In the world of heavy machinery, the functionality and efficiency of equipment depend heavily on the intricate design and arrangement of its various elements. This section delves into the specifics of a well-known excavator model, focusing on the essential components that ensure its optimal performance. By gaining insight into these elements, operators and enthusiasts can enhance their understanding of maintenance and repairs.

Every machine consists of numerous parts, each playing a crucial role in its operation. From hydraulic systems to structural frameworks, recognizing how these elements interconnect provides valuable knowledge for both novice users and seasoned professionals. Furthermore, being aware of potential wear and tear can lead to more effective preventative measures, ultimately prolonging the lifespan of the equipment.

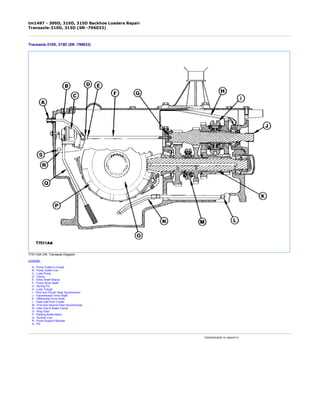

For those seeking clarity, visual representations serve as indispensable tools. A comprehensive overview of the assembly layout not only aids in identification but also streamlines the process of troubleshooting and replacing specific components. As we explore this particular model, we will highlight the most critical areas of focus, enabling users to navigate maintenance with confidence and precision.

Understanding the John Deere 310B

This section explores the intricacies of a renowned piece of machinery, focusing on its essential components and functionality. The equipment is celebrated for its versatility and reliability in various applications, making it a favorite among operators.

Key Features: The machine is equipped with robust hydraulics, ensuring efficient operation and smooth performance. Its design prioritizes ease of use, allowing for seamless navigation in diverse work environments.

Maintenance Considerations: Regular upkeep is crucial to prolonging its lifespan. Operators should familiarize themselves with the primary elements to enhance productivity and minimize downtime.

Key Features of the 310B Backhoe

The machine in question is renowned for its robust design and versatility, making it an essential tool for various construction and excavation tasks. With a combination of power, precision, and user-friendly operation, it stands out in the field of earthmoving equipment.

Powerful Engine: Equipped with a high-performance engine, this model delivers exceptional horsepower, enabling it to handle heavy loads and challenging terrains with ease. The engine’s efficiency not only boosts productivity but also ensures reliability over extended periods of use.

Hydraulic System: A state-of-the-art hydraulic system enhances the functionality of the equipment, allowing for smooth and precise movements. This system supports a range of attachments, making it adaptable for various jobs, from digging to lifting.

Ergonomic Operator Controls: Designed with the operator’s comfort in mind, the controls are intuitively placed for easy access. This thoughtful layout minimizes operator fatigue and increases overall efficiency during operation.

Durable Construction: Built with high-quality materials, the structure is designed to withstand tough conditions and heavy use. This durability ensures longevity, reducing the need for frequent repairs or replacements.

Compact Design: Its compact size allows for maneuverability in tight spaces, making it ideal for urban projects where space is limited. This feature does not compromise its capability, as it retains powerful performance despite its dimensions.

Maintenance Accessibility: Routine maintenance is simplified, with easy access to critical components. This thoughtful design feature helps operators keep the machine in optimal condition, reducing downtime and extending its lifespan.

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding the assembly and maintenance of machinery. They serve as essential tools for technicians and enthusiasts alike, allowing for efficient repairs and replacements.

Enhanced Understanding

These illustrations provide clarity by detailing the arrangement and function of various elements. This visual aid helps users:

- Quickly identify individual components

- Understand how parts interact

- Facilitate problem-solving during maintenance

Efficiency in Repairs

Using these visual references leads to more streamlined repair processes. Benefits include:

- Reduced time spent searching for information

- Minimized errors during assembly

- Increased likelihood of successful repairs on the first attempt

Common Components of the 310B

This section explores essential elements found in the model, highlighting their significance and functionality. Understanding these components can enhance maintenance and operational efficiency.

