In the realm of internal combustion engines, efficient fuel delivery is crucial for optimal performance. A comprehensive exploration of the intricate elements that facilitate this process unveils the engineering marvels behind maintaining a precise air-fuel mixture. By dissecting the structure and function of these vital mechanisms, enthusiasts and mechanics alike can gain valuable insights into enhancing engine efficiency.

Each element within this assembly plays a significant role in ensuring seamless operation. The interplay between air and fuel is finely tuned, allowing for the smooth functioning of engines across various applications. Identifying the specific components and their respective functionalities aids in diagnosing issues and performing necessary maintenance effectively.

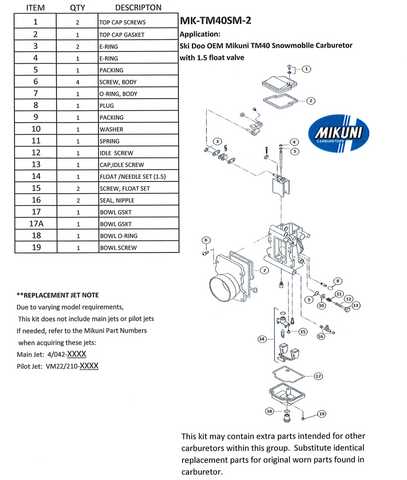

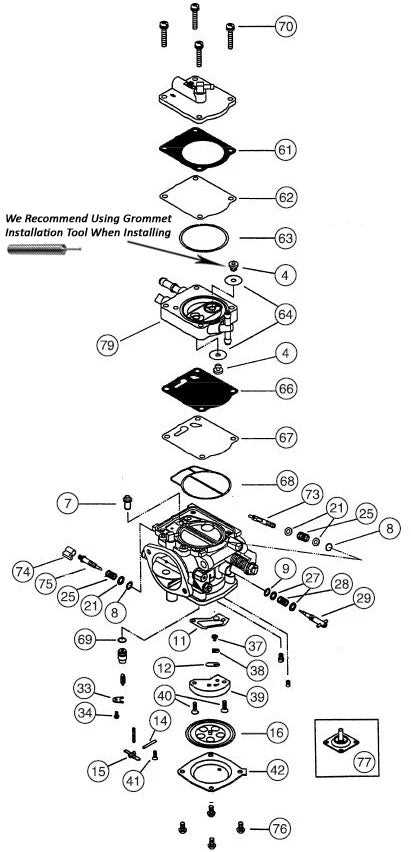

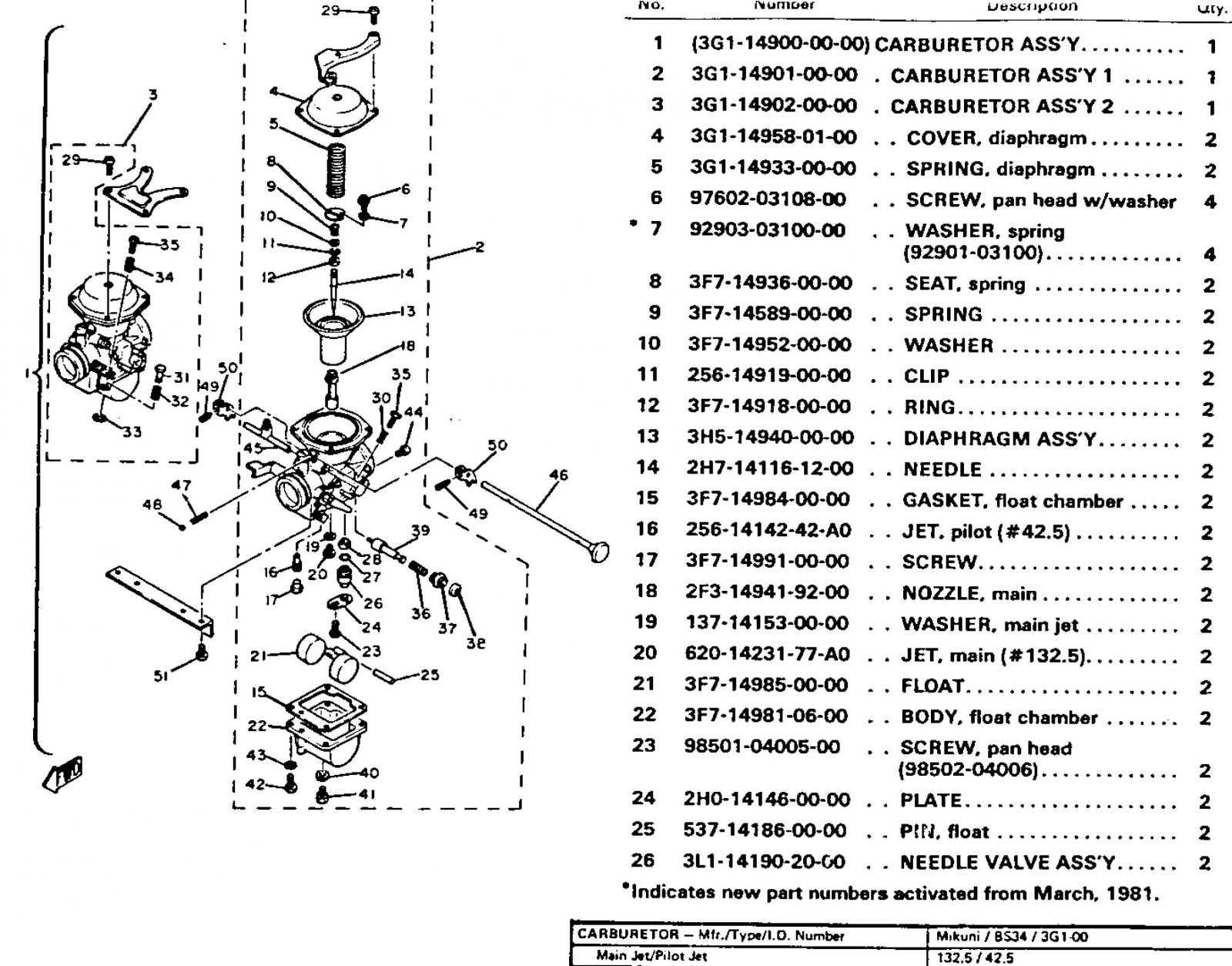

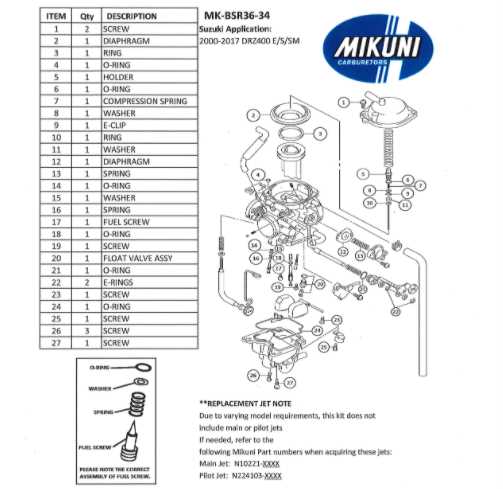

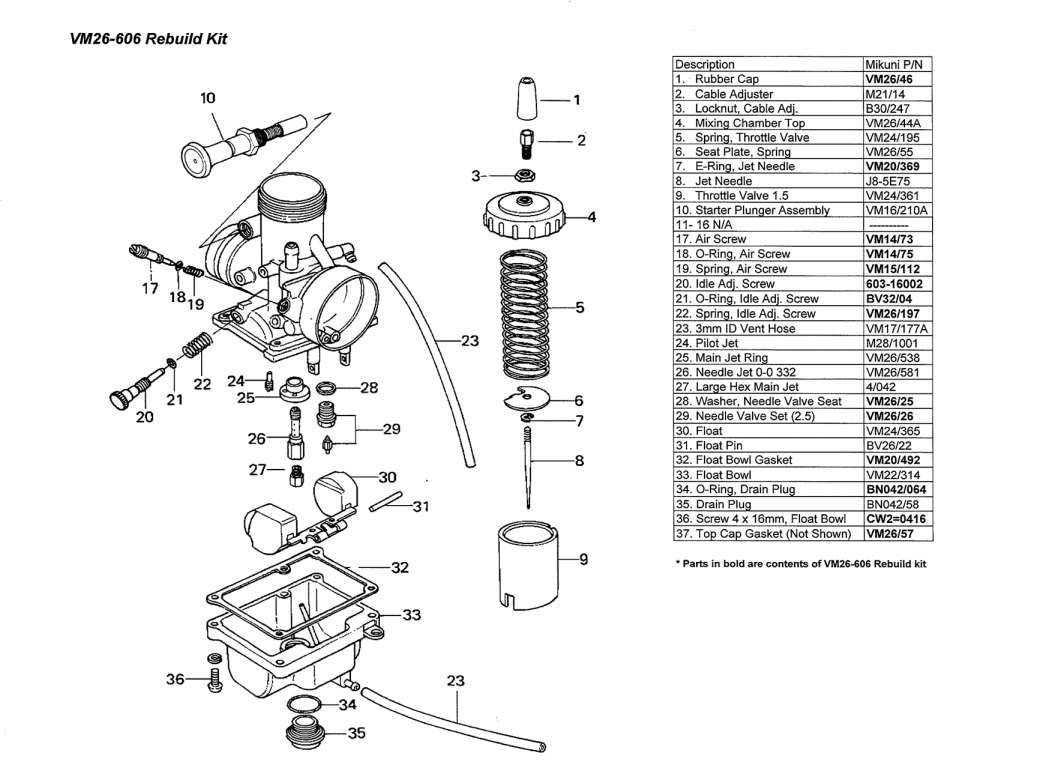

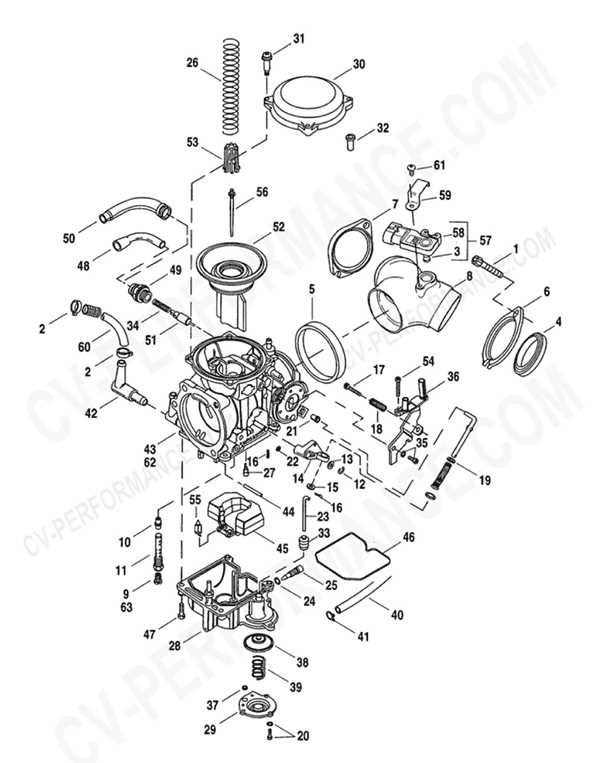

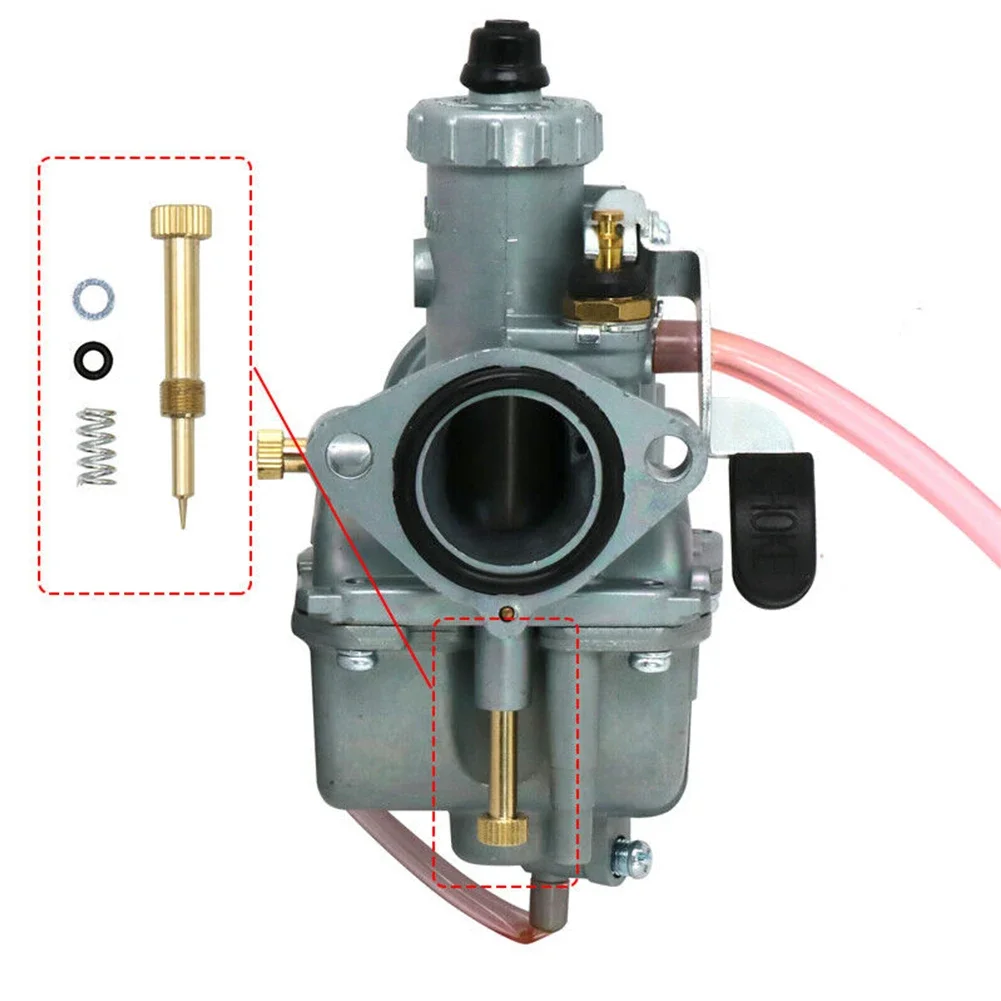

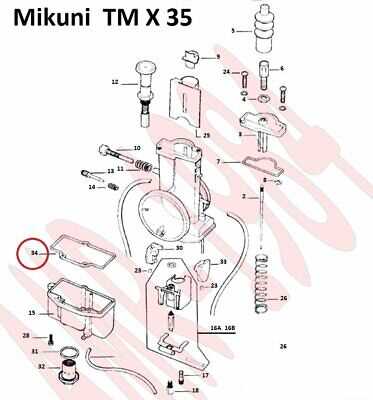

For those eager to delve deeper, visual representations of these elements provide a clearer understanding of their layout and interrelationships. Such illustrations not only clarify the assembly but also serve as essential references for both novice and seasoned technicians in their pursuit of excellence in engine performance.

