In the realm of farming equipment, comprehending the intricate layout of machinery is essential for efficient operation and maintenance. A thorough grasp of each element’s function allows operators to enhance productivity and ensure longevity in performance. This section aims to illuminate the interconnectedness of various components, providing valuable insights for both seasoned professionals and newcomers to the field.

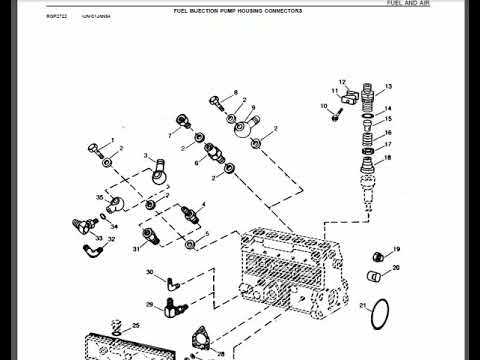

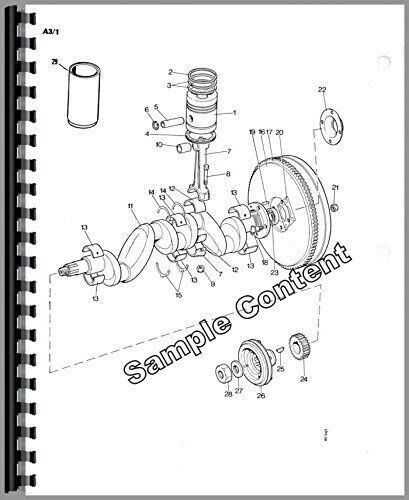

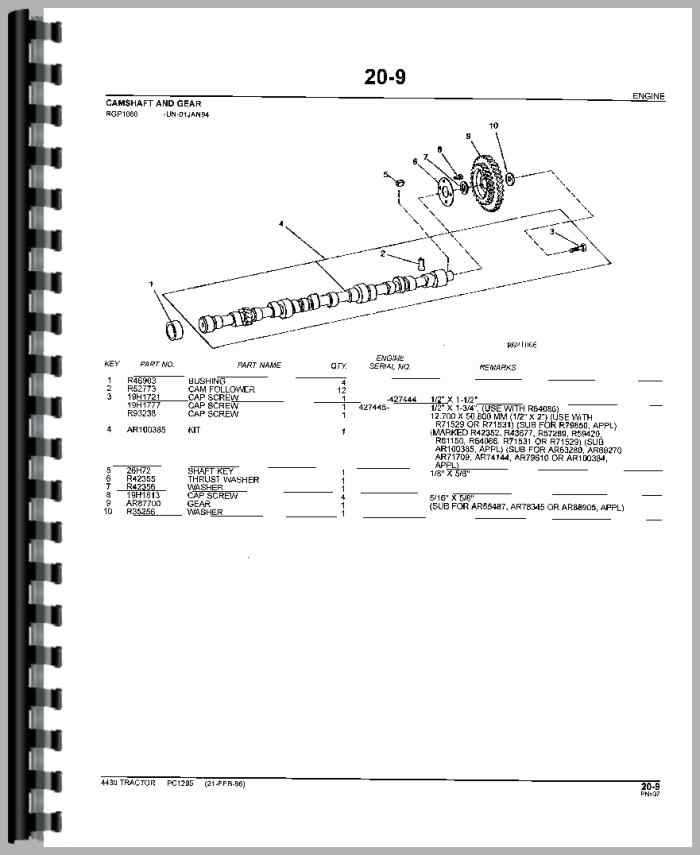

Visual representations serve as crucial tools in deciphering complex machinery systems. By studying detailed illustrations, one can easily identify specific segments and their respective roles within the overall framework. This approach not only aids in troubleshooting but also facilitates informed decision-making when it comes to repairs and upgrades.

Moreover, gaining knowledge about these mechanical systems fosters a deeper appreciation for the technology that underpins modern agriculture. Understanding how each part contributes to the whole empowers operators to optimize their use of equipment, ultimately leading to greater efficiency and success in farming endeavors.

Overview of John Deere 4430 Parts

This section provides a comprehensive look at the essential components that make up a classic agricultural machine. Understanding these elements is crucial for maintenance and repairs, ensuring optimal performance in the field.

Key components include the engine, transmission, and hydraulic systems, each playing a vital role in functionality. Regular inspections of these areas help identify wear and tear, allowing for timely interventions.

Additionally, accessories such as filters, belts, and electrical systems are integral for efficient operation. Knowledge of these parts empowers operators to keep their machinery in peak condition.

Importance of Parts Diagrams

Understanding the intricacies of machinery relies heavily on visual representations that illustrate various components. These schematics serve as essential tools for both technicians and enthusiasts, providing clarity in complex systems. By breaking down assemblies into manageable sections, these illustrations enhance comprehension and facilitate efficient maintenance and repair tasks.

Enhancing Maintenance Efficiency

Utilizing visual guides offers several benefits:

- Quick Identification: Users can easily locate specific elements within an assembly.

- Streamlined Repairs: Knowing where each piece fits accelerates the troubleshooting process.

- Improved Communication: Technicians can discuss issues using standardized visuals, reducing misunderstandings.

Supporting Educational Initiatives

These illustrations also play a vital role in training and education:

- Learning Aid: Visuals help learners grasp concepts more effectively.

- Hands-On Training: Trainees can follow along with diagrams to understand assembly and disassembly processes.

- Resource for Future Reference: Having a visual guide ensures users can revisit critical information as needed.

