When exploring the intricacies of engine performance, one cannot overlook the importance of the fuel delivery mechanism. This vital component ensures optimal air-fuel mixture, directly impacting efficiency and power output. A comprehensive understanding of its structure can enhance maintenance and repair efforts.

For enthusiasts and mechanics alike, dissecting the elements of these systems reveals the underlying mechanics that contribute to smooth operation. Each section plays a crucial role, and familiarity with these pieces can lead to more effective troubleshooting and upgrades.

In this exploration, we will delve into the various components that make up the fuel delivery assembly, focusing on their functions and interconnections. By grasping this information, users can achieve the ultimate performance from their engines while minimizing potential issues.

Understanding Honda GX390 Carburetor Function

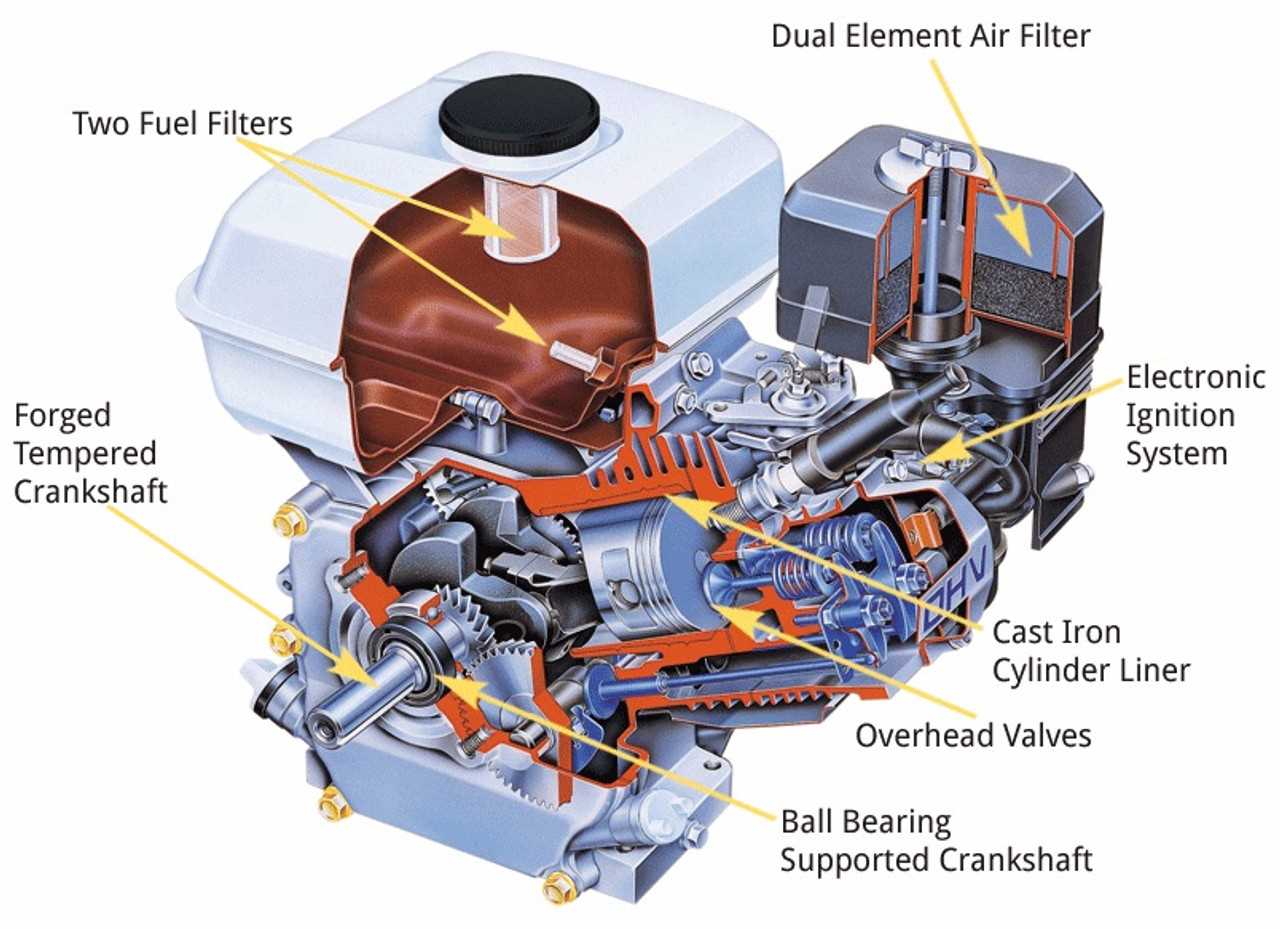

The component in question plays a crucial role in the operation of small engines, blending fuel and air to facilitate combustion. Its proper functioning is essential for optimal performance and efficiency, as it directly influences the engine’s power output and fuel consumption.

Key Functions of the Component

- Air-Fuel Mixture: The device ensures the correct ratio of air to fuel, which is vital for effective combustion.

- Throttle Control: It regulates the flow of the air-fuel mixture to match the engine’s demands during different operational conditions.

- Starting Assistance: It provides an enriched mixture for easier starting, especially in cold conditions.