Mikuni Carburetor Overview

This section provides an essential understanding of a critical component in the fuel delivery system, highlighting its functionality, design, and significance in optimizing engine performance. These mechanisms are designed to mix air and fuel efficiently, ensuring smooth operation across various conditions.

Design and Functionality

Engineered with precision, these devices utilize a series of jets and valves to regulate the flow of fuel. Their design allows for adjustments to be made easily, enabling users to tailor performance to specific requirements, whether for racing or everyday use.

Importance in Performance

The role of this mechanism cannot be overstated, as it directly influences the power output and fuel efficiency of an engine. Understanding its workings can lead to enhanced performance and longevity of the vehicle, making it an ultimate focus for enthusiasts and mechanics alike.

Key Components Explained

This section delves into the essential elements that contribute to the functionality of fuel delivery systems. Understanding these components is crucial for effective maintenance and optimization of performance.

- Float Chamber: This reservoir maintains the correct fuel level for consistent operation.

- Jetting System: Regulates the fuel-air mixture by controlling the flow of fuel into the airstream.

- Throttle Valve: Adjusts the amount of air entering the engine, influencing power and speed.

- Needle and Seat: Works in conjunction with the float to manage fuel flow into the chamber.

- Choke Mechanism: Enriches the mixture for easier starting in cold conditions.

Each of these elements plays a vital role in ensuring optimal engine performance and efficiency. A thorough understanding of their functions aids in troubleshooting and improving overall operation.

How to Read the Diagram

Understanding a visual representation of components can greatly enhance your ability to identify and work with various elements. This section will guide you through the essential aspects of interpreting such illustrations effectively, allowing you to navigate and comprehend the relationships between different elements more confidently.

Identifying Key Elements

The first step in deciphering the visual representation is to recognize the main components depicted. Each element typically includes a label or identifier that indicates its function or placement. Familiarizing yourself with these labels is crucial, as they serve as a reference for understanding the layout and operation.

Interpreting Relationships

Once you have identified the individual components, the next step is to analyze how they interact with one another. Look for connecting lines or arrows that indicate flow or linkage. These connections often reveal how components work together, contributing to the overall functionality of the system.

| Symbol | Description |

|---|---|

| A | Main assembly housing |

| B | Fuel inlet |

| C | Air mixture adjustment |

| D | Throttle control |

| E | Choke mechanism |

Common Issues and Solutions

Understanding the common challenges associated with fuel delivery systems can significantly enhance performance and reliability. Various factors can lead to inefficiencies, impacting the overall operation of engines. Identifying these issues promptly allows for effective troubleshooting and maintenance.

1. Poor Fuel Flow: One frequent problem is inadequate fuel flow, which may cause stalling or rough idling. This issue can stem from a clogged filter or fuel lines. Regularly inspecting and replacing these components ensures smooth operation.

2. Difficulty Starting: If the engine struggles to start, it could indicate issues with the air-fuel mixture. Adjusting the mixture to the correct ratio often resolves this. Additionally, ensuring that the choke functions properly can prevent starting difficulties.

3. Uneven Idling: An unstable idle can be caused by various factors, including vacuum leaks or improper adjustments. Checking for air leaks in gaskets and hoses is crucial. Making necessary adjustments can stabilize the idle and improve overall performance.

4. Excessive Fuel Consumption: High fuel consumption often indicates that the mixture is too rich. This can be addressed by adjusting the needle and seat or inspecting for any leaks. Regular tuning can help maintain optimal efficiency.

5. Performance Loss: A noticeable decrease in power may occur due to blockages or misadjustments. Cleaning the internal components and ensuring that all settings are within manufacturer specifications can restore performance levels.

By being aware of these common issues and their respective solutions, individuals can ensure that their fuel delivery systems remain in optimal condition, contributing to better performance and longevity.

