Efficient management of water quality is crucial for ensuring the longevity and performance of plumbing systems. A variety of essential elements work together to maintain optimal functionality in these systems, allowing households to enjoy cleaner and softer water. Familiarizing oneself with these key components can enhance understanding and maintenance of the overall setup.

Each individual segment plays a significant role in the treatment process, from filtration to regeneration. Grasping the relationship between these parts can aid users in troubleshooting issues that may arise and provide insight into the proper care and handling of the entire assembly. An informed approach can lead to improved efficiency and effectiveness in maintaining high-quality water.

Additionally, recognizing the distinct functions of each component empowers users to make informed decisions when selecting replacements or upgrades. Understanding how these elements interact with one another is fundamental to achieving a well-functioning water treatment system. This knowledge not only supports operational efficiency but also contributes to the overall satisfaction of users.

Understanding the fundamental components of these systems is crucial for maintaining optimal performance and efficiency. Each element plays a vital role in the overall function, contributing to the effective treatment of the liquid resource. Familiarity with these key components allows users to troubleshoot issues and ensure longevity.

| Component | Function |

|---|---|

| Control Valve | Regulates the flow and distribution of the treated liquid. |

| Brine Tank | Houses the salt solution necessary for regeneration. |

| Media Tank | Contains the resin beads that remove impurities from the liquid. |

| Bypass Valve | Allows for bypassing the system when necessary. |

| Drain Line | Facilitates the removal of waste during regeneration cycles. |

Functionality of Each Component

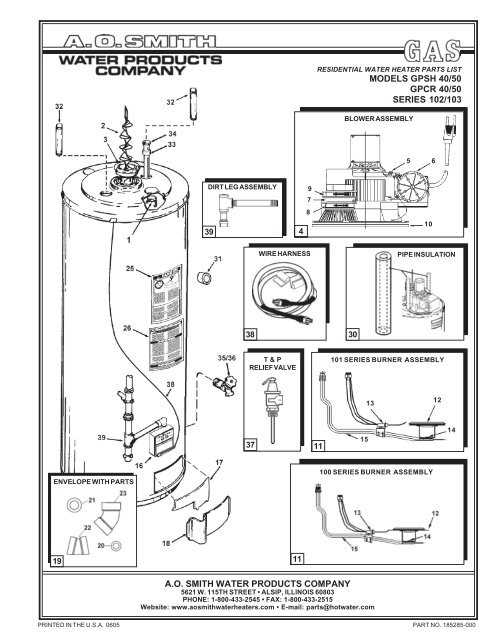

Understanding the role of each element within a conditioning system is essential for effective operation and maintenance. Each component contributes to the overall efficiency, ensuring optimal performance and longevity of the apparatus. By examining these elements, users can better appreciate their interconnectivity and functionality.

Key Elements of the System

The core elements include a mineral removal mechanism, a regeneration feature, and a monitoring system. The mineral removal mechanism is responsible for eliminating excess hardness in the supply, while the regeneration feature replenishes the system’s capabilities after usage. Additionally, the monitoring system tracks performance metrics, ensuring the device operates within specified parameters.

Supporting Features

Several supporting features enhance the functionality of the main components. These may include filters that capture impurities, valves that control flow, and control panels that allow for user interaction. Each of these aspects plays a vital role in the smooth operation of the entire setup, ultimately improving user experience and system reliability.

Common Issues with Water Softeners

Understanding the frequent challenges encountered with systems designed to reduce hardness in fluids is essential for efficient maintenance. These complications can arise from various factors, leading to diminished performance or failure in operation. Recognizing and addressing these issues promptly can ensure longevity and optimal functionality.

Clogged Resin Beds

One prevalent problem is the obstruction of resin beds. Over time, particles and contaminants can accumulate, hindering the system’s ability to effectively purify the liquid. Regular maintenance and cleaning can help mitigate this issue, restoring flow and efficiency.

Salt Bridges

Another common complication is the formation of salt bridges within the brine tank. This occurs when salt crystals harden and create a barrier, preventing the dissolution of salt necessary for the regeneration process. Periodic inspections and proper salt levels are crucial to avoid this situation.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the extended lifespan of your system. Regular maintenance can help prevent issues and enhance overall performance. By following a few straightforward guidelines, you can maximize the efficiency and reliability of your equipment.

Regular Inspections

Conducting routine checks can identify potential problems before they escalate. Focus on the following:

- Inspect for leaks and corrosion.

- Check the condition of filters and cartridges.

- Examine seals and connections for wear.

Cleaning and Flushing

Periodic cleaning is crucial to maintain optimal functionality. Consider these steps:

- Flush the system regularly to remove buildup.

