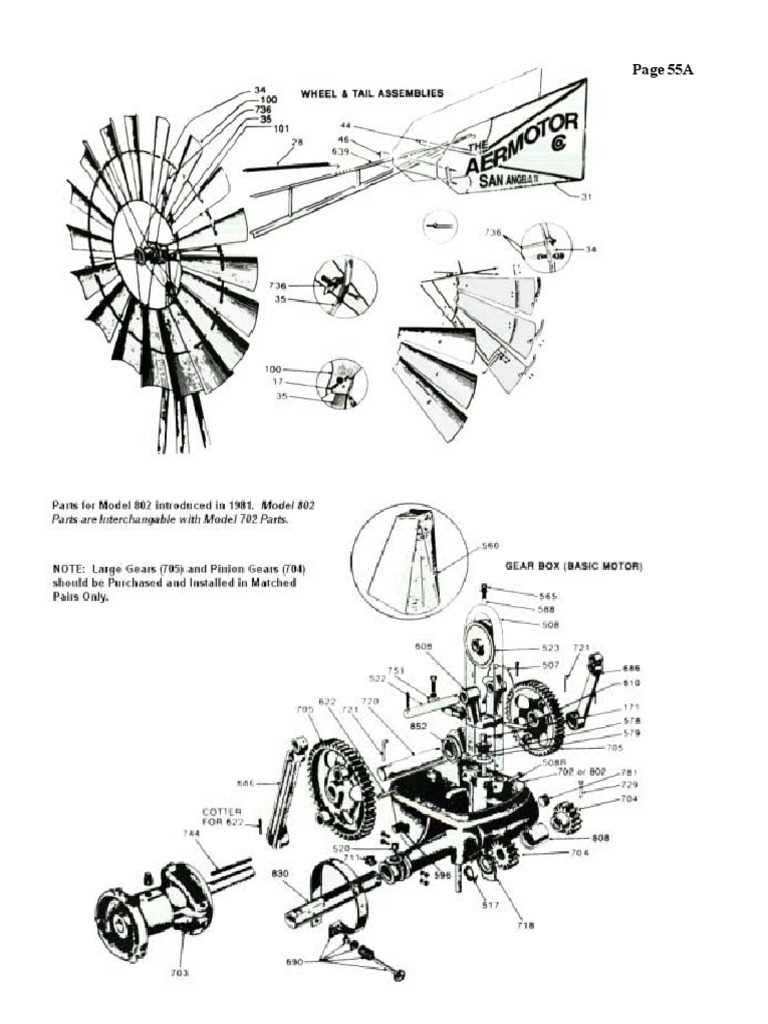

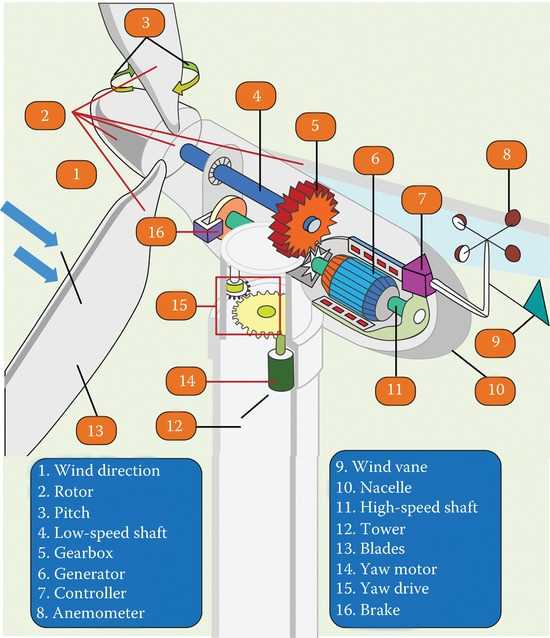

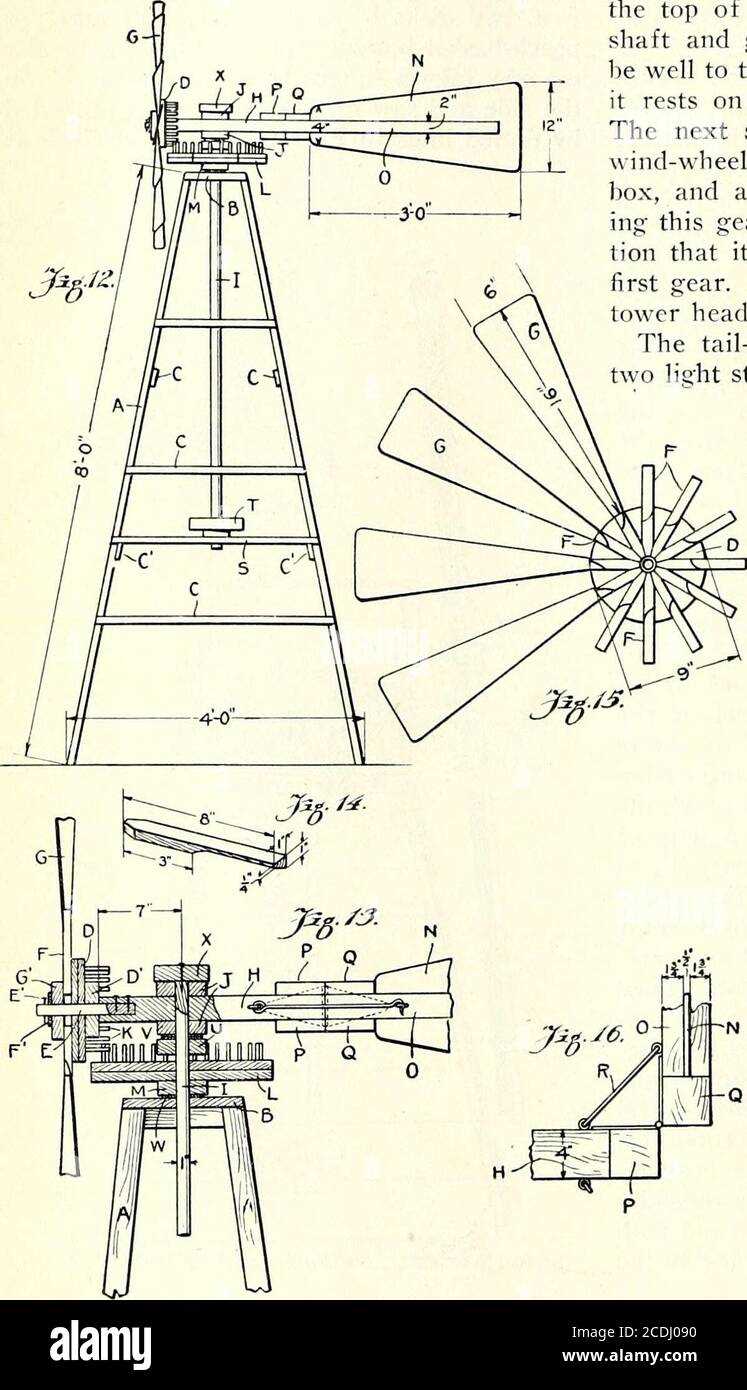

The blades are pivotal, capturing wind currents and initiating motion. This movement is transferred through a central shaft to generate power. Supporting structures provide stability and balance, ensuring the mechanism operates smoothly under varying environmental conditions.

Within the assembly, gears and bearings facilitate the transformation of rotational motion, optimizing energy output. Additionally, the tower elevates the entire system, allowing access to stronger winds. Understanding these elements enhances appreciation for the ingenuity behind this sustainable technology.

Key Parts of a Windmill

The structure harnessing the power of the wind consists of several essential elements, each contributing to its overall functionality and efficiency. Understanding these components provides insight into how energy is captured and converted, illustrating the remarkable interplay between nature and engineering.

Rotor and Blades

The rotor, equipped with blades, plays a critical role in energy collection. When the wind flows over the blades, it generates lift, causing the rotor to spin. The design and material of the blades significantly influence the amount of energy harnessed, making them a vital feature of this mechanism.

Gearbox and Generator

Connected to the rotor is the gearbox, which adjusts the rotational speed before transmitting energy to the generator. This component converts mechanical energy into electrical power. The efficiency of the gearbox and generator combination is crucial for maximizing energy output and ensuring reliable operation.

Functionality of Windmill Elements

The operation of these towering structures relies on a variety of components, each playing a crucial role in harnessing natural energy. Understanding the functions of these elements is essential for appreciating how they convert wind into usable power. From capturing the breeze to transforming it into mechanical motion, each element contributes to the overall efficiency and effectiveness of the system.