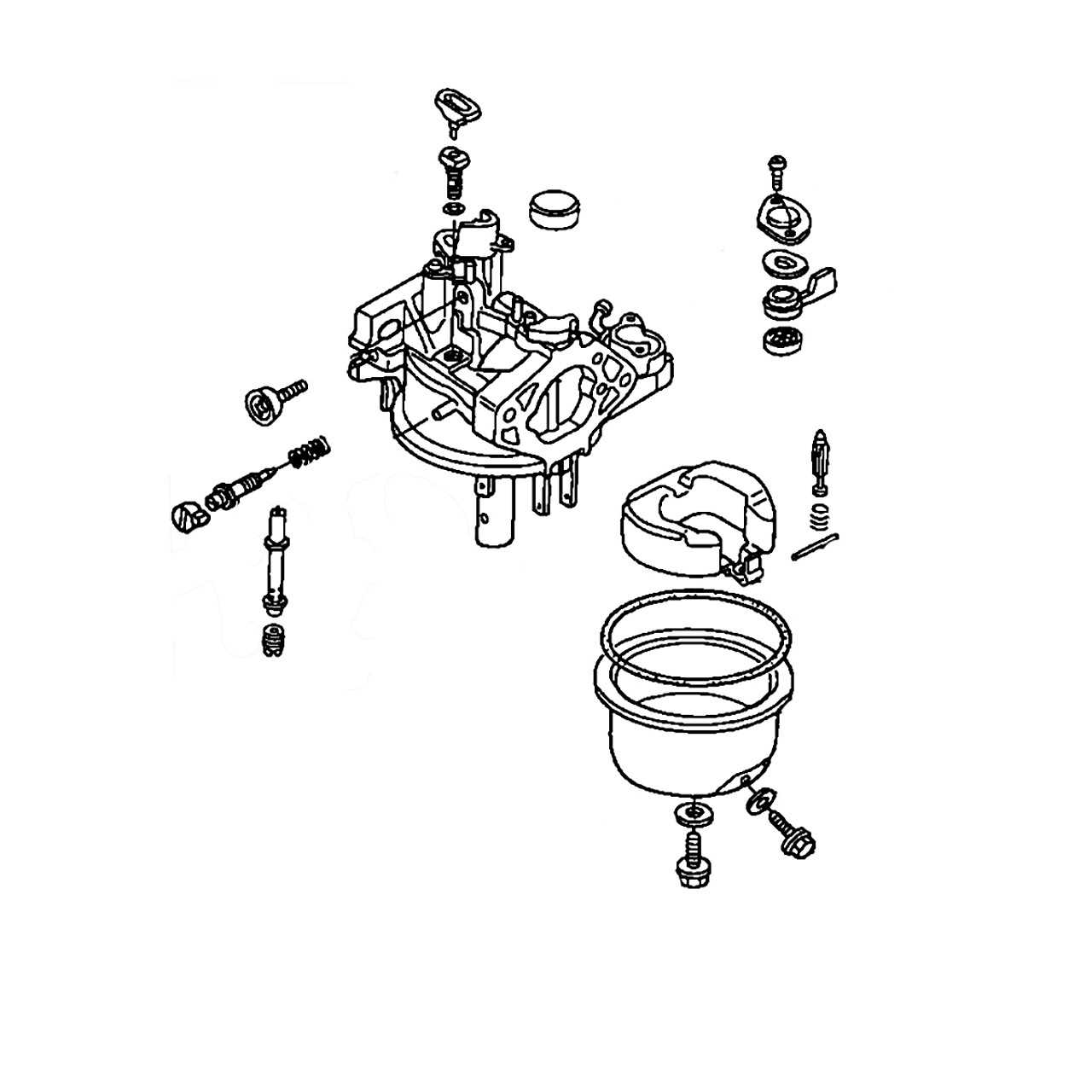

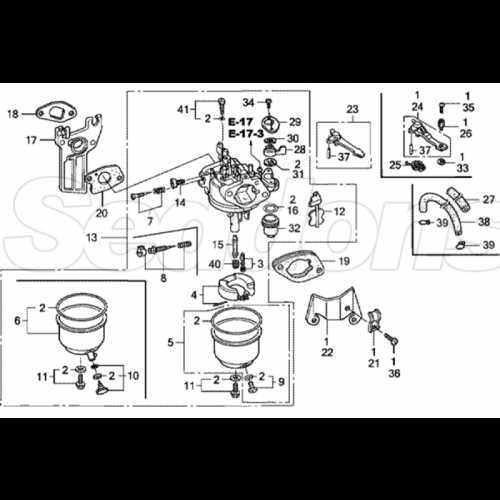

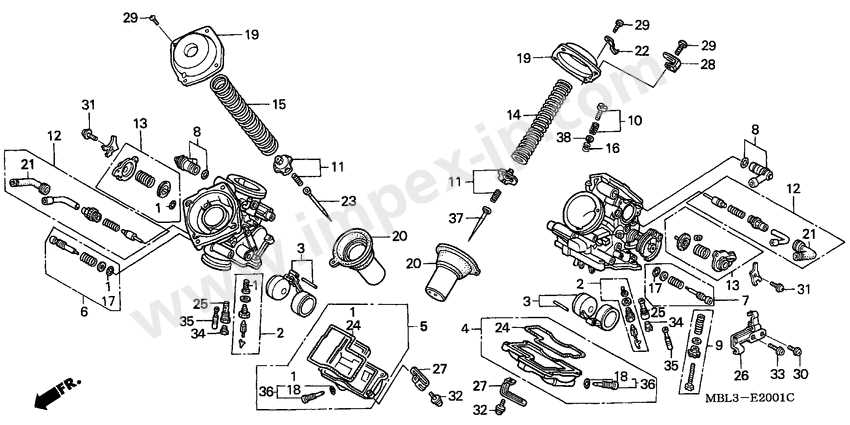

Components Involved

- Jet: Determines the amount of fuel delivered based on engine speed and load.

- Float Chamber: Maintains a steady supply of fuel by regulating its level.

- Venturi: Creates a vacuum effect that draws fuel into the airstream.

Understanding how these functions and components work together can help diagnose issues and improve the overall performance of the engine.

