The intricate systems that power heavy machinery are essential for efficient operation in various industries. A comprehensive understanding of their individual elements is crucial for maintenance and repair. By breaking down these complex mechanisms, users can ensure optimal performance and longevity.

In this section, we will explore the different components that make up these robust systems. Each piece plays a vital role in the overall functionality, and familiarity with their arrangement can aid in troubleshooting and servicing. Whether you are a technician or an enthusiast, grasping the layout and interaction of these elements will enhance your knowledge.

Through detailed visual representations and descriptions, this guide aims to clarify the relationships and functions of each component. Emphasizing clarity and accessibility, we invite readers to delve into the world of mechanical systems, equipping them with the information needed for effective engagement with their machinery.

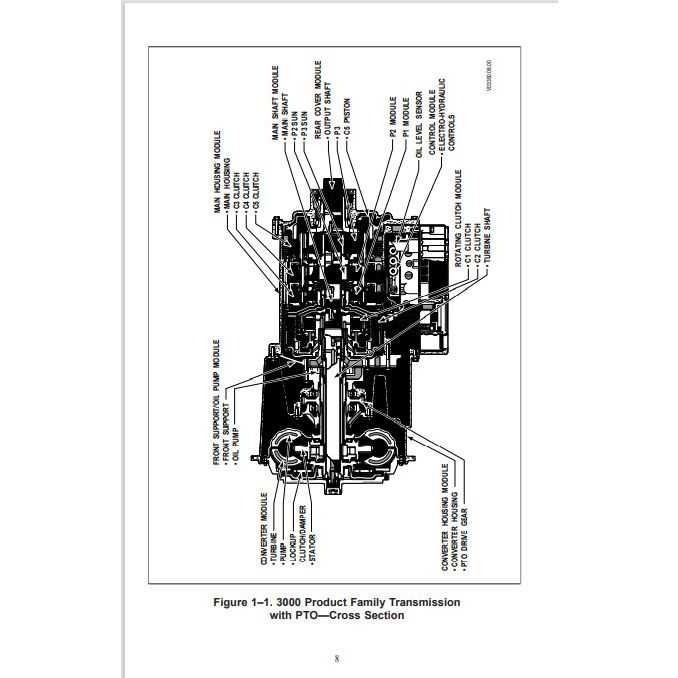

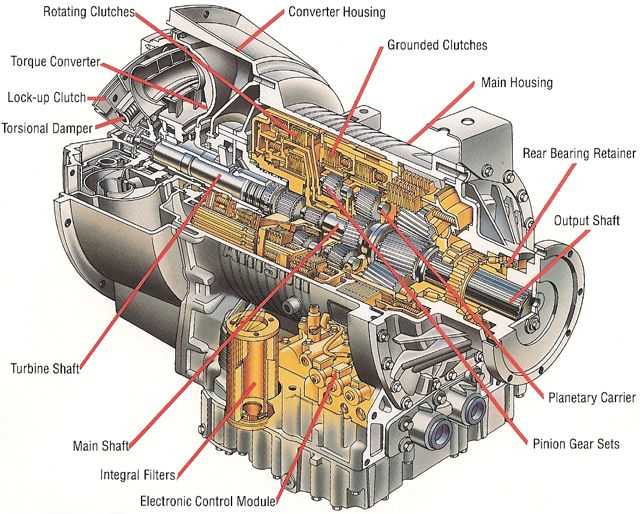

Understanding the Allison 3000 Transmission

This section provides a comprehensive overview of a widely used automatic gearbox designed for medium to heavy-duty vehicles. Known for its durability and reliability, this system plays a crucial role in enhancing performance and ensuring smooth operation under various conditions.

Key Features

- Advanced electronic controls for optimal efficiency.

- Robust construction for high-torque applications.

- Multiple gear ratios to improve acceleration and fuel economy.

- Integrated diagnostics for monitoring performance.

