In the realm of heavy-duty transportation, a crucial component ensures the stability and efficiency of the entire system. This pivotal element plays a significant role in connecting the towing unit with the cargo section, facilitating seamless movement across various terrains. A clear comprehension of its components and functionality is essential for both maintenance and operation.

The intricacies of this connection system encompass various elements that work in unison to provide safety and reliability during transit. Each component has a specific function, contributing to the overall performance of the vehicle. By exploring these elements in detail, one can gain insights into their importance and interrelation.

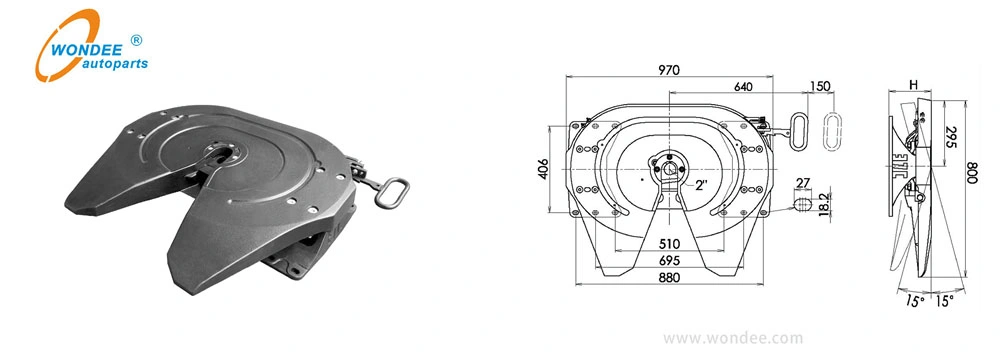