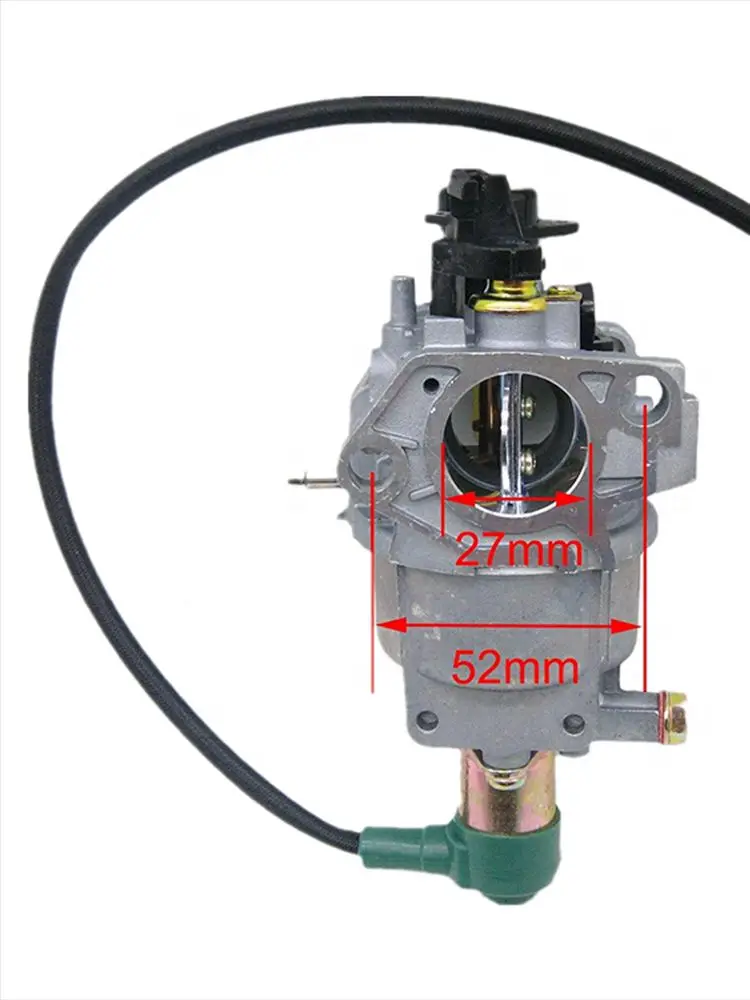

Essential Components of the Carburetor

The efficiency of any fuel delivery system hinges on a few key elements that work in harmony to ensure optimal performance. Understanding these crucial components can help in diagnosing issues and maintaining functionality.

- Float Chamber: This section regulates the fuel level, ensuring a consistent supply to the mixing area.

- Jet System: The jets are responsible for controlling the fuel flow, allowing precise mixtures with air for combustion.

- Venturi: A narrow passage that creates a vacuum effect, drawing fuel into the airstream and mixing it effectively.

- Throttle Valve: This component controls the amount of air-fuel mixture entering the engine, influencing speed and power.

- Choke: A mechanism used to restrict airflow during startup, aiding in easier ignition by enriching the mixture.

- Needle and Seat: These elements work together to regulate fuel flow from the chamber, preventing overflow and maintaining balance.

Each of these components plays a vital role in the overall functionality, contributing to the performance and efficiency of the engine. Regular inspection and maintenance of these elements can lead to prolonged service life and enhanced operation.

Common Issues with GX390 Carburetors

When dealing with fuel delivery systems, various challenges can arise that affect engine performance. Understanding these issues can help in diagnosing and resolving common problems, ensuring optimal functionality.

Fuel Flow Disruptions

One prevalent issue is the interruption of fuel flow, which can stem from clogged filters or malfunctioning valves. This can lead to insufficient fuel reaching the combustion chamber, causing poor engine operation.

Air-Fuel Mixture Imbalance

An improper balance between air and fuel can result in hard starting, stalling, or rough idling. This often occurs due to debris in the jets or gaskets that have deteriorated over time.

| Issue | Symptoms | Possible Causes |

|---|---|---|

| Fuel Flow Disruption | Engine stalling, poor acceleration | Clogged filters, faulty valves |

| Air-Fuel Mixture Imbalance | Hard starting, rough idling | Dirty jets, worn gaskets |

Step-by-Step Repair Process

Repairing engine fuel delivery systems requires careful attention to detail and a systematic approach. By following these steps, you can ensure a thorough inspection and successful restoration of functionality. Each phase plays a crucial role in achieving optimal performance.

