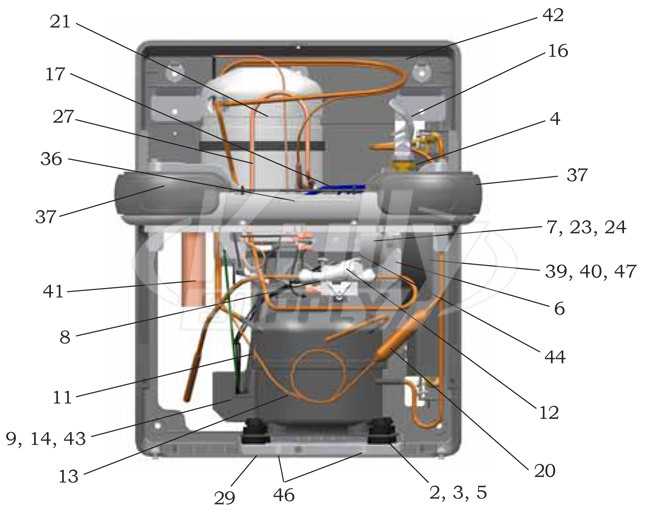

Understanding the essential elements and how they work together can greatly enhance both maintenance and functionality. This guide aims to break down each feature in detail, providing clear insight into the various mechanisms that ensure smooth operation. By exploring the major sections, you can easily identify which specific elements might require attention or replacement.

Through this exploration, you will gain a deeper understanding of how various sections interact to provide continuous and reliable service. It is important to familiarize yourself with the individual units to address any potential issues promptly and efficiently.

Whether you are performing routine maintenance or troubleshooting, this comprehensive look into the internal structure will provide you with the necessary knowledge to keep everything running smoothly. Each part plays a vital role, and being aware of their functions will help you make informed decisions when it comes to repairs or upgrades.

Understanding Halsey Taylor Fountains

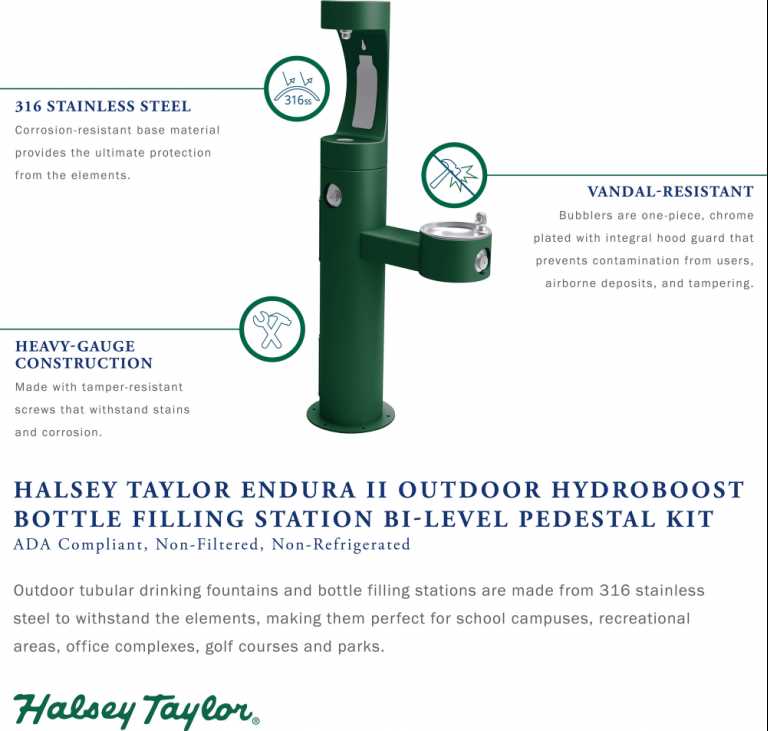

Innovative hydration systems have become a staple in public spaces, providing a convenient and eco-friendly solution for quenching thirst. These devices are engineered with precision to ensure durability, hygiene, and ease of maintenance. Their design caters to both high-traffic environments and accessibility needs, making them a versatile choice for indoor and outdoor areas. To ensure optimal performance, it’s important to familiarize oneself with the key elements and mechanisms that keep these systems running smoothly.

| Component | Function |

|---|---|

| Cooling Unit | Responsible for regulating the temperature of the liquid. |

| Filtration System | Removes impurities, ensuring the liquid remains clean and safe. |

| Nozzle | Dispenses the liquid in a smooth, controlled manner. |

| Push Button or Sensor | Activates the flow, allowing for hands-free or manual operation. |

Components of Water Fountain Systems

Understanding the core elements of these hydration units is essential for ensuring efficient operation and maintenance. Each system is composed of multiple interconnected components, all working together to provide a seamless experience for users. By breaking down these elements, one can better grasp how the unit functions and how to address potential issues that may arise.

