Maintaining the functionality of your outdoor machinery is essential for achieving optimal performance. Each piece of equipment consists of various elements that work together harmoniously. Gaining insight into these components can significantly enhance your understanding and upkeep of your device.

Identifying individual elements and their interactions allows for better troubleshooting and repairs. When issues arise, a comprehensive knowledge of how these parts fit together can save time and resources. This exploration aims to provide clarity on the various sections and mechanisms involved in your equipment.

By familiarizing yourself with the essential components, you can ensure that your device operates smoothly and efficiently. Whether you are performing routine maintenance or addressing specific concerns, understanding these critical elements will empower you to take control of your machinery’s performance.

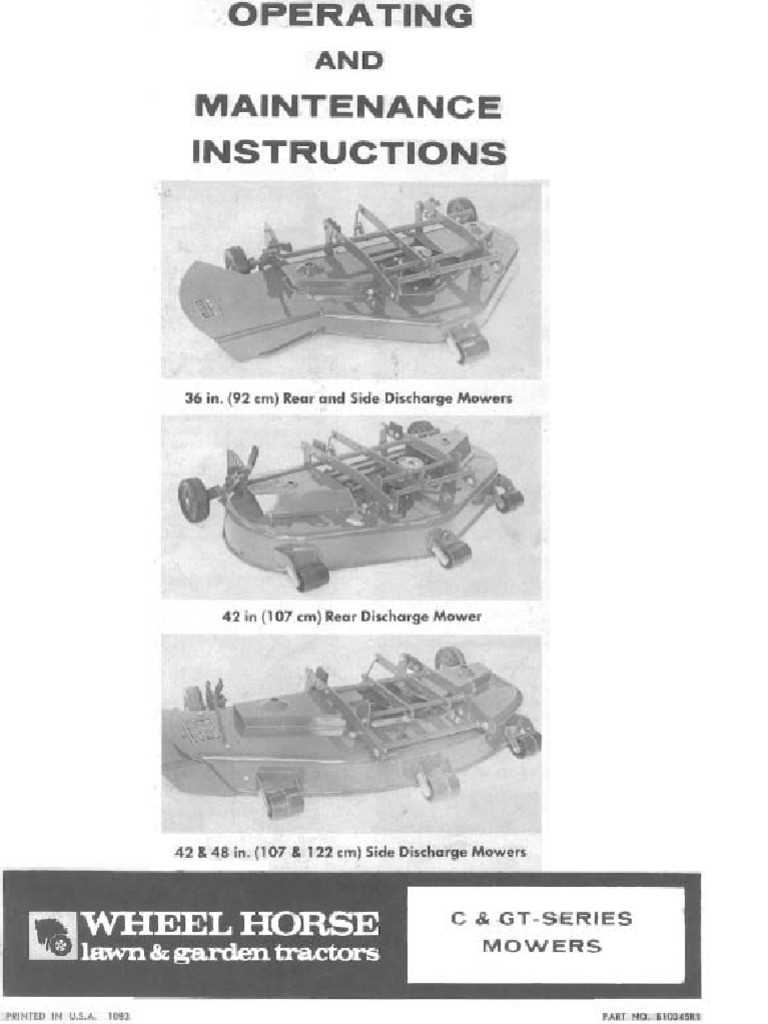

Understanding Wheel Horse Mower Decks

Grasping the intricacies of lawn care machinery can enhance both the efficiency of the equipment and the quality of your landscape. Knowledge of the essential components and their functions plays a pivotal role in ensuring optimal performance and longevity.

To fully appreciate the workings of these machines, it is important to familiarize oneself with the main elements involved. Each component contributes to the overall functionality, making maintenance and troubleshooting more manageable.

- Blades: Critical for achieving a clean cut, these elements vary in size and design.

- Spindles: These rotating parts hold the blades and are crucial for their movement.

- Belts: They transfer power from the engine to the cutting components, ensuring smooth operation.

- Mounting brackets: These secure the entire assembly in place, maintaining stability during use.

- Adjusters: Used for height modification, they allow for customizable cutting lengths.

Understanding the role of each component not only aids in effective maintenance but also assists in diagnosing potential issues before they escalate. Regular inspections and timely replacements can prevent unexpected breakdowns and extend the lifespan of the equipment.

In summary, a solid grasp of the various elements involved in lawn maintenance machinery fosters a more productive and enjoyable gardening experience. Familiarity with the functions and maintenance of these components is essential for any operator looking to achieve excellence in their outdoor endeavors.

