Modern vehicles rely on a complex system of mechanical elements that work together to ensure efficient power delivery from the engine to the wheels. These components play a crucial role in the vehicle’s overall performance, influencing how smoothly it operates on various terrains and under different conditions.

At the heart of this system lies a set of interrelated mechanisms responsible for distributing power and controlling the speed and torque. Understanding the individual units involved in this process is essential for anyone looking to maintain or enhance their vehicle’s functionality.

Each part within this setup works in harmony to manage energy flow and ensure optimal operation. Whether you’re focusing on repair or simply enhancing your knowledge, grasping how these elements interact can provide valuable insights into your

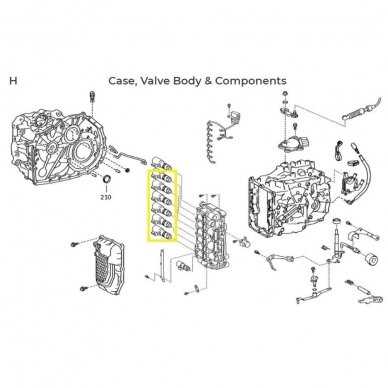

Overview of the 46RE Transmission Components

The system responsible for shifting gears in many vehicles is complex and includes various elements that work in harmony. Each component plays a crucial role in ensuring smooth operation and efficiency, enabling the system to adapt to different driving conditions. Understanding how these parts interact provides valuable insight into its overall functionality.

Key Structural Elements

Within this mechanism, there are several core elements that contribute to the efficient flow of power. These include the primary gear sets, which manage the power distribution, and several regulating devices responsible for fluid control. The seamless cooperation of these sections is critical for performance.

- Main gear assemblies for adjusting torque and speed

- Control mechanisms to manage fluid pressure and flow

- Linkage systems connecting to the overall drive

Supporting Elements

Supporting structures assist in maintaining stability and ensuring the longevity of the system. These include casing elements that protect internal components and cooling systems designed to maintain optimal temperature.

- Protective housing

Main Functions of Transmission Gears

The primary role of gears within a mechanical system is to regulate power distribution from the engine to the wheels, ensuring efficient performance and adaptability to varying driving conditions. These components allow for smoother acceleration and deceleration, helping maintain control at different speeds.

Gears play a vital role in adjusting torque and speed, directly influencing how a vehicle responds during operation. Each gear ratio is designed to meet specific driving demands, from initial movement to maintaining high speeds.

Gear Type Function First Gear Provides maximum torque for initial acceleration from a standstill. Second Gear Continues to enhance acceleration while reducing torque as speed increases. Third Gear Torque Converter Structure and Role

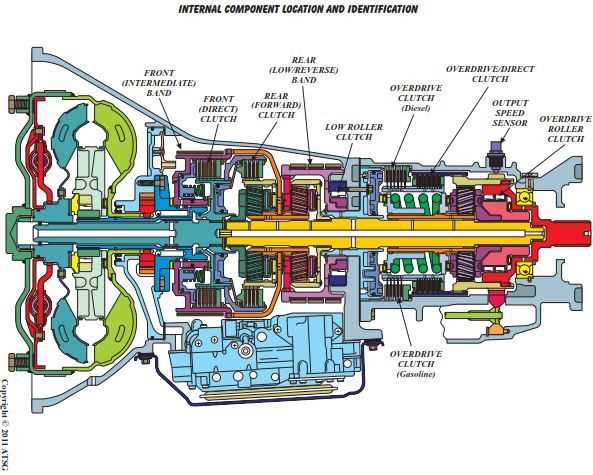

The torque converter is a crucial element in the power transfer process, playing a vital role in how energy moves between the engine and other systems. It serves to connect different components, ensuring smooth operation and efficient power delivery without the need for direct mechanical contact.

Main Components of the Torque Converter

At its core, the torque converter consists of several key components, each working together to manage energy flow. The impeller, turbine, and stator are the primary elements that interact to transfer fluid and control the distribution of force. This interaction enables a gradual, smooth transmission of power, allowing the engine to operate efficiently at various speeds.

