In the world of outdoor equipment, a comprehensive understanding of machinery is essential for effective maintenance and repair. Knowing the individual elements that make up a machine can significantly enhance its longevity and performance. This section delves into the intricate details of a specific mowing device, providing insight into its functionality and essential features.

Identifying and comprehending the various components of a lawn mower is crucial for anyone looking to optimize its use. From the engine to the cutting blades, each part plays a vital role in the overall operation. By familiarizing oneself with these elements, users can ensure that their equipment runs smoothly and efficiently.

Moreover, having a clear picture of the layout and design of the machine assists in troubleshooting potential issues. Whether it’s for routine maintenance or more extensive repairs, understanding the configuration of the components can lead to more effective solutions. This exploration aims to provide the necessary knowledge to navigate the complexities of a mowing device confidently.

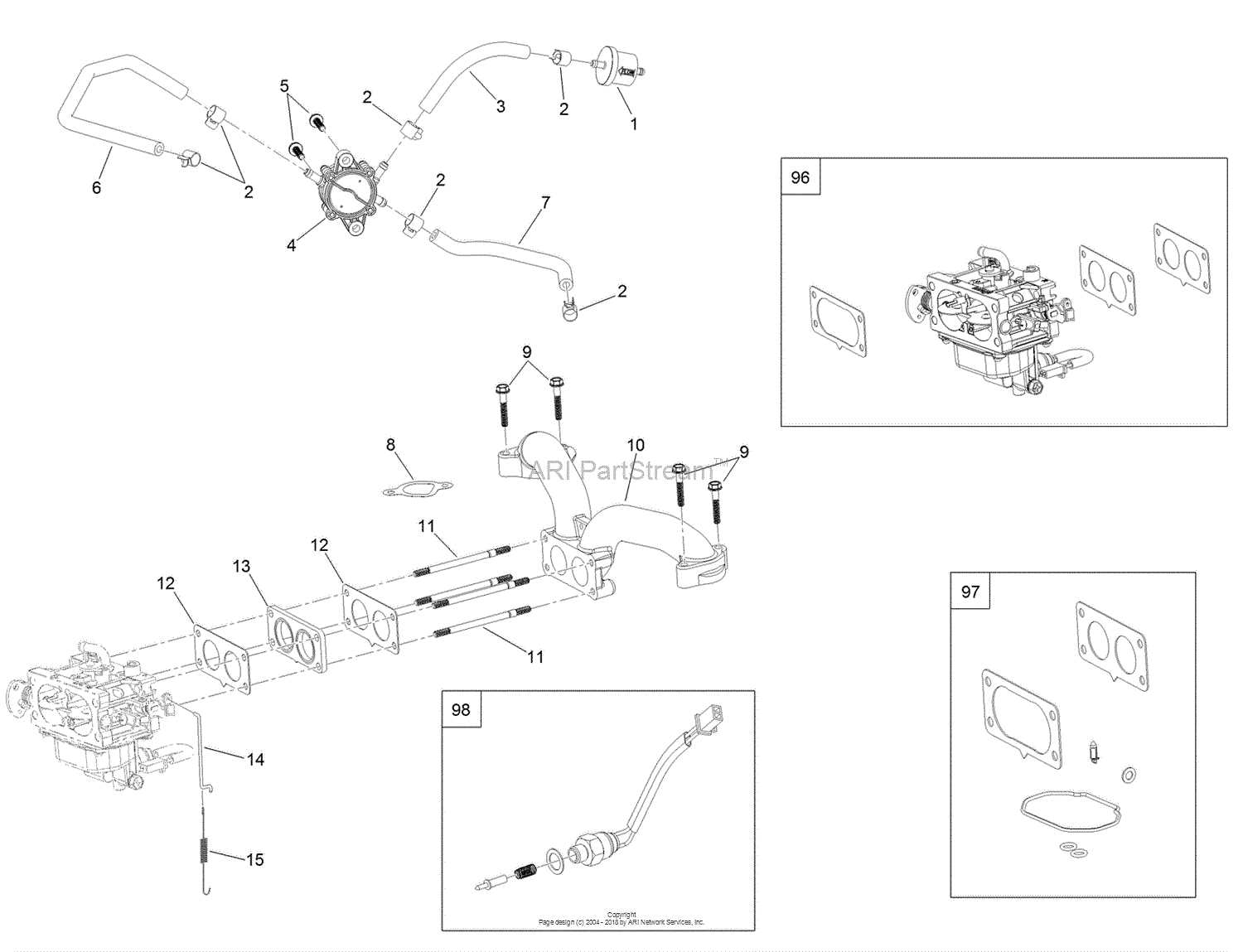

Understanding the components of a motor is essential for maintenance and troubleshooting. Each element plays a crucial role in the engine’s performance and efficiency. Familiarizing oneself with these parts helps ensure optimal functionality and longevity.

Main Components

- Cylinder Block: The core structure housing various engine elements.

- Pistons: Moving parts that create the power needed to drive the machine.

- Crankshaft: Converts the linear motion of the pistons into rotational motion.