Maintenance Tips for Longevity

Regular upkeep is essential to ensure the extended lifespan of your engine’s fuel management system. By adhering to a few simple practices, you can enhance performance and prevent premature wear.

Routine Cleaning

Keep components clean to avoid build-up that can impede functionality. Use a suitable cleaner and soft brushes to reach tight spaces, ensuring optimal operation.

Periodic Inspections

Frequent checks for wear and tear can help identify potential issues before they escalate. Look for cracks, leaks, or corrosion, and replace any damaged elements promptly.

Choosing the Right Parts

Selecting the appropriate components for your engine’s fuel delivery system is crucial for optimal performance. Understanding the intricacies of these elements will enable you to enhance efficiency, improve throttle response, and achieve a smooth operation. In this section, we will delve into essential considerations to help you make informed decisions.

Key Considerations

- Compatibility: Ensure that the components are designed to work harmoniously with your specific engine type.

- Quality: Opt for high-quality materials to ensure durability and reliability over time.

- Performance Needs: Assess your performance goals to choose components that align with your desired outcomes.

- Expert Recommendations: Seek advice from professionals or experienced users to identify trusted brands and products.

Tips for Selection

- Research thoroughly to understand the different options available in the market.

- Compare specifications and features of various alternatives.

- Read customer reviews and feedback to gauge the effectiveness of components.

- Purchase from reputable suppliers to ensure authenticity and support.

By taking these factors into account, you can ensure that the chosen elements will contribute positively to the overall functioning of your machinery.

Installation Process Made Easy

Setting up your fuel delivery system can seem daunting, but with a clear guide, the process can be straightforward and efficient. Understanding the essential components and their functions will help streamline your efforts, making it an enjoyable experience.

Preparation Steps

Before you begin, ensure you have all the necessary tools at hand. Gather components, cleaning materials, and a reliable manual to refer to during the installation. A well-organized workspace enhances focus and reduces the likelihood of errors.

Step-by-Step Guide

Start by carefully removing the existing assembly, taking note of the arrangement of each element. Install the new components following the instructions, ensuring a snug fit. Double-check connections and adjust settings as needed for optimal performance. With patience and attention to detail, your setup will be ready for action in no time!

Performance Enhancements Available

Optimizing engine efficiency and responsiveness is crucial for enthusiasts seeking to elevate their vehicle’s performance. Various modifications can significantly improve air-fuel delivery and combustion efficiency, ultimately leading to enhanced power output and throttle response.

Upgraded Components: Replacing standard elements with high-performance alternatives can result in better airflow and fuel atomization. Look for options such as precision jets and optimized floats.

Tuning Options: Fine-tuning the mixture and idle settings allows for a more tailored performance, catering to specific driving conditions and preferences. This ensures the engine runs at its best across different scenarios.

Additional Modifications: Incorporating features like velocity stacks or high-flow filters can further augment the intake process, resulting in more efficient power delivery. These enhancements collectively contribute to a more dynamic driving experience.

Ultimately, these performance enhancements not only boost power but also improve overall reliability and longevity of the engine.

FAQs About Mikuni Carburetors

This section aims to address common inquiries regarding fuel management systems and their components. Understanding these elements can enhance performance and ensure proper maintenance.

What are the signs that I need to replace my fuel delivery system? Common indicators include poor engine performance, irregular idling, and excessive fuel consumption. If you notice these issues, it might be time to investigate further.

How often should I clean my fuel management system? Regular maintenance is key. It’s advisable to clean it every few months, especially if you ride frequently or in harsh conditions.

Can I tune my system myself? Yes, but it requires some knowledge and experience. Make sure to follow reliable guides to achieve the best results.

What tools do I need for maintenance? Essential tools include screwdrivers, wrenches, and cleaning solutions. Having the right equipment makes the process much smoother.

Are there any specific adjustments for different weather conditions? Yes, atmospheric changes can affect performance. Adjustments may be necessary to ensure optimal functioning in varying temperatures.