Role in Power Transmission

The main function of the torque converter is to enhance power delivery while maintaining flexibility in performance. It ensures that the energy produced by the engine is utilized effectively, adjusting to different driving conditions without losing power or efficiency. This dynamic process is essential for maintaining a smooth and responsive driving

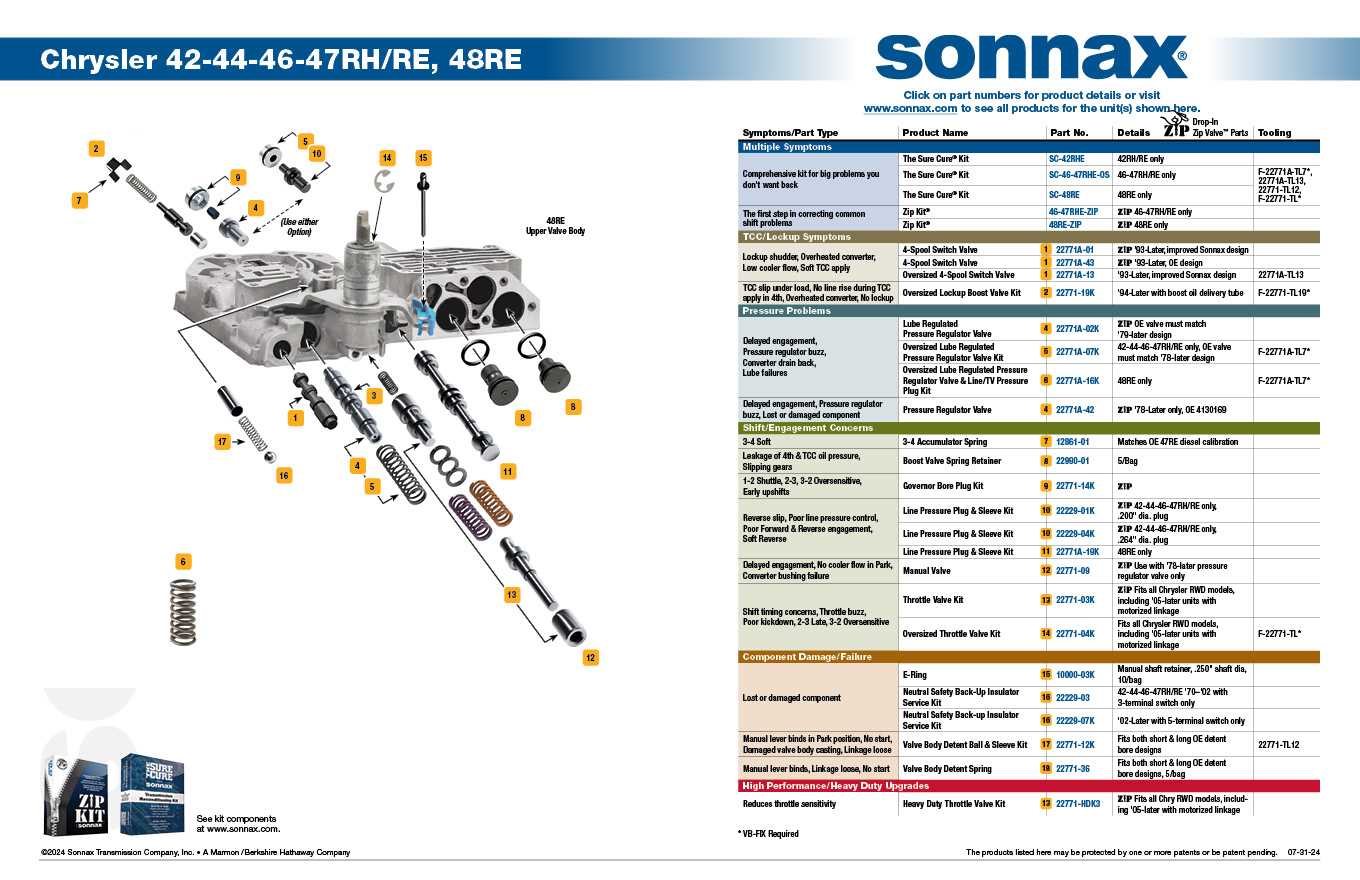

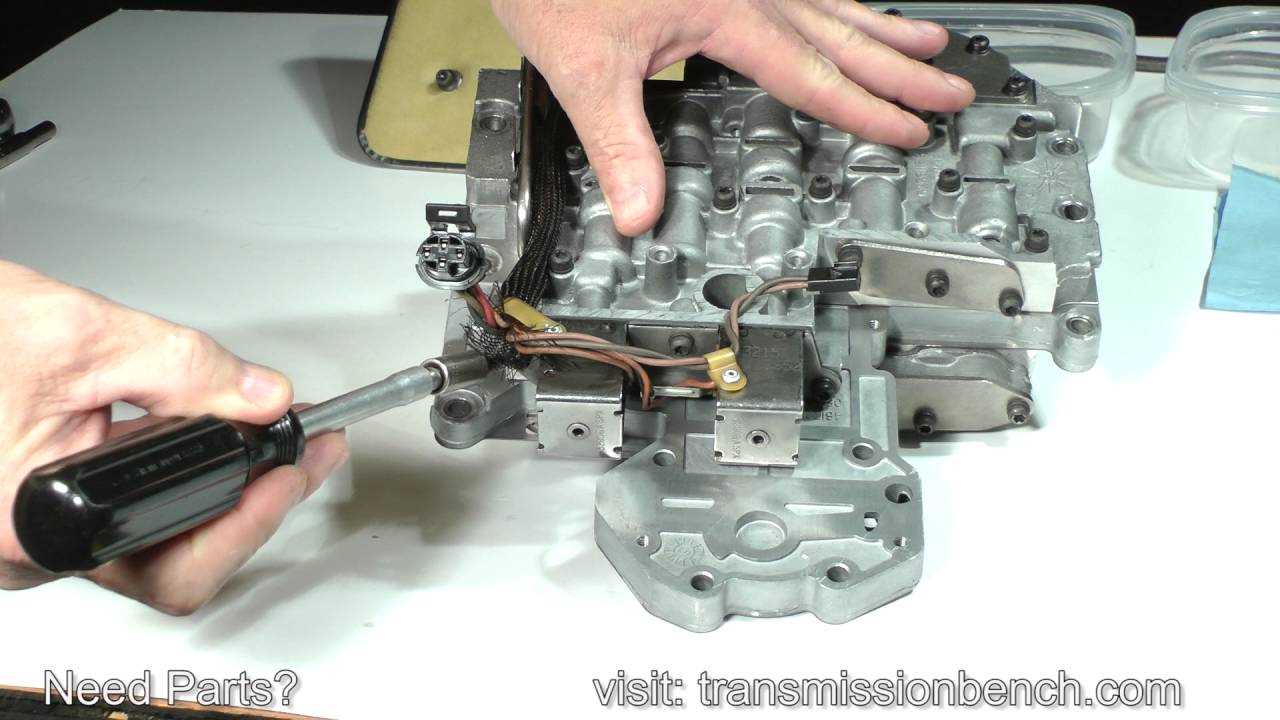

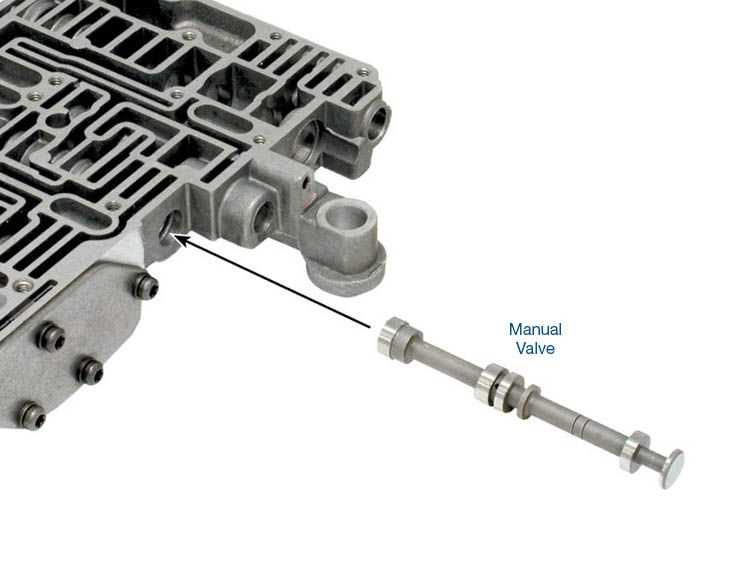

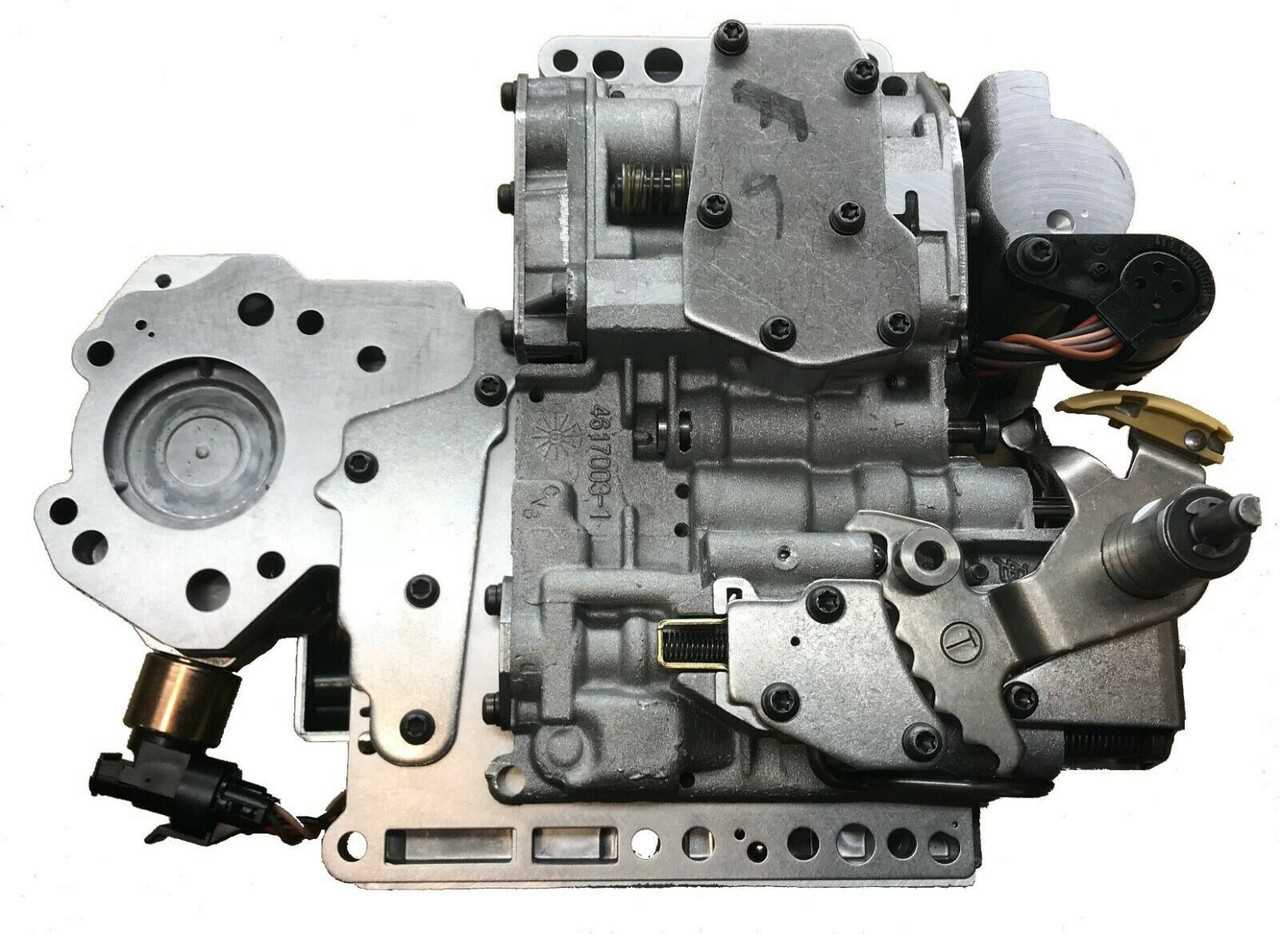

Valve Body Mechanism and Operation

The valve body serves as a crucial component responsible for managing the flow of hydraulic pressure, which controls various functions of the system. This intricate mechanism coordinates fluid distribution, allowing for seamless gear changes and operational efficiency. Without its precise regulation, the system’s performance would be compromised, leading to potential disruptions in driving dynamics.

