The intricate assembly of a particular gearbox plays a vital role in ensuring efficient power transfer within a vehicle. Understanding the various elements involved is essential for both enthusiasts and professionals alike. Each component contributes to the overall functionality, making it crucial to grasp their respective roles and interconnections.

In this section, we will explore the essential constituents of this gearbox, highlighting their arrangement and significance. By gaining insight into how these elements interact, readers can better appreciate the complexities of automotive engineering. This knowledge serves as a foundation for anyone looking to engage in maintenance, repair, or enhancement of the system.

As we delve deeper, we will outline the individual elements and their functions. Recognizing the importance of each part aids in diagnosing issues and implementing effective solutions. Emphasizing clarity and detail, this exploration aims to provide a comprehensive understanding of the assembly, enabling informed decisions and fostering a greater appreciation for automotive craftsmanship.

The discussion centers around a crucial component of modern vehicles, which plays an essential role in power transfer and vehicle performance. Understanding its structure and functionality is vital for both enthusiasts and professionals alike. This section provides an overview of the elements that comprise this sophisticated mechanism, shedding light on their interconnections and significance in the overall operation.

The primary aim is to equip readers with a foundational understanding of how this assembly operates, highlighting its complexity and the importance of each element. The following points will guide the exploration:

- Basic Functionality: An outline of how this component facilitates vehicle movement.

- Key Components: A look at the essential elements that make up the system.

- Construction Materials: An examination of the materials used in building these elements for durability.

- Common Issues: An overview of typical problems faced and their impact on performance.

- Maintenance Tips: Recommendations for keeping the assembly in optimal condition.

- Replacement Parts: Information on sourcing quality components when replacements are necessary.

- Performance Upgrades: Suggestions for enhancing the efficiency of the system.

- Conclusion: A summary emphasizing the importance of understanding this assembly for effective maintenance and upgrades.