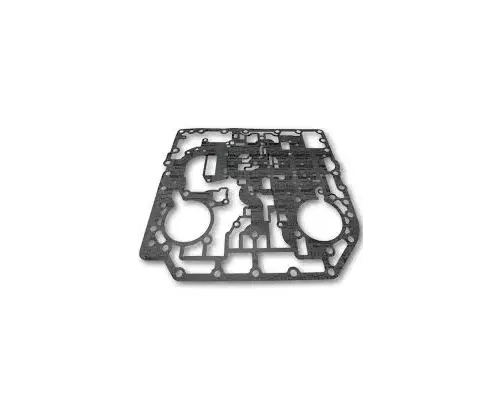

Components Overview

Understanding the individual elements of this system is essential for effective maintenance and repair. Below are some critical components:

- Hydraulic system: Responsible for shifting gears smoothly.

- Torque converter: Enhances engine power delivery.

- Planetary gear sets: Provide various gear ratios for different driving conditions.

- Control module: Manages the electronic functions and shifting patterns.

Each of these elements contributes to the overall functionality, ensuring that the gearbox performs efficiently and reliably over time.

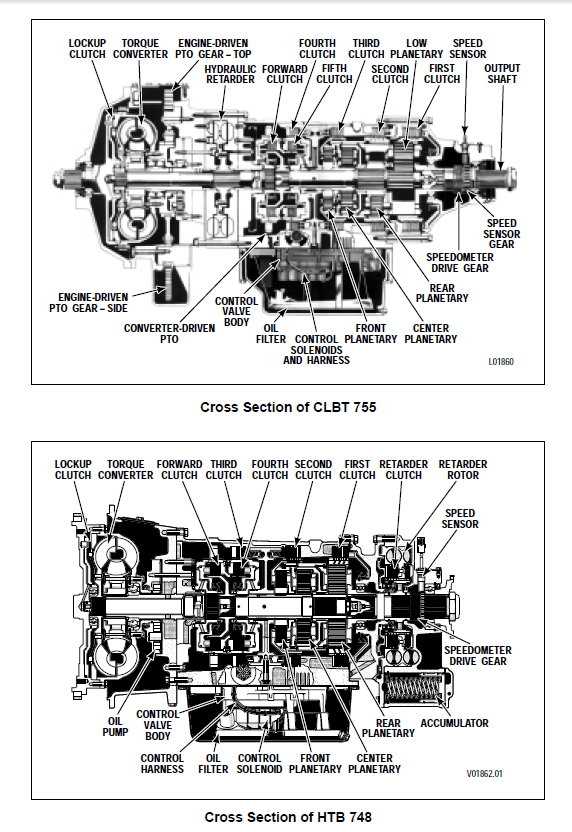

Key Components of the Transmission

The intricate machinery within a vehicle’s gear system is essential for optimal performance and efficiency. Each element plays a crucial role in ensuring smooth operation and reliability. Understanding these components is vital for maintenance and troubleshooting.

Among the primary elements are the fluid pump, which circulates hydraulic fluid, and the clutch system, responsible for engaging and disengaging gears. The gear sets enable various speed ratios, while the control unit oversees the operation, adjusting performance based on driver input and conditions.

Additionally, the filter ensures that the hydraulic fluid remains clean, preventing damage to internal components. Together, these parts form a complex network that requires careful coordination to deliver the ultimate driving experience.