Hydraulic channels within the valve body direct fluid to different circuits, each designed to activate specific operations. These channels work in harmony with valves, which open and close according to the system’s needs. The fluid pressure is carefully monitored, ensuring that each function is executed at the right time and under optimal conditions.

Another vital role of the valve body is managing shift timing. It operates through a combination of sensors and actuators, ensuring that shifts are smooth and accurately timed. By maintaining proper fluid control, it effectively coordinates different phases of operation, contributing to a balanced and responsive driving experience.

Solenoids and Their Key Responsibilities

Solenoids play a vital role in managing the smooth operation of various mechanical systems. These components are designed to regulate fluid flow, controlling how different sections of the system interact. Through precise electronic signals, solenoids help optimize performance and ensure responsiveness under changing conditions.

Main Functions of Solenoids

- Controlling pressure levels to maintain efficient system operation

- Regulating flow to different sections depending on real-time needs

- Ensuring that components operate in harmony to prevent malfunctions

How Solenoids Impact Overall Performance

By swiftly adjusting their position based on electrical inputs, solenoids provide real-time management, which directly influences efficiency and reliability. Their precise control over the flow mechanisms results in smoother transitions and reduces wear on system components.

Clutch System in Automatic Transmissions

The clutch mechanism plays a crucial role in the seamless transfer of power within an automatic vehicle. This system ensures smooth engagement and disengagement of components, allowing for efficient control over gear changes. Without the proper functioning of these parts, the overall operation of the system would be compromised, leading to reduced performance.

In automatic setups, the clutch operates in a more complex manner compared to its manual counterpart. Instead of direct user input, it works through a series of hydraulic and electronic controls that manage the engagement of gears. This sophisticated design minimizes wear and enhances the durability of the drivetrain.

Another important aspect is the role of friction materials within the clutch. These materials are designed to endure high temperatures and pressure, ensuring long-term reliability. Proper maintenance of the system is essential to avoid slippage and other performance issues

