The intricacies of fuel delivery systems play a crucial role in the optimal performance of various engines. This segment aims to elucidate the essential elements that contribute to the seamless operation of these mechanisms. By delving into the various components, one can appreciate the engineering that ensures efficient fuel management.

Each element within these systems serves a specific purpose, facilitating the precise mixture of air and fuel required for combustion. Recognizing how these individual pieces interact enhances our understanding of the overall functionality and reliability of the system.

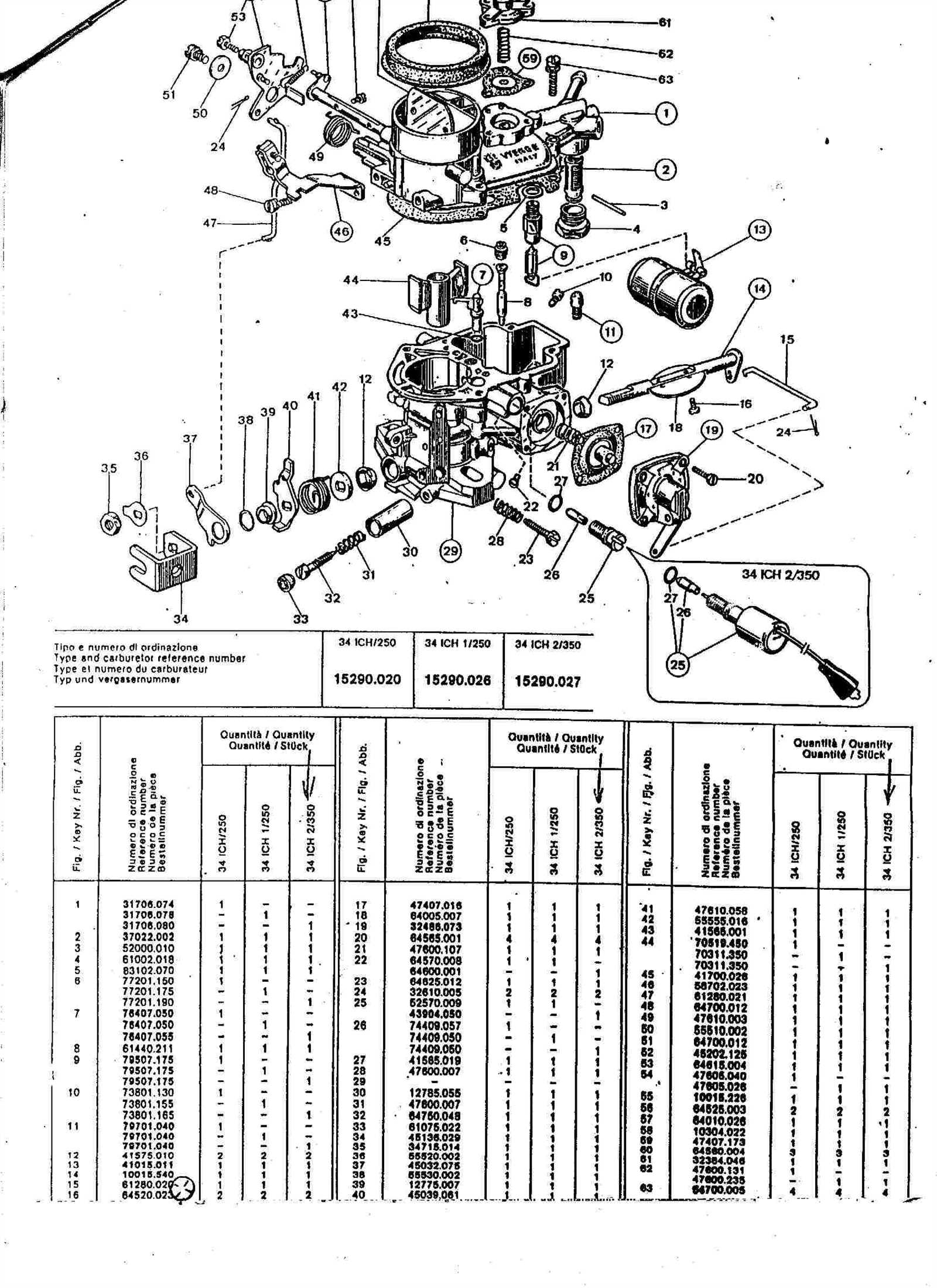

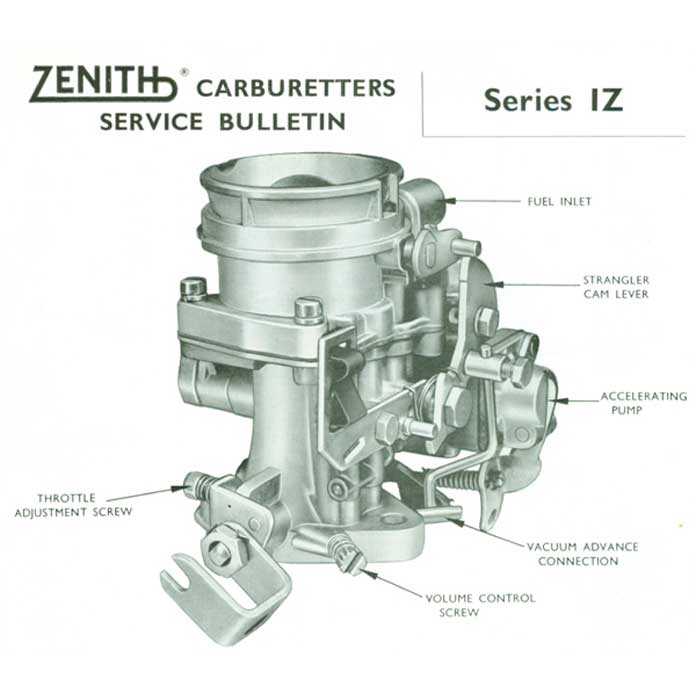

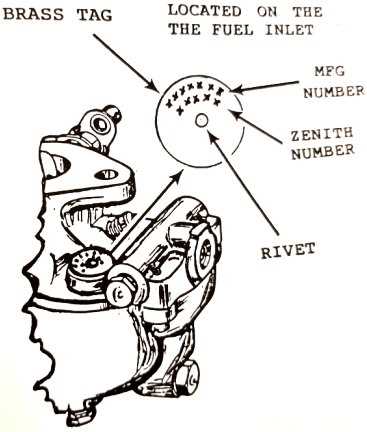

Moreover, visual representations of these components can significantly aid in both troubleshooting and maintenance. A well-structured illustration provides clarity, allowing enthusiasts and professionals alike to identify and address any issues with ease. Thus, familiarizing oneself with the layout and relationships of these vital elements is essential for anyone looking to optimize engine performance.

Understanding Zenith Carburetor Functionality

The operation of fuel delivery systems is crucial for the efficiency and performance of internal combustion engines. These mechanisms are designed to mix air and fuel in precise ratios, ensuring optimal combustion. A comprehensive understanding of their components and how they interact is essential for troubleshooting and maintenance.

Key Components and Their Roles

Each element within the system plays a specific role in the overall functionality:

- Air Intake: This component allows ambient air to enter the system, crucial for the mixing process.

- Fuel Chamber: It holds the fuel, regulating its flow into the mixing zone.

- Venturi: This section narrows the airflow, creating a vacuum that draws fuel into the airstream.

- Throttle Valve: Controls the volume of the air-fuel mixture entering the engine, directly affecting power output.

How the Mixing Process Works

The process of blending air with fuel involves several steps:

- The ambient air is drawn in through the air intake.

- This air passes through the venturi, where its velocity increases and pressure decreases.

