In the realm of farming machinery, efficient performance hinges on the intricate relationship between various components. Knowing how these elements interact not only enhances functionality but also extends the lifespan of the equipment. This section delves into the essential features that ensure smooth operation, providing a comprehensive overview for enthusiasts and professionals alike.

Maintenance and repairs are vital for any piece of machinery, and having a clear visual representation of its structure can significantly simplify these processes. Familiarity with the layout of components facilitates easier troubleshooting and allows for more informed decision-making during upgrades or replacements.

Moreover, understanding the assembly of equipment empowers users to optimize their tools for specific tasks. This knowledge fosters greater efficiency in the field, enabling operators to maximize productivity while minimizing downtime. A thorough grasp of the machine’s intricacies ultimately contributes to successful farming practices.

Understanding the Ford 501 Sickle Mower

This piece of agricultural equipment is designed to efficiently cut through grass, weeds, and other vegetation. It operates by using a series of cutting blades mounted on a framework, allowing the operator to manage overgrown areas with ease. The mechanism ensures smooth operation even in tough conditions, providing reliable performance for farmers and land managers.

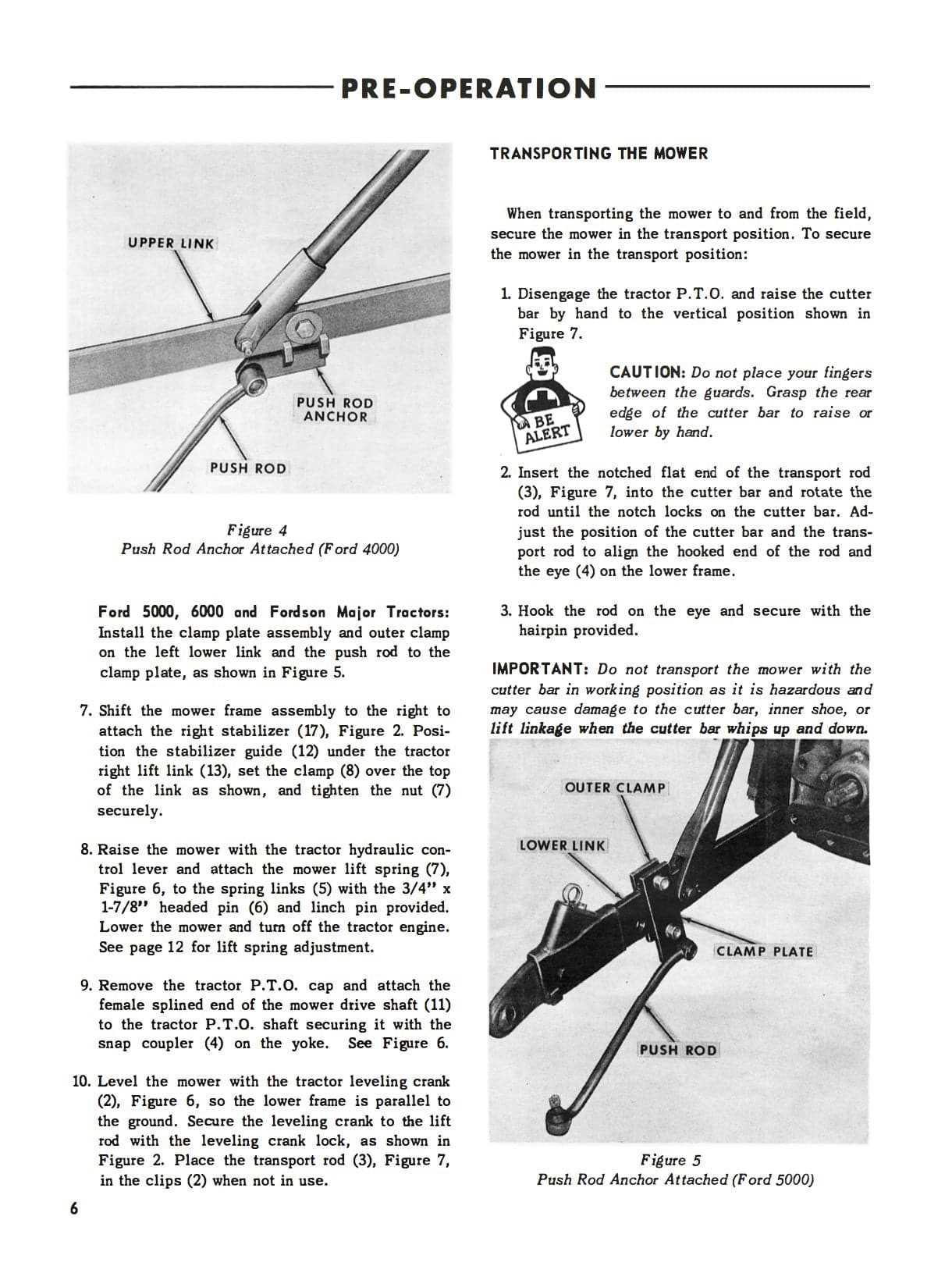

The system is composed of several key components that work together to ensure optimal functionality. Understanding each part’s role can significantly enhance the effectiveness of the machine. Here are some of the essential elements:

- Cutting Mechanism: The main component responsible for severing vegetation, typically operated through a reciprocating motion.

- Frame: The supporting structure that holds all moving parts in place and ensures stability during operation.

- Drive System: A mechanism that transfers power from the tractor to the cutting components, enabling efficient operation.

- Safety Features: Various elements designed to protect the operator and ensure the safe operation of the machine.

Each of these components plays a critical role in ensuring that the tool remains functional and effective in various field conditions. Knowing how they interact will help users maintain and troubleshoot the machine effectively.