- Valves: Control the intake of air and the exhaust of gases.

- Camshaft: Regulates the timing of valve operations.

Additional Elements

- Fuel Injectors: Deliver fuel to the combustion chamber.

- Ignition Coil: Generates the high voltage necessary for spark plugs.

- Cooling System: Maintains optimal operating temperatures.

- Oil Filter: Cleans the engine oil to ensure smooth operation.

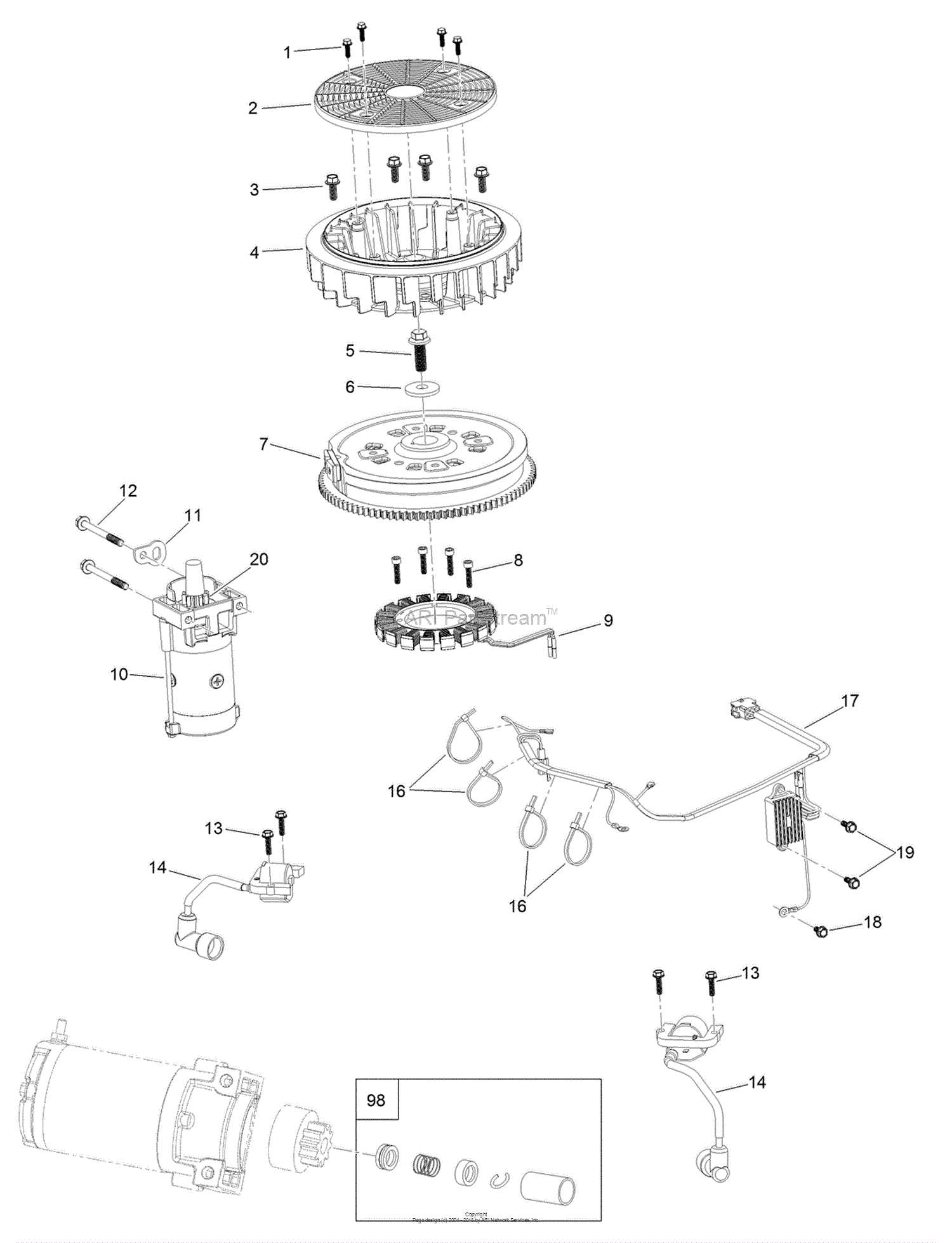

Transmission System Overview

The transmission system is a crucial component in modern machinery, responsible for transferring power from the engine to the wheels. This system plays a vital role in enhancing efficiency and performance by regulating the speed and torque of the vehicle. Understanding its structure and functionality can lead to better maintenance and operational practices.

Typically, the transmission consists of various elements, including gears, shafts, and belts, all working in harmony to ensure smooth operation. Gears are essential for altering the torque output, while shafts transmit rotational force. Additionally, belts serve to connect components, allowing for flexible movement and energy transfer throughout the system.

Regular inspection and timely replacement of worn parts are necessary to maintain optimal performance. Neglecting these aspects can lead to inefficient operation and potential breakdowns, ultimately affecting the overall functionality of the equipment. By familiarizing oneself with the transmission system, users can ensure longevity and reliability in their machinery.