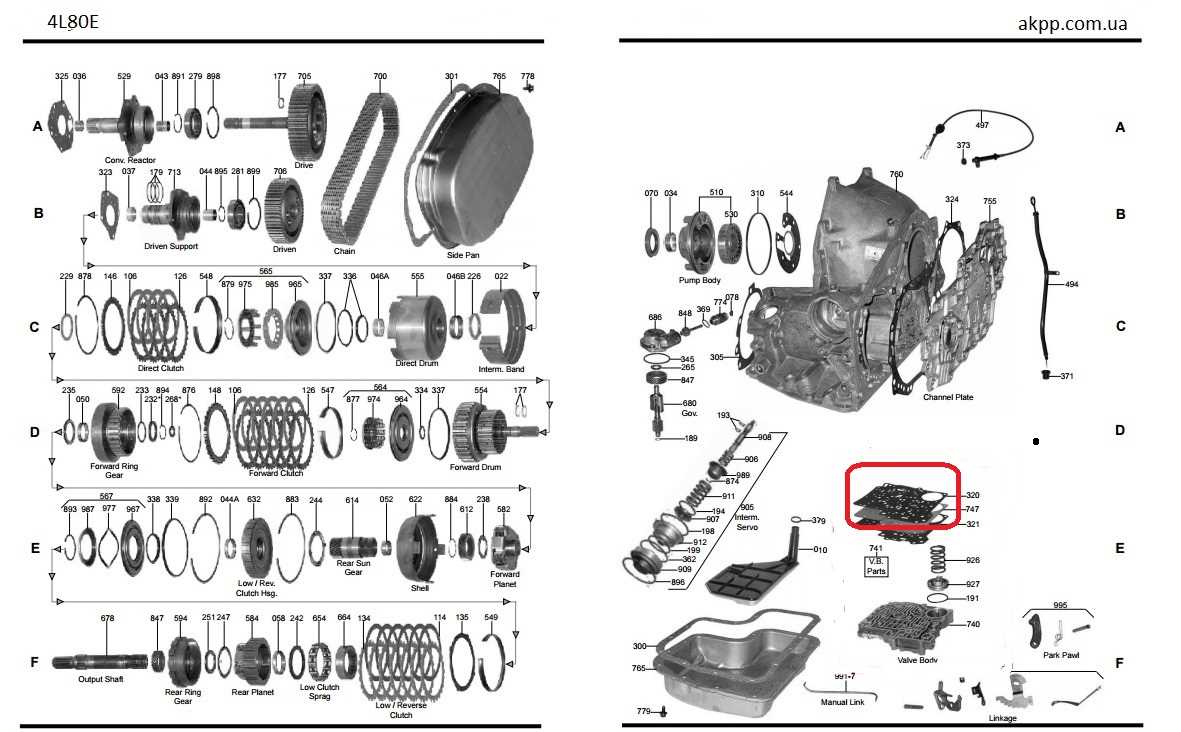

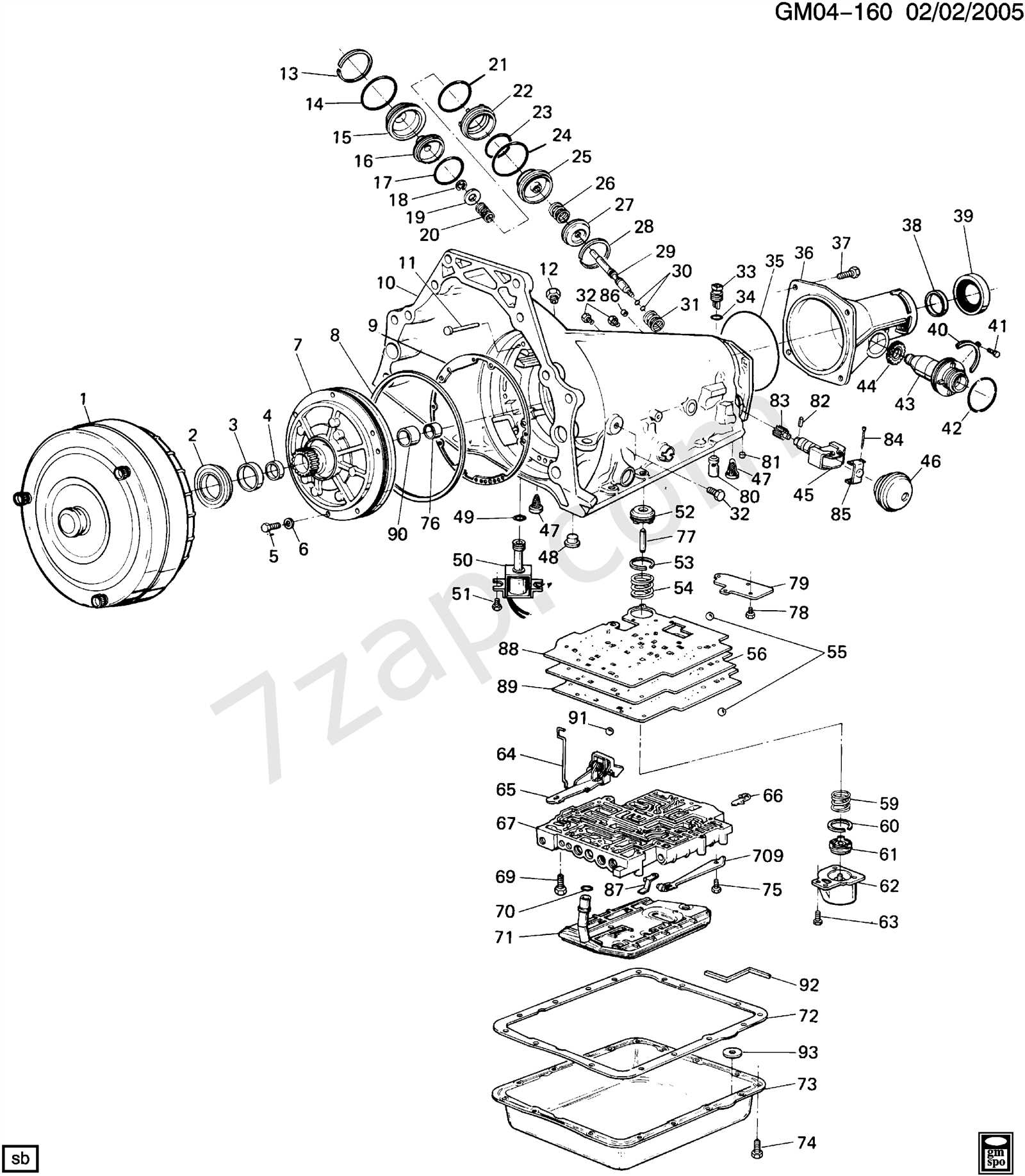

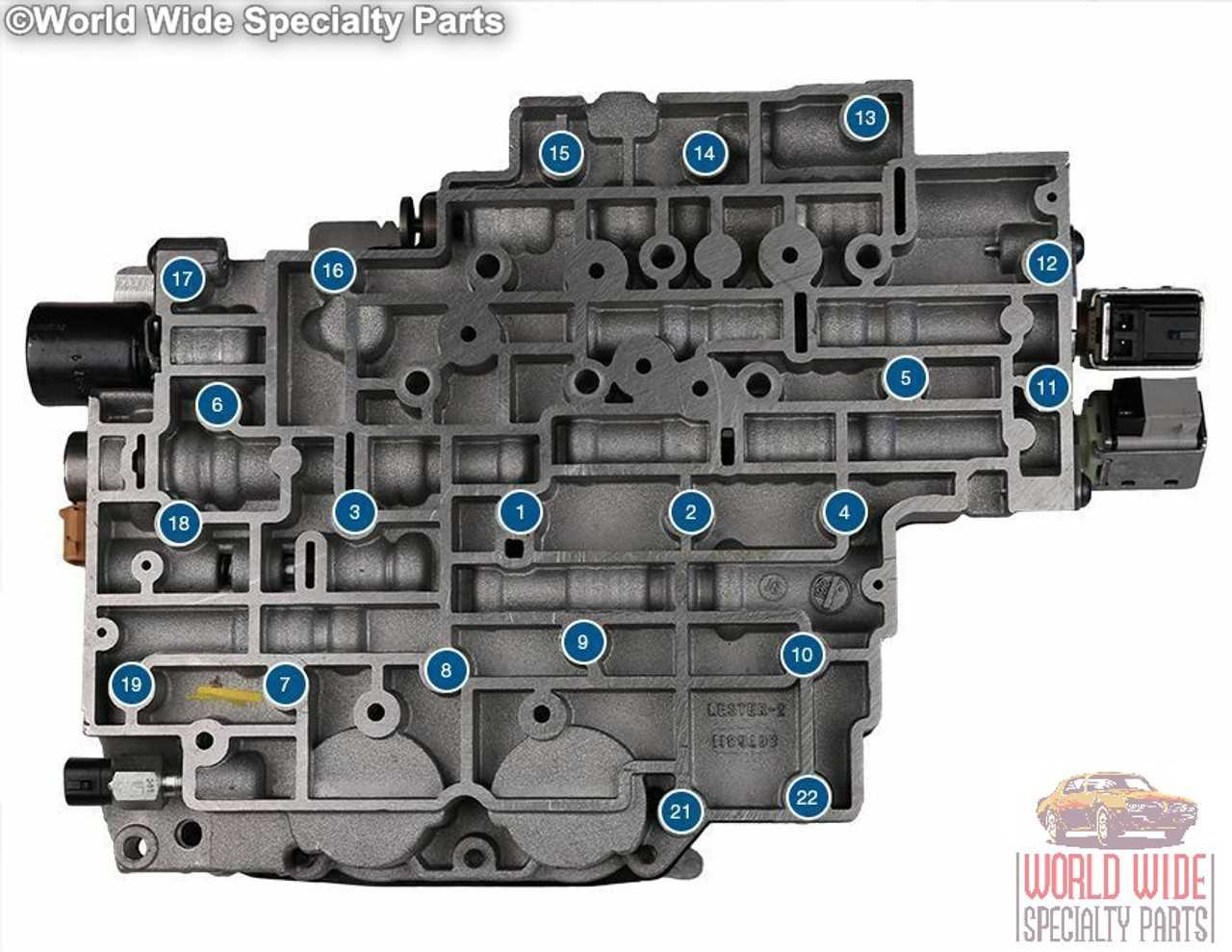

Key Components of the 4L80E

This section delves into the essential elements that contribute to the functionality and efficiency of a specific automatic gearbox. Understanding these components is crucial for maintenance, repair, and performance enhancement. Each part plays a vital role in ensuring smooth operation and reliability over time.

Clutch Packs

Clutch packs are integral to the shifting mechanism, allowing for seamless transitions between gears. These assemblies consist of multiple friction discs that engage and disengage based on hydraulic pressure, ensuring optimal power transfer from the engine to the wheels.

Planetary Gear Sets

The planetary gear sets are responsible for providing various gear ratios, facilitating acceleration and deceleration. This intricate arrangement of gears allows the system to adapt to different driving conditions, enhancing overall performance and driving experience.