- The drop in pressure draws fuel from the chamber into the airstream.

- The mixture is then directed to the engine for combustion.

Understanding these fundamental aspects is key to optimizing performance and ensuring reliable operation of the system. Regular maintenance and knowledge of the various components can lead to enhanced efficiency and longevity.

Common Parts of Zenith Carburetors

This section explores the essential components found in a specific type of fuel-air mixing device, highlighting their functions and interrelationships. Understanding these elements is crucial for effective maintenance and performance optimization.

| Component | Description |

|---|---|

| Float Chamber | Holds fuel and maintains the proper level for consistent operation. |

| Jet | Controls the flow of fuel into the mixing area, influencing the air-fuel ratio. |

| Throttle Valve | Regulates airflow, affecting engine power and responsiveness. |

| Mixture Screw | Allows adjustment of the fuel mixture for optimal combustion. |

| Choke Valve | Reduces airflow during startup, aiding in engine ignition. |

| Venturi | Creates a vacuum that draws fuel into the airstream, enhancing mixing. |

| Gaskets | Provide seals between components to prevent leaks and ensure proper function. |

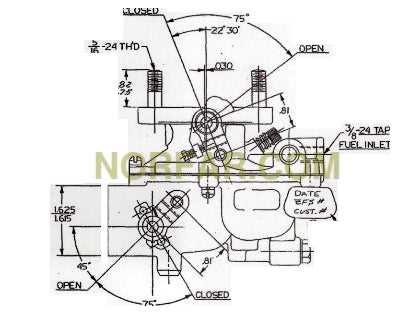

How to Read Carburetor Diagrams

Understanding technical illustrations can be challenging, yet it is essential for effective maintenance and repair. These visuals provide a wealth of information, allowing one to grasp the structure and function of various components. Familiarity with symbols and layout is crucial for interpreting these images accurately, ensuring successful troubleshooting and assembly.

Key Elements to Identify

When examining a technical illustration, focus on the following components:

| Element | Description |

|---|---|

| Labels | Names or codes indicating specific components, essential for identification. |

| Lines and Arrows | Show connections and flow paths, highlighting how parts interact. |

| Symbols | Represent specific functions or types of components, often standardized. |

Step-by-Step Approach

To effectively interpret the illustration, follow these steps:

- Start with the title or legend to understand the overall context.

