In the realm of modern machinery, the intricate assemblies that facilitate the movement of vehicles play a pivotal role. These systems are composed of various elements, each serving a distinct function that contributes to the overall operation and efficiency of the mechanism. Gaining insight into these components not only enhances one’s understanding but also aids in effective maintenance and troubleshooting.

From hydraulic mechanisms to electronic controls, the synergy of these components ensures seamless functionality. Each segment is designed to withstand significant stress and wear, highlighting the importance of quality materials and precise engineering. Whether for performance enhancements or routine servicing, a comprehensive grasp of these elements empowers users to make informed decisions.

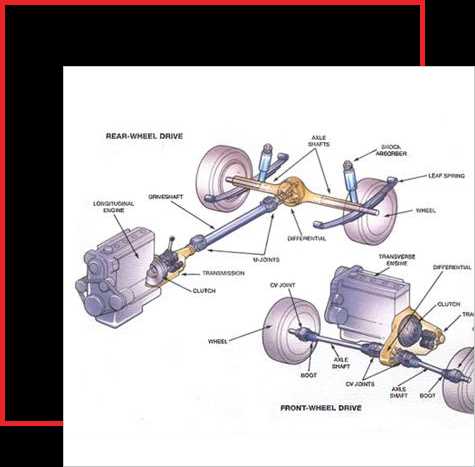

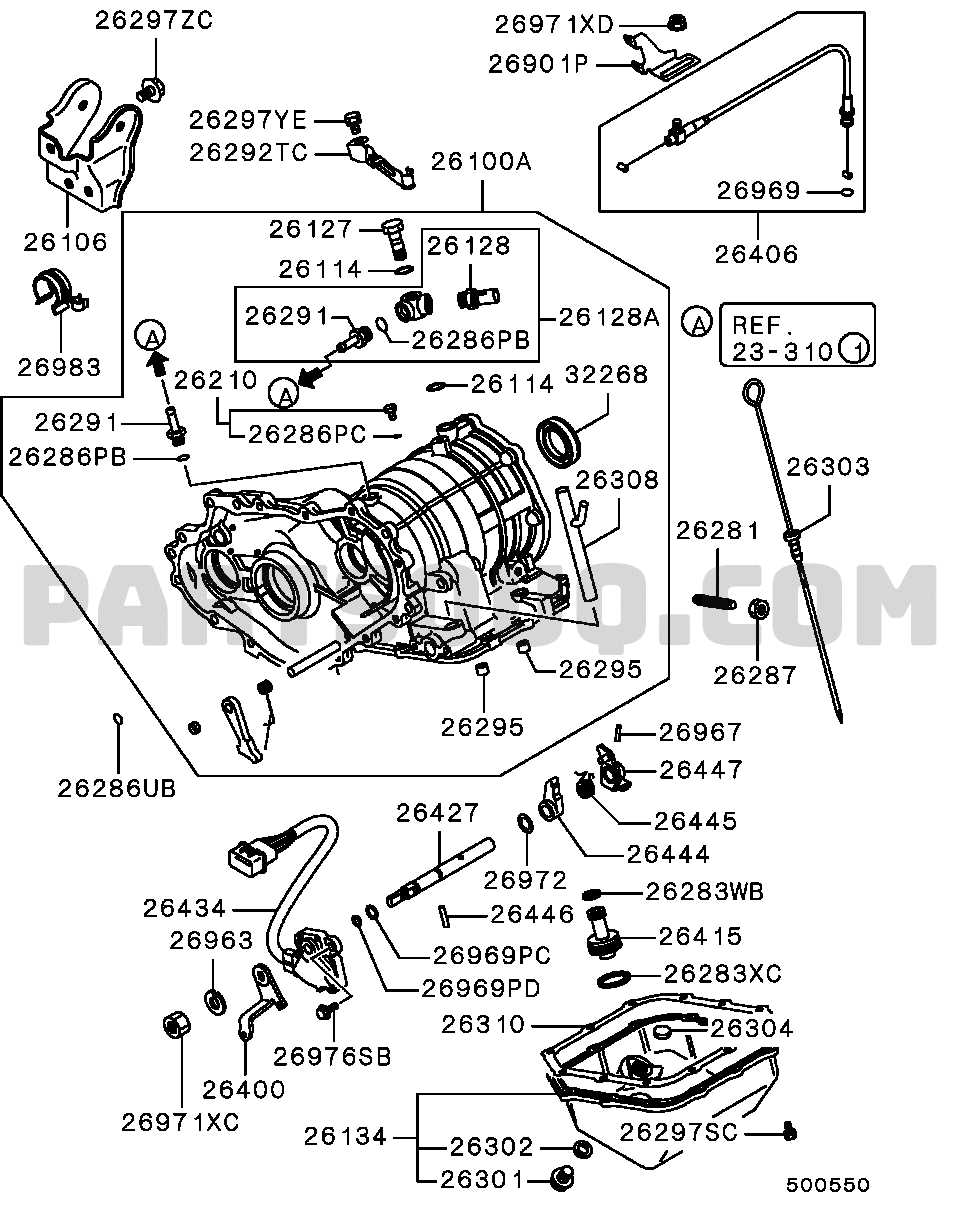

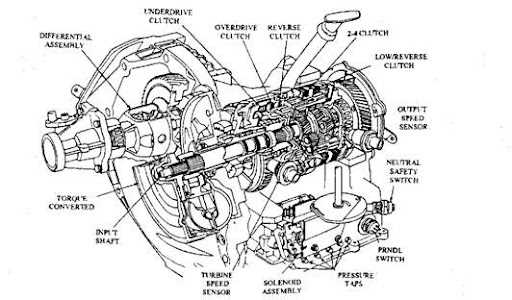

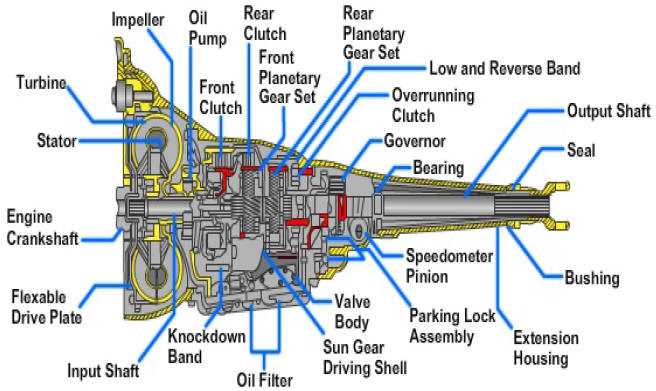

Furthermore, visual representations of these assemblies can be invaluable tools for both professionals and enthusiasts alike. Such illustrations provide clarity on the relationship between different components, making it easier to identify potential issues and implement solutions. A thorough exploration of these systems fosters a deeper appreciation for the complexity involved in mechanical engineering.

Understanding Automatic Transmission Components

Automatic systems in vehicles consist of a variety of essential elements that work together to facilitate smooth gear changes and enhance driving comfort. Grasping the function and interrelation of these components is vital for understanding how the entire mechanism operates efficiently. This knowledge is crucial for effective maintenance and troubleshooting, ensuring optimal performance over time.