Capturing Wind Energy

The blades are designed to catch the wind, optimizing their shape and angle to maximize energy absorption. This aerodynamic feature allows the mechanism to convert kinetic energy into rotational movement. The design and material of the blades significantly influence performance, making their role vital in the energy conversion process.

Energy Conversion Mechanisms

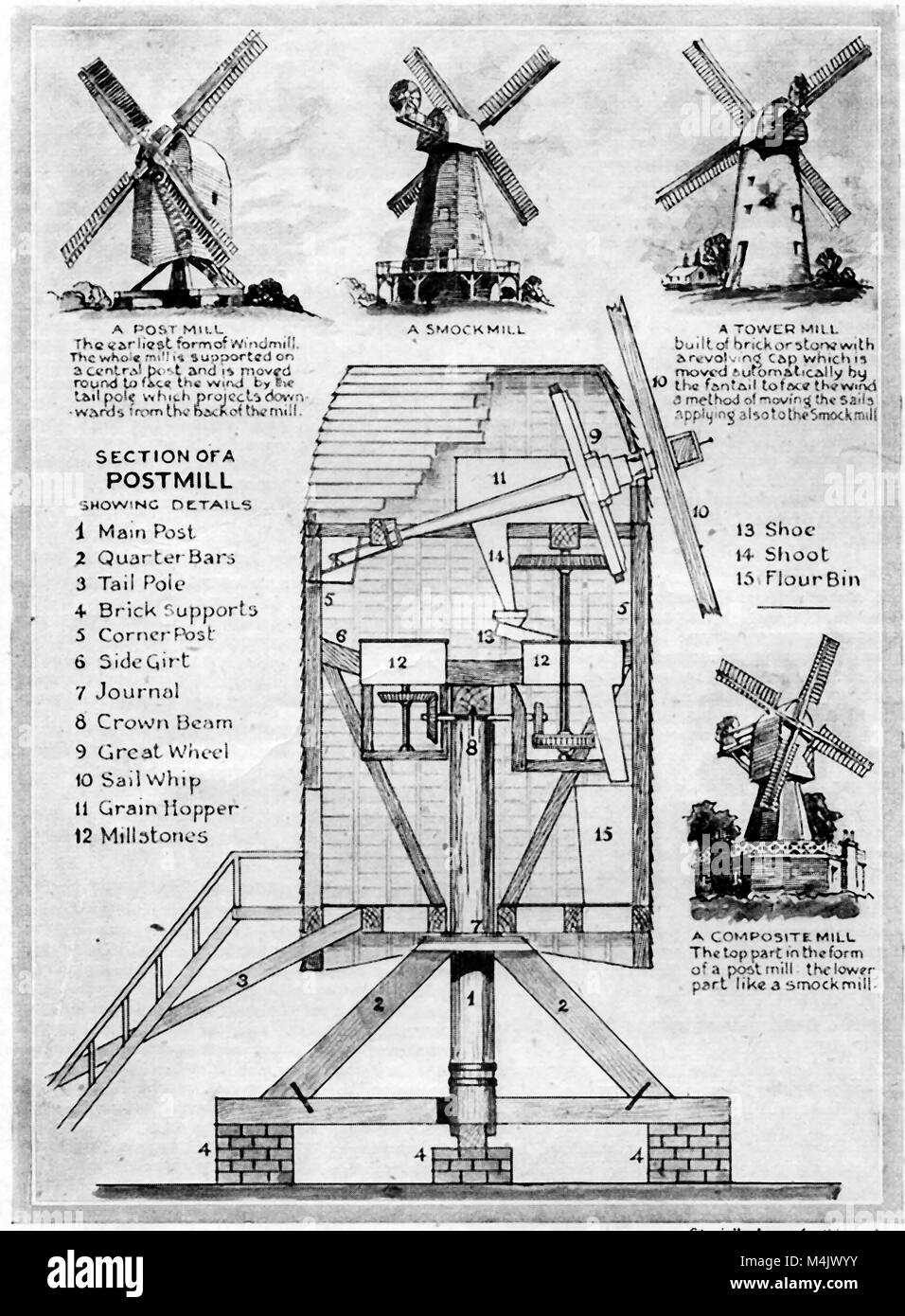

Types of Windmills Explained

Throughout history, various structures harnessing the power of the wind have evolved, each serving distinct functions and purposes. Understanding these diverse designs allows for a deeper appreciation of their significance in energy production, agriculture, and beyond.