Key Mechanical Elements

- Pumps: These are responsible for circulating liquid through the system, ensuring continuous flow.

- Filters: Installed to remove impurities, ensuring that the dispensed liquid remains clean and safe for consumption.

- Valves: These regulate pressure and control the flow rate, ensuring proper distribution within the system.

Additional System Components

- Dispensing Mechanism: Designed to allow easy access for users, providing a controlled release of liquid.

Importance of Regular Maintenance

Performing consistent upkeep on any device or equipment is crucial to ensure its longevity and optimal performance. When systems are regularly inspected and serviced, potential issues can be detected early, preventing costly repairs or replacements. This process also helps maintain efficiency, reducing energy consumption and extending the life of the system.

Key Benefits of Routine Care

By adhering to a regular maintenance schedule, users can avoid sudden malfunctions and downtime. Proper care minimizes wear and tear, which can significantly extend the operational lifespan of mechanical components. In addition, it enhances the overall functionality, ensuring that every part works as intended, providing reliable performance.

Maintenance Checklist

Task Frequency Benefit Inspect for visible damage Monthly Prevents deterioration of components Identifying Common Issues

Understanding the usual challenges that can occur with public hydration systems is essential for maintaining functionality. Many users encounter problems that could be easily addressed with basic troubleshooting, helping to restore normal operation quickly. Below are some typical concerns that may arise, along with potential solutions.

Low Flow Rate

A reduced flow rate often points to blockages or a malfunction in the internal mechanisms. This could be caused by debris in the filtration system or issues with the piping. Regular cleaning and inspection can prevent this, ensuring a consistent output.

Unusual Noises

Strange sounds coming from the unit might indicate a problem with the motor or pump. Vibrations or grinding noises can suggest wear and tear, which may require part replacement or mechanical adjustments to resolve the issue and prevent further damage.

Replacement Parts Overview

This section aims to provide a comprehensive insight into the essential components necessary for restoring functionality to hydration units. Understanding the various elements that make up these systems is crucial for effective maintenance and replacement. Each component plays a vital role in ensuring optimal performance and longevity.

Key Components and Their Functions

Among the primary elements are the valves, which regulate the flow of liquid, and the filters that ensure cleanliness and purity. Additionally, seals and gaskets are essential for preventing leaks, while control mechanisms manage the operation. Familiarity with these components enables users to identify issues quickly and replace parts efficiently.

Finding Suitable Replacements

When searching for appropriate replacements, consider the specifications of each unit. It is advisable to consult manufacturer guidelines or authorized dealers to ensure compatibility and quality. Investing in reliable components not only enhances the functionality of the system but also extends its lifespan.

