In the realm of small machinery, the efficiency and performance of engines heavily depend on the intricate arrangement of various essential elements. These components work in harmony to ensure optimal functionality, contributing to the overall effectiveness of the equipment. A clear comprehension of these elements is crucial for both maintenance and troubleshooting, allowing users to address any issues that may arise during operation.

Visual aids play a significant role in understanding the intricate relationships between these components. By examining a detailed schematic, one can grasp how each part interacts within the system. Such illustrations serve as invaluable references, simplifying the process of identification and assembly, ultimately leading to enhanced performance and longevity of the machinery.

Whether you are a seasoned technician or a novice user, familiarizing yourself with the assembly and layout of these critical components is vital. This knowledge not only empowers you to make informed decisions during repairs but also fosters a deeper appreciation for the engineering behind these machines. Embracing this understanding can lead to improved maintenance practices and a more efficient operation overall.

Understanding Honda GCV160 Carburetor Functionality

The mechanism responsible for fuel and air mixture delivery plays a crucial role in the efficient operation of small engines. It ensures that the correct proportions of both elements reach the combustion chamber, facilitating optimal performance and reliability. By regulating this mixture, the device significantly impacts engine start-up, acceleration, and overall functionality.

At its core, this assembly utilizes the principles of aerodynamics and fluid dynamics. As air flows through the device, it creates a vacuum that draws fuel from the reservoir. The size and shape of the openings dictate the volume of air and fuel, which directly influences engine efficiency and power output. Proper functioning is essential; any obstruction or malfunction can lead to poor performance or operational failure.

Moreover, this assembly often includes various components such as jets, floats, and needles, each serving a specific purpose in the mixture process. Understanding how these elements interact can help diagnose issues and ensure longevity. Regular maintenance is vital for optimal operation, preventing buildup and ensuring a consistent supply of fuel and air.

Ultimately, a well-functioning system is key to enhancing performance, improving fuel efficiency, and extending the life of the engine. Familiarity with its operation can empower users to troubleshoot and maintain their equipment effectively.

Essential Components of the Carburetor

The intricate assembly responsible for mixing air and fuel plays a crucial role in engine performance. Understanding its fundamental elements is vital for anyone looking to maintain or repair the system effectively. Each component contributes to the optimal functioning, ensuring the engine runs smoothly and efficiently.

Main Elements

At the heart of the assembly is the fuel chamber, which holds the liquid that powers the engine. Its design allows for a consistent flow, feeding the necessary mixture to the combustion chamber. Additionally, the venturi, a narrowing section within the structure, creates a pressure drop that aids in drawing fuel into the airstream.

Control mechanisms, such as the throttle valve, regulate the amount of mixture entering the engine, influencing acceleration and power output. Proper adjustment of these elements is essential for achieving desired performance levels, while also impacting fuel efficiency and emissions.

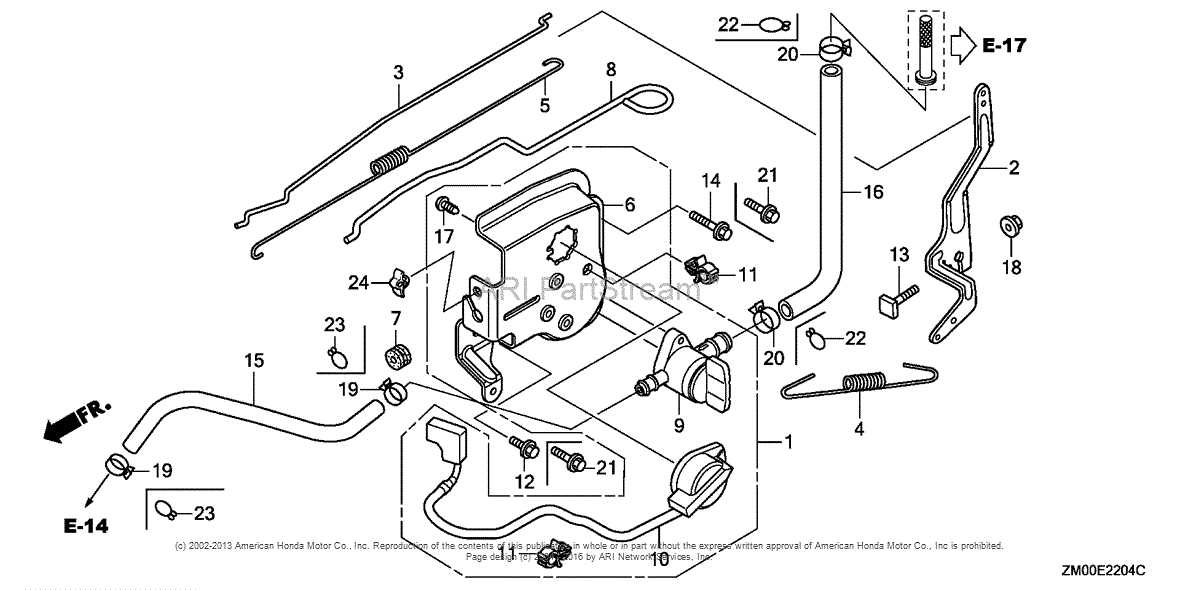

Detailed Parts Diagram Explanation

This section provides an in-depth look at the essential components of a specific engine accessory, highlighting their roles and relationships. Understanding these elements is crucial for effective maintenance and troubleshooting.

Key components include:

- Fuel delivery mechanisms

- Air intake systems

- Adjustable settings for performance tuning

- Sealing elements to prevent leaks

- Fasteners and connectors for assembly

Each of these items serves a unique function:

- Fuel delivery mechanisms: These ensure a consistent flow of fuel, which is vital for optimal operation.