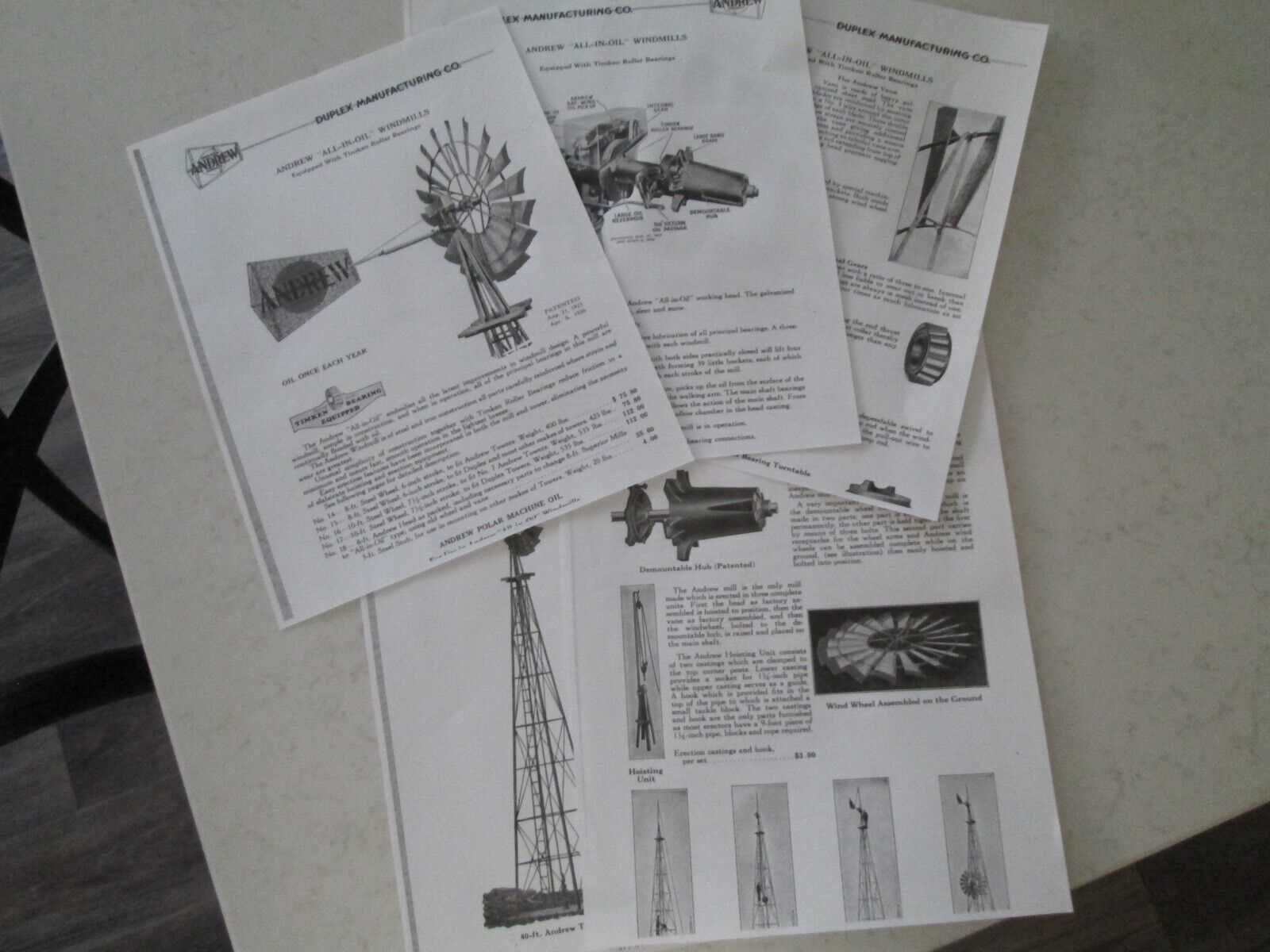

Traditional Designs

Traditional constructions are often recognized for their iconic shapes and historical importance. These models typically feature a large rotating element that captures wind energy to perform mechanical tasks, such as grinding grain or pumping water. Their robust build and simplicity have made them a staple in rural landscapes for centuries.