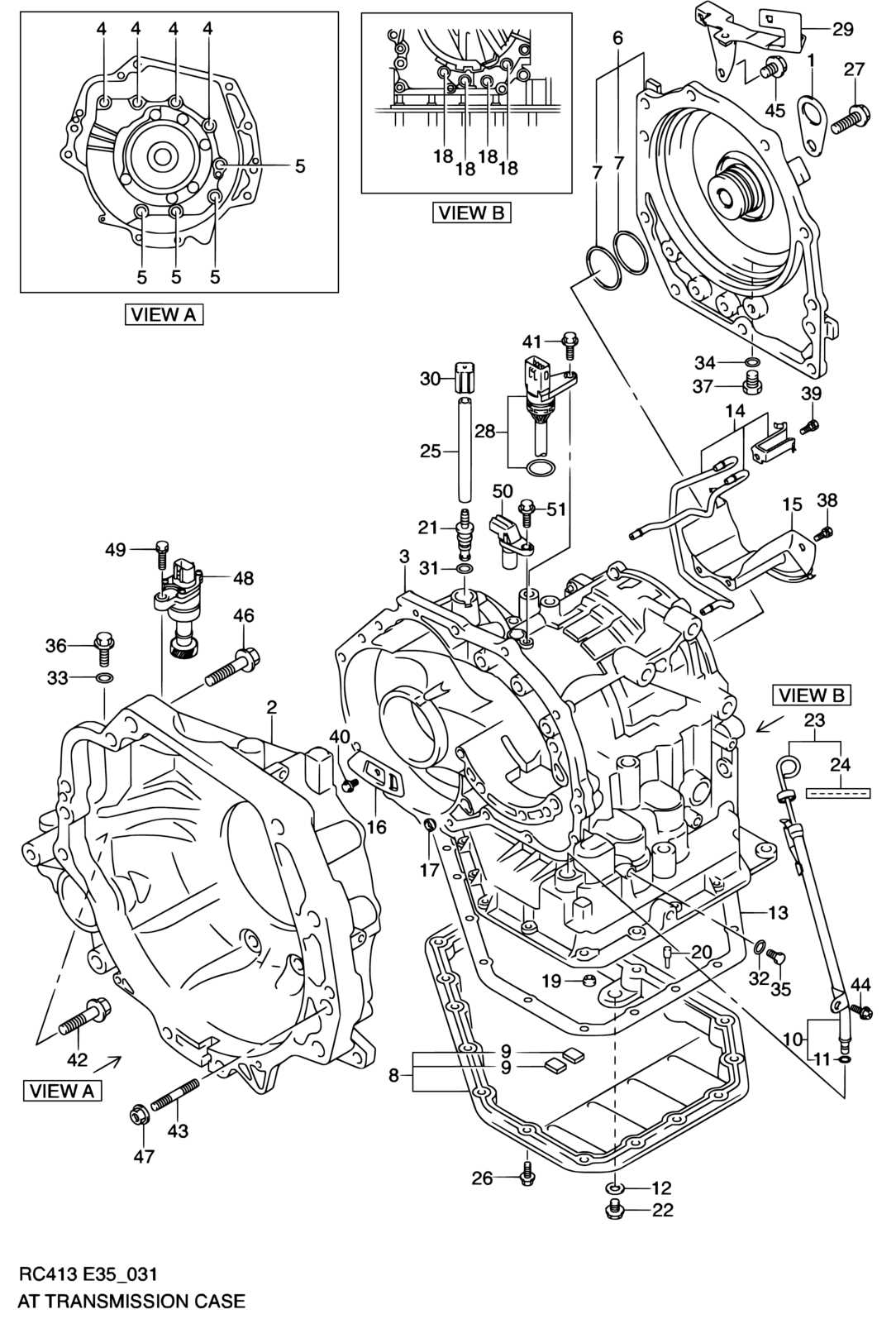

Understanding the Transmission Diagram

Comprehending the layout of mechanical systems is essential for effective maintenance and troubleshooting. A well-structured representation provides insights into the various elements that contribute to the overall functionality of the mechanism.

In this section, we will explore key aspects that help decode these intricate layouts:

- Components Overview: Each element serves a specific role, ensuring smooth operation. Identifying these parts is crucial for understanding how they interact.

- Flow of Motion: Recognizing how power transfers from one part to another can help in diagnosing issues and enhancing performance.

- Assembly Arrangement: The layout reveals how components fit together, which is vital for repairs and replacements.

By grasping these concepts, individuals can gain a deeper appreciation for the mechanics involved and improve their skills in handling repairs and modifications.