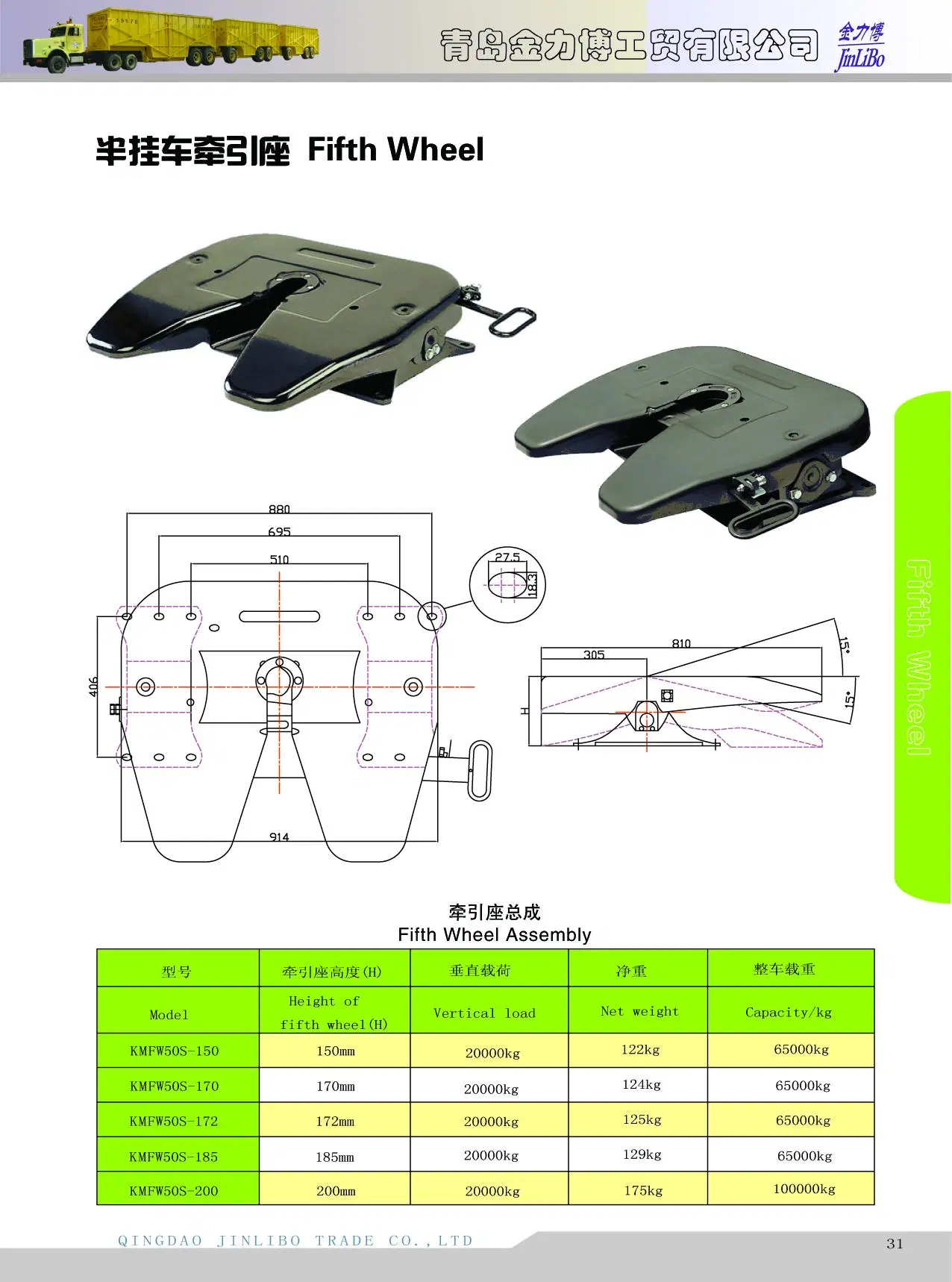

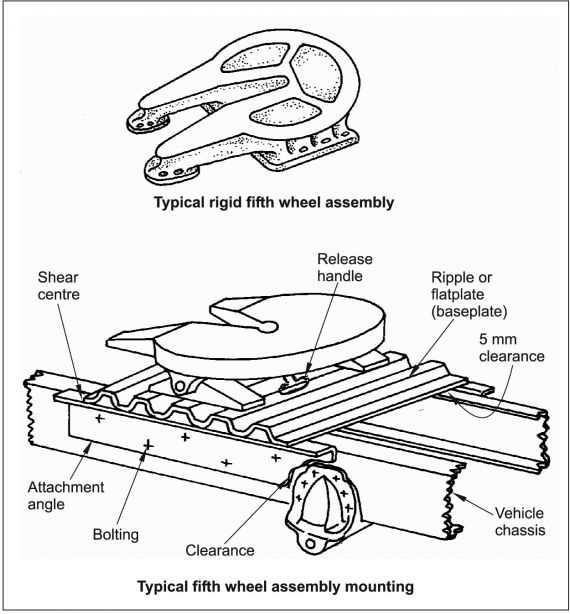

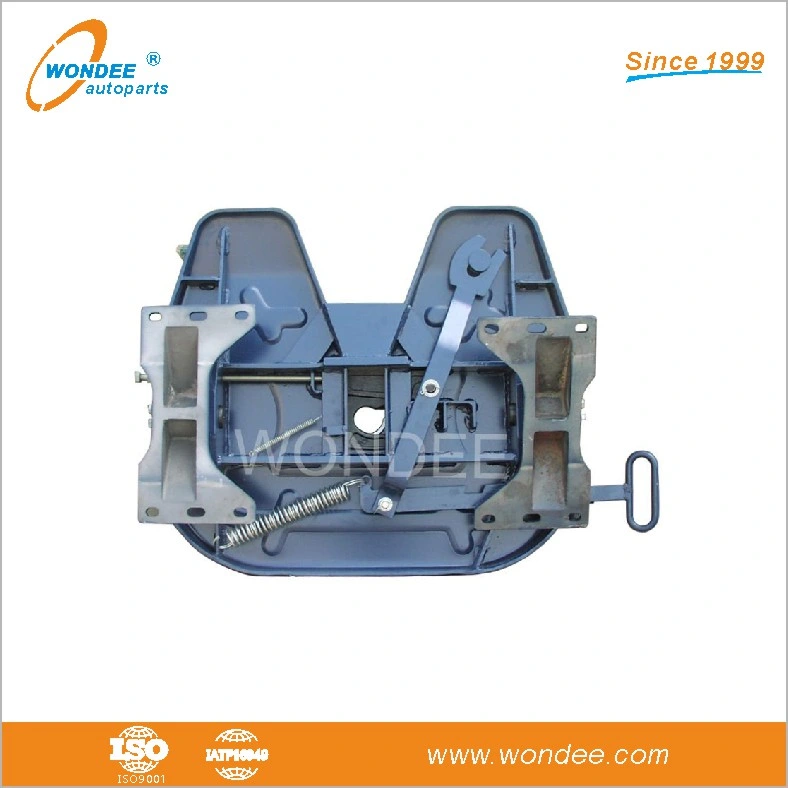

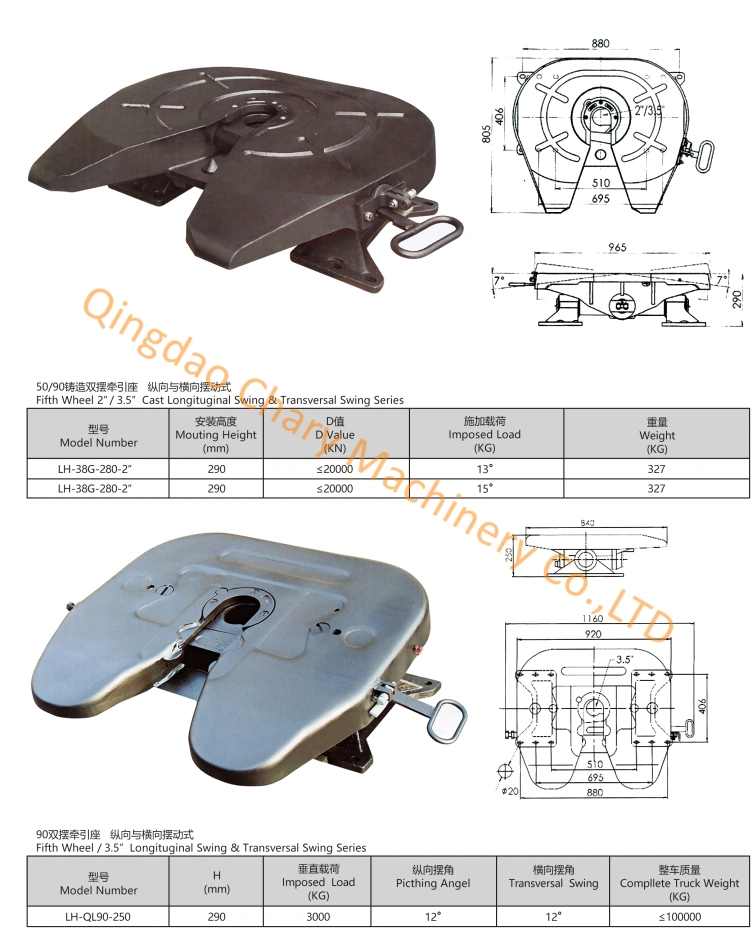

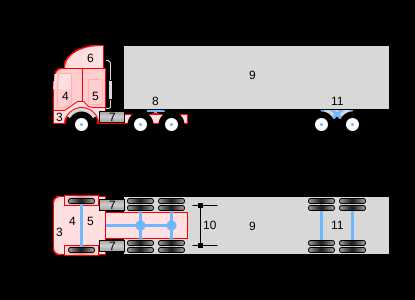

Visual representations of this connection mechanism can enhance understanding and aid in troubleshooting. An illustrative guide offers a comprehensive overview, highlighting each component’s role and positioning. This knowledge is invaluable for operators seeking to ensure optimal performance and longevity of their vehicles.

Semi Truck Fifth Wheel Overview

This section provides a comprehensive insight into a critical component used in heavy-duty transportation. Understanding its structure and functionality is essential for ensuring the effective operation of large vehicles, which are vital in logistics and freight movement.

Functionality

The mechanism serves as a coupling device, connecting the tractor to the trailer. Its design allows for the following key functions:

- Secure attachment of the trailer to the towing vehicle.

- Facilitating smooth maneuverability during turns.

- Absorbing shocks and vibrations during transit.

Components

Several integral elements contribute to the efficient performance of this mechanism. Key components include:

- Coupling Plate: The main surface that makes contact with the trailer.

- Locking Mechanism: Ensures the trailer remains securely attached.

- Adjustment System: Allows for proper alignment and height adjustments.

- Lubrication Points: Essential for reducing friction and wear over time.