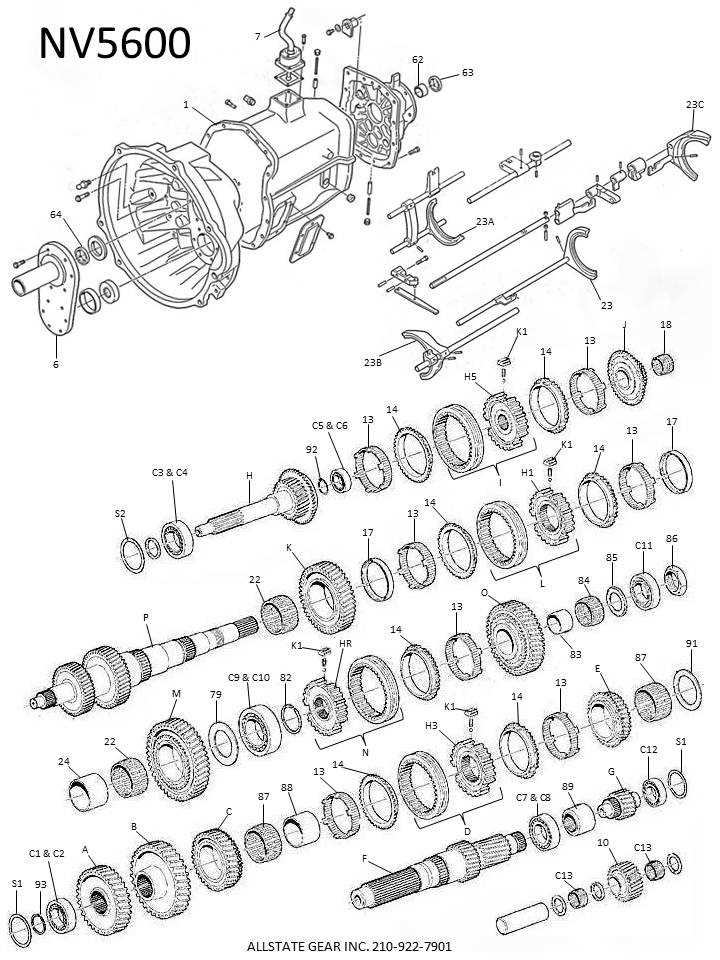

Planetary Gear Sets and Their Purpose

Planetary gear systems are a crucial component in various mechanical applications, allowing for efficient power transmission and speed variation. These systems consist of multiple gears that work together to achieve desired performance characteristics, making them integral to many automotive and industrial mechanisms.

Components of Planetary Gear Sets

The main elements of a planetary gear system include:

- Sun Gear: The central gear around which other gears rotate.

- Planet Gears: These gears orbit the sun gear and engage with both the sun and ring gears.

- Ring Gear: A gear that encircles the planet gears and meshes with them, allowing for power distribution.

- Carrier: The structure that holds the planet gears and allows them to rotate together.

Benefits of Planetary Gear Systems

Implementing planetary gear configurations offers several advantages:

- Compact Design: These systems provide high gear reduction ratios in a smaller footprint compared to other gear types.

- High Efficiency: The load distribution across multiple gears reduces friction, enhancing overall efficiency.

- Versatility: Planetary gear sets can be configured in various ways to meet specific speed and torque requirements.