Preparation

- Gather all necessary tools: screwdrivers, wrenches, and cleaning supplies.

- Ensure the work area is clean and well-lit.

- Review the service manual for specific guidelines related to your model.

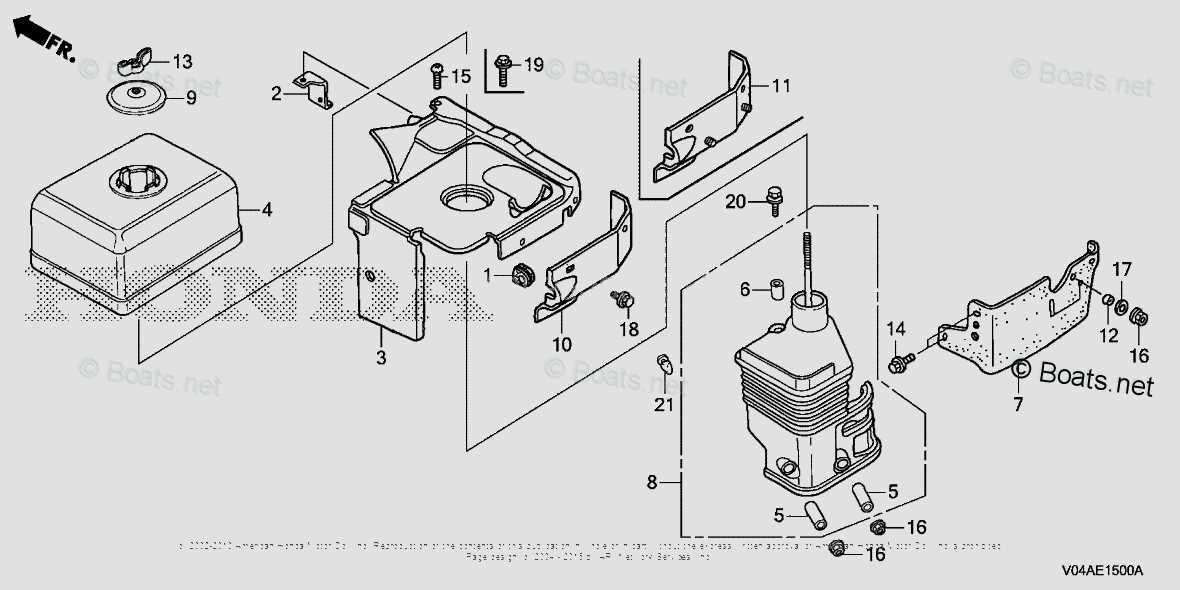

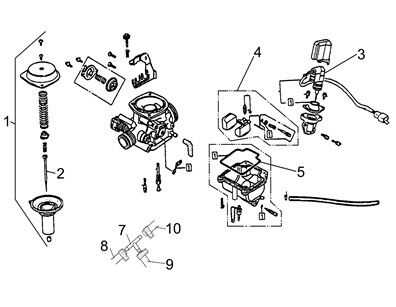

Disassembly

- Turn off the engine and disconnect the spark plug for safety.

- Carefully remove the outer casing and any connected components.

- Take note of the arrangement of parts to facilitate reassembly.

Cleaning and Inspection

- Clean all components with appropriate solvents.

- Inspect for wear and damage, paying special attention to seals and gaskets.

- Replace any worn or damaged items as necessary.

Reassembly

- Reinstall all components in the reverse order of disassembly.

- Ensure that all screws and fasteners are securely tightened.

- Reconnect any electrical components and ensure proper alignment.

Testing

- Reconnect the spark plug and start the engine.

- Monitor performance for any irregularities or leaks.