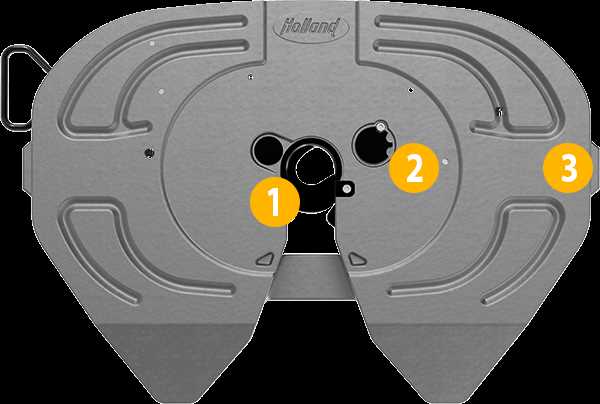

Understanding Fifth Wheel Components

Grasping the intricacies of connection mechanisms in heavy-duty vehicles is essential for ensuring stability and safety on the road. These assemblies play a crucial role in the effective coupling of towing and towed units, facilitating seamless transport of goods over long distances.

Each element within this assembly serves a specific function, contributing to the overall performance and reliability of the system. Key components include the locking mechanism, which secures the connection, and the pivot point, allowing for necessary movement during operation. Understanding how these parts interact provides valuable insights into maintenance and troubleshooting practices.

Additionally, the material composition and design features of these components are paramount. Durability and resistance to wear are critical for enduring the rigors of transportation. Regular inspections and familiarity with the assembly’s operation can help prevent malfunctions and enhance longevity.

Ultimately, a comprehensive understanding of these vital components not only promotes safety but also optimizes performance, ensuring that vehicles operate efficiently under various conditions.

Functionality of Fifth Wheel Mechanism

The mechanism in question plays a crucial role in the connection between a towing vehicle and its load. It is designed to provide a secure and stable link that allows for smooth transportation over various terrains. Understanding its functionality is essential for ensuring safe operation and effective handling during travel.

At its core, this assembly allows for a pivoting motion, enabling the attached load to follow the towing vehicle’s movements seamlessly. This is particularly important during turns, as it reduces the risk of disconnecting and minimizes stress on both the towing apparatus and the load. The mechanism also accommodates vertical and horizontal adjustments, ensuring that different sizes and types of cargo can be secured effectively.

Additionally, the design incorporates safety features that prevent accidental disengagement. These elements are critical in maintaining control and stability while in transit, providing peace of mind to operators. Regular maintenance and inspections of this mechanism are vital for ensuring optimal performance and longevity.

Common Issues with Fifth Wheel Parts

When it comes to heavy-duty vehicles, certain components are prone to wear and tear, leading to various complications. Understanding these common problems is crucial for maintaining optimal performance and ensuring safety on the road.

- Inadequate Lubrication: Insufficient lubrication can result in increased friction, causing premature wear and potentially leading to failure of critical components.

- Corrosion: Exposure to harsh weather conditions and road salt can lead to rust and corrosion, compromising the integrity of essential fixtures.

- Misalignment: Improper alignment can cause uneven stress distribution, leading to structural damage and difficulties during coupling and uncoupling.

- Worn Bushings: Over time, bushings can degrade, resulting in instability and excessive movement during operation.

- Cracks and Breaks: Physical damage from impacts or heavy loads can lead to cracks or breaks, necessitating immediate inspection and repair.

Addressing these issues promptly can enhance durability and performance, minimizing the risk of more serious problems down the line.

Maintenance Tips for Fifth Wheel Systems

Regular upkeep of connection mechanisms is essential for ensuring safe and efficient operation. Proper maintenance not only extends the lifespan of components but also enhances overall performance. Adopting a proactive approach can prevent potential issues and costly repairs down the line.

Routine Inspections

Conduct periodic checks to identify any signs of wear or damage. Look for cracks, corrosion, or excessive play in the connections. Lubrication is key; ensure that all moving parts are adequately greased to minimize friction and wear. Regularly tighten bolts and fasteners to maintain structural integrity.

Cleaning and Care

Keep the connection area free from debris and contaminants. Use a suitable cleaner to remove dirt and grime that can hinder performance. Inspection of seals and gaskets is vital; replace any that show signs of deterioration to prevent leaks and ensure a tight fit. Consider implementing a cleaning schedule to maintain optimal condition.