Key Elements of the System

Among the fundamental elements are those responsible for fluid management, gear selection, and control mechanisms. The hydraulic system plays a pivotal role in transferring power through fluid movement, while various sensors and actuators ensure accurate responses to driver inputs. Additionally, the clutch assemblies engage and disengage gears as required, enabling seamless shifts that contribute to a better driving experience.

Maintenance and Common Issues

Regular upkeep of these components is essential for longevity and performance. Common issues can arise from fluid leaks, worn seals, or malfunctioning sensors, leading to erratic behavior or failure to shift. Awareness of these potential problems allows for timely interventions, preserving the functionality of the system and ensuring safe operation on the road.

Key Elements of Auto Transmission Systems

The functionality of a vehicle’s gear-shifting mechanism relies on several critical components that work in harmony to ensure smooth operation and efficiency. These elements play a vital role in converting engine power into motion, allowing for seamless transitions between different speeds and torque levels. Understanding these components is essential for anyone interested in automotive engineering or maintenance.

Fluid Management

Hydraulic fluid is the lifeblood of the gear-shifting mechanism, serving multiple purposes, including lubrication, cooling, and power transmission. The fluid circulates through various channels and pumps, enabling the system to engage and disengage gears based on driver input. Maintaining proper fluid levels and quality is crucial for the longevity and performance of the mechanism.

