In many traditional crafting techniques, various mechanical instruments play a vital role in creating textiles. Understanding the individual elements of these tools is essential for anyone looking to master the art of yarn production. Each section of the device has its unique function, working together harmoniously to transform fibers into thread.

By exploring these structures, we can better appreciate the balance between form and function that these devices exhibit. Whether used by artisans or hobbyists, their intricate design reflects centuries of refinement. Recognizing how each piece contributes to the overall process provides valuable insights into this timeless craft.

Understanding Spinning Wheel Mechanics

The intricacies of fiber crafting devices rely on a balance between multiple interconnected elements, working together to transform raw materials into thread. To fully grasp how these mechanisms function, it is essential to consider their coordination, movement, and efficiency.

Key Functions and Their Roles

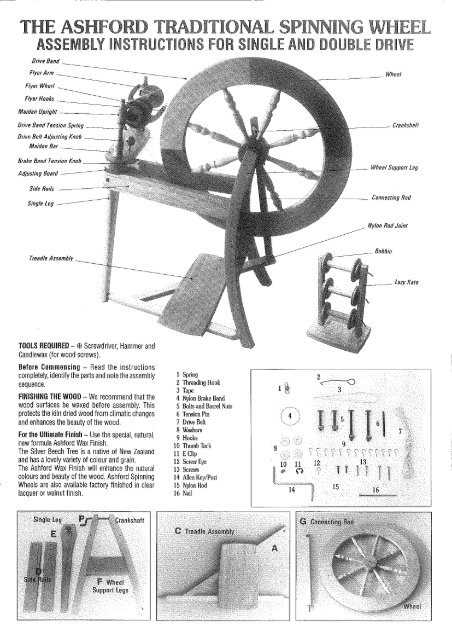

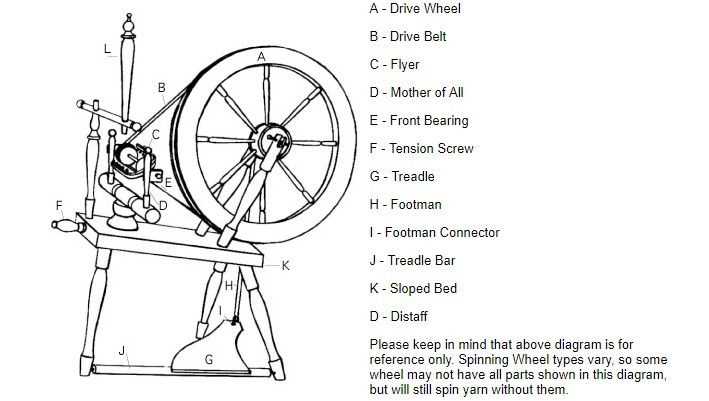

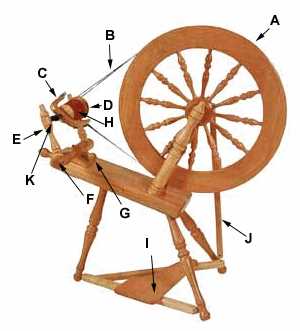

Various parts of the system contribute to the seamless operation of the whole process. Each component plays a crucial role in the transformation, regulating tension, twist, and motion. These functions are harmonized, ensuring smooth operation and high-quality results.

Mechanical Coordination

Effective synchronization is critical to maintaining stability and efficiency. The harmonious interaction of the system’s components ensures continuous motion, allowing for uniform production. Any disruption in this coordination can affect the final outcome.

| Component | Function | |||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Drive System | Initiates movement, ensuring consistency in operation. | |||||||||||||||||||||||||||||||||

| Tension Adjuster | Controls the amount of pull on the material, influencing its final texture. | |||||||||||||||||||||||||||||||||

| Component | Function | |||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