Key Elements

Each machine comprises vital parts that contribute to its overall performance. Recognizing these elements is crucial for effective troubleshooting and repair.

| Component | Description |

|---|---|

| Engine | Powers the entire system, providing the necessary force for various operations. |

| Hydraulic System | Enables movement and operation of attachments, crucial for digging and lifting tasks. |

| Transmission | Facilitates power transfer from the engine to the wheels, allowing for movement. |

| Chassis | Serves as the framework, supporting all components and providing stability. |

Maintenance Tips

Regular inspection and upkeep of these fundamental parts can prevent costly repairs and ensure longevity. Prioritizing care for each component is essential for optimal performance.

Finding Replacement Parts Easily

Locating the necessary components for heavy machinery can often be a daunting task. However, with the right approach and resources, you can streamline the process significantly. Understanding where to search and what to look for can save both time and effort, allowing you to get your equipment back in optimal working condition.

Online Resources are among the best places to begin your search. Various websites specialize in equipment components, offering detailed listings and often providing visual aids to help identify the right items. Make sure to check trusted platforms and forums where enthusiasts share their experiences and recommendations.

Local Suppliers can also be invaluable. Establishing a relationship with a nearby distributor ensures access to genuine items and expert advice. They may also have the capability to order specific components that may not be readily available in stock.

Manuals and Catalogs serve as excellent references. These documents typically include part numbers and specifications, making it easier to find the exact component needed. Familiarizing yourself with these resources can help you make informed choices quickly.

Lastly, community groups and online forums dedicated to equipment maintenance can be great sources of information. Engaging with fellow users can lead to recommendations for reliable suppliers and even insights on alternative components that might serve your needs just as well.

Tips for Maintaining Your Backhoe

Regular upkeep is essential for ensuring the longevity and efficiency of your digging machine. By following a consistent maintenance routine, you can prevent costly repairs and enhance performance, allowing for seamless operations on any job site.

Routine Checks

- Inspect hydraulic fluid levels regularly.

- Check engine oil and coolant for optimal performance.

- Examine filters and replace them as necessary.

Cleaning and Lubrication

- Keep the machine free from dirt and debris to prevent wear.

- Apply lubricant to moving parts to reduce friction.

- Wash the exterior periodically to maintain visibility and functionality.

Using Diagrams for Repairs

Utilizing visual representations during maintenance and repair tasks can significantly enhance understanding and efficiency. These illustrations serve as valuable guides, providing clarity on the assembly and functionality of various components. By referring to detailed visuals, individuals can more easily identify parts and their interconnections, leading to more effective troubleshooting and repairs.

Benefits of Visual Guides

Visual aids are essential for both novice and experienced technicians. They simplify complex procedures, allowing users to grasp concepts quickly. Moreover, they can help prevent errors by clearly outlining the necessary steps and components involved in the repair process.

Key Elements to Consider

When working with visual guides, several factors should be kept in mind to maximize their effectiveness:

| Element | Description |

|---|---|

| Clarity | Ensure the illustrations are easy to read and understand. |

| Detail | Look for diagrams that provide comprehensive details about each component. |

| Labels | Check that all parts are clearly labeled for quick identification. |

| Instructions | Follow any accompanying text to understand the sequence of operations. |

Where to Buy Quality Parts

Finding reliable components for your machinery can significantly enhance performance and longevity. It is essential to source these items from reputable vendors who prioritize quality and customer satisfaction. Here are some effective strategies to locate high-quality replacements for your equipment.

Authorized Dealers

One of the most trustworthy options is to visit authorized dealers. These establishments offer genuine components specifically designed for your model, ensuring compatibility and reliability. Furthermore, they often provide valuable expertise and support, helping you make informed decisions.

Online Marketplaces

In the digital age, online marketplaces have become a popular avenue for purchasing machinery components. Websites that specialize in equipment supplies offer a vast selection and competitive pricing. Look for sellers with positive reviews and robust return policies to guarantee a satisfying purchase experience. Always verify the authenticity of the items to avoid subpar alternatives.

By exploring these avenues, you can secure the necessary components that meet the highest standards of quality and performance.