Key Components of the Sickle Mower

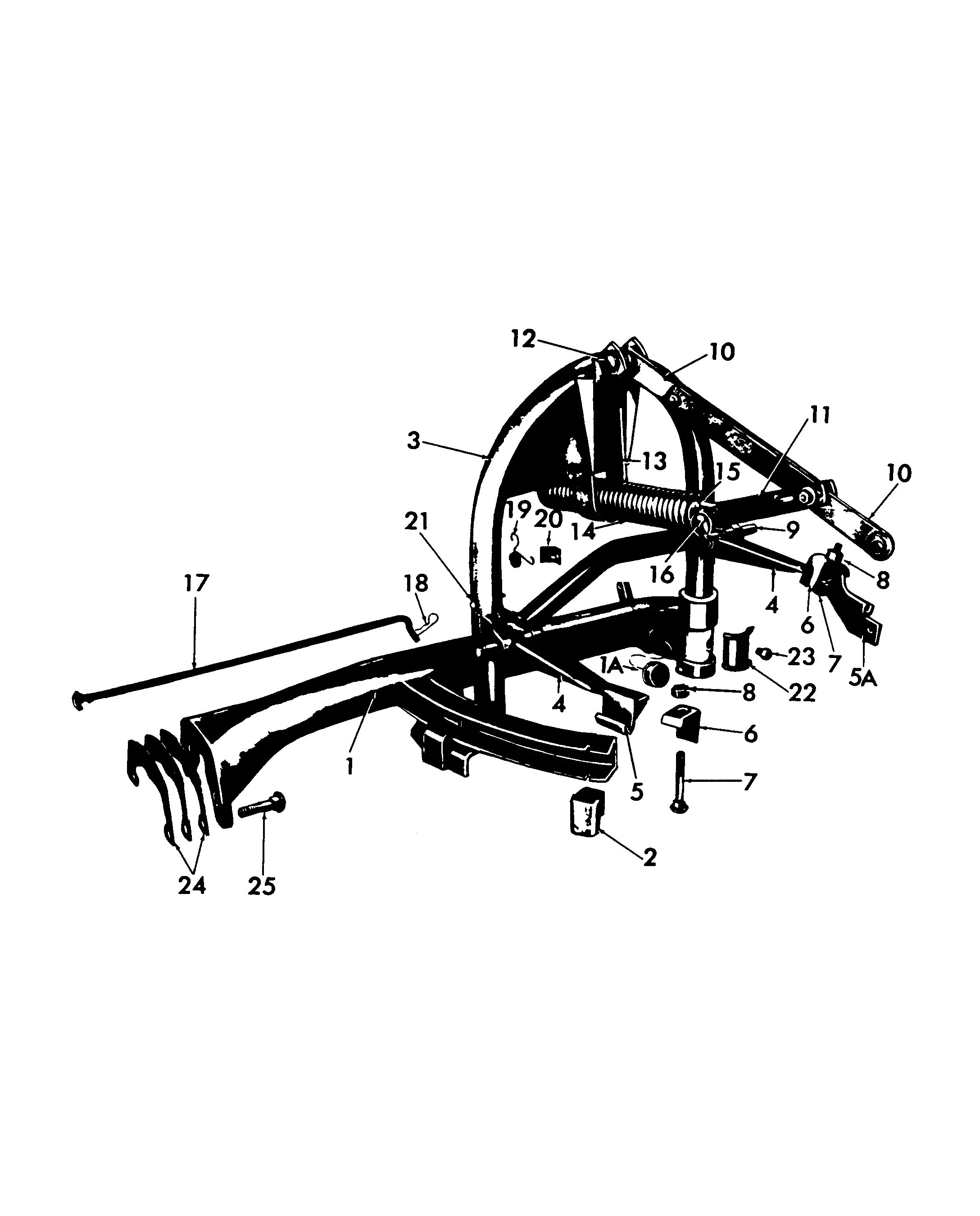

Understanding the primary elements of a cutting machine is essential for proper maintenance and optimal performance. These machines are designed with specific parts working together to achieve efficient cutting, often employed in agricultural tasks. Below, we explore the key components that play a vital role in the overall functioning of such equipment.

Crucial Moving Parts

The effectiveness of the equipment largely depends on the moving elements that interact during operation. These include blades and rotating mechanisms that are central to the cutting action. Proper alignment and sharpening are necessary to ensure smooth and precise operation.

Supportive Framework and Accessories

A robust structural design supports the moving components. Additionally, various attachments and accessories help secure the machinery during use and enhance its versatility, allowing it to be adapted for different tasks.

| Component | Function | Maintenance Tips |

|---|---|---|

| Cutting Blade | Responsible for cutting vegetation with a sharp edge. | Regularly sharpen the blade and check for wear. |

| Drive Mechanism | Transfers motion from the power source to the blades. | Inspect for wear and lubricate moving parts. |

| Frame | Supports all components, ensuring stability during operation. | Ensure it is free of rust and damage; tighten any loose bolts. |

Benefits of Using a Sickle Mower

When it comes to cutting tall vegetation, certain tools stand out for their efficiency and ease of use. These machines are designed to handle tough grasses and crops with precision. Their robust construction allows for fast and clean cutting, ensuring that the job is done right the first time. With the right technique, users can enjoy optimal performance without straining the equipment or themselves.

Enhanced Cutting Efficiency

The primary advantage of these machines is their ability to cut through dense vegetation with minimal effort. Their design ensures that even the toughest plants are managed with ease, making them a perfect choice for large fields and agricultural tasks.