Control Mechanisms

At the heart of the system lies a complex array of control mechanisms that manage the operation of gears. These include sensors that detect speed and load conditions, as well as electronic control units that process this information to determine the optimal gear selection. The integration of advanced technology has enhanced the precision and responsiveness of these control systems, resulting in improved efficiency and driver experience.

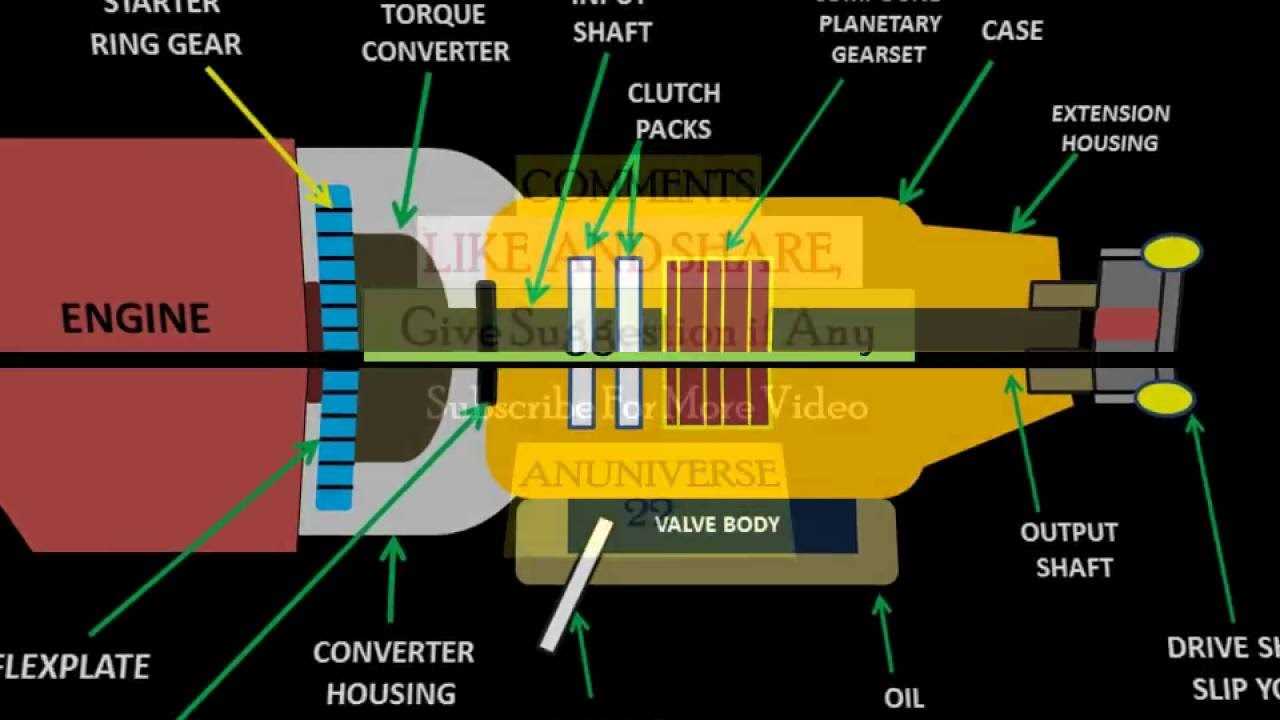

How Auto Transmissions Operate

The mechanism that facilitates the seamless transfer of power from the engine to the wheels is a marvel of engineering. It ensures smooth acceleration and deceleration, allowing vehicles to adapt to various driving conditions without driver intervention. Understanding this complex system reveals how it efficiently manages gear ratios to optimize performance and fuel efficiency.

Components Involved

This system consists of several key elements that work in harmony. The primary components include hydraulic fluid, gears, clutches, and electronic controls. Each part plays a vital role in engaging and disengaging different gears as the vehicle moves, ensuring optimal power delivery.

Functionality Overview

When the vehicle is in motion, the system continuously monitors speed and load, adjusting the gear ratios accordingly. This automatic adjustment allows for responsive driving and enhances fuel efficiency. Through a series of hydraulic and electronic signals, the mechanism ensures that the right gear is selected at the right time, providing a smooth driving experience.

