In the realm of mechanical engineering, the intricate mechanisms that facilitate movement play a vital role in the functionality of various vehicles and machinery. A thorough comprehension of these essential elements is crucial for anyone involved in design, maintenance, or operation. Each component contributes to the overall performance, influencing stability, speed, and efficiency.

The interplay between various elements forms a cohesive system, where each piece has a distinct purpose yet relies on the others for optimal performance. By analyzing these components, one gains insight into how they interact under different conditions, ultimately leading to a better understanding of motion dynamics.

Exploring this topic enables enthusiasts and professionals alike to deepen their knowledge, improve repair skills, and enhance performance. Whether you’re a hobbyist tinkering with models or an engineer refining sophisticated machines, recognizing the significance of these components can lead to innovation and improved functionality in a range of applications.

Understanding Wheel Parts and Their Functions

The intricate design of circular components in vehicles plays a crucial role in their overall performance and safety. Each element within this assembly contributes uniquely to functionality, enhancing both movement and stability. A clear comprehension of these individual elements is essential for effective maintenance and troubleshooting.

| Component | Function |

|---|---|

| Rim | Supports the tire and maintains its shape while providing a mounting surface. |

| Tire | Provides traction, absorbs shocks, and ensures contact with the road. |

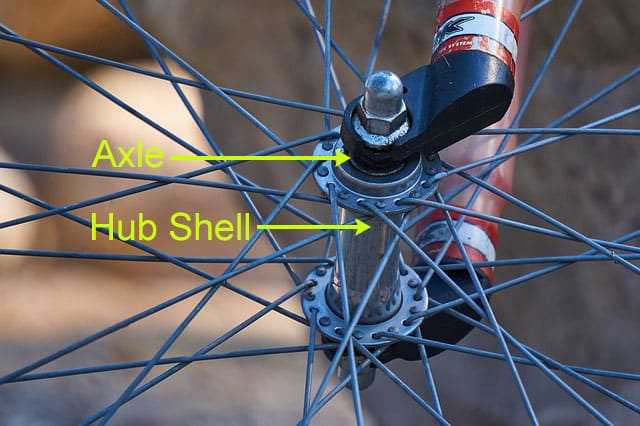

| Hub | Connects the circular unit to the axle and allows rotation. |

| Spokes | Distribute weight evenly and provide structural integrity to the assembly. |

| Brake Disc | Facilitates braking by creating friction when engaged by brake pads. |

Understanding these elements and their roles not only enhances appreciation for engineering but also aids in recognizing the importance of regular inspections and upkeep for optimal performance.

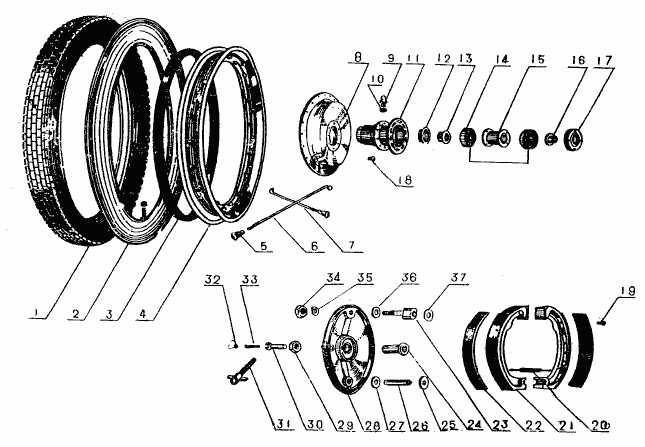

Essential Components of Wheel Assembly

The assembly of rolling mechanisms is a complex system that relies on various crucial elements working in harmony. Understanding these components is vital for ensuring optimal performance and safety in vehicles and machinery. Below are the key constituents that make up this essential mechanism.

- Rim: The outer circular edge that supports the tire and provides structural integrity.

- Tire: The outer covering that provides traction and absorbs shocks from the ground.

- Hub: The central part that houses the axle and connects the assembly to the vehicle’s frame.

- Spokes: The rods that connect the rim to the hub, distributing weight and providing support.

- Bearings: Components that allow for smooth rotation and reduce friction between moving parts.