- Air intake systems: Responsible for mixing air with fuel, they play a critical role in combustion efficiency.

- Adjustable settings: Allow users to modify performance based on environmental conditions and operational needs.

- Sealing elements: Prevent fuel and air from escaping, maintaining the efficiency of the system.

- Fasteners and connectors: Facilitate secure assembly, ensuring all components function together smoothly.

By comprehensively understanding these components, users can enhance the longevity and performance of their machinery, leading to improved efficiency and reduced maintenance costs.

Common Issues with Carburetor Parts

Maintaining optimal performance in small engines often hinges on the functionality of their fuel delivery systems. Various complications can arise in these mechanisms, leading to inefficiencies and operational challenges. Understanding these common issues is essential for effective troubleshooting and repair.

Frequent Problems

Several issues can affect the smooth operation of fuel delivery systems. Here are some of the most prevalent:

| Issue | Description | Symptoms |

|---|---|---|

| Clogged Jets | Accumulation of debris can obstruct fuel flow, causing poor engine performance. | Stalling, rough idling |

| Worn Gaskets | Gaskets can degrade over time, leading to air leaks and improper fuel mixture. | High fuel consumption, erratic engine speed |

| Sticking Float | A float that doesn’t move freely can cause overflow or inadequate fuel supply. | Fuel leaks, difficulty starting |

| Corroded Components | Rust or corrosion can hinder the function of critical elements, disrupting fuel delivery. | Decreased power, starting issues |

Troubleshooting Tips

Addressing these issues often requires careful inspection and, in some cases, replacement of affected components. Regular maintenance and cleaning can prevent many of these complications from arising, ensuring long-lasting performance and reliability.

Step-by-Step Carburetor Disassembly Guide

Disassembling the fuel delivery system can be an essential task for maintenance and repairs. This guide provides a clear, structured approach to help you navigate the process efficiently. Following these steps will ensure that you carefully take apart the unit without causing damage to any components.

- Prepare your workspace:

- Choose a clean, well-lit area.

- Gather necessary tools: screwdrivers, wrenches, and cleaning supplies.

- Have a container for small parts to avoid losing them.

- Disconnect the fuel supply and any electrical connections.

- Unfasten any screws or bolts securing the assembly.

- Carefully remove the air intake or filter.

- Take off any external levers or linkages.

- Unscrew the top cover to expose internal parts.

- Gently lift out the float assembly, noting its orientation.

- Unscrew any jets or needles, ensuring to keep track of their order.

- Take out the main body and inspect for wear or blockage.

- Use a cleaning solution to remove residue from all parts.

- Check for any damaged seals or gaskets that may need replacement.

Following these steps will help ensure a successful disassembly process. Once the unit is reassembled, it will be ready for further use.

Maintenance Tips for Longevity

Regular upkeep is essential for enhancing the lifespan of your outdoor machinery. By following a few key practices, you can ensure optimal performance and prevent premature wear and tear. Consistent care not only improves efficiency but also saves money on repairs over time.

Routine Cleaning

One of the simplest yet most effective maintenance tasks is keeping the equipment clean. Debris buildup can hinder performance and lead to malfunctions. Ensure to remove dirt, grass, and other contaminants from all accessible areas after each use.

Regular Inspections

Frequent checks for wear and damage can help identify potential issues before they escalate. Inspect components like filters and seals for any signs of deterioration, and replace them as needed to maintain functionality.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Clean equipment | After each use | Prevents buildup and rust |

| Inspect filters | Every month | Replace if clogged |

| Check oil levels | Every use | Ensure optimal lubrication |

| Sharpen blades | Every season | Improves cutting efficiency |

Identifying Genuine Honda Parts

When maintaining outdoor equipment, ensuring the use of authentic components is crucial for optimal performance and longevity. Genuine items are specifically designed to fit seamlessly and function effectively within the machinery. Recognizing these elements can prevent potential issues caused by inferior alternatives.

Quality Assurance: Authentic products undergo rigorous testing and meet high standards, providing peace of mind for users. Look for official markings or packaging that signifies genuine craftsmanship.

Supplier Reliability: Purchase from authorized dealers or trusted sources. This ensures that the components you acquire are legitimate and come with appropriate warranties.

Visual Inspection: Examine the item closely for any inconsistencies in color, shape, or materials. Genuine components typically exhibit superior craftsmanship compared to imitations.

Performance Consistency: Using authentic components ensures reliable operation. If issues arise, they are often easier to resolve due to standardized compatibility.

Ultimately, being diligent in identifying genuine items contributes significantly to the efficiency and durability of your equipment, allowing you to delve into your tasks with confidence.

Tools Required for Carburetor Repair

Repairing the fuel delivery system of small engines necessitates a specific set of tools to ensure efficiency and precision. Having the right equipment at your disposal can significantly streamline the process, allowing for a thorough inspection and effective maintenance.

Essential Tools

Here is a list of essential equipment you will need for a successful overhaul:

| Tool | Purpose |

|---|---|

| Screwdriver Set | To remove screws and fasteners from the assembly. |

| Socket Wrench | For loosening and tightening nuts and bolts. |

| Cleaning Brushes | To clean components and remove deposits. |

| Gasket Scraper | To remove old gaskets and ensure a proper seal. |

| Compressed Air Blower | To blow out debris and ensure components are clear. |

Additional Accessories

In addition to the basic tools, having a few accessories can enhance your repair experience:

| Accessory | Function |

|---|---|

| Safety Goggles | To protect your eyes from debris. |

| Gloves | To keep your hands clean and safe from chemicals. |

| Magnetic Tray | To keep small fasteners organized and prevent loss. |

| Multimeter | For checking electrical components if necessary. |