Functionality of Major Parts

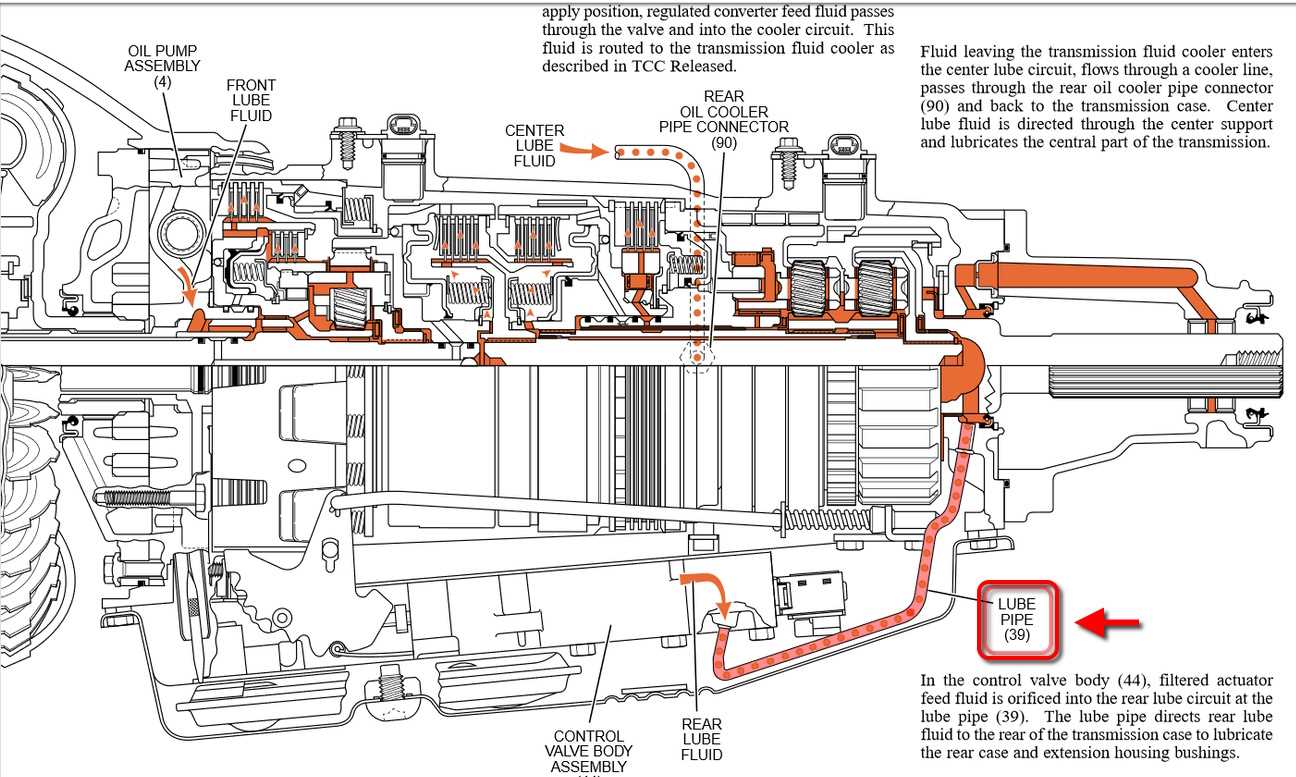

The components of an automatic shifting mechanism play a crucial role in ensuring optimal performance and efficiency of the vehicle’s drivetrain. Each element works in harmony to facilitate smooth gear changes and enhance the overall driving experience.

Gear Set is fundamental in determining the speed and torque characteristics of the system. It enables the transfer of power from the engine to the wheels, adjusting ratios as needed to match driving conditions.