Each of these elements plays a significant role in the functionality and efficiency of the entire system. Regular maintenance and understanding of these components can lead to improved performance and longevity.

- Inspecting the rim for cracks or damage.

- Checking tire pressure and tread wear.

- Ensuring the hub is securely attached and free of rust.

- Monitoring spoke tension to prevent failure.

- Lubricating bearings to minimize wear.

By being aware of these fundamental components and their functions, users can enhance the overall performance and safety of their vehicles.

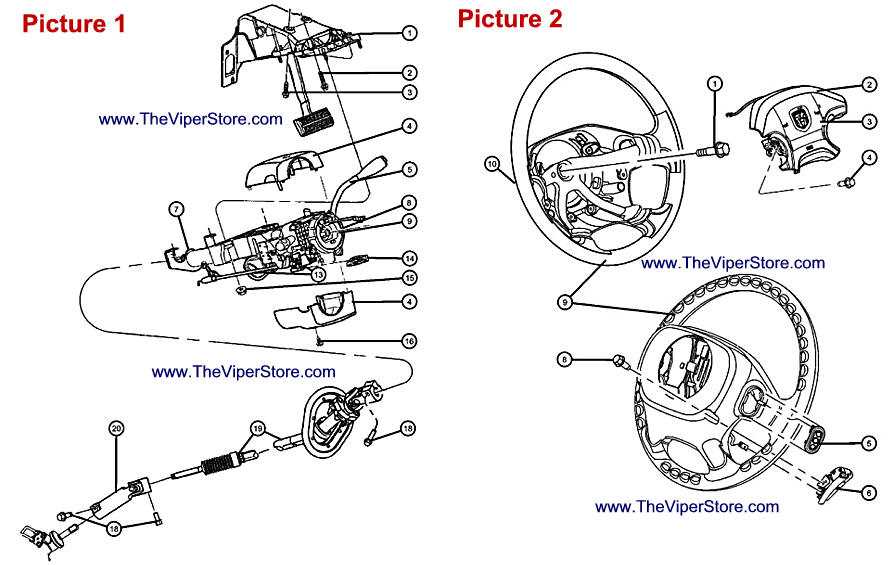

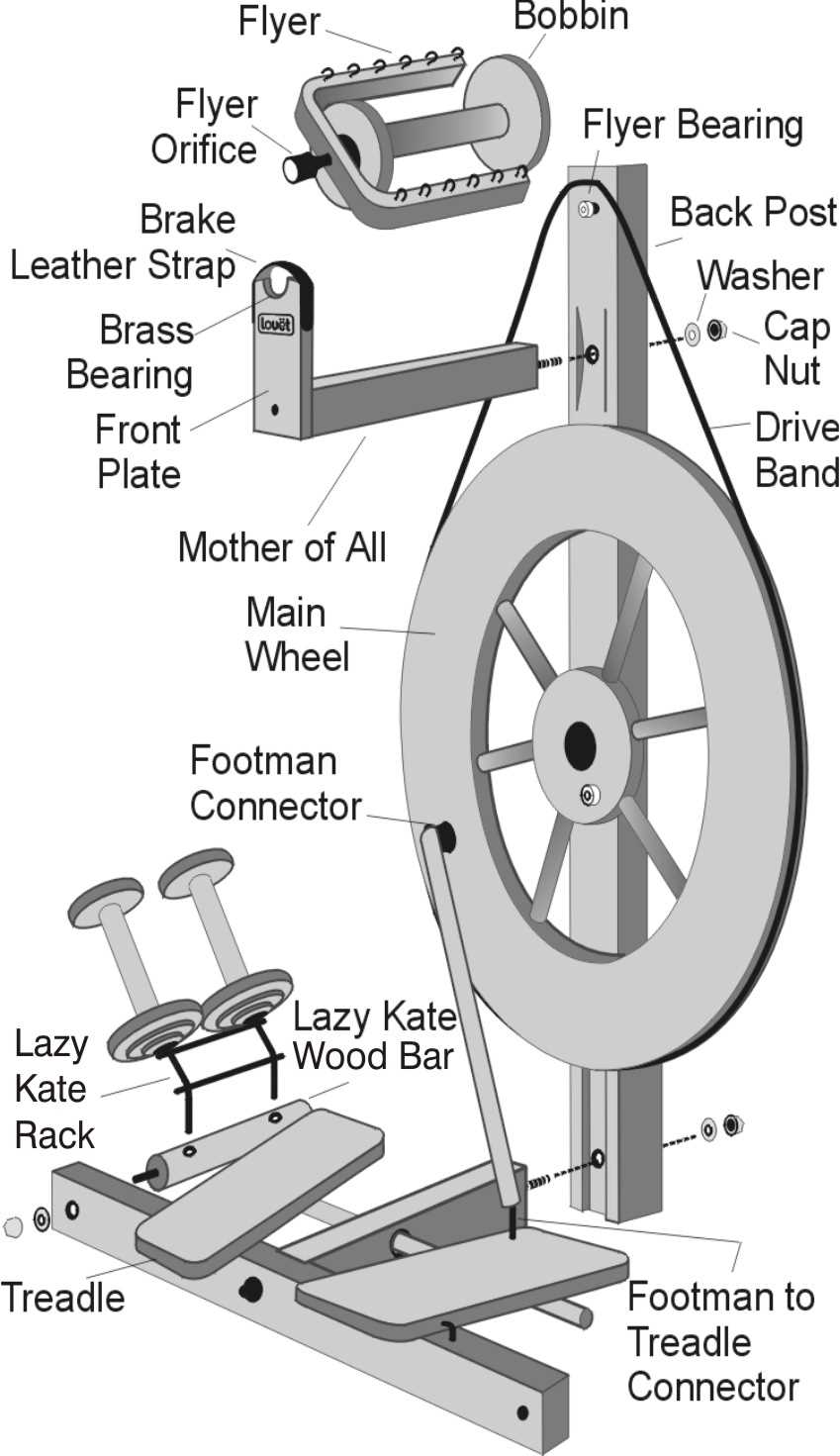

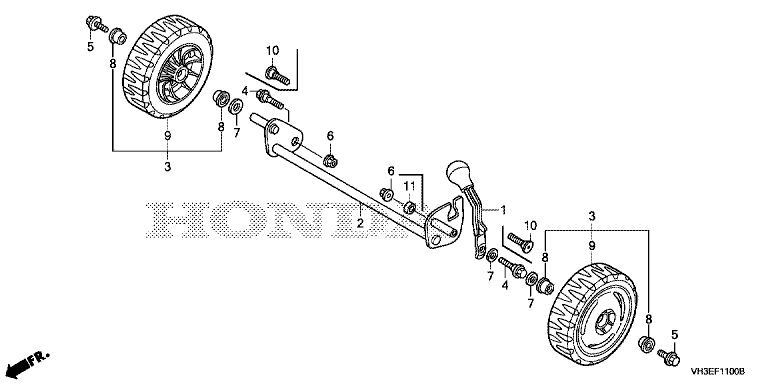

How to Read a Wheel Diagram

Understanding a schematic representation of circular components is essential for effective maintenance and repair. By familiarizing yourself with the layout and symbols used, you can gain insights into the functionality and interrelationships of each element within the assembly.

Identifying Key Components

Begin by recognizing the essential elements illustrated in the schematic. Each symbol typically represents a specific function or physical feature, allowing you to discern how they contribute to the overall mechanism.

Interpreting Connections

Next, examine the lines and connections that link the various elements. These indicate how each component interacts, helping you understand the flow of forces and the assembly’s operational dynamics.

Common Issues with Wheel Parts

When it comes to the components that enable smooth movement, several challenges can arise over time. Understanding these issues is crucial for maintaining optimal performance and ensuring safety. Regular inspection and timely intervention can help prevent significant problems down the road.

Wear and Tear

One of the most prevalent concerns is the natural degradation of elements due to constant use. This can lead to decreased efficiency and responsiveness. Regular checks for signs of fraying or cracking can help identify issues before they escalate.

Misalignment and Imbalance

Another common dilemma is improper alignment, which can affect handling and stability. This issue may arise from impacts or gradual wear. Balancing the components is essential to ensure even distribution of forces, enhancing both safety and performance.