Key Components of Mower Decks

Understanding the essential elements that contribute to the functionality and efficiency of grass-cutting equipment is crucial for optimal performance. Each component plays a significant role in ensuring a seamless operation, affecting the overall outcome of the landscaping task.

- Blades: Sharp cutting instruments that directly impact the quality of the cut.

- Spindles: Support and rotate the blades, crucial for maintaining consistent cutting height.

- Housing: The protective casing that encases the blades and spindles, providing safety and durability.

- Belts: Transfer power from the engine to the blades, essential for effective operation.

- Chassis: The structural framework that supports all components, ensuring stability and balance during use.

Each of these elements is interdependent, and maintaining them is vital for extending the lifespan of the equipment and achieving the best results in lawn care.

Importance of Maintenance and Care

Regular upkeep and attention to machinery play a crucial role in ensuring optimal performance and longevity. By prioritizing maintenance, users can prevent potential issues and enhance the overall efficiency of their equipment. This proactive approach not only saves time and resources but also contributes to a safer working environment.

Benefits of Regular Upkeep

Consistent care leads to several advantages, including:

| Benefit | Description |

|---|---|

| Increased Lifespan | Routine checks and replacements can significantly extend the service life of the machinery. |

| Enhanced Efficiency | Well-maintained equipment operates more smoothly, reducing energy consumption and improving performance. |

| Safety Improvements | Regular inspections can identify potential hazards, ensuring a safer operation for users. |

Key Maintenance Practices

Implementing a few essential practices can lead to effective management:

- Perform routine inspections to identify wear and tear.

- Replace filters and fluids as per the manufacturer’s guidelines.

- Keep machinery clean to prevent build-up that can hinder performance.

Common Issues with Mower Deck Parts

When maintaining your lawn equipment, various complications can arise that may hinder performance. Understanding these frequent challenges is crucial for ensuring optimal functioning and longevity. Below are some typical concerns associated with essential components.

| Issue | Description | Possible Solution |

|---|---|---|

| Uneven Cutting | This can occur when blades are dull or improperly aligned, leading to inconsistent grass height. | Sharpen or replace blades and adjust their positioning. |

| Clogging | Debris accumulation can obstruct movement and efficiency, resulting in poor performance. | Regularly clean the underside and remove any buildup. |

| Vibration | Excessive shaking may indicate a loose component or an imbalanced blade. | Tighten loose elements and check for proper blade balance. |

| Rust and Corrosion | Exposure to moisture can lead to degradation of metal parts, affecting durability. | Store equipment in a dry place and apply protective coatings. |

| Drive Belt Wear | Continuous use can lead to fraying or breaking of belts, impacting power transfer. | Inspect regularly and replace worn belts as necessary. |