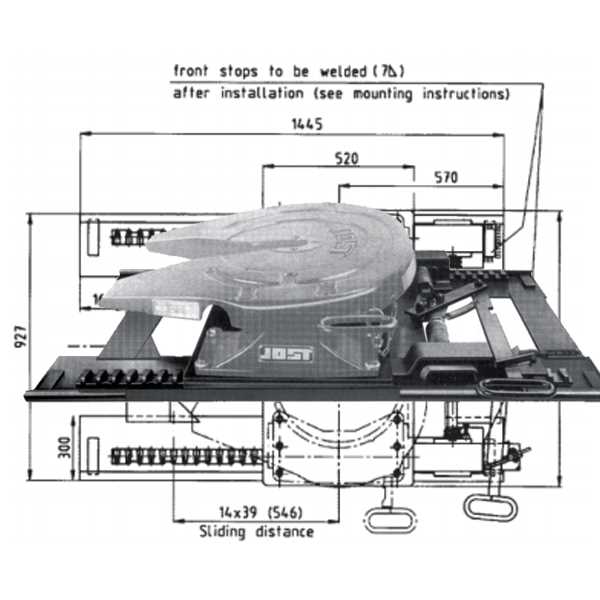

Installation Guide for Fifth Wheel Assembly

This section provides a comprehensive approach to assembling the pivotal connection device crucial for towing heavy loads. Proper installation ensures safety and efficiency during transportation, making it essential to follow guidelines closely.

Before beginning the installation, gather all necessary tools and components. Ensure you have a clean workspace to facilitate an organized assembly process.

| Step | Description |

|---|---|

| 1 | Position the base securely on the frame, ensuring it is level and stable. |

| 2 | Align the connecting components and insert the pins, confirming they are properly seated. |

| 3 | Tighten all bolts to the manufacturer’s specifications, verifying each connection. |

| 4 | Perform a thorough inspection to ensure everything is securely fastened and aligned. |

Following these steps will lead to a successful installation, paving the way for reliable performance on the road.

Safety Considerations in Fifth Wheel Use

Ensuring safety during the operation and maintenance of coupling mechanisms is crucial for preventing accidents and enhancing the overall efficiency of transport activities. Awareness of potential risks and adherence to best practices can significantly reduce hazards associated with these vital components.

Regular Inspections

Routine checks are essential to maintain optimal functionality. Inspecting the connection points, locking mechanisms, and structural integrity helps identify wear and tear before they lead to failures.

| Inspection Item | Frequency | Action Required |

|---|---|---|

| Locking Mechanism | Daily | Ensure proper engagement |

| Connection Points | Weekly | Check for signs of wear |

| Structural Integrity | Monthly | Inspect for cracks or damage |

Proper Usage Techniques

Utilizing appropriate methods during coupling and uncoupling is vital for minimizing risk. Always follow manufacturer guidelines and engage safety protocols to ensure secure attachment and detachment.

Upgrading Your Fifth Wheel Components

Enhancing the essential components of your towing apparatus can significantly improve performance, safety, and overall efficiency. This process not only involves replacing outdated elements but also selecting advanced alternatives that provide greater reliability and durability. Whether you are looking for improved handling or reduced wear, upgrading these vital mechanisms can lead to a smoother experience on the road.

Here are some key components to consider when planning your upgrades:

- Hitch Assembly: Upgrading to a heavier-duty hitch can provide better stability and weight distribution.

- Kingpin: Consider a reinforced kingpin for enhanced strength and to prevent wear over time.

- Coupler: A high-quality coupler can improve the connection and reduce play, leading to better towing control.

- Safety Chains: Investing in durable safety chains ensures an additional layer of security during transport.

- Shock Absorbers: Upgraded shock absorbers can enhance ride comfort and reduce stress on your towing setup.

When selecting replacements, always prioritize high-quality materials and trusted brands. Conduct thorough research to compare options and seek recommendations from experienced users. Implementing these enhancements will not only increase the longevity of your equipment but also contribute to safer and more efficient journeys.

Fifth Wheel Troubleshooting Techniques

Addressing issues related to coupling systems is essential for safe and efficient operation. Identifying symptoms and applying appropriate methods can enhance performance and extend longevity. This section outlines effective strategies to diagnose and resolve common concerns.

Common Issues and Symptoms

- Difficulty in coupling or uncoupling

- Excessive play or movement in the connection

- Unusual noises during operation

- Visible wear or damage on components

Troubleshooting Steps

- Inspect all components for wear and damage.

- Check for proper alignment during coupling.

- Lubricate moving parts as per manufacturer guidelines.

- Examine locking mechanisms for proper engagement.

- Test the system under various load conditions.

By systematically addressing these areas, operators can ensure optimal functionality and minimize the risk of failure.