- Make any final adjustments if needed.

Importance of Proper Maintenance

Ensuring the longevity and efficiency of small engines requires regular upkeep. Neglecting this vital practice can lead to decreased performance, increased fuel consumption, and costly repairs. By implementing a consistent maintenance routine, you can enhance the reliability and functionality of your equipment.

Benefits of Regular Upkeep

- Improved Performance: Regular attention helps maintain optimal functionality.

- Extended Lifespan: Consistent care can significantly prolong the life of your engine.

- Cost Savings: Preventive maintenance reduces the likelihood of expensive repairs.

- Enhanced Safety: Proper maintenance minimizes risks associated with engine failure.

Key Maintenance Practices

- Regularly check and replace filters to ensure clean air and fuel flow.

- Inspect and clean spark plugs to promote efficient ignition.

- Monitor fuel quality and replace old fuel to prevent contamination.

- Lubricate moving parts to reduce wear and tear.

In conclusion, dedicating time to routine maintenance is crucial for achieving the best performance and reliability from your machinery. Implementing these practices not only enhances efficiency but also safeguards your investment for the future.

Tools Required for Carburetor Work

Working on the fuel delivery system of an engine requires a specific set of tools to ensure precision and effectiveness. Having the right equipment can significantly streamline the process and lead to better outcomes. Below is a guide to essential instruments needed for this type of maintenance.

Essential Tools

- Socket Set: A variety of sockets to fit different fasteners.

- Wrenches: Both adjustable and fixed wrenches for loosening and tightening components.

- Screwdrivers: Flathead and Phillips for various screws.

- Fuel Line Pliers: Specially designed to handle fuel lines without damage.

- Cleaning Brushes: To remove debris and build-up from surfaces.

- Compressed Air: For clearing passages and drying parts.

Additional Instruments

- Torque Wrench: To ensure components are secured to the manufacturer’s specifications.

- Safety Goggles: For eye protection during disassembly and cleaning.

- Work Gloves: To protect hands from sharp edges and fuel.

- Magnetic Tray: To keep small parts organized and prevent loss.

- Measuring Tools: Calipers or gauges to check component dimensions accurately.

Where to Find Replacement Parts

Finding suitable components for maintenance can be essential for ensuring optimal performance. Various sources offer a range of options to help you locate what you need efficiently.

- Authorized Dealers: Check with local authorized distributors for genuine items.

- Online Retailers: Websites like Amazon and eBay often have a wide selection.

- Specialty Shops: Look for stores focusing on outdoor equipment and machinery.

- Forums and Communities: Engage with online communities for recommendations and advice.

- Local Repair Shops: Sometimes, they can order specific components for you.

Comparing prices and availability across these sources can lead you to the best options for your needs.

Benefits of OEM vs. Aftermarket Parts

When considering components for machinery, the choice between original equipment manufacturer (OEM) items and alternatives can significantly impact performance and longevity. Each option offers distinct advantages, appealing to different needs and preferences of users.

OEM items are crafted by the same manufacturer that produced the original components, ensuring compatibility and reliability. These components often come with warranties and are subject to stringent quality control standards, which can enhance the overall performance of the equipment.

On the other hand, aftermarket alternatives can provide cost savings and a wider variety of options. Many users appreciate the availability of enhanced features or upgraded designs, which can lead to improved efficiency or functionality. However, the quality of these alternatives can vary, so it’s crucial to select reputable brands.

| Aspect | OEM Items | Aftermarket Alternatives |

|---|---|---|

| Quality Assurance | High, due to manufacturer standards | Varies by brand |

| Cost | Typically higher | Often more affordable |

| Availability | Limited to manufacturer distribution | Widely available |

| Warranty | Usually comes with a warranty | Warranties may vary |

| Performance | Designed for optimal performance | Can vary, some may exceed OEM |

Ultimately, the decision between these options should be informed by individual priorities, such as budget constraints, desired performance levels, and the specific requirements of the machinery in question.