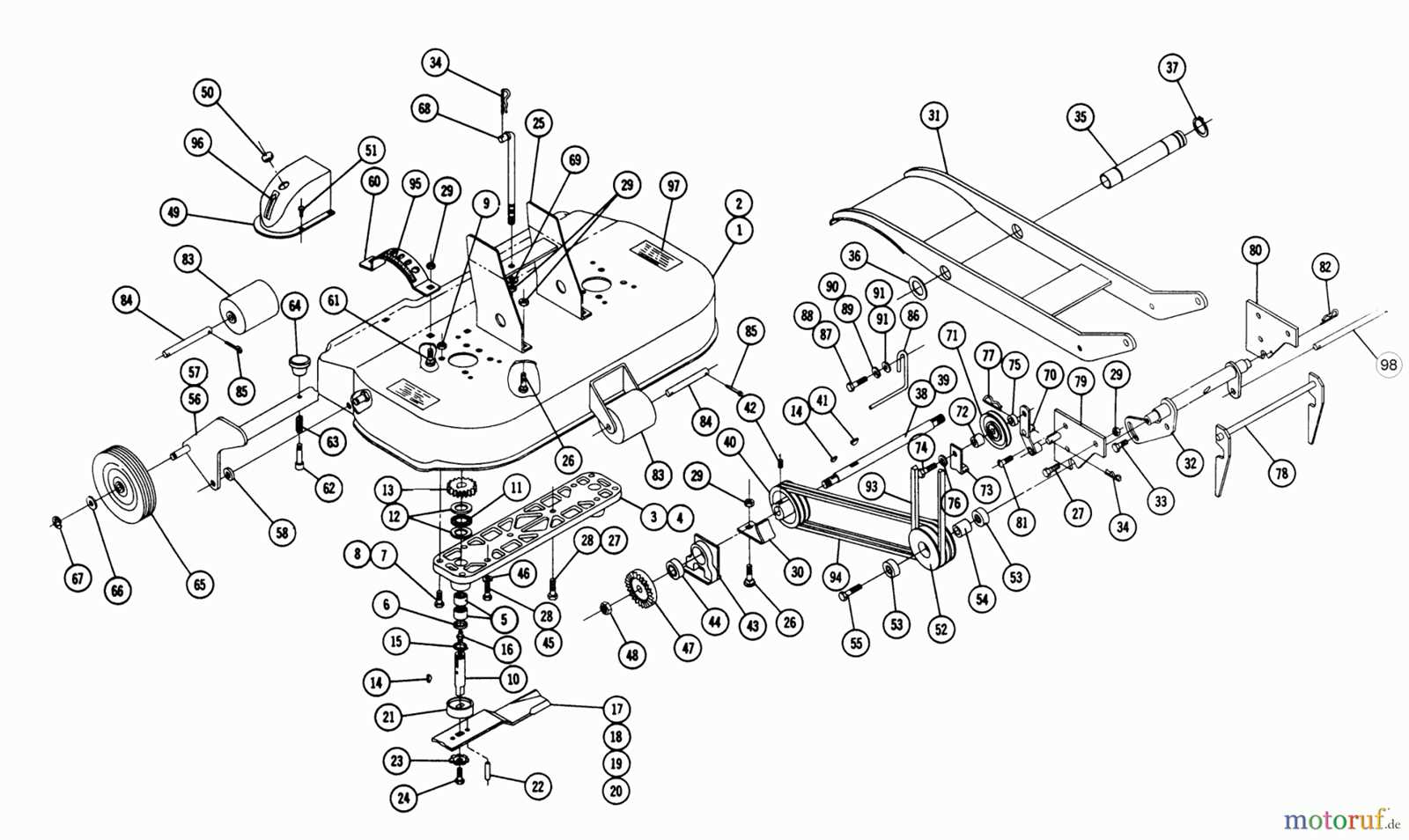

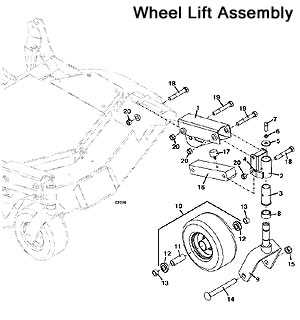

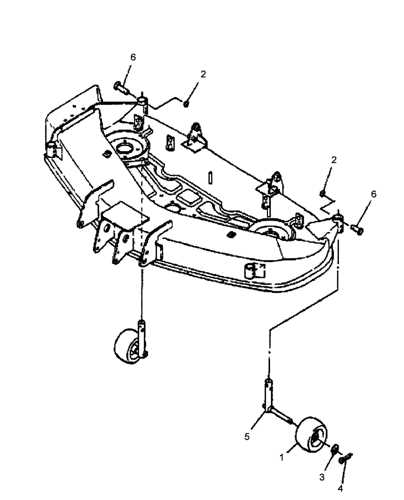

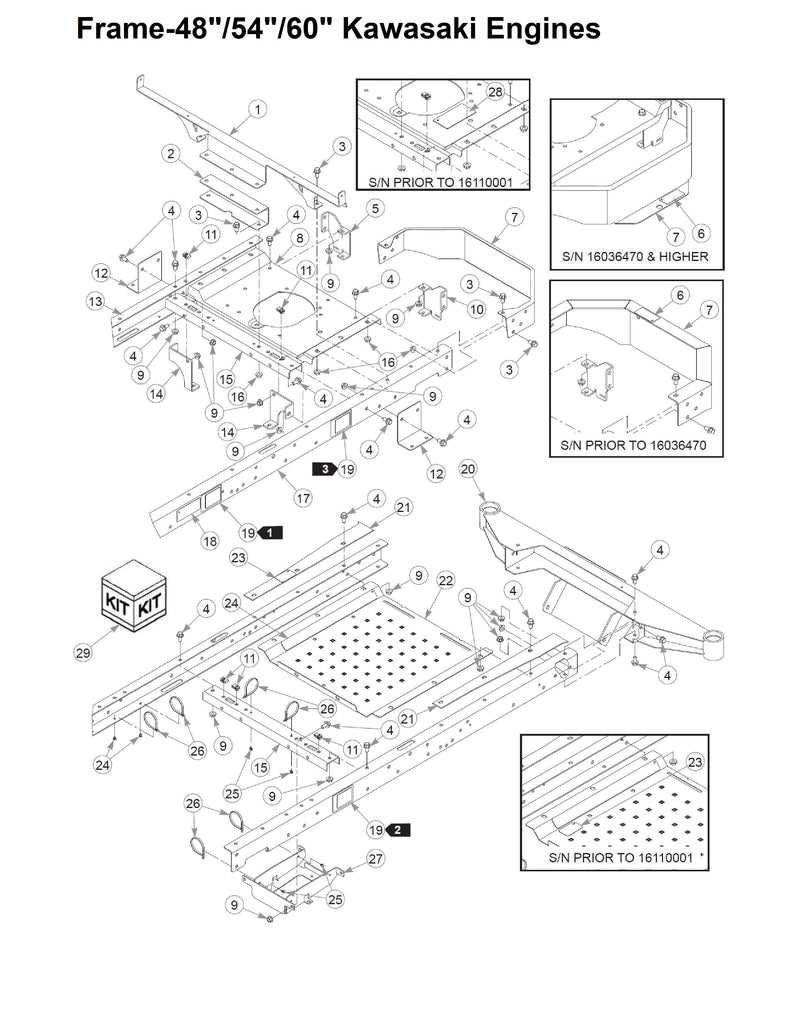

Identifying Parts in Diagrams

Understanding the various components illustrated in schematics is crucial for effective maintenance and repair. Each element plays a specific role, and recognizing them can significantly enhance your ability to troubleshoot issues and perform replacements accurately.

Common Elements and Their Functions

Diagrams typically include labels and symbols that correspond to different components. Familiarizing yourself with these markers allows you to quickly identify essential parts, facilitating smoother assembly and disassembly processes. For instance, connectors, gears, and belts may be depicted with unique icons that distinguish their functions.

Interpreting Symbolic Representations

Many visual representations employ standardized symbols to convey information efficiently. By learning these conventions, you can decipher complex illustrations with ease. This understanding not only aids in identifying individual elements but also helps you grasp how they interact within the overall system, leading to more informed decisions during repairs.