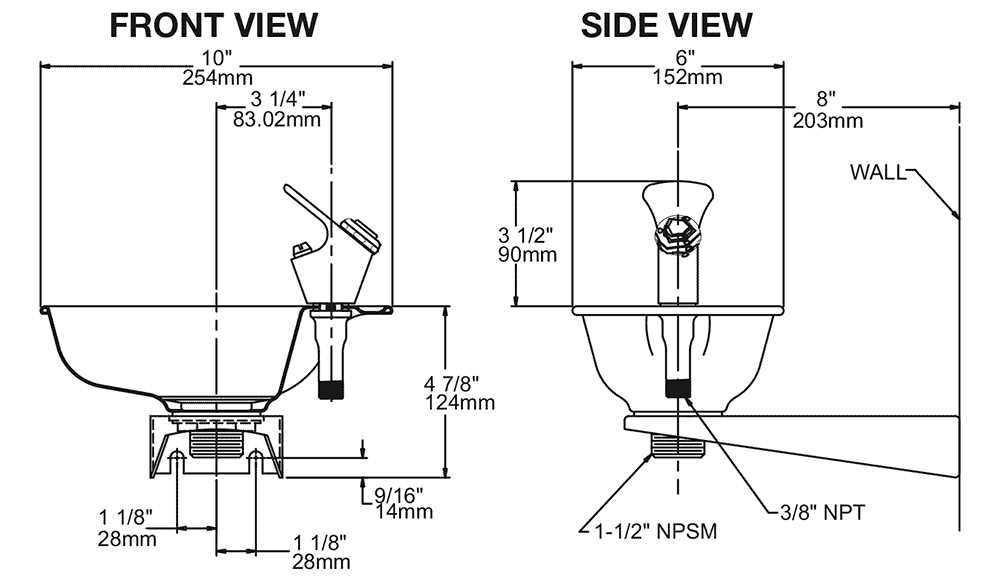

How to Read Diagrams

Understanding visual representations is essential for interpreting complex systems and components effectively. These illustrations provide a simplified view of intricate structures, enabling users to grasp the relationships and functions of various elements quickly. Mastering the ability to read such visuals can greatly enhance troubleshooting, assembly, and maintenance tasks.

Key Components to Identify

When examining an illustration, it’s crucial to recognize key elements that contribute to its overall function. Look for symbols, lines, and labels that indicate connections and functionalities. Familiarity with common conventions can significantly improve comprehension.

Reading Strategies

Approaching a visual representation can be made easier by following specific strategies:

- Start by identifying the overall structure and flow.

- Focus on individual elements and their labels for detailed information.

- Use legends or keys to clarify symbols used in the illustration.

Symbol Description Circle Represents a connection point or junction. Arrow Indicates direction of flow or movement. Square Denotes a component or functional unit. Tools Required for Repairs

When undertaking maintenance tasks, having the right instruments at your disposal is essential for ensuring a smooth and effective process. The appropriate tools not only enhance efficiency but also contribute to achieving high-quality results. Below is a list of essential equipment that may be needed for your repair endeavors.

Basic Hand Tools

Start with a set of basic hand tools that every technician should have. This typically includes screwdrivers of various sizes, pliers, and adjustable wrenches. These items are crucial for disassembling components and making necessary adjustments during the repair process.

Specialized Equipment

In addition to standard tools, some specialized instruments may be required. Wrenches and socket sets are vital for tightening or loosening specific fittings. Moreover, a multimeter can assist in diagnosing electrical issues effectively. Having these tools on hand will facilitate a comprehensive repair experience.

Safety Precautions During Maintenance

Ensuring safety during maintenance procedures is crucial for preventing accidents and injuries. Following proper guidelines can help mitigate risks associated with handling equipment and performing repairs. By adhering to safety protocols, technicians can create a secure environment while addressing any issues effectively.

Personal Protective Equipment (PPE)

Using appropriate personal protective gear is essential when conducting maintenance. This includes gloves, safety goggles, and masks to protect against debris and hazardous materials. Ensuring that all personnel wear the necessary equipment minimizes exposure to potential dangers during the maintenance process.

Tools and Equipment Safety

Before starting maintenance, it is vital to inspect all tools and equipment for any signs of wear or damage. Using faulty tools can lead to accidents and ineffective repairs. Additionally, keeping the workspace organized reduces the risk of tripping or misplacing tools, enhancing overall safety during the maintenance activities.

Finding Reliable Suppliers Online

Locating dependable vendors on the internet is crucial for ensuring the quality and availability of products and services. A thorough approach can help streamline the procurement process and foster long-term relationships with trustworthy providers. By utilizing various strategies, individuals and businesses can effectively identify reliable sources that meet their specific needs.

Here are some key factors to consider when searching for credible suppliers:

Criteria Description Reputation Check reviews and ratings from previous customers to gauge their experiences. Certifications Ensure the supplier holds relevant certifications and adheres to industry standards. Customer Support Assess the level of customer service available for inquiries and support. Pricing Compare prices to ensure they align with the quality of the products offered. Shipping Policies Review shipping options, costs, and delivery timelines for efficiency. By applying these criteria, you can enhance your search for suppliers that not only meet your requirements but also contribute positively to your overall experience.