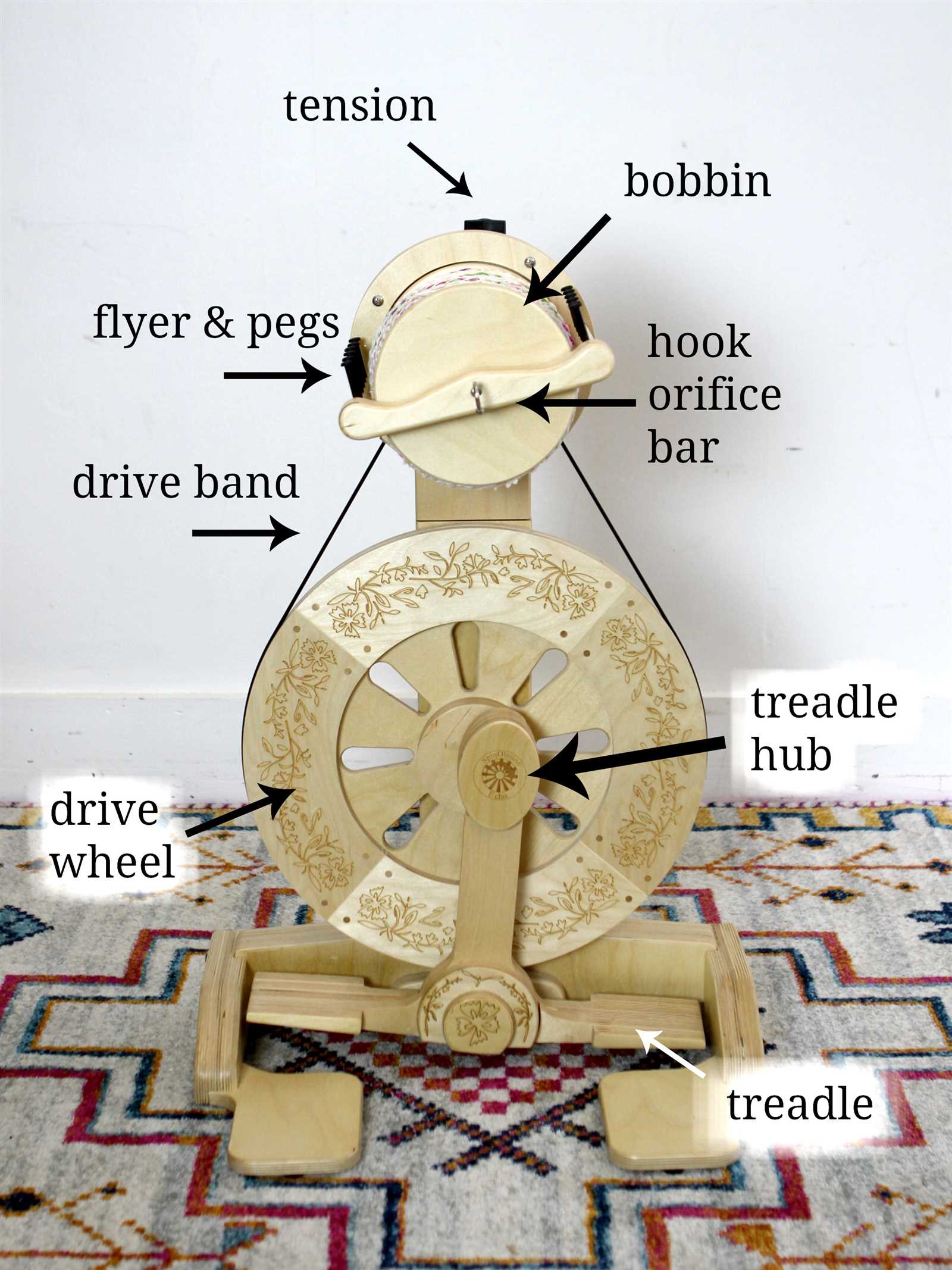

| Flyer | This part rotates to guide and twist fibers, ensuring consistent tension as material is drawn in. | |||||||||||||||||||||||

| Bobbin | Used to collect and store the spun material as it is twisted, controlling the speed of winding. | |||||||||||||||||||||||

| Treadle | Activated by foot, it powers the mechanism, allowing hands-free control over the process. | |||||||||||||||||||||||

| Whorl | Works in tandem with the drive system to regulate the speed of rotation, affecting the twist strength. | |||||||||||||||||||||||

| Drive Band |

| Maintenance Task | Recommended Frequency | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Lubrication | Every

Importance of the Tension Adjustment

Proper regulation of tension is essential to ensure a smooth and consistent flow during operation. The balance achieved through adjusting the tension impacts both the quality and speed of the process, influencing the overall outcome. Without the right balance, there can be disruptions that may lead to uneven results or inefficiencies. Achieving consistency is key when managing tension. By fine-tuning this aspect, one can maintain steady performance, preventing breaks or irregularities. The right tension helps control not only the pace but also ensures that the outcome remains uniform and high-quality. Precision is crucial in maintaining the correct tension settings, as even minor adjustments can have significant effects. It’s important to monitor this closely to ensure optimal functionality and to reduce unnecessary strain or wear during extended use. How the Flyer Mechanism Operates

The flyer system is a crucial element in transforming fibers into continuous thread. Its design allows for efficient rotation and distribution of the material during the process, ensuring an even and consistent output. By controlling the tension and twist, the device ensures a uniform result throughout the process. The core function relies on a coordinated movement between the rotating arms and the bobbin, which collect the material into a controlled loop. This interaction regulates the thickness and tightness of the final product, making the flyer essential for both accuracy and quality.

|