In the realm of hydration solutions, it’s essential to grasp the intricate assembly that ensures optimal functionality. Each element plays a crucial role in the seamless delivery of refreshment, contributing to both efficiency and user experience.

Exploring the anatomy of these systems reveals how various sections interact to provide reliable service. From the reservoir to the delivery mechanism, understanding each component enhances our appreciation of its design and purpose.

By delving into the specifics, users can identify potential issues, enabling effective maintenance and troubleshooting. Ultimately, this knowledge empowers individuals to maximize the lifespan and performance of their hydration units.

Understanding Water Dispenser Components

Every appliance designed to provide hydration relies on a series of interconnected elements that facilitate its operation. Grasping how these components function together can enhance user experience and inform maintenance practices. This section delves into the key constituents, their roles, and how they contribute to overall performance.

Main Elements

- Reservoir: The container that holds the liquid, ensuring a steady supply.

- Cooling System: A mechanism that lowers the temperature of the fluid for refreshing consumption.

- Heating Element: Designed to warm liquids, making them suitable for various beverages.

- Tap or Spout: The outlet through which the liquid is dispensed, often featuring a user-friendly mechanism.

- Control Panel: The interface that allows users to operate the device, including temperature settings and power functions.

Additional Features

- Filtration System: Enhances taste and quality by removing impurities.

- Drip Tray: Collects excess liquid, preventing spills and maintaining cleanliness.

- Base: Provides stability and houses essential internal components.

- Indicators: Visual cues that alert users about temperature settings and refill status.

By understanding these elements, users can make informed choices, ensuring efficient and effective usage of their hydration systems.

Key Parts of a Water Dispenser

Understanding the essential components of this appliance is crucial for proper functioning and maintenance. Each element plays a significant role in delivering hydration efficiently, ensuring both convenience and reliability for users.

The upper reservoir is vital for storing liquid, while the lower container collects any unused or excess fluid. The cooling mechanism is responsible for regulating temperature, providing refreshing drinks on demand. Additionally, the tap or spout allows for easy access, facilitating smooth pouring without spills. Lastly, the control panel enables users to adjust settings, enhancing the overall experience.

How Water Dispensers Function

The operation of a hydration unit revolves around a series of interconnected mechanisms designed to deliver refreshing liquids efficiently. These devices often consist of a reservoir, a cooling or heating system, and a user interface, all working harmoniously to ensure optimal functionality. Understanding the inner workings provides insight into how these units meet the demands for chilled or heated refreshments.

Cooling and Heating Mechanisms

At the core of many hydration units are specialized components that either cool or heat the liquid. Typically, a refrigerant circulates through coils, absorbing heat and lowering the temperature of the fluid. Conversely, for heated beverages, a heating element warms the liquid through conduction. This dual capability enables users to enjoy their preferred temperature.

User Interaction and Dispensing

When a user engages with the control interface, a series of sensors and switches activate the desired function. The mechanism then releases the selected amount of liquid through a tap or spout, ensuring ease of access. Some advanced models even feature programmable settings for personalized experiences. This blend of technology and design ensures that hydration needs are met promptly and effectively.

Importance of Maintenance and Care

Regular upkeep and attention to your hydration equipment are crucial for ensuring optimal performance and longevity. Neglecting these practices can lead to inefficiencies and potential health risks. A consistent maintenance routine not only enhances functionality but also preserves the quality of the liquid dispensed.

Benefits of Regular Upkeep

Maintaining your hydration unit has several advantages, including improved efficiency, reduced energy consumption, and a longer operational lifespan. Furthermore, proper care minimizes the risk of contaminants and ensures that the served product remains safe and pleasant.

Key Maintenance Tasks

| Task | Frequency | Description |

|---|---|---|

| Cleaning | Weekly | Wipe down surfaces and interior components to prevent buildup. |

| Filter Replacement | Every 6 months | Change filters to ensure purity and taste. |

| Inspect Seals | Monthly | Check for wear and tear to avoid leaks and inefficiencies. |

| Service Check | Annually | Professional inspection to address any potential issues. |

Common Issues with Dispenser Parts

Many users encounter various challenges when it comes to the components of their hydration units. Understanding these common problems can help in maintaining optimal functionality and prolonging the lifespan of the equipment. Here, we explore some prevalent issues and their potential solutions.

Frequent Challenges

- Leaks: A common occurrence that can stem from worn seals or improper assembly.

- Temperature Fluctuations: Inconsistent temperatures may indicate a malfunctioning cooling system or faulty thermostat.

- No Dispensing: This issue can arise from clogged tubes or a blocked outlet.

- Noisy Operation: Unusual sounds may suggest loose components or mechanical failure.

Maintenance Tips

- Regularly inspect seals and gaskets for wear and replace them as necessary.

- Clean the internal pathways periodically to prevent clogs.