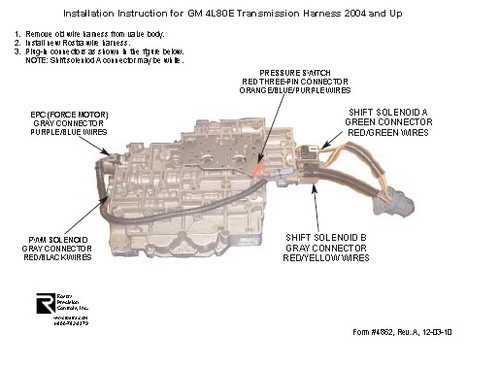

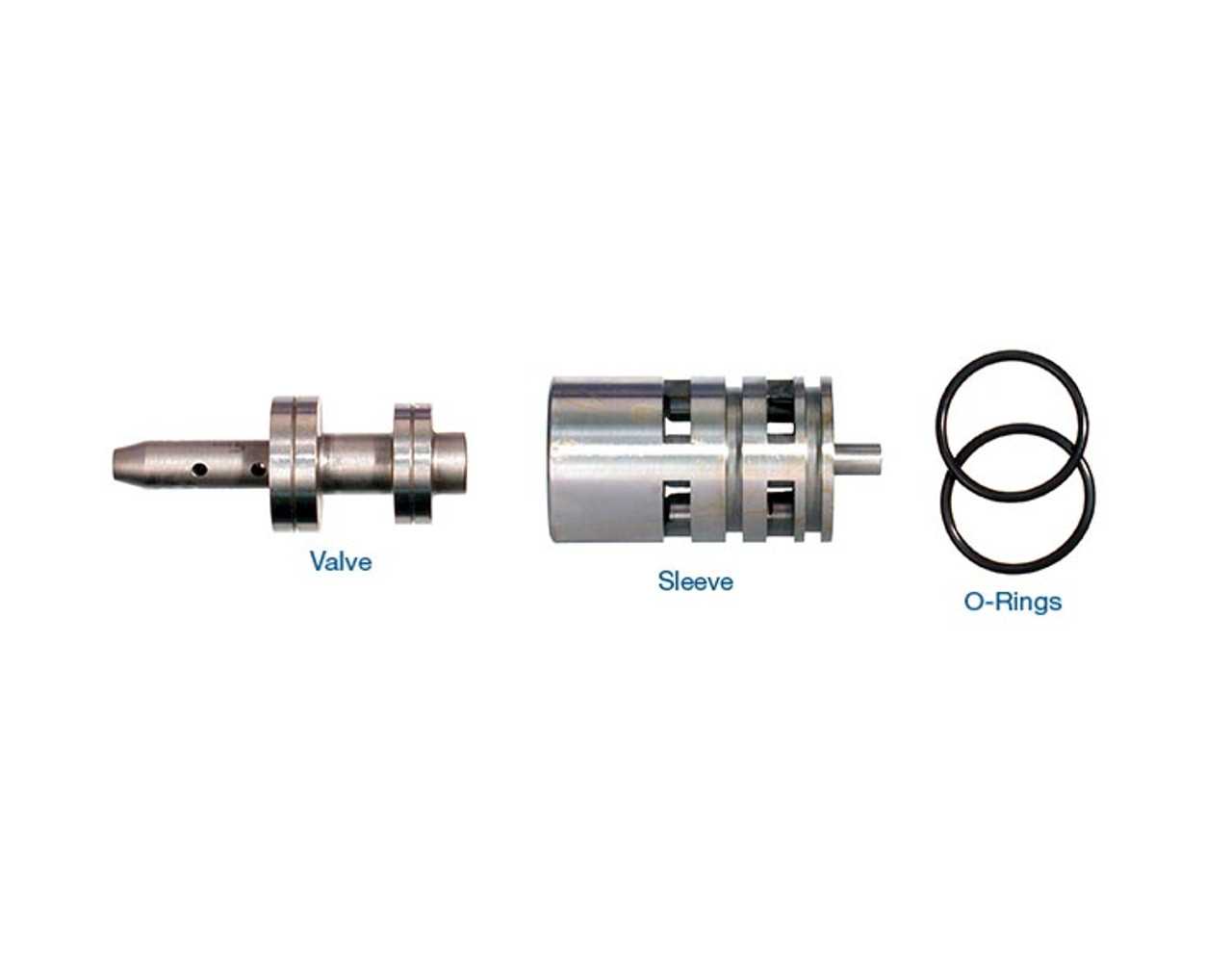

Hydraulic System utilizes pressurized fluid to operate various mechanisms, including clutches and bands. This system is essential for engaging and disengaging different gear ratios, ensuring that transitions are seamless and responsive.

Control Module acts as the brain of the system, processing input from various sensors and making real-time adjustments to optimize performance. It monitors factors such as vehicle speed and engine load, ensuring that shifting occurs at the most advantageous moments.

Clutch Packs are critical for the engagement and disengagement of different gears. They enable smooth transitions and prevent slippage, contributing to the overall reliability of the drivetrain.

Planetary Gear System provides multiple gear ratios in a compact design, allowing for efficient power distribution. Its unique arrangement allows for both forward and reverse motion, making it a vital component of the assembly.

