The functionality of any mechanical system relies heavily on the seamless integration of its individual elements. Whether in residential or industrial settings, efficient fluid movement requires an understanding of how each component contributes to the overall operation. Knowing how these systems are designed allows users to maintain and repair them effectively, ensuring long-term performance and reliability.

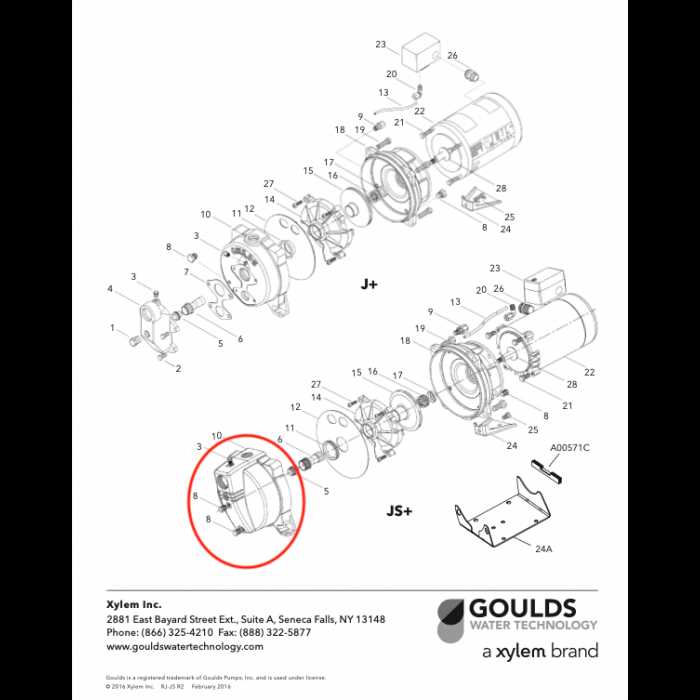

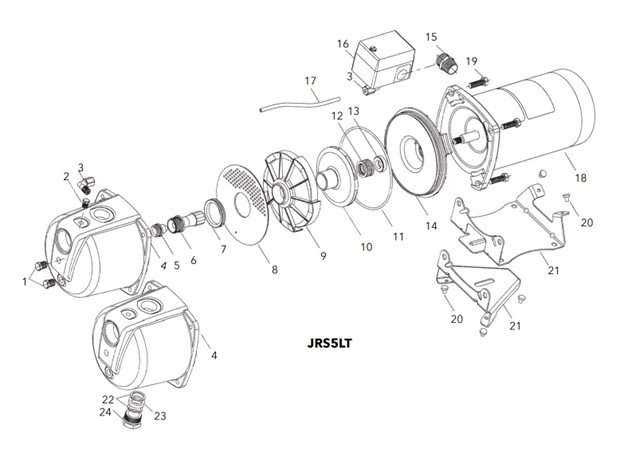

Mechanical assemblies used for fluid circulation are intricate. Every part is meticulously crafted to play a specific role in transferring liquids. Each element, whether small or large, must work in harmony to achieve optimal flow, pressure, and operation. Understanding the blueprint of these assemblies is essential for troubleshooting, upgrades, or routine maintenance.

From intricate internal mechanisms to external connectors, each piece plays an indispensable role. With the right knowledge of how they interlock, users can easily diagnose inefficiencies and replace faulty components. This guide aims to provide a clear, detailed breakdown of these structures to assist in better understanding their operation and upkeep.

Overview of Goulds Water Pump Components

This section provides a detailed explanation of the key elements that make up a typical fluid handling device. These mechanisms are designed to work together efficiently to transfer liquids, offering reliable and long-term performance in various applications. Understanding these elements and how they interact is essential for maintaining the functionality and durability of the system.

Main Structural Elements

Each system is composed of various structural components that support its functionality. The casing serves as the outer protective shell, designed to withstand internal pressure and external environmental conditions. Inside, a central rotating element drives the movement of fluids, ensuring consistent flow through the device. Seals and gaskets are also critical, preventing leaks and ensuring the integrity of the internal processes.