- Quick and uniform results

- Less wear and tear on the machine

- Reduces operator fatigue during long hours of use

Durability and Longevity

These tools are built to last. With proper maintenance, they can endure various weather conditions and operate efficiently for many years. Their tough components ensure that they remain reliable, even when used under challenging conditions.

- Resistant to wear and damage

- Minimal need for repairs or part replacements

- Great for both commercial and personal use

Maintenance Tips for Optimal Performance

Regular upkeep is essential for ensuring smooth operation and prolonging the life of your equipment. Proper attention to maintenance tasks can help avoid unnecessary breakdowns, improve efficiency, and prevent costly repairs. Here are some key tips to keep in mind for maintaining peak performance:

- Inspect and clean all moving components regularly to prevent debris buildup and ensure free movement.

- Lubricate all joints and bearings to reduce friction and extend the lifespan of parts.

- Check the tension of belts and chains to ensure they are neither too loose nor too tight, as this can affect performance.

- Sharpen blades periodically to maintain cutting efficiency and reduce strain on the motor.

- Examine tires for proper inflation to ensure stable operation and prevent uneven wear.

- Replace any worn or damaged components immediately to prevent further damage to the system.

Incorporating these maintenance steps into your regular routine will enhance overall reliability and minimize downtime during use.

Common Issues and Troubleshooting Guide

When working with agricultural equipment, certain mechanical problems may arise over time. These issues can often be traced to wear and tear, improper maintenance, or environmental factors. Addressing these challenges promptly can help improve performance and extend the lifespan of the machine. This section offers guidance on identifying and resolving common malfunctions.