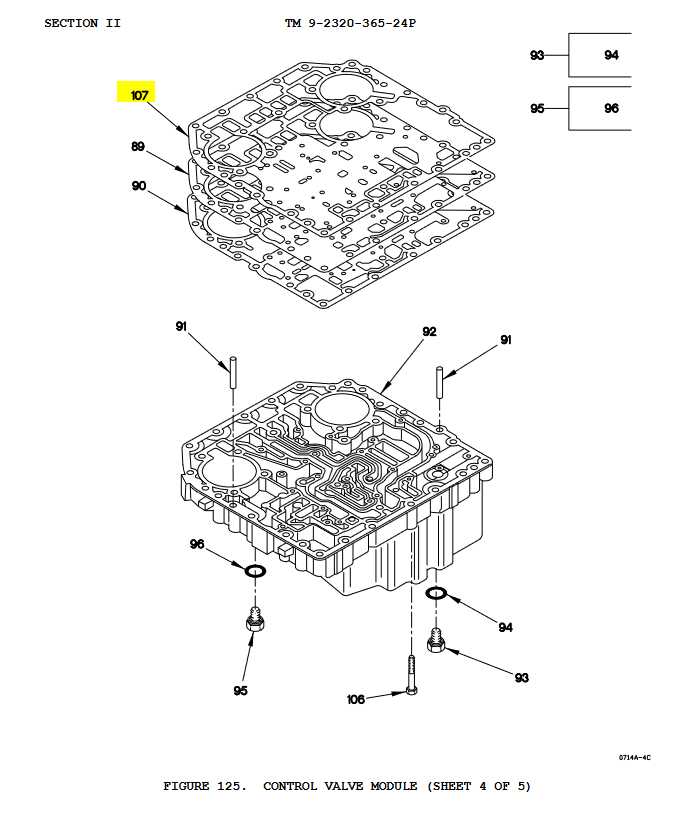

Importance of Parts Diagrams

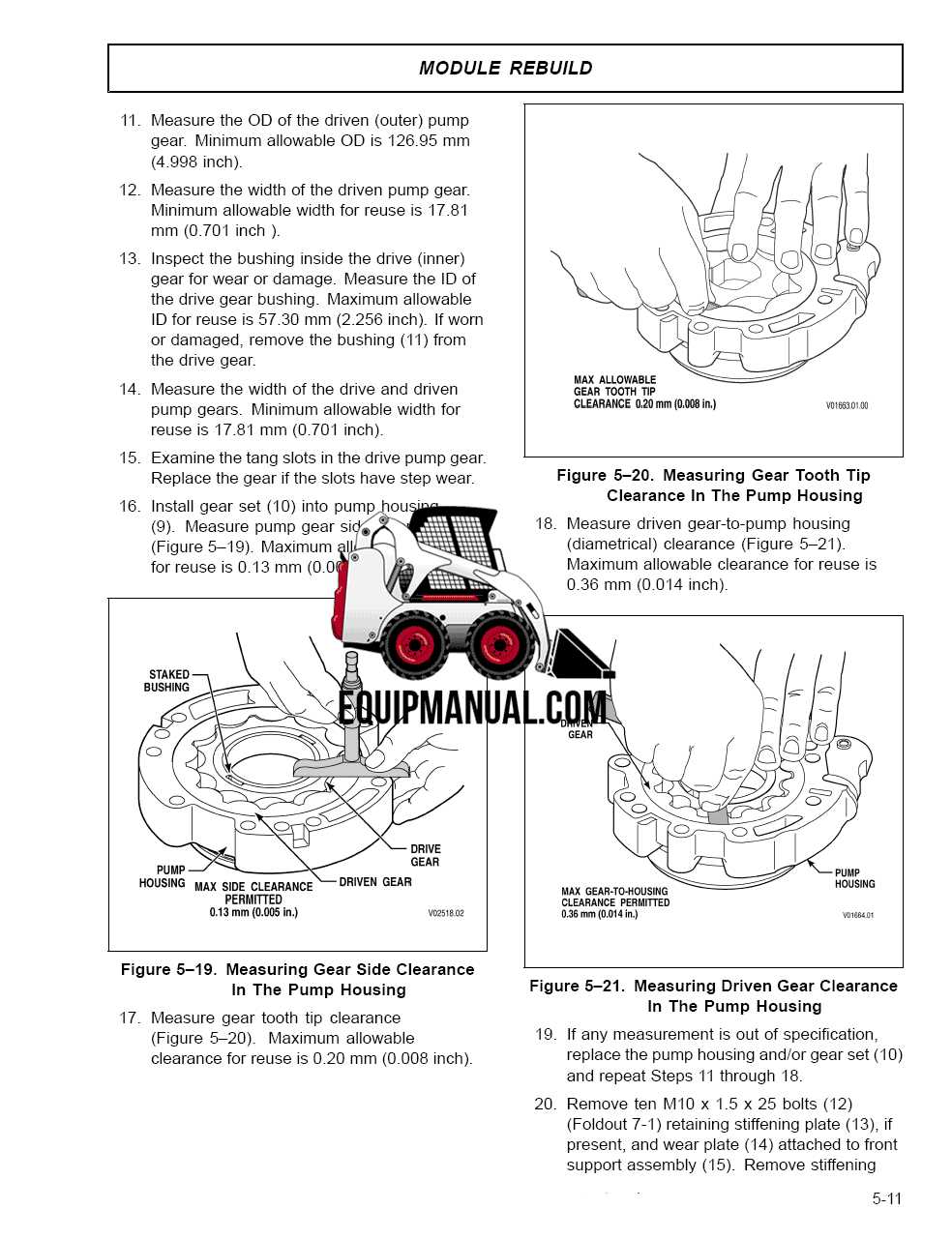

Understanding the components of a mechanical system is essential for efficient maintenance and repair. Visual representations that detail each element play a critical role in ensuring the longevity and proper functioning of equipment. These illustrations serve not only as guides but also as educational tools, enhancing both knowledge and execution.

Here are some key reasons why these visual aids are vital:

- Clarity: They provide a clear view of how each component fits together, simplifying complex structures.

- Efficiency: Technicians can quickly identify parts, reducing the time spent on repairs or replacements.

- Training: New personnel can learn about systems more effectively through visual aids, fostering a better understanding of the mechanics involved.

- Accuracy: Detailed visuals minimize the risk of errors during assembly or disassembly, ensuring correct installation.

- Documentation: These resources serve as a valuable reference for future maintenance, promoting consistent practices.

In conclusion, effective visual representations of mechanical elements are indispensable tools that enhance understanding, efficiency, and accuracy in maintenance practices.

Common Issues with Allison 3000

Many vehicle operators encounter various challenges with automatic gear systems, leading to potential performance issues. Understanding these common problems can aid in identifying and resolving them effectively.

Here are some prevalent concerns associated with these systems:

| Issue | Description |

|---|---|

| Overheating | Excessive temperatures can cause damage to internal components, often due to fluid breakdown or insufficient cooling. |

| Fluid Leaks | Leaks can arise from seals and gaskets, leading to low fluid levels and potential failure of the system. |

| Shifting Problems | Difficulty in shifting gears may indicate issues with the control system or mechanical failures within the unit. |

| Noisy Operation | Unusual sounds during operation can signal wear or damage to components, necessitating immediate inspection. |

| Warning Lights | Activation of warning indicators on the dashboard often points to underlying malfunctions requiring attention. |

Addressing these issues promptly can help maintain optimal performance and extend the lifespan of the system.

How to Read Parts Diagrams

Understanding schematics is essential for effective maintenance and repair work. These illustrations provide a visual representation of components, helping users identify and locate individual elements within a system. By mastering the interpretation of these visuals, one can streamline troubleshooting and ensure accurate reassembly.