Common Issues with 4L80E Components

Various mechanical and hydraulic components in automatic gear systems can encounter issues over time, leading to performance problems and reduced efficiency. Understanding these common challenges can aid in timely maintenance and repairs, ensuring optimal functionality.

Worn Clutch Packs: Over time, clutch assemblies may wear down, resulting in slipping or harsh shifting. This deterioration can significantly affect acceleration and overall driving experience.

Leaking Seals: Seals play a crucial role in preventing fluid leaks. If they become worn or damaged, it can lead to fluid loss, causing inadequate lubrication and overheating, which further exacerbates component wear.

Faulty Sensors: Sensors that monitor fluid levels and pressure are vital for the proper operation of hydraulic systems. Malfunctioning sensors can trigger error codes and lead to erratic shifting behavior.

Overheating Issues: Excessive heat can cause various components to fail prematurely. Regular inspection of the cooling system is essential to prevent overheating and prolong the lifespan of the assembly.

Debris Accumulation: Contaminants in the fluid can accumulate in filters and passageways, leading to blockages and reduced flow. Regular fluid changes and system cleanings can help mitigate this problem.

Maintenance Tips for Longevity

Ensuring the durability of your vehicle’s drivetrain components requires regular attention and care. By following some essential practices, you can enhance the performance and extend the lifespan of these critical systems. Proper maintenance not only prevents premature wear but also contributes to smoother operation and better efficiency.

Regular Fluid Checks: It is vital to monitor and maintain the correct fluid levels, as they play a significant role in lubrication and cooling. Inspect the fluid condition regularly, and change it according to the manufacturer’s recommendations to ensure optimal performance.

Routine Inspections: Conduct frequent examinations of the various components to identify any signs of wear or damage. This proactive approach allows you to address potential issues before they escalate into costly repairs.

Heat Management: Excessive heat can lead to premature failure of essential components. Ensure that your cooling system is functioning efficiently, and consider using an aftermarket cooler if you regularly engage in heavy-duty applications.

Quality Components: When replacing any elements, always opt for high-quality parts that meet or exceed original specifications. Using inferior components can compromise the integrity of the entire system.

Professional Servicing: Engage a qualified technician for any complex repairs or adjustments. Their expertise can help maintain the efficiency and reliability of your vehicle’s drivetrain, preventing future issues.

By adhering to these maintenance tips, you can significantly improve the longevity and reliability of your vehicle’s essential systems, ensuring a smoother and more enjoyable driving experience.