Key Components of the 4430 Model

This section explores the essential elements that contribute to the functionality and efficiency of this iconic agricultural machine. Understanding these components is vital for maintenance and optimal performance.

Engine and Transmission

The powerhouse of the machine, the engine, delivers robust performance and reliability. Coupled with a responsive transmission system, it ensures smooth operation across various terrains, enhancing productivity.

Hydraulic System

The hydraulic system plays a crucial role in lifting and operating implements. Its design allows for precision control, making it easier to tackle demanding tasks in the field.

Finding OEM vs. Aftermarket Parts

When it comes to sourcing components for machinery, understanding the difference between original equipment manufacturer options and alternative solutions is crucial. Each category has its unique advantages and potential drawbacks, which can significantly impact performance and longevity.

Advantages of OEM Components

- Designed specifically for your machinery, ensuring perfect fit and compatibility.

- Often backed by warranties, providing peace of mind for the buyer.

- Typically made from high-quality materials, contributing to durability.

Benefits of Aftermarket Alternatives

- Usually available at lower prices, making them an attractive option for budget-conscious users.

- Often come with enhanced features or improvements over the original designs.

- A wider variety of options, allowing for more flexibility in repairs and upgrades.

Ultimately, the choice between OEM and alternative options depends on individual needs, preferences, and budget considerations. Conducting thorough research is essential to ensure the best outcome for your equipment.

Common Issues and Replacement Parts

In the realm of agricultural machinery, understanding frequent problems and their respective solutions is crucial for maintaining optimal performance. Operators often encounter various challenges that can hinder the efficiency of their equipment. Recognizing these issues early can prevent further complications and ensure smoother operations.

Engine Overheating: A prevalent concern in many machines is overheating. This can stem from coolant leaks, a malfunctioning thermostat, or a blocked radiator. Regular inspection of the cooling system is essential to prevent damage and ensure longevity.

Transmission Difficulties: Shifting gears can become problematic due to worn components or low fluid levels. It’s important to check the transmission fluid regularly and replace filters as needed to keep the system functioning smoothly.

Hydraulic System Failures: The hydraulic system is vital for various functions. Common issues include leaks and unresponsive controls. Routine maintenance, such as checking hoses and seals, can help identify potential failures before they escalate.

Electrical Problems: Electrical faults can cause erratic behavior or failure to start. Inspecting wiring connections and replacing faulty components can resolve these issues and enhance reliability.

When facing these challenges, sourcing quality replacement components is imperative. Ensuring that the substitutes meet or exceed original specifications will facilitate a seamless restoration of functionality and performance.

Maintenance Tips for Longevity

Ensuring the extended life of your agricultural machinery requires a proactive approach to upkeep and care. Regular maintenance not only enhances performance but also prevents costly repairs down the line. By adopting a few essential practices, operators can significantly improve the durability and efficiency of their equipment.

Regular Inspections

Frequent checks on key components are crucial. Look for signs of wear and tear, such as leaks or unusual noises. Hydraulic systems and belts should be closely monitored, as they play vital roles in operation. Documenting these inspections helps in identifying patterns that may indicate larger issues.

Fluid Maintenance

Maintaining optimal fluid levels is essential for smooth operation. Regularly change oils and filters to ensure that the machinery runs efficiently. Coolant and fuel should also be regularly checked and replaced as needed. Using high-quality fluids can greatly enhance the performance and lifespan of various systems.

Where to Buy Replacement Parts

Finding quality components for agricultural machinery can be a daunting task. It is essential to ensure that the items you purchase are reliable and compatible with your equipment. Various sources offer a range of options, making it easier to find what you need for maintenance or repairs.

Online Retailers are one of the most convenient options for sourcing replacement items. Numerous websites specialize in equipment supplies, providing detailed catalogs and the ability to compare prices. Customer reviews and ratings can help guide your choice.

Local Dealerships often carry a selection of original components tailored to specific machinery models. Establishing a relationship with a trusted dealer can lead to personalized service and advice on the best solutions for your needs.

Salvage Yards can be a treasure trove for budget-conscious buyers. These places often have used parts that are still in good condition, offering a more economical alternative. However, inspecting items for wear and compatibility is crucial before making a purchase.

Finally, consider manufacturer websites, where you can find official resources and sometimes direct purchasing options. These sites may also provide valuable information on compatible components and updates regarding new releases.

Regardless of where you decide to shop, thorough research will ensure you acquire the necessary components to keep your machinery running smoothly.

Understanding Service Manuals

Service manuals are essential resources that provide comprehensive information for maintenance and repair tasks. They serve as detailed guides, helping users understand the inner workings of machinery and equipment. By breaking down complex systems into manageable sections, these manuals ensure that users can perform their tasks efficiently and effectively.

Typically, a service manual includes various components, such as troubleshooting tips, maintenance schedules, and technical specifications. Understanding how to navigate these documents can significantly enhance the user’s ability to keep their equipment running smoothly.

| Section | Description |

|---|---|

| Introduction | An overview of the equipment and its purpose. |

| Specifications | Technical details and performance metrics. |

| Maintenance | Guidelines for regular upkeep and servicing. |

| Troubleshooting | Common issues and solutions for effective repair. |

| Diagrams | Visual representations to aid in understanding assembly and components. |

Utilizing these manuals not only fosters a deeper comprehension of the equipment but also empowers users to take proactive steps in care and repair. Ultimately, mastering the use of service manuals leads to improved performance and longevity of the machinery.