Internal Mechanisms

Within the system, several core mechanisms play crucial roles in controlling the flow and pressure of the liquid. The impeller is a rotating component that increases the velocity of the liquid, while the

Common Materials Used in Pump Construction

The components of fluid transport systems are built using a variety of materials to ensure durability, efficiency, and resistance to different environmental factors. Each material is chosen for specific properties that make it suitable for different applications, including resistance to corrosion, heat, and wear.

Metals

- Cast Iron: Known for its durability and cost-effectiveness, cast iron is commonly used for the external body due to its strength and moderate resistance to corrosion.

- Stainless Steel: Highly resistant to corrosion and chemicals, stainless steel is ideal for components that come into contact with aggressive fluids or high temperatures.

- Bronze: Often used in marine environments, bronze provides excellent corrosion resistance, especially in saltwater applications.

Non-Metallic Materials

- Thermoplastics: Lightweight

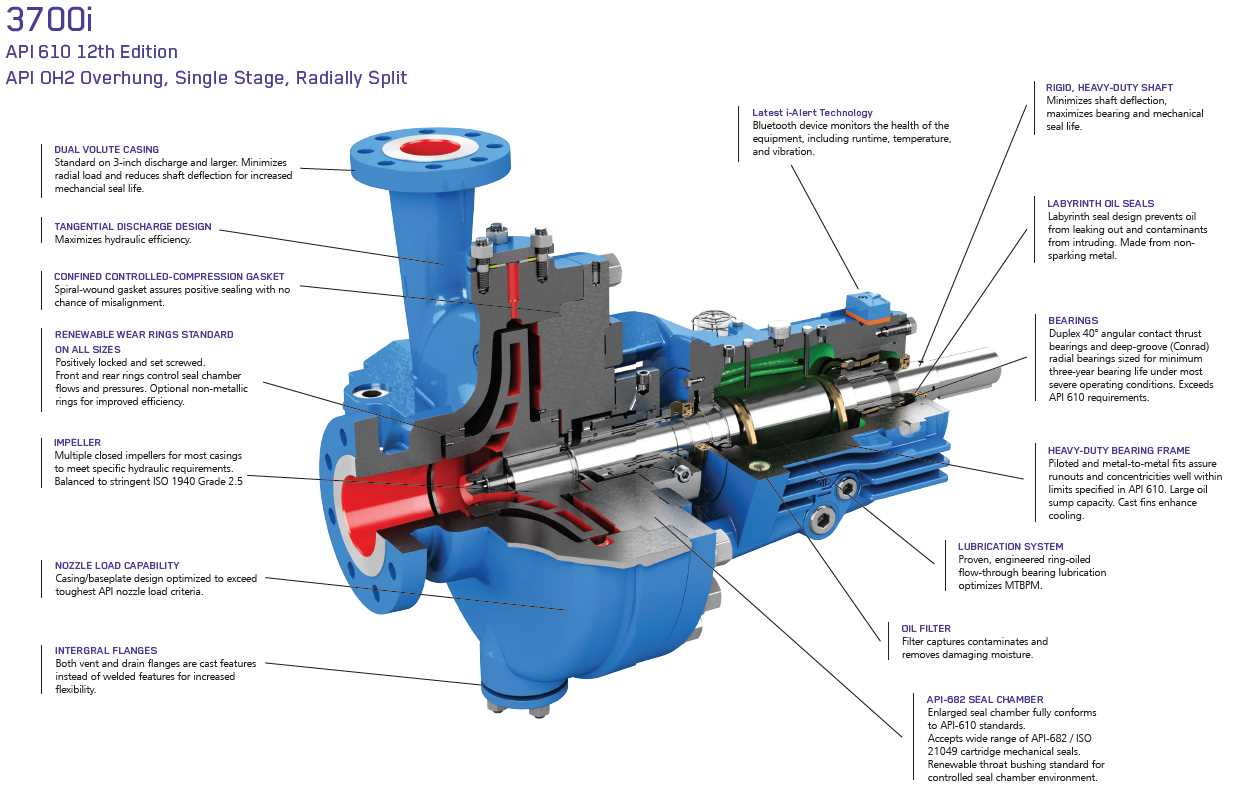

Key Features of Goulds Pump Designs

The designs of these mechanical devices are well-known for their durability, efficiency, and adaptability. They are engineered to perform under a wide range of conditions, ensuring that they meet diverse operational demands. These systems are built with precision, providing long-lasting solutions for various applications.

- Robust Construction: The materials used in crafting these devices are selected for their ability to withstand harsh environments, ensuring reliability over time.

- Energy Efficiency: Many of these systems are designed to minimize energy consumption, leading to cost savings and reduced environmental impact.

- Versatility: These devices are adaptable to different settings, making them suitable for both industrial and residential use.

- Low Maintenance Requirements: Advanced engineering minimizes the need for frequent servicing, contributing to lower operational costs.