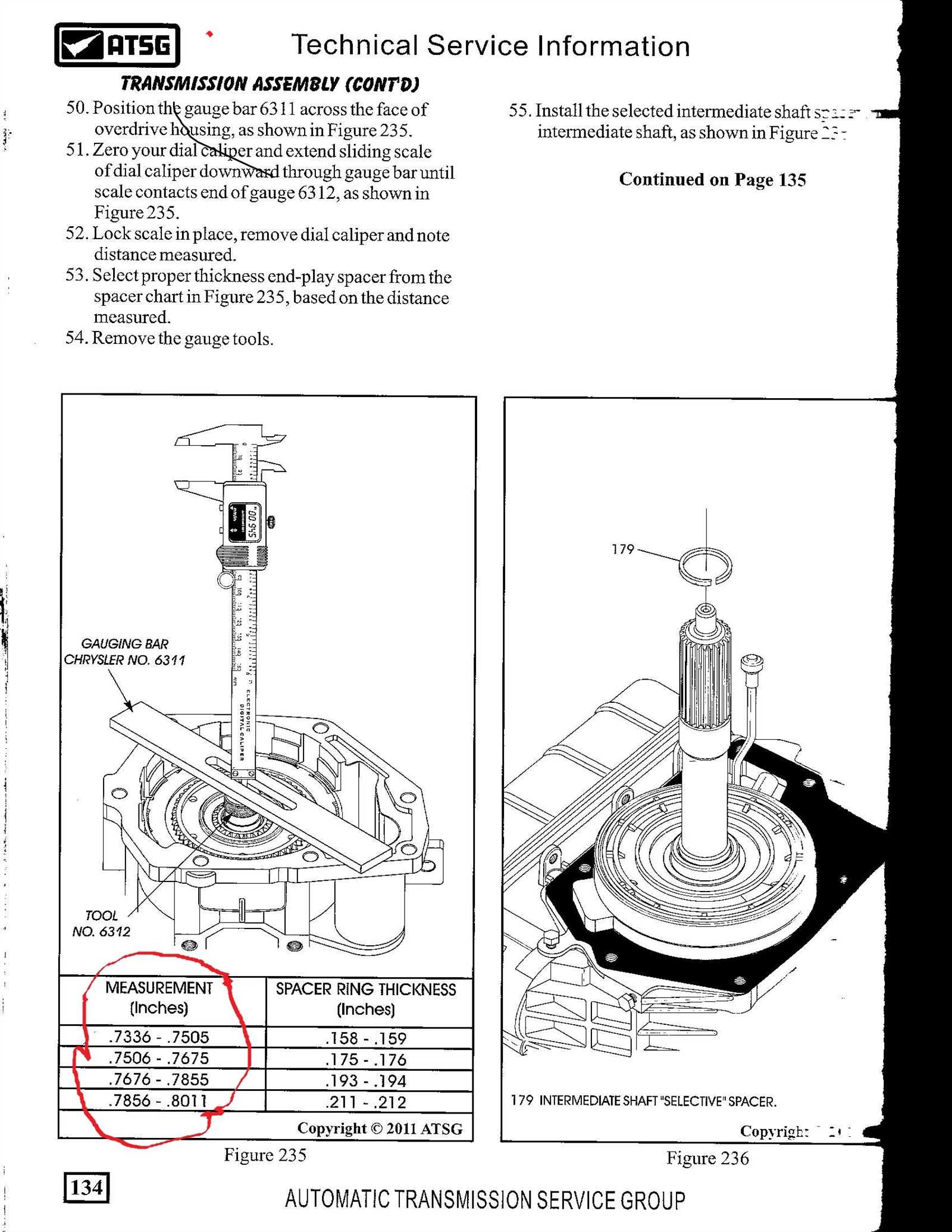

Fluid Pathways and Circulation

The movement and distribution of hydraulic fluid within a vehicle’s shifting mechanism play a crucial role in its operation. Understanding the pathways through which this essential fluid flows is vital for ensuring optimal performance and longevity of the system. Proper circulation facilitates the necessary pressure and lubrication, contributing to the efficient functioning of the various components involved.

Fluid circulation begins as the pump draws the lubricant from the reservoir, channeling it through a series of meticulously designed pathways. This flow not only aids in lubricating moving parts but also engages control mechanisms that influence gear changes. The efficiency of this system directly affects responsiveness and overall driving experience.

Pathway Description Intake The initial entry point where fluid is drawn from the reservoir. Pump Device that generates pressure to push the fluid through the system. Valve Body A crucial component that directs fluid flow to various channels based on operational demands. Cooling Circuit Path that allows fluid to pass through a cooling unit, reducing temperature and preventing overheating. Return Line Pathway for fluid to flow back to the reservoir after circulating through the system. Common Wear and Tear on Key Parts

In any mechanical assembly, certain components experience more significant degradation over time due to continuous use and the stresses of operation. Understanding the typical signs of wear can aid in proactive maintenance and help ensure optimal functionality.

Signs of Deterioration

The most prevalent indicators of wear include unusual noises, vibrations, and a decrease in performance. For instance, friction surfaces may become polished or grooved, resulting in less effective engagement. Additionally, seals and gaskets can harden or crack, leading to fluid leaks and compromised efficiency.

Preventative Measures

To extend the lifespan of crucial components, regular inspections and maintenance are essential. Replacing worn seals and ensuring proper lubrication can significantly reduce wear. Additionally, monitoring operating temperatures can help identify issues before they escalate into more serious problems.