- Clean components according to the manufacturer’s recommendations.

- Replace filters as needed to ensure clean operation.

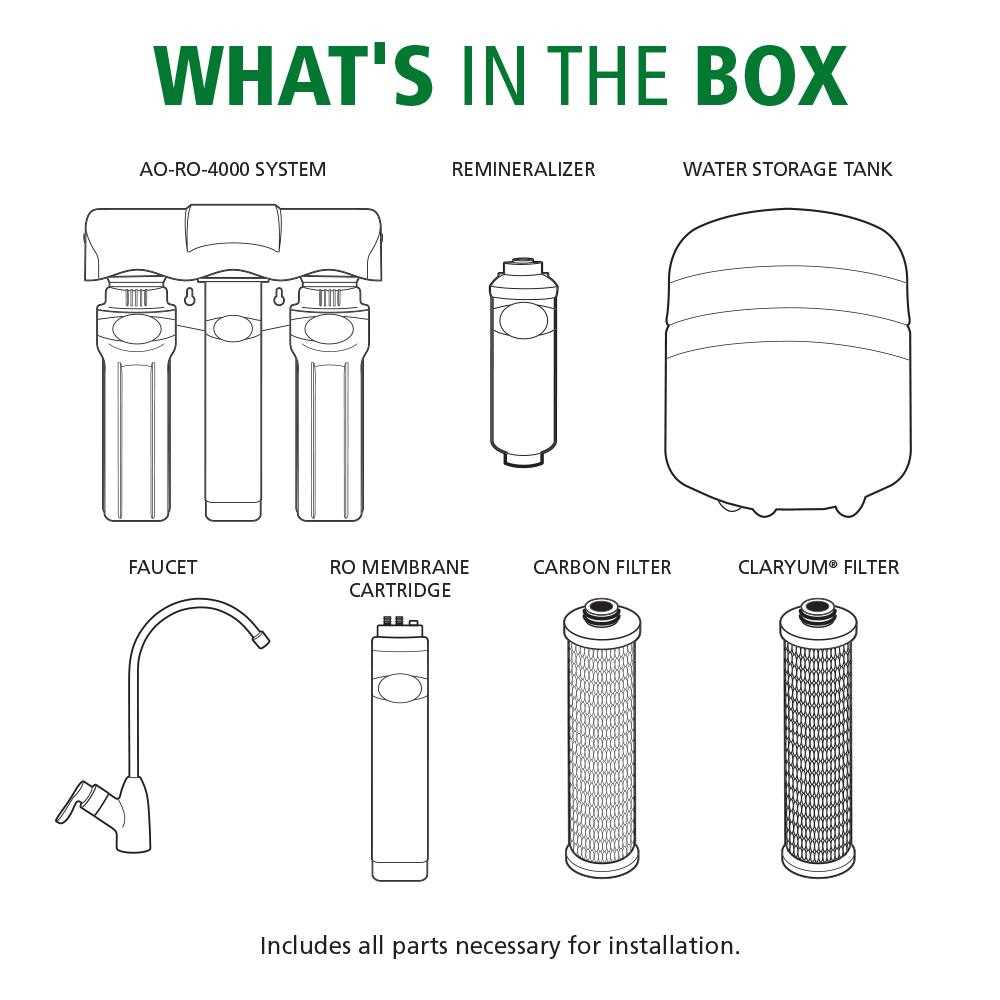

Replacement Components and Enhancements

In any system that requires optimal performance, the availability of high-quality components and potential upgrades is essential. Regular maintenance and timely replacements can significantly enhance functionality and extend the lifespan of the unit. This section delves into various options for replacing elements and implementing improvements that contribute to efficiency and reliability.

| Component | Description | Benefits |

|---|---|---|

| Resin Tank | Container that holds the resin media for ion exchange. | Improved ion exchange efficiency and capacity. |

| Brine Tank | Reservoir for salt used in the regeneration process. | Enhanced salt storage, reducing frequency of refills. |

| Control Valve | Regulates water flow and manages regeneration cycles. | Improved automation and control, enhancing user experience. |

| Bypass Valve | Allows for the diversion of water during maintenance. | Convenience during servicing without affecting water supply. |

| Replacement Media | Material that facilitates the ion exchange process. | Increased effectiveness in softening and filtration. |

Understanding the Flow of Water

The movement of liquid through a system is essential for its efficient operation. Grasping how this flow works provides insights into optimizing performance and enhancing functionality. This section explores the various components and mechanisms involved in directing the liquid, ensuring it travels smoothly from one point to another.