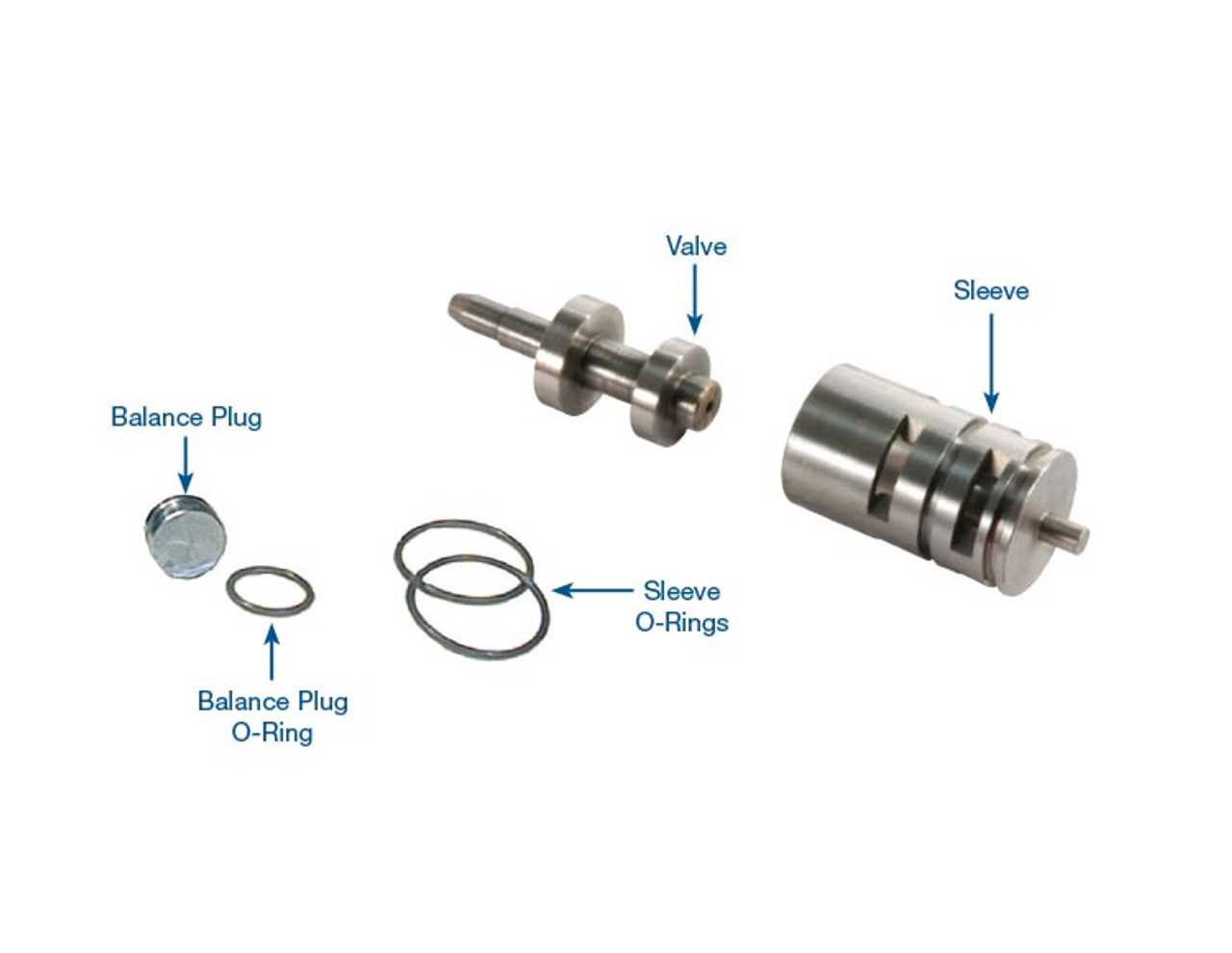

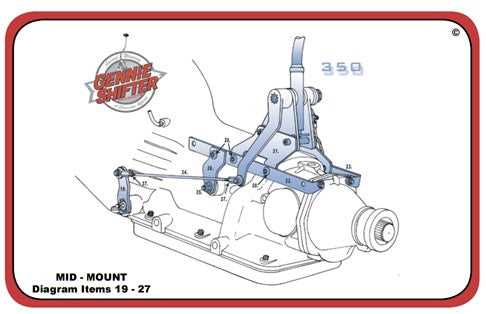

Aftermarket Parts and Upgrades

Upgrading components in your vehicle’s driveline can significantly enhance performance, reliability, and overall driving experience. Various enhancements available on the market provide options for individuals looking to optimize their systems for specific needs, whether for racing, towing, or everyday use. Investing in quality aftermarket offerings can lead to noticeable improvements in efficiency and durability.

Performance Enhancements

High-performance clutches and custom valve bodies are popular choices for those seeking increased power transfer and responsiveness. These upgrades allow for quicker shifts and improved handling under demanding conditions. Additionally, incorporating better cooling systems can help maintain optimal operating temperatures, which is crucial for maintaining performance over time.

Durability and Reliability

Choosing heavy-duty components designed to withstand higher torque loads can prolong the lifespan of your system. Enhanced bushings, bearings, and seals play a vital role in minimizing wear and tear. Upgrading to reinforced units ensures that your setup remains reliable even under the most challenging circumstances, reducing the risk of failure and costly repairs.

Installation Guidelines for New Parts

When undertaking the installation of new components in your vehicle’s system, it is essential to follow specific procedures to ensure optimal performance and longevity. Proper installation not only enhances functionality but also minimizes the risk of potential issues in the future. Understanding the steps involved will contribute to a smoother and more efficient process.

Preparation Steps

Before beginning the installation, gather all necessary tools and components required for the task. Ensure that the workspace is clean and well-organized to facilitate an efficient workflow. Review the manufacturer’s instructions thoroughly to familiarize yourself with the installation process. Taking these initial steps will help prevent common mistakes and save time.

Installation Process

Start by carefully removing any existing components that may obstruct access to the new elements. Pay close attention to the orientation and arrangement of the parts being replaced, as this information will be crucial for proper reassembly. Secure the new components in place, ensuring that all fasteners are tightened to the manufacturer’s specifications. Finally, perform a comprehensive inspection to confirm that everything is correctly installed before reassembling the system.