Modern Innovations

In contrast, contemporary variations focus on efficiency and sustainability. These advanced systems employ aerodynamic principles to maximize energy capture. They often consist of sleek, tall structures equipped with multiple blades designed to optimize performance. Additionally, modern iterations can be found in both large-scale farms and individual installations, showcasing their adaptability to various environments.

In summary, each type of these energy-converting structures reflects a unique blend of tradition and innovation, highlighting humanity’s enduring quest to utilize natural resources effectively.

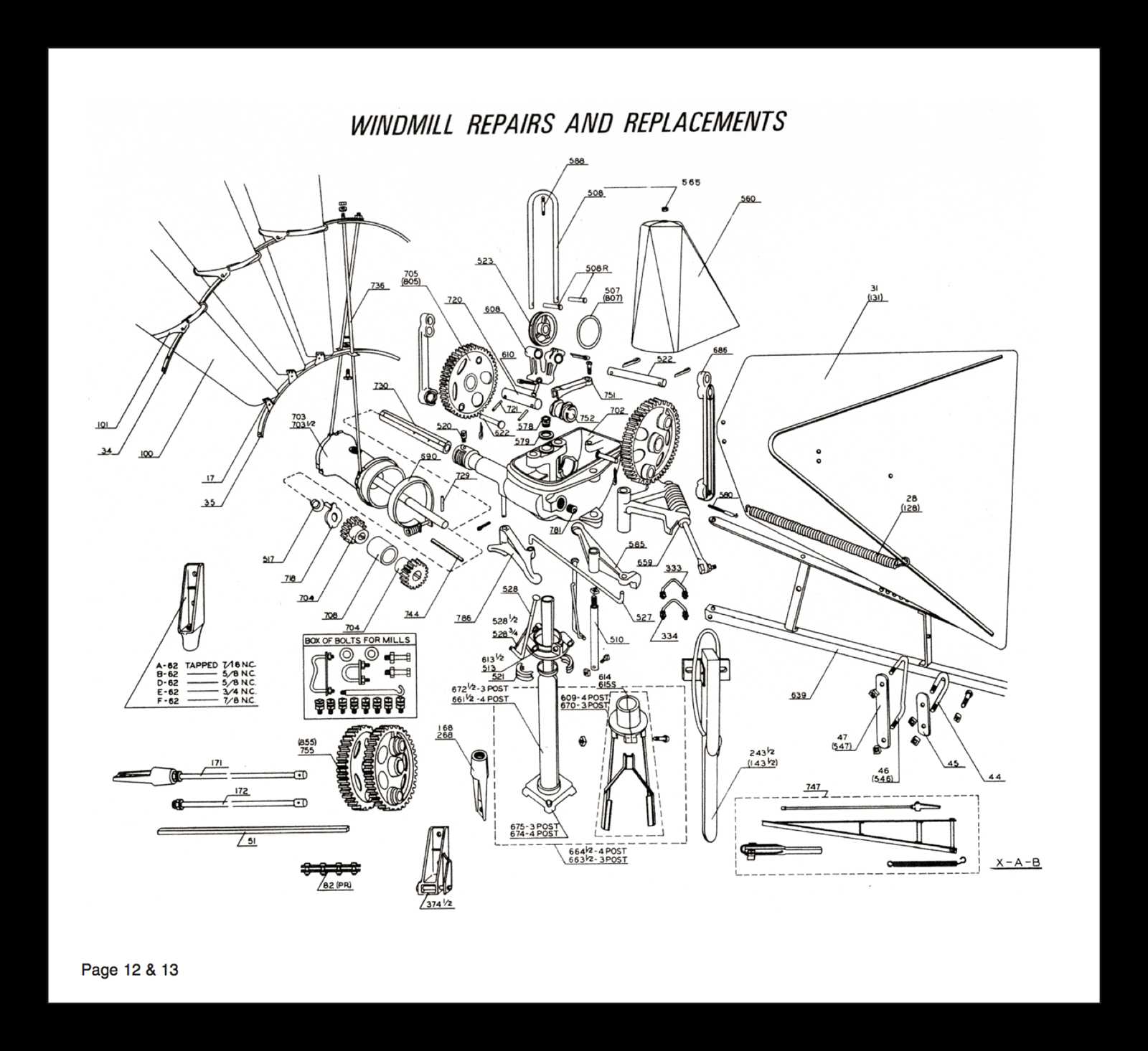

Importance of Maintenance Practices

Regular upkeep is crucial for ensuring the efficiency and longevity of any mechanical system. Implementing consistent maintenance routines can prevent unexpected breakdowns and extend the operational lifespan of equipment.