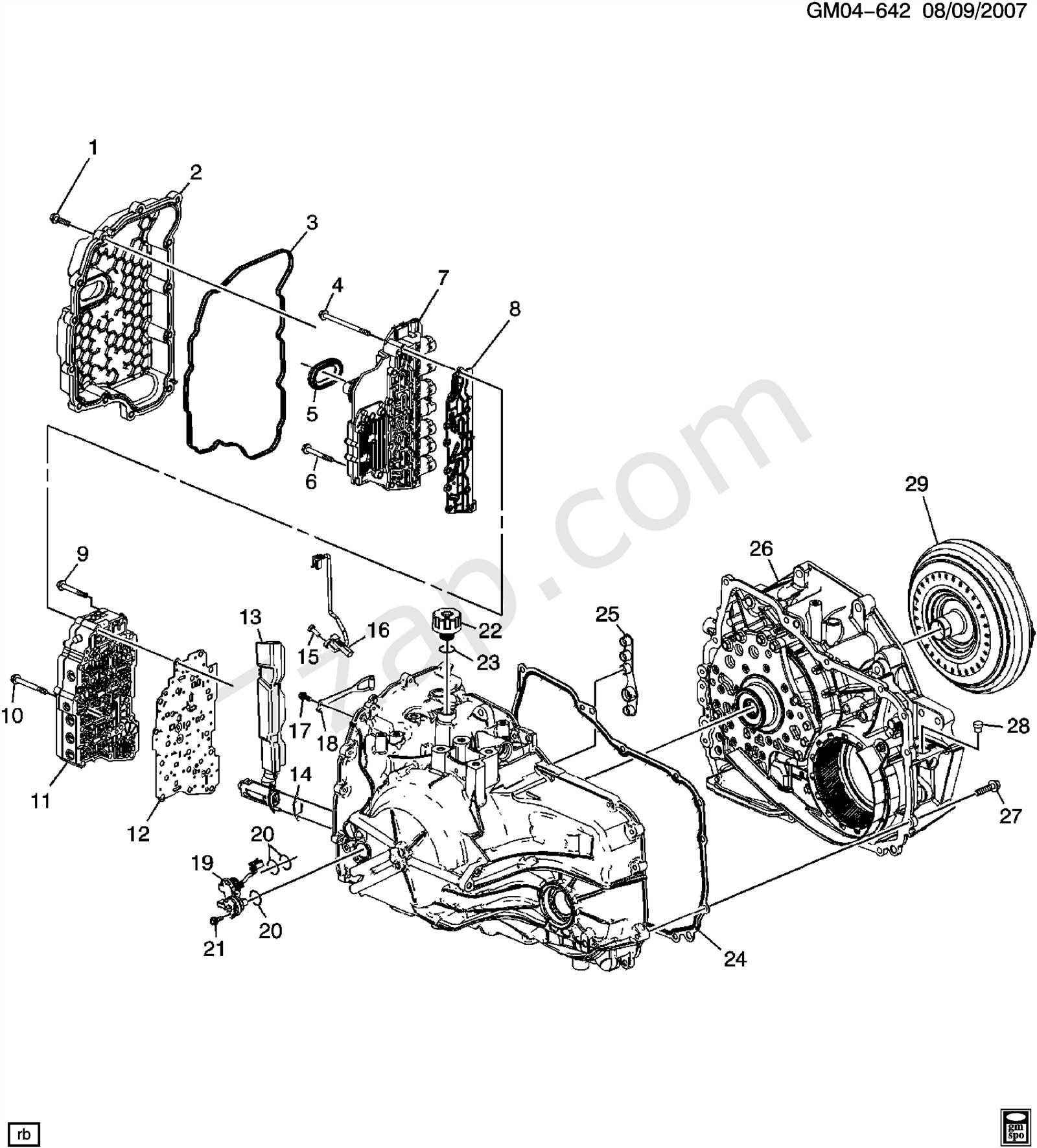

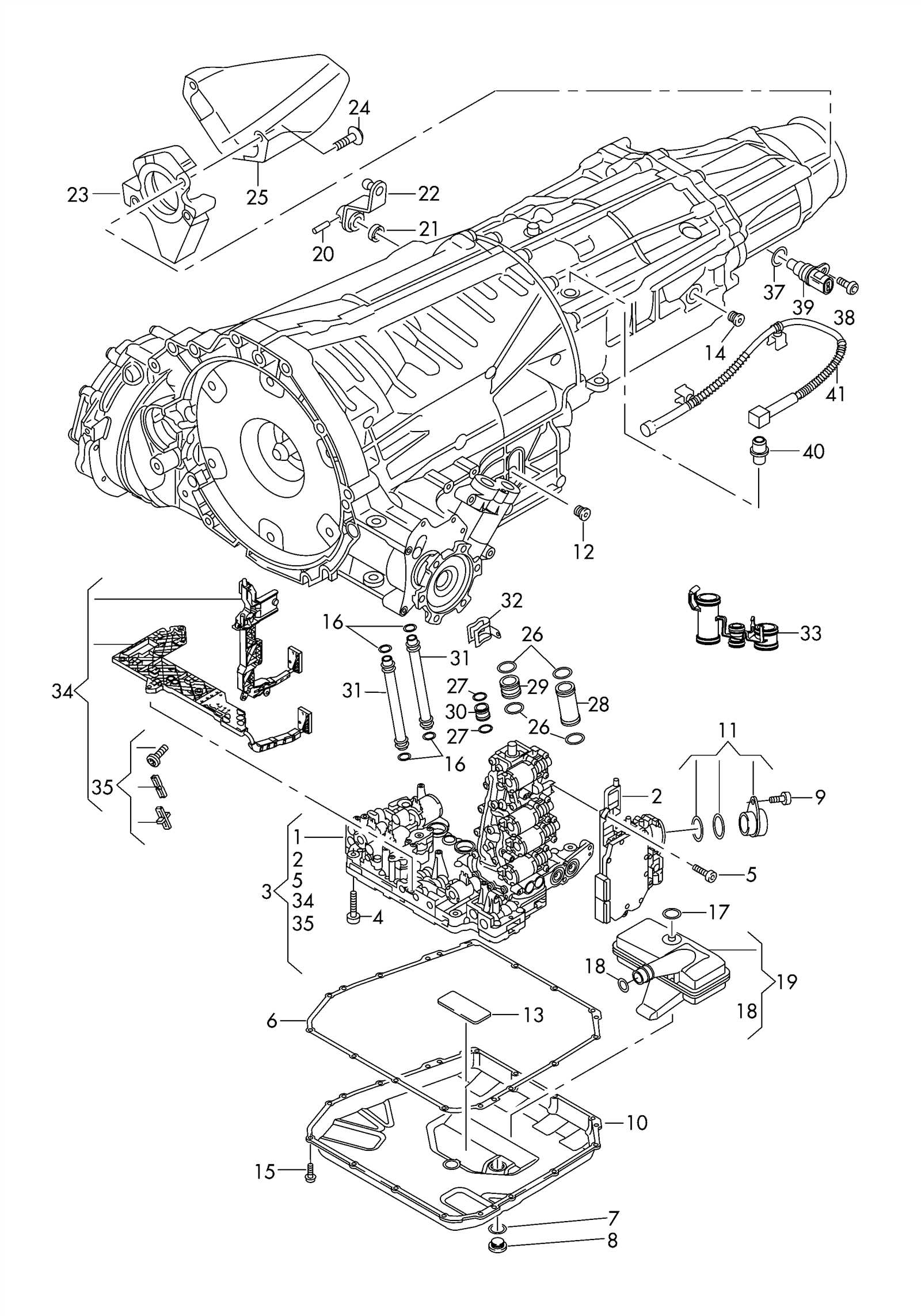

Parts of a Transmission Assembly

The assembly responsible for transferring power within a vehicle consists of various components, each playing a crucial role in its functionality. Understanding these elements is essential for diagnosing issues and ensuring optimal performance. This segment explores the fundamental elements that comprise this intricate system.

Key Components

At the heart of the assembly is the gear set, which enables the adjustment of speed and torque. This mechanism relies on intricate designs to facilitate smooth transitions between different operating conditions. Additionally, the hydraulic system plays a vital role, utilizing fluid pressure to control the operation of the gears, ensuring seamless functionality.

Supporting Elements

Other significant components include the control module, responsible for managing the entire assembly’s operation, and the filter, which maintains the cleanliness of the hydraulic fluid, preventing contamination and prolonging the system’s lifespan. Understanding these supporting elements is essential for effective maintenance and troubleshooting.