Key Components of Liquid Movement

Several elements play a crucial role in facilitating the seamless transit of fluid. Pumps are vital, as they generate the necessary pressure to propel the liquid through the entire system. Additionally, valves control the direction and volume of the flow, allowing for precise management of the distribution process. Filters and screens also contribute by removing impurities, ensuring the integrity of the liquid remains intact.

The Importance of Flow Direction

Understanding the direction in which the fluid travels is paramount for maintaining system efficiency. Proper alignment of pipes and connections minimizes resistance, enhancing the overall flow rate. Moreover, strategic placement of components ensures that any potential obstacles are circumvented, further optimizing performance. By comprehending these dynamics, users can make informed decisions regarding maintenance and upgrades.

Installation Process of Softener Parts

Proper assembly of the essential components is crucial for the effective functioning of the filtration system. This section outlines the systematic approach to integrate various elements, ensuring a seamless operation. Following the guidelines provided will help achieve optimal performance and longevity of the system.

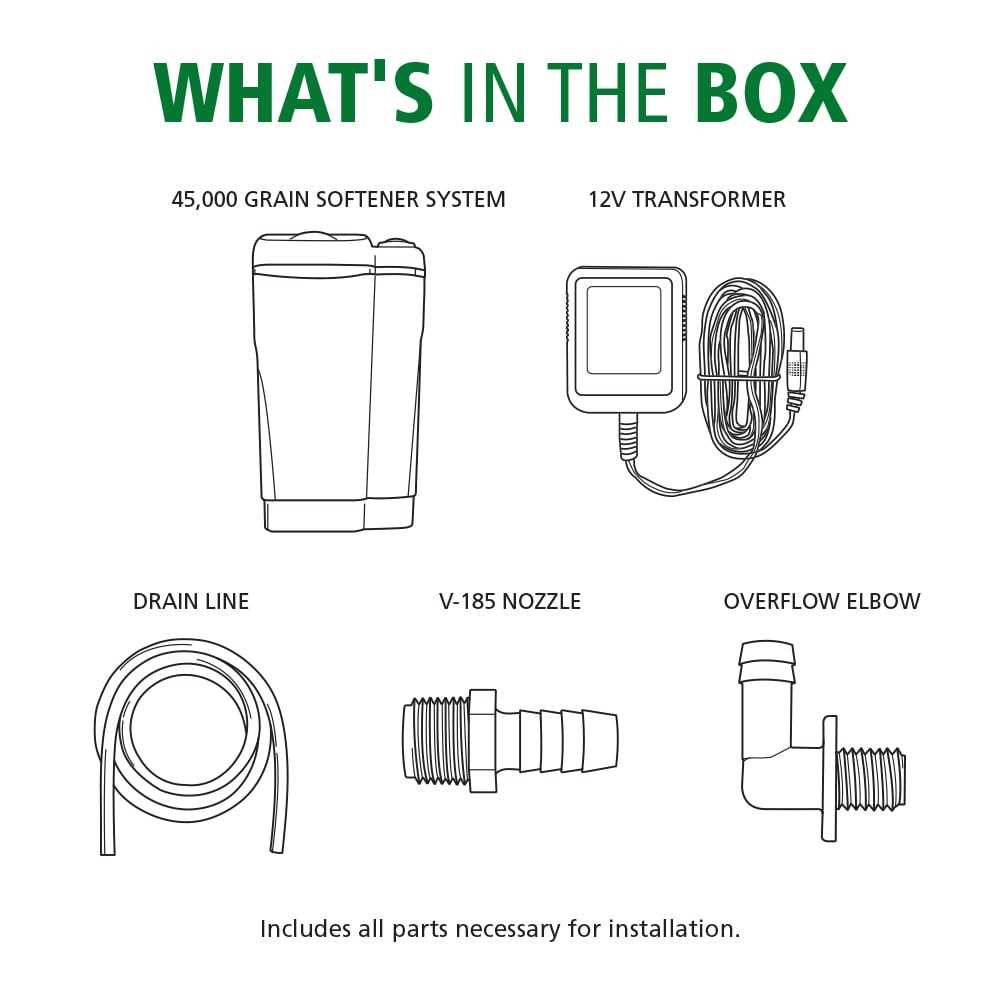

The installation begins with gathering all necessary tools and materials. It is essential to follow a step-by-step method to avoid complications later. Below is a table outlining the primary components and their corresponding installation steps.

| Component | Installation Steps |

|---|---|

| Brine Tank | Position the tank near the main unit and connect the inlet and outlet lines securely. |

| Control Valve | Attach the control valve to the resin container, ensuring proper sealing to prevent leaks. |

| Resin Bed | Fill the container with resin beads evenly, following the manufacturer’s recommended quantity. |

| Drain Line | Connect the drain line to the designated outlet, ensuring it is positioned correctly for efficient water flow. |

| Bypass Valve | Install the bypass valve to allow water to flow through the system without filtration if needed. |

Completing each step carefully will ensure that all components function together effectively, resulting in a reliable and efficient system.