- Advanced Fluid Dynamics: Optimized for fluid transfer, these machines ensure smooth operation, reducing wear and tear on components.

By integrating these key attributes, these mechani

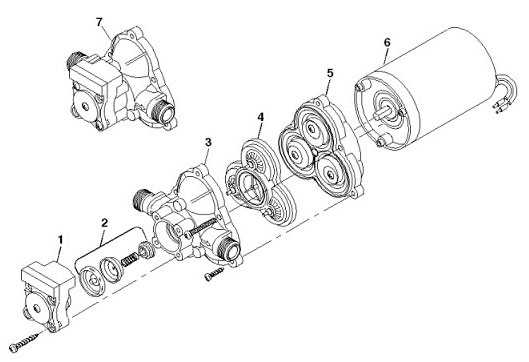

Understanding the Role of the Impeller

The impeller is a vital component in fluid-handling devices. It plays a crucial role in moving liquids efficiently by creating rotational energy, which is then transferred to the fluid. This motion allows the system to function effectively, maintaining a consistent flow and pressure.

How the Impeller Works

The impeller operates by spinning rapidly, drawing liquid into the device and pushing it out with increased velocity. This rotation helps to convert mechanical energy into kinetic energy, driving the liquid through the system. The design of the impeller, including its blades and structure, directly impacts its efficiency.

Impact on System Performance

An efficiently designed impeller ensures smooth fluid movement, reducing energy consumption and wear on the overall system. A well-maintained impeller can significantly improve operational longevity and reduce maintenance needs, making it a key focus for optimal performance.

Maintenance Tips for Seals and Bearings

Proper care of seals and bearings ensures the long-term reliability and smooth operation of mechanical systems. Regular inspection and maintenance are key to preventing premature wear, leaks, and costly repairs. Following the best practices for these components will extend their service life and improve the overall efficiency of the system.

Below are essential maintenance tips to help keep seals and bearings in optimal condition:

Task Description Frequency Visual Inspection Regularly check for signs of wear, damage, or leaks. Look for abnormal noise or vibration as an indicator of issues. Monthly Lubrication Ensure proper lubrication of bearings according to manufacturer guidelines to avoid friction and overheating. Every 6 months How the Motor Connects to the Pump