Common Issues with Transmission Parts

Understanding the frequent problems that can arise within the various components responsible for gear shifting is essential for maintaining optimal vehicle performance. These challenges can lead to significant disruptions if not addressed promptly, affecting the overall functionality and reliability of the system.

Typical Problems Encountered

- Fluid Leaks: Insufficient fluid levels can result in overheating and premature wear. Regular checks for any leaks are crucial.

- Slipping Gears: Inconsistent shifting can indicate underlying issues, potentially leading to complete failure if ignored.

- Unusual Noises: Grinding or whining sounds may suggest that components are not functioning correctly or are in need of lubrication.

Signs of Malfunction

- Delayed engagement when shifting from park to drive.

- Warning lights illuminating on the dashboard.

- Vibration or shaking during gear changes.

Prompt identification and resolution of these issues are vital to ensure the long-term reliability of your vehicle’s functionality.

Maintenance Tips for Transmission Longevity

Ensuring the long-term functionality of your vehicle’s shifting mechanism involves a combination of regular care, timely interventions, and a proactive approach to potential issues. By adhering to specific maintenance practices, you can enhance the durability of the system and avoid costly repairs.

Regular Fluid Checks

One of the most crucial aspects of upkeep involves monitoring the quality and level of the fluid. Neglecting this can lead to significant wear and tear, affecting overall performance.

| Fluid Type | Check Frequency | Signs of Degradation |

|---|---|---|

| Standard Fluid | Every 30,000 miles | Dark color, burnt smell |

| Synthetic Fluid | Every 50,000 miles | Contaminated appearance, unusual noises |

Routine Inspections

Conducting regular evaluations of the entire system can help identify issues before they escalate. Pay attention to any irregular sounds or changes in shifting behavior.