To effectively analyze these illustrations, it is helpful to follow a structured approach:

| Step | Description |

|---|---|

| 1. Familiarize with Symbols | Each illustration uses specific symbols to represent different components. Take time to learn what each symbol signifies. |

| 2. Identify Sections | Typically, illustrations are divided into sections. Understanding these segments can help pinpoint areas of interest more quickly. |

| 3. Note Connections | Pay attention to how components are linked. This will assist in understanding the overall functionality and flow of the system. |

| 4. Refer to the Legend | Most schematics include a legend or key that explains the symbols and colors used. Always consult this for clarification. |

| 5. Cross-Reference with Manuals | Use these visuals in conjunction with service manuals for detailed explanations on installation and maintenance. |

By following these steps, you will enhance your ability to read and interpret technical illustrations, making your repair processes more efficient and accurate.

Maintenance Tips for Longevity

Ensuring the durability of your vehicle’s essential components requires regular attention and care. Adopting a proactive maintenance routine not only enhances performance but also extends the lifespan of critical systems. Here are some key practices to keep in mind.

Regular Fluid Checks

Maintaining proper fluid levels is vital for optimal operation. Regularly inspect and replace fluids according to the manufacturer’s recommendations. This includes ensuring that lubricants are clean and at the appropriate levels to minimize wear and tear.

Scheduled Inspections

Conducting routine inspections helps identify potential issues before they escalate. Look for signs of wear, such as leaks or unusual noises, and address them promptly. A detailed check-up can save time and money in the long run, ensuring reliable functionality.

Aftermarket Parts vs. OEM Components

The choice between aftermarket components and original equipment manufacturer (OEM) offerings is a critical decision for many vehicle owners. Each option comes with its own set of advantages and potential drawbacks, impacting performance, reliability, and cost. Understanding these differences can help in making an informed decision tailored to individual needs and preferences.

Advantages of Aftermarket Components

Aftermarket alternatives often provide a broader range of options at competitive prices. Many manufacturers specialize in enhancing performance, offering upgrades that can lead to better efficiency or power. Additionally, the diversity in design and features may appeal to enthusiasts seeking customization and personalization for their vehicles.

Benefits of OEM Offerings

On the other hand, OEM components guarantee compatibility and quality assurance, as they are produced to meet specific manufacturer standards. This can lead to improved longevity and less frequent replacements. Furthermore, opting for OEM parts can ensure that warranties remain intact, providing peace of mind for owners concerned about potential repairs.

Where to Find Replacement Parts

Finding components for your heavy-duty machinery can be a challenge, but there are various avenues to explore that can lead you to the right items. Whether you are looking for new or refurbished elements, understanding where to search is crucial for efficiency and cost-effectiveness.

Online Resources

- Manufacturer’s Website: Check for authorized dealers or online catalogs.

- Specialty Retailers: Websites dedicated to heavy equipment often have extensive inventories.

- Marketplaces: Platforms like eBay or Amazon can offer a range of options.

Local Options

- Dealerships: Local distributors may stock or order the necessary components.

- Auto Parts Stores: Some stores specialize in commercial vehicle parts.

- Junkyards: Salvage yards can be a treasure trove for used items.

Upgrades and Modifications Available

Enhancing the performance and longevity of your vehicle’s gear system can be achieved through a variety of upgrades and modifications. These improvements can significantly boost efficiency, responsiveness, and overall driving experience. Whether you’re looking to increase power handling or improve shifting smoothness, there are several options to consider.

Performance Kits are a popular choice for those seeking to maximize efficiency. These kits often include improved valve bodies and enhanced fluid flow components, ensuring smoother and quicker shifts. Upgrading these elements can lead to a noticeable increase in power delivery.

Cooling Systems are essential for maintaining optimal operating temperatures, especially in high-performance scenarios. Adding an aftermarket cooler can help prevent overheating, ensuring your setup remains reliable even under heavy loads.

For enthusiasts interested in fine-tuning their ride, electronic control modules can provide custom tuning options. These modules allow for adjustments to shift points and torque management, catering to specific driving styles and preferences.

Finally, consider heavy-duty components for enhanced durability. Upgrading to stronger gears and clutches can withstand greater stress and provide a longer lifespan, particularly for those who frequently tow or haul heavy loads.