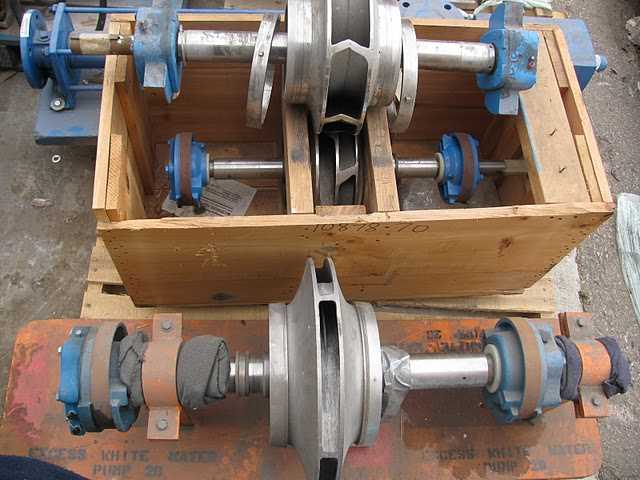

The connection between the motor and the mechanism is essential for efficient operation. The motor generates rotational energy, which is transmitted to the mechanism through a carefully designed coupling system. This interaction ensures smooth and reliable functioning, allowing the system to perform its intended task without any interruptions or inefficiencies.

The coupling system typically includes the following key components:

- Coupling shaft: This component links the motor to the mechanism, transmitting rotational force.

- Seals and gaskets: These ensure a secure connection, preventing leaks and maintaining pressure integrity.

- Bearings: Bearings are used to reduce friction, allowing for smooth rotation of the shaft and preventing wear and tear.

In some systems, the motor and mechanism are directly connected, while in others, an intermediate component, such as a flexible coupling, is used. The choice of connection type depends on the specific design and operational requirements.

Regular maintenance of these connection components is crucial to avoid misalignment and ensure long-lasting performance. It is important to check for any signs of wear, corrosion, or misalignment to prevent potential breakdowns and ensure optimal operation.

Troubleshooting Common Pump Malfunctions

Addressing issues that may arise with fluid-moving devices is essential for maintaining their efficiency and longevity. Recognizing symptoms early can help identify the root cause, ensuring effective remedies can be applied promptly. Common complications can stem from various factors, including mechanical wear, operational mishaps, or installation errors.

Identifying Symptoms

When experiencing inefficiencies, start by observing performance indicators. Unusual noises, vibrations, or fluctuations in output can signal underlying problems. Leaking fluid or irregular pressure readings may further indicate a malfunction. Thoroughly inspecting the unit can reveal signs of wear and tear or foreign debris that may be obstructing flow.

Common Solutions

Once the issue is identified, implementing basic maintenance procedures can often resolve the problem. Cleaning or replacing damaged seals and gaskets can prevent leaks, while ensuring all connections are secure can help restore optimal operation. Regularly checking for signs of corrosion and tightening loose components are also vital steps in maintaining functionality.

Exploring Different Pump Models and Sizes

When selecting an appropriate model for fluid transfer, understanding the various configurations and dimensions available is crucial. Each design serves specific requirements and operational contexts, making it essential to identify the best fit for your application. The differences in size and structure can significantly influence efficiency, performance, and suitability for particular tasks.

Submersible units are designed for deep installations, allowing them to operate underwater, while centrifugal units excel in handling larger volumes at lower pressures. Additionally, diaphragm models are favored for their ability to handle viscous substances and provide consistent flow rates. It’s vital to consider the operational environment, such as whether the unit will be exposed to corrosive materials or extreme temperatures, as this will affect longevity and reliability.

Moreover, understanding the flow rate and pressure capabilities of each model is key. Different applications may require varying capacities; hence, it’s beneficial to evaluate these specifications thoroughly. Selecting the right configuration not only enhances productivity but also reduces maintenance costs and extends the lifespan of the equipment.