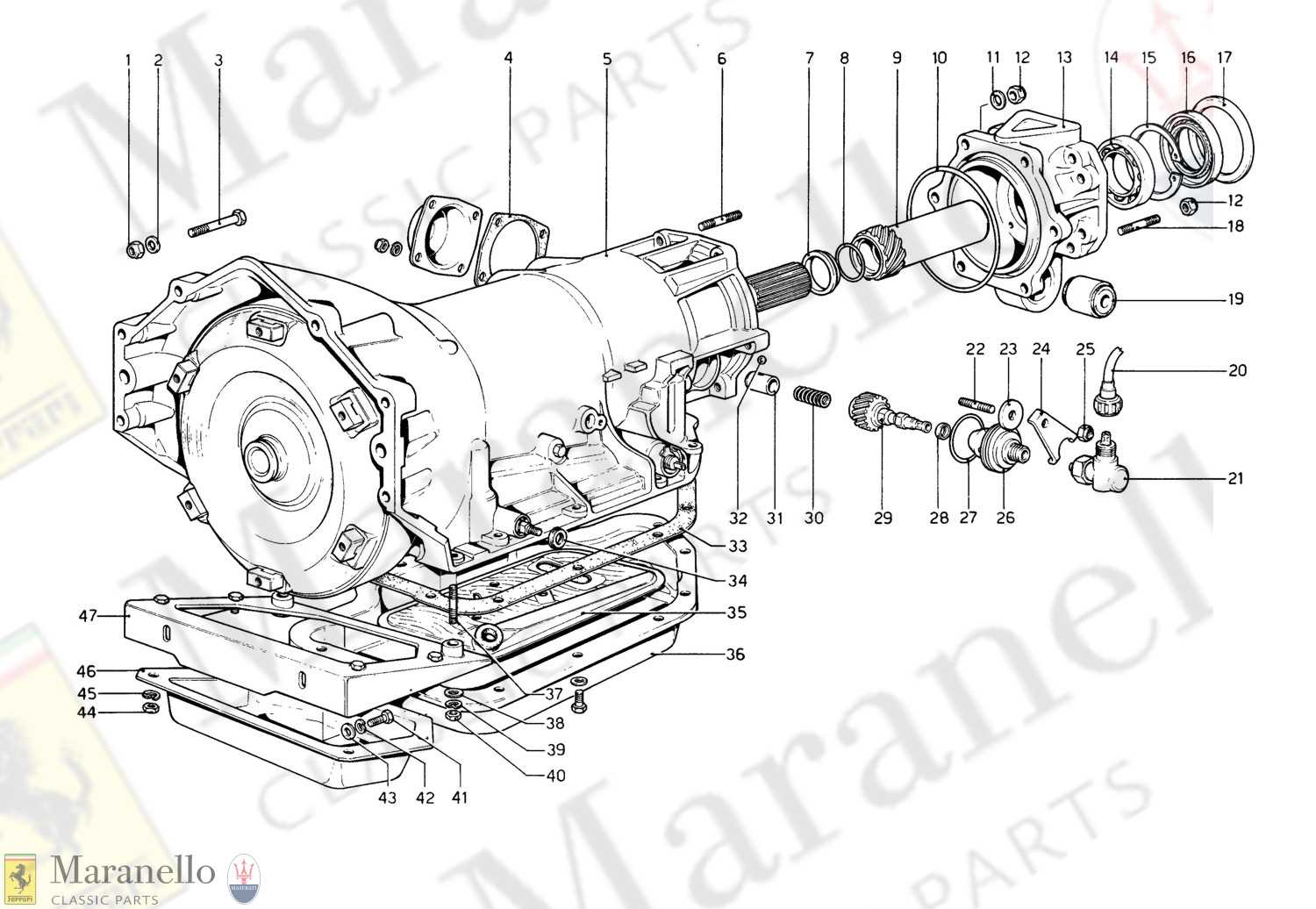

Visual Aids: Transmission Diagrams

Visual representations serve as crucial tools in understanding the intricate mechanisms involved in vehicle gear systems. These illustrations simplify complex concepts, making it easier for both enthusiasts and professionals to grasp how components interact within the assembly. Utilizing these aids enhances learning and retention, allowing users to quickly identify and troubleshoot issues.

Importance of Visual Representations

- Clarifies complex interactions between various components.

- Aids in the identification of specific areas needing maintenance or repair.

- Facilitates better communication among technicians and engineers.

Types of Visual Aids

- Schematic Illustrations: Simplified views highlighting functional relationships.

- Exploded Views: Detailed representations showing the assembly of parts in relation to one another.

- Flow Charts: Diagrams that outline operational sequences within the mechanism.

Replacement Parts for Auto Transmissions

When it comes to maintaining a vehicle’s performance, understanding the essential components responsible for gear shifting and power distribution is crucial. Over time, certain elements may wear out or fail, necessitating replacement to ensure optimal functionality. This section explores the various elements involved in these crucial mechanisms, providing insights into their roles and importance.

Common Components Needing Replacement

- Clutches: Vital for engaging and disengaging gears, these components can deteriorate due to heat and friction.

- Seals: Ensuring fluid containment, damaged seals can lead to leaks and reduced efficiency.

- Filters: These elements prevent contaminants from entering the system, and a clogged filter can hinder performance.

- Gaskets: Essential for maintaining pressure, worn gaskets can cause fluid loss and operational issues.

- Valve Body: This assembly directs hydraulic fluid to the appropriate passages and may require replacement if it becomes damaged.

Choosing the Right Components

Selecting appropriate replacements is essential for ensuring durability and compatibility. Consider the following factors when making a choice:

- Compatibility: Ensure the component fits the specific make and model of the vehicle.

- Quality: Opt for high-quality replacements to avoid frequent failures.

- Manufacturer Reputation: Research brands known for reliability and performance.

- Warranty: A good warranty can provide peace of mind regarding the durability of the component.

Choosing the Right Transmission System

Selecting the appropriate system for gear shifting is crucial for the performance and efficiency of any vehicle. The right setup can enhance driving experience, improve fuel efficiency, and ensure longevity of the vehicle. Various factors influence this decision, and understanding them can lead to better outcomes.

When considering a gear shifting mechanism, several elements should be taken into account:

- Driving Style: Assess how the vehicle will be used. Is it for daily commuting, off-road adventures, or performance driving? Each use case may require a different configuration.

- Fuel Efficiency: Some systems are designed for better fuel economy. Research options that maximize efficiency while meeting performance needs.

- Maintenance Requirements: Consider the ease of maintenance and potential repair costs associated with different systems. Some configurations may require more frequent service than others.

- Vehicle Compatibility: Ensure that the chosen system is compatible with the vehicle’s make and model. Mismatched components can lead to poor performance.

- Technological Features: Look for modern enhancements, such as adaptive settings or automated controls, which can improve user experience.

Evaluating these factors will help you make an informed decision when selecting the optimal gear shifting mechanism for your vehicle.