Maintaining Your Wheel System

Proper upkeep of your rolling mechanism is crucial for ensuring smooth performance and longevity. Regular attention not only enhances functionality but also prevents potential issues that could lead to more significant repairs. Establishing a routine maintenance schedule can keep everything in optimal condition, contributing to a safer and more enjoyable experience.

Regular Inspections

Conducting frequent assessments is essential for identifying wear and tear before it becomes problematic. Look for signs of damage or deterioration, such as cracks or misalignments. Pay special attention to the surfaces that come into contact with the ground, as they often bear the most stress. Timely intervention can save you both time and money in the long run.

Lubrication and Cleaning

Keeping moving components clean and well-lubricated is vital for ensuring efficiency. Dust and debris can accumulate, leading to friction and wear. Use appropriate cleaning agents to remove buildup, and apply suitable lubricants to maintain smooth operation. Regular lubrication not only enhances performance but also extends the lifespan of critical components.

Choosing the Right Wheel for Your Vehicle

Selecting the appropriate rim for your automobile is crucial for both performance and aesthetics. A well-matched rim enhances driving dynamics and ensures safety on the road. Factors such as size, material, and design should be thoroughly considered to achieve the ultimate balance between style and functionality.

Factors to Consider

When choosing a rim, size is paramount. It impacts handling, comfort, and overall performance. Additionally, material plays a significant role; options range from lightweight alloys to durable steel, each with unique benefits. Lastly, consider the design, as it not only reflects personal style but also influences aerodynamics.

Benefits of Proper Selection

Making informed choices leads to improved vehicle handling, increased fuel efficiency, and enhanced visual appeal. A compatible rim can also contribute to a smoother ride and better traction, ultimately elevating your driving experience.

The Evolution of Wheel Design

The journey of circular transportation components has undergone remarkable transformations throughout history. Initially crafted from solid materials, these innovations have continuously adapted to meet the demands of speed, efficiency, and durability. As technology advanced, so did the complexity and functionality of these crucial elements, leading to designs that not only enhance performance but also aesthetics.

In ancient times, the earliest versions were simple wooden disks, essential for reducing friction and enabling movement. Over centuries, artisans began to experiment with different materials, incorporating metals and eventually composites. This shift allowed for lighter and stronger designs, which in turn facilitated faster and more agile modes of transport.

With the Industrial Revolution, the introduction of spokes and rim constructions marked a significant milestone. This not only reduced weight but also improved strength, leading to a new era of speed and reliability. The evolution continued into the 20th century with the advent of pneumatic technology, which revolutionized comfort and handling, allowing vehicles to traverse varied terrains with ease.

Today, cutting-edge advancements such as 3D printing and smart materials are shaping the future of these essential circular mechanisms. As manufacturers explore sustainable options and enhanced performance features, the quest for the perfect design continues, merging tradition with innovation to meet modern needs.

Safety Tips for Wheel Inspections

Ensuring the integrity of your vehicle’s rolling components is crucial for safe operation. Regular assessments can prevent potential hazards, enhance performance, and extend the lifespan of essential elements. Adopting a few precautionary measures during these evaluations can significantly reduce risks and promote a safer experience.

Preparation and Equipment

Before starting any examination, ensure you have the proper tools and safety gear. A sturdy jack, wheel chocks, and personal protective equipment like gloves and safety glasses are essential. Additionally, perform inspections on level ground to prevent accidents. Familiarize yourself with the manufacturer’s recommendations and guidelines to know what to look for during your check-up.

Inspection Process

When conducting the evaluation, start by visually inspecting for any visible damage or wear. Pay close attention to the surface and edges, checking for cracks or deformities. Rotate each element to check for uneven wear and listen for unusual noises during movement. If you identify any irregularities, consult a professional for further assessment before taking the vehicle on the road.

Innovations in Wheel Technology

Recent advancements in rolling mechanisms have transformed transportation and mobility, leading to enhanced performance and efficiency. Innovative materials and designs are driving this evolution, offering both sustainability and superior functionality.

Material Enhancements

Lightweight composites and advanced alloys have become prominent, reducing overall weight and improving durability. These materials allow for greater energy efficiency, resulting in lower fuel consumption and emissions.

Smart Technologies

Integration of smart sensors and connectivity features enables real-time monitoring of performance. This technology facilitates predictive maintenance, ensuring optimal functionality and safety throughout usage.