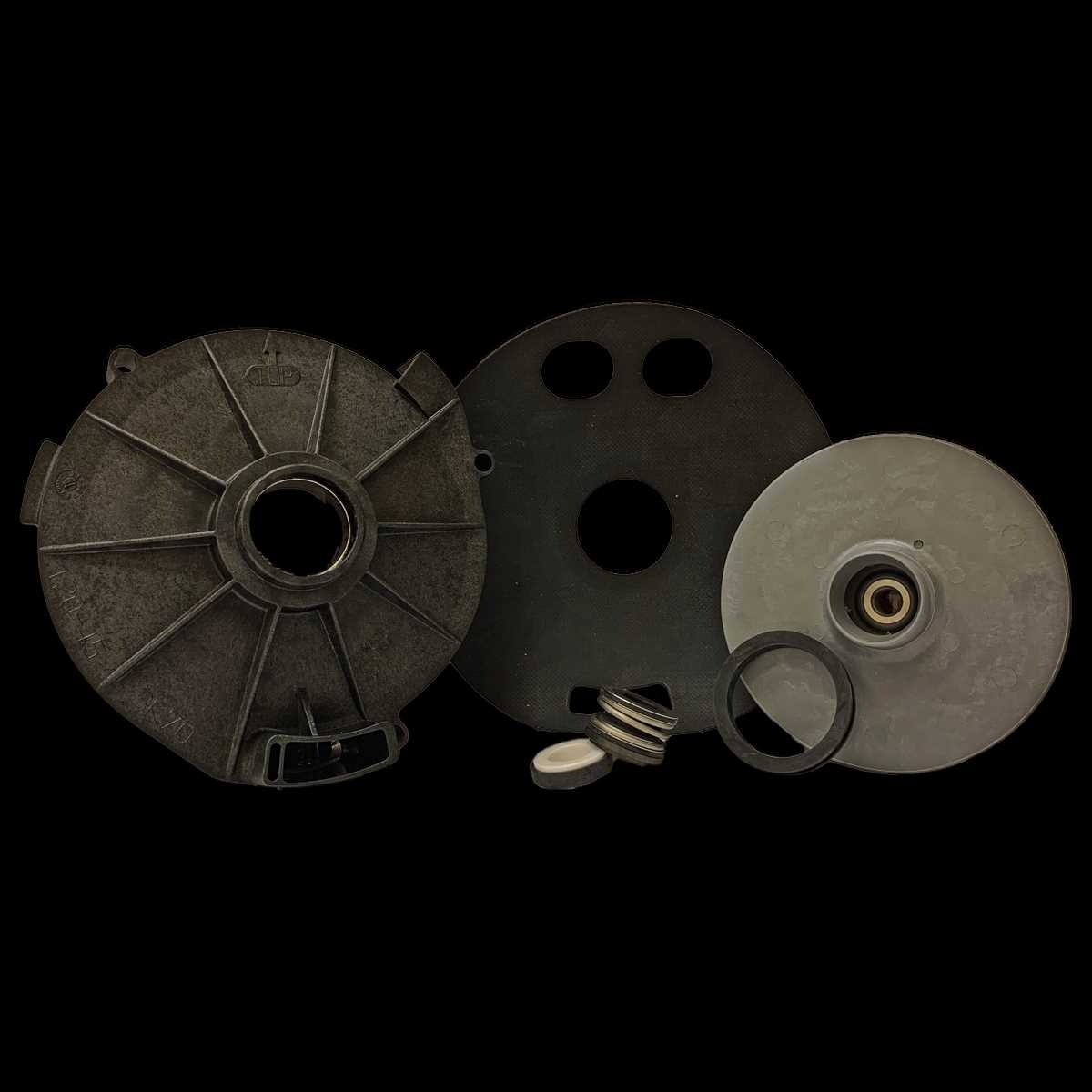

Choosing Replacement Parts for Optimal Performance

Selecting the right components for your machinery is crucial to ensure efficiency and longevity. Each element plays a vital role in the overall functionality, making it essential to understand the specific needs of your system. By opting for high-quality alternatives that meet compatibility standards, you can significantly enhance operational effectiveness.

Factors to Consider

When searching for suitable replacements, several key factors should be taken into account:

Factor Description Material Quality Choose durable materials that can withstand wear and tear over time. Compatibility Ensure that new components match specifications of your existing system. Manufacturer Reputation Select components from reputable manufacturers known for reliability. Benefits of Quality Components

Investing in superior replacements leads to enhanced performance and reduced maintenance costs. Reliable components not only improve efficiency but also extend the lifespan of your machinery, ultimately resulting in significant cost savings. Prioritize quality to ensure optimal functionality and peace of mind.