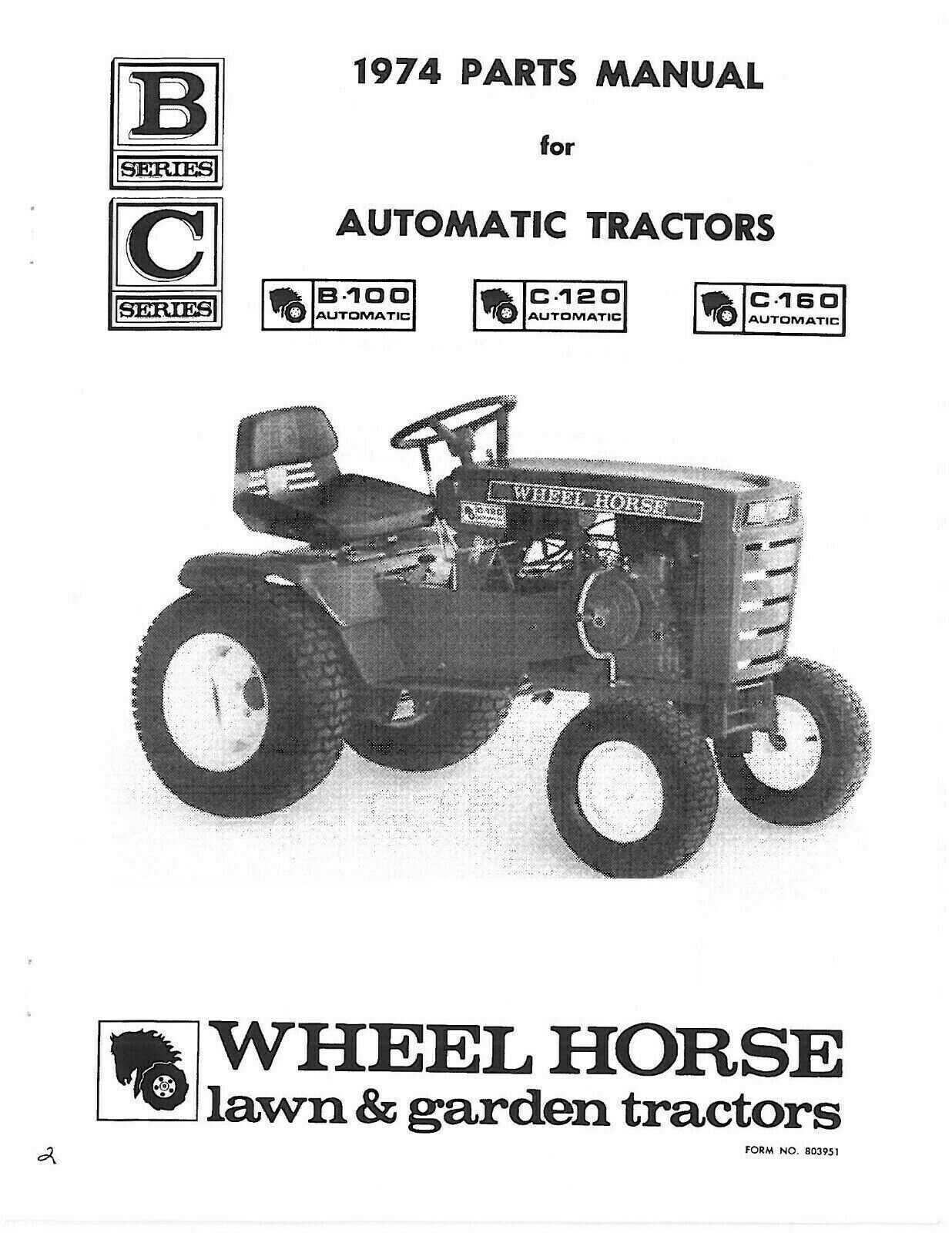

Replacement Parts and Compatibility

Ensuring optimal performance requires understanding how various components work together and what alternatives are available. Compatibility between different elements can significantly affect the overall functionality of your equipment.

- Check manufacturer specifications for approved components.

- Consider aftermarket options for cost-effective solutions.

- Verify compatibility with your specific model to avoid issues.

It’s advisable to consult user manuals or online resources to delve into the ultimate choices suited for your setup. Following proper guidelines can enhance longevity and efficiency.

Tools Needed for Repairs

When undertaking maintenance tasks, having the right equipment is crucial for ensuring efficiency and effectiveness. Proper tools not only facilitate the process but also enhance safety and precision, making it easier to achieve the desired outcomes.

Essential Tools

A basic toolkit should include wrenches, screwdrivers, pliers, and socket sets. These items are fundamental for loosening and tightening components, ensuring that everything is securely fastened.

Advanced Equipment

For more intricate tasks, consider adding torque wrenches, multimeters, and diagnostic tools to your collection. These specialized instruments can help you delve deeper into repairs, identifying issues that may not be immediately visible.

Step-by-Step Repair Guide

This section provides a comprehensive approach to addressing common issues with your cutting equipment. By following a structured method, you can efficiently diagnose problems and implement effective solutions, ensuring optimal performance and longevity.

Step 1: Gather Necessary Tools

Before beginning, collect all essential tools and materials. Typical items include wrenches, screwdrivers, and replacement components specific to your model.

Step 2: Safety Precautions

Always prioritize safety. Disconnect the power source and wear protective gear such as gloves and goggles to safeguard against potential injuries.

Step 3: Inspect and Identify Issues

Examine the unit thoroughly. Look for signs of wear or damage, and note any irregular sounds or movements during operation. This step is crucial for effective troubleshooting.

Step 4: Disassemble Relevant Components

Carefully remove the necessary sections for access. Keep track of all screws and parts to facilitate reassembly. Refer to your specific model’s manual for guidance on disassembly.

Step 5: Replace or Repair Defective Elements

Based on your inspection, replace worn or broken components with new parts. Ensure that any repairs are performed correctly to maintain the integrity of the unit.

Step 6: Reassemble and Test

Once repairs are completed, reassemble the equipment carefully. Double-check that all parts are securely in place. After reassembly, conduct a test run to ensure everything functions smoothly.

Step 7: Regular Maintenance

To prevent future issues, implement a regular maintenance schedule. Clean components, check for wear, and address any small problems promptly to prolong the life of your machinery.

Where to Find Quality Parts

Finding high-quality components for your outdoor equipment is essential for maintaining performance and longevity. Whether you’re looking for replacements or upgrades, knowing where to source these items can make a significant difference in your experience. Below are some reliable avenues to explore.

Authorized Dealers

One of the most trustworthy sources for quality components is through authorized dealers. These establishments provide original equipment manufacturer (OEM) items, ensuring compatibility and reliability. By purchasing from authorized vendors, you also benefit from expert advice and customer support, helping you make informed choices.

Online Retailers

The internet offers a vast selection of retailers specializing in outdoor equipment components. Websites dedicated to these products often feature customer reviews, detailed specifications, and competitive pricing. Look for established platforms that prioritize customer satisfaction and offer return policies. Additionally, consider forums and community groups where enthusiasts share their recommendations and experiences.