- Identify all labeled elements to familiarize yourself with the layout.

- Trace lines and arrows to see how different components are interconnected.

- Refer to a glossary if symbols are unclear to gain clarity.

By mastering these techniques, one can significantly enhance their ability to work with technical visuals, leading to more efficient repairs and better understanding of machinery.

Identifying Key Components and Their Roles

Understanding the essential elements of a fuel delivery system is crucial for effective maintenance and performance. Each component plays a specific role in ensuring optimal operation, contributing to the overall functionality and efficiency of the engine. Recognizing these individual parts allows for better troubleshooting and enhancements.

The main structure is responsible for regulating airflow, which directly influences the mixture of fuel and air that enters the combustion chamber. This balance is vital for efficient combustion and power output. Another critical element involves the mechanism that controls fuel flow, ensuring that the correct amount reaches the engine under varying conditions.

Additionally, the adjustment tools allow for fine-tuning the system to meet specific performance needs, catering to different driving conditions or user preferences. A float system plays a significant role in maintaining the correct fuel level, preventing overflow and ensuring consistent supply. Understanding these components enhances both performance and reliability, making regular checks and adjustments necessary for longevity.

Troubleshooting Issues with Zenith Models

When working with specific fuel delivery systems, users often encounter various challenges that can impact performance and efficiency. Identifying and resolving these issues is crucial for optimal operation and longevity of the equipment. This guide aims to assist in diagnosing common problems and offers practical solutions.

Common Symptoms and Their Causes

Many users report issues such as inconsistent power output, excessive fuel consumption, or difficulty starting the engine. These symptoms can often be traced back to a few key areas:

- Clogged Pathways: Blockages in the fuel flow can lead to insufficient delivery.

- Faulty Adjustments: Incorrect settings may cause a rich or lean mixture, affecting combustion.

- Worn Components: Age and wear can result in ineffective sealing or movement.

Step-by-Step Diagnostic Process

To effectively address these challenges, follow this structured approach:

- Visual Inspection: Start by examining all visible components for signs of wear, leaks, or blockages.

- Functionality Check: Test the operation under varying conditions to identify when issues occur.

- Adjustment Review: Ensure that all settings are aligned with manufacturer specifications.

By systematically evaluating these areas, users can significantly improve functionality and resolve prevalent issues efficiently.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the durability and performance of any mechanical system. Regular attention to details can significantly enhance efficiency and extend the lifespan of components, ultimately saving time and resources in the long run. Here are some practical suggestions to keep your equipment running smoothly.

Regular Inspections

Conducting frequent assessments is crucial for identifying wear and tear before it leads to major issues. Check for any signs of leaks, corrosion, or buildup, and address these concerns promptly. Establishing a routine maintenance schedule can help ensure that no component is overlooked.

Cleanliness is Key

Keeping the assembly free from dirt and debris is vital for optimal function. Use appropriate cleaning solutions and tools to remove contaminants without causing damage. Ensuring a clean environment reduces the risk of clogs and improves overall efficiency, contributing to the longevity of the system.

Upgrading Parts for Improved Performance

Enhancing the functionality of your engine often involves focusing on specific components that directly affect efficiency and responsiveness. By selecting higher-quality materials or advanced technologies, enthusiasts can achieve noticeable gains in performance and reliability. This section explores effective strategies for upgrading elements to maximize your system’s potential.

Choosing Superior Components

Investing in top-tier alternatives can significantly improve your machine’s operation. Components crafted from durable materials not only last longer but also provide better fuel atomization, leading to a more efficient combustion process. Performance-oriented upgrades can help achieve smoother acceleration and improved throttle response, making your vehicle more enjoyable to drive.

Tuning for Optimal Performance

In addition to component upgrades, fine-tuning the system is essential for achieving peak efficiency. Adjustments to airflow and fuel delivery can optimize the overall performance. Regular maintenance of these elements ensures they work in harmony, ultimately contributing to a powerful and reliable engine.

Where to Find Replacement Components

Locating suitable replacement elements for your engine can be a straightforward process if you know where to look. Various resources are available to help enthusiasts and mechanics obtain the necessary components to keep their machinery running smoothly. From specialized retailers to online marketplaces, a variety of options exist to ensure you find exactly what you need.

Start by checking with local auto parts stores, which often carry a selection of essential items or can order them for you. Additionally, many specialized shops focus on vintage or performance vehicles, providing expert advice and high-quality replacements. Online platforms such as auction sites or dedicated automotive websites can also offer a vast array of components, sometimes at competitive prices.

Another great resource is forums and community groups where enthusiasts share insights and may even offer spare components for sale or trade. Networking within these communities can lead to valuable recommendations for trustworthy suppliers and hard-to-find items. Lastly, don’t overlook manufacturer websites, as they often provide catalogs and ordering options for original equipment replacements.