Effective maintenance practices offer several benefits:

- Enhanced Performance: Regular checks and servicing help maintain optimal functionality.

- Cost Savings: Preventative measures reduce the likelihood of costly repairs or replacements.

- Safety: Proper maintenance minimizes the risk of accidents and injuries associated with equipment failure.

- Environmental Impact: Well-maintained systems operate more efficiently, leading to reduced emissions and waste.

To achieve these advantages, consider the following key practices:

- Regular Inspections: Schedule routine evaluations to identify wear and tear.

- Timely Repairs: Address issues immediately to prevent escalation.

- Lubrication: Ensure moving parts are properly lubricated to reduce friction.

- Documentation: Keep detailed records of maintenance activities for future reference.

In conclusion, prioritizing maintenance is essential for the seamless operation of any system. By adopting diligent practices, operators can safeguard their investments and ensure continued efficiency.

Materials Used in Windmill Construction

The choice of materials in constructing these energy-generating structures plays a crucial role in their efficiency, durability, and overall performance. Various elements are utilized, each selected for specific properties that enhance the functionality and longevity of the installation.

Primary Materials

Wood has historically been a popular choice, especially for traditional designs, due to its availability and workability. Steel and aluminum are commonly used in modern constructions for their strength and resistance to environmental factors. Concrete also serves as a foundational material, providing stability and support.

Additional Components

To improve efficiency, composite materials are increasingly utilized for blades, offering a blend of lightweight characteristics and structural integrity. Glass fiber and carbon fiber are notable examples, enhancing performance while minimizing weight.

Windmill Energy Conversion Process

The process of harnessing natural forces to generate power involves several crucial stages. By transforming kinetic energy from air movement into mechanical energy, systems can effectively convert this energy into electricity or other useful forms. Understanding these stages provides insight into the efficiency and functionality of such renewable energy systems.

Conversion Stages

Initially, the dynamic energy present in the atmosphere is captured by a rotating mechanism. This movement initiates a series of transformations that ultimately lead to electrical generation. Each stage is integral to maximizing energy yield and ensuring sustainable operations.

| Stage | Description |

|---|---|

| 1. Energy Capture | Airflow causes the blades to spin, converting wind energy into rotational motion. |

| 2. Mechanical to Electrical | The rotational energy is transmitted to a generator, where it is transformed into electrical energy. |

| 3. Energy Distribution | Generated electricity is distributed for use in homes, businesses, or the grid. |

Efficiency Factors

Several factors influence the overall efficiency of the energy conversion process. Design elements, environmental conditions, and maintenance practices all play a significant role. Optimizing these aspects can lead to enhanced performance and greater energy output, making it essential for operators to consider them in their systems.

Historical Development of Windmills

The evolution of devices harnessing the power of the wind is a fascinating journey through time, reflecting advancements in technology and changes in societal needs. These structures have played a vital role in various cultures, adapting to different environments and uses.

Early Innovations

Initially, early civilizations utilized simple mechanisms to convert wind energy. Key milestones include:

- Persian use of vertical-axis systems around 500-900 AD.

- Medieval Europe adopting horizontal-axis designs in the 12th century.

- The incorporation of sails and gear systems to improve efficiency.

Modern Advancements

In recent centuries, the approach to these structures has transformed significantly:

- The Industrial Revolution introduced larger and more efficient models.

- Technological advancements led to the integration of modern materials.

- Current trends focus on renewable energy, highlighting sustainability.

Modern Innovations in Windmill Design

Recent advancements in renewable energy technology have led to remarkable improvements in the efficiency and functionality of traditional energy-generating structures. These innovations focus on optimizing performance while reducing environmental impact, enhancing both design and usability.

Enhanced Materials and Structures

New composite materials provide increased strength and durability, allowing for larger and more efficient blades. Lightweight yet robust components enable systems to harness energy even in low-wind conditions, ultimately maximizing output.

Smart Technology Integration

The incorporation of smart sensors and IoT technology facilitates real-time monitoring and predictive maintenance. This data-driven approach ensures optimal performance and longevity, transforming how these systems operate and adapt to changing environmental conditions.