- Check connections and tighten any loose fittings to avoid leaks.

- Consult the manufacturer’s guidelines for troubleshooting specific issues.

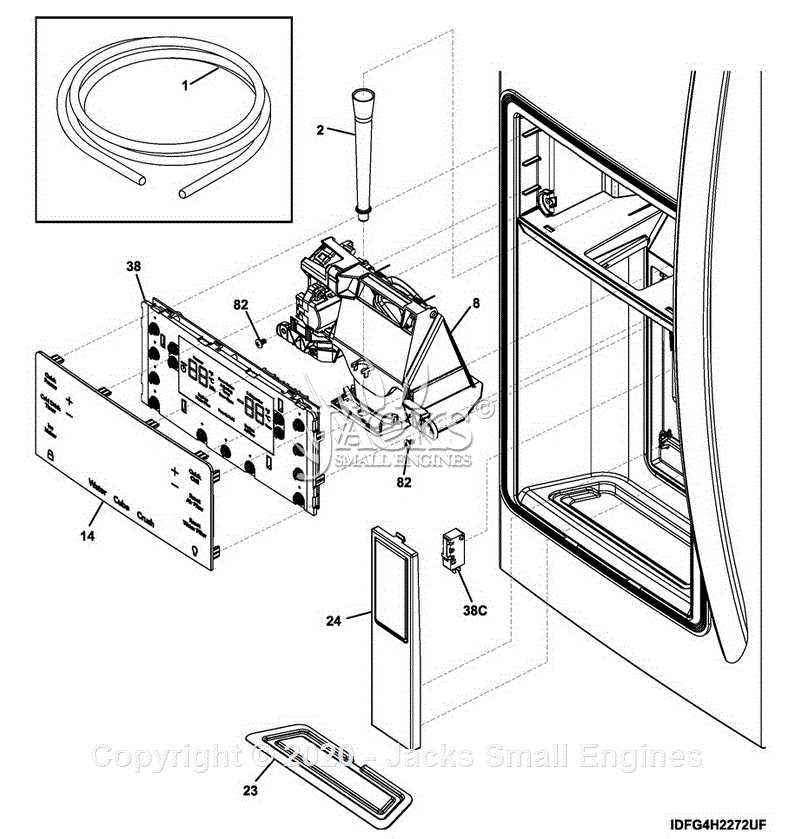

Identifying Each Component’s Role

Understanding the functionality of each element within a hydration appliance is essential for effective use and maintenance. Each component contributes uniquely to the overall operation, ensuring optimal performance and reliability. By recognizing the significance of every part, users can troubleshoot issues more effectively and enhance their experience.

Key Elements and Their Functions

Reservoir: This crucial section holds the liquid and is often designed to accommodate various volumes, providing convenience based on user needs.

Tap Mechanism: This component facilitates the controlled release of the liquid, allowing users to dispense just the right amount with ease. Its design often ensures smooth operation and minimizes spillage.

Supporting Features

Cooling System: This feature is responsible for maintaining a refreshing temperature, ensuring that the fluid remains at a desirable level for consumption.

Filtration Unit: Integral for enhancing the quality of the liquid, this unit removes impurities, ensuring a cleaner and safer drinking experience.

Replacing Water Dispenser Parts

Maintaining a reliable hydration unit often requires timely replacements of essential components to ensure optimal functionality. Understanding the various elements involved and how to effectively substitute them can enhance performance and extend the lifespan of the device.

Identifying Components for Replacement

Before beginning the replacement process, it’s crucial to identify which elements are malfunctioning. Common issues may arise from the reservoir, valves, or tubing, all of which play a significant role in the unit’s operation. Assessing these areas can help pinpoint specific needs.

Steps to Replace Key Elements

To proceed with the substitution, first, ensure the unit is unplugged for safety. Carefully detach the faulty element, following the manufacturer’s guidelines. Once removed, install the new component, securing it firmly in place. Finally, reconnect the unit and perform a test to confirm proper functionality.

Safety Tips for Repairs and Maintenance

Ensuring safety during repair and upkeep activities is crucial to prevent accidents and promote a secure working environment. Adhering to proper guidelines can significantly minimize risks associated with these tasks.

- Always disconnect power sources before beginning any maintenance work.

- Use appropriate personal protective equipment (PPE), including gloves and safety glasses.

- Keep the workspace well-ventilated to avoid inhaling harmful fumes.

- Familiarize yourself with the tools and materials required for the job.

Moreover, follow these best practices to enhance safety:

- Read the manufacturer’s manual for specific instructions and safety recommendations.

- Avoid working alone, especially during complex tasks.

- Inspect tools and equipment for wear or damage before use.

- Keep emergency contact numbers readily available in case of accidents.

By implementing these precautions, you can ensure a safer environment while effectively maintaining your equipment.