Comparing Different Softener Models

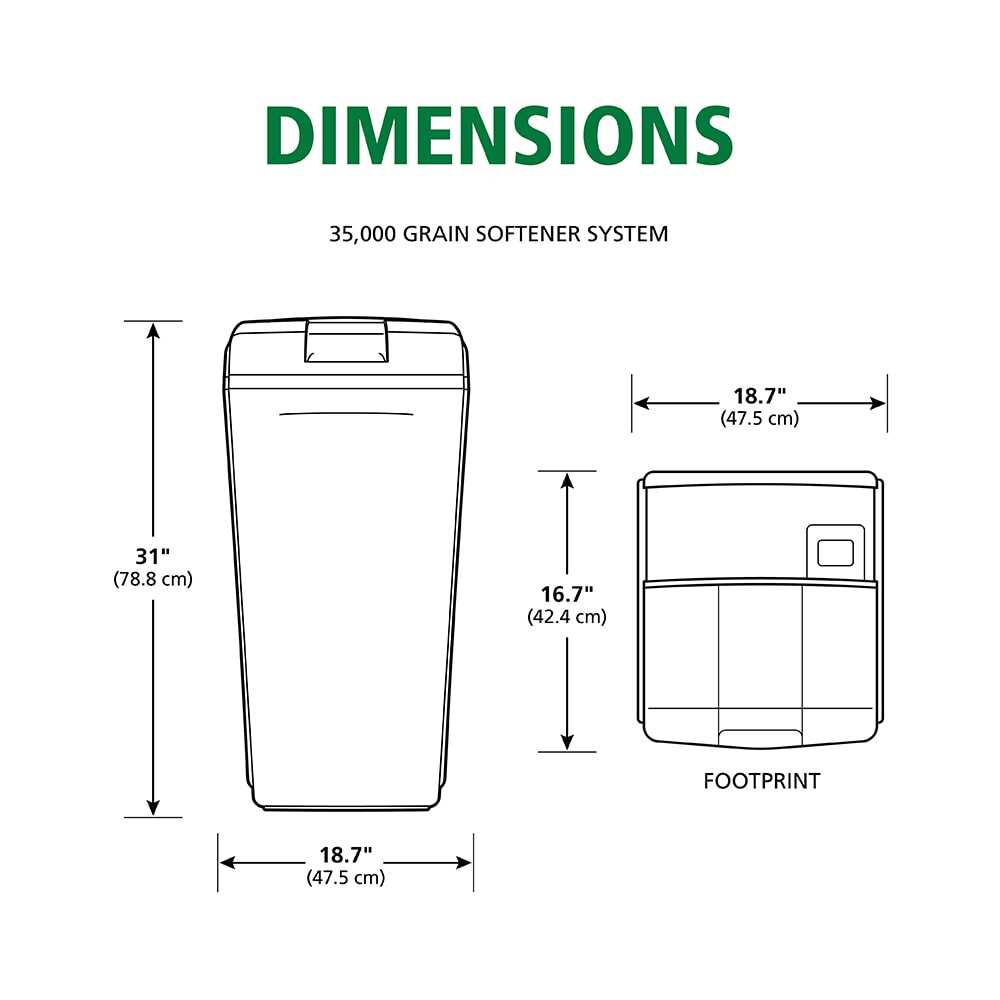

When evaluating various purification systems, it’s essential to understand the distinctions among the available options. Each model presents unique features and functionalities that cater to diverse needs. By examining these differences, users can make informed decisions to select the most suitable solution for their specific requirements.

Design and Efficiency: Different configurations often impact overall performance and efficiency. Some units may utilize advanced technology, enhancing their effectiveness in reducing impurities, while others may focus on simplicity and ease of use.

Capacity and Size: The scale of the system can also vary significantly between models. It’s crucial to assess the volume of treated fluid required for daily use, as larger units may provide a more continuous supply but take up more space. Conversely, compact designs might be ideal for limited areas but may require more frequent maintenance.

Maintenance Requirements: Each model comes with its maintenance demands. Some systems might need regular replenishment of materials or components, while others offer lower upkeep requirements, making them more convenient for users who prefer minimal involvement.

By considering these factors, individuals can navigate the myriad of options available, ensuring they choose the right solution for their purification needs.