1. Excessive Vibration and Noise

Unusual vibrations and noises are often signs of loose or worn components. Check for any misalignment or damaged parts, such as blades or gears. Tightening fasteners and replacing any faulty elements should resolve most cases. Regular lubrication of moving parts can also prevent friction-related issues.

2. Difficulty in Cutting or Uneven Results

If the equipment fails to cut evenly or struggles with thick vegetation, the sharpness of the cutting blades might be compromised. Inspect the cutting edge for signs of dullness or damage and sharpen or replace them as necessary. Additionally, ensure that the machine is properly adjusted to maintain optimal cutting height and tension.

How to Access Replacement Parts

When it’s time to replace certain components of your equipment, knowing where and how to find quality replacements is essential for ensuring optimal performance. Whether you’re looking to restore functionality or upgrade your machine, understanding your options for sourcing the right items can make the process much smoother.

Exploring Authorized Dealers and Online Stores

Authorized dealers are often the most reliable source for original replacements. They ensure that the components you purchase meet the manufacturer’s standards. Additionally, online platforms and specialized websites offer an extensive range of products, often with the convenience of home delivery. Be sure to check reviews and product specifications to ensure compatibility with your model.

Consideration of Local Distributors and Salvage Yards

Local distributors can be a valuable resource for obtaining parts, especially if you’re seeking alternatives or want to avoid shipping costs. Salvage yards or equipment refurbishers may also offer used or refurbished components at a lower cost, though this requires careful inspection to guarantee the condition of the items.

Comparing Ford 501 to Other Models

When evaluating various agricultural machinery options, it is essential to compare different models to understand their unique features, capabilities, and efficiencies. Each model in the market is designed with specific functions in mind, catering to different needs and working environments. By examining the similarities and differences, one can make a more informed decision on which equipment is the best fit for their tasks.

Performance and Efficiency

One of the primary aspects to consider is how each machine performs under various conditions. While some models are optimized for heavy-duty tasks, others might excel in precision and finer operations. Performance can be influenced by engine power, cutting width, and overall design, all of which impact efficiency and productivity in the field.

Durability and Maintenance

Another important factor is how well these machines stand the test of time. Durability is often linked to the materials used in construction, as well as the design and engineering behind the machinery. Additionally, the ease of maintenance plays a crucial role in keeping the equipment running smoothly for years, minimizing downtime and repair costs.

In summary, while all models offer certain strengths, the choice largely depends on the specific requirements of the job at hand. Evaluating performance, durability, and maintenance needs will help determine which machine is best suited for a given task.

Historical Significance of the Ford 501

The model in question represents a key milestone in agricultural machinery development, playing a crucial role in the transformation of farming practices during the mid-20th century. It was a significant advancement in the efficiency and ease of harvesting crops, offering farmers a more reliable and cost-effective solution compared to manual labor or earlier mechanical alternatives. This innovation contributed to the modernization of farming, greatly impacting productivity and the agricultural economy as a whole.

As an essential piece of equipment, it streamlined crop cutting and collection, reducing the physical strain on workers and enabling them to manage larger areas in less time. The machine became widely adopted for its durability and adaptability, enduring various agricultural conditions over the years.

| Feature | Impact |

|---|---|

| Design and Functionality | Improved productivity by simplifying crop harvesting processes. |

| Durability | Allowed for prolonged use in various farming environments. |

| Adoption Rate | Quickly became a standard tool for farmers across multiple regions. |

User Experiences and Testimonials

In this section, we will explore the feedback and insights shared by individuals who have worked with similar equipment. Their stories highlight the practical aspects, performance, and reliability of the machine, offering valuable information for anyone considering its use. Real-life experiences often reveal nuances and challenges that may not be apparent in manuals or technical specifications, providing a deeper understanding of its functionality.

Many users have found the tool to be a dependable and efficient asset for handling tough tasks, but others have shared their concerns regarding certain components. Below, we have compiled some of the most common comments from those who have used the equipment extensively.

| User | Experience | Rating |

|---|---|---|

| John D. | “The machine performed exceptionally well during my harvest season, offering great efficiency and minimal maintenance.” | 4.5/5 |

| Emily R. | “A solid choice for small farms, but I did have a few issues with wear and tear on some parts after frequent use.” | 3/5 |

| Michael T. | “I found the setup a bit challenging, but once I got everything aligned, it worked smoothly and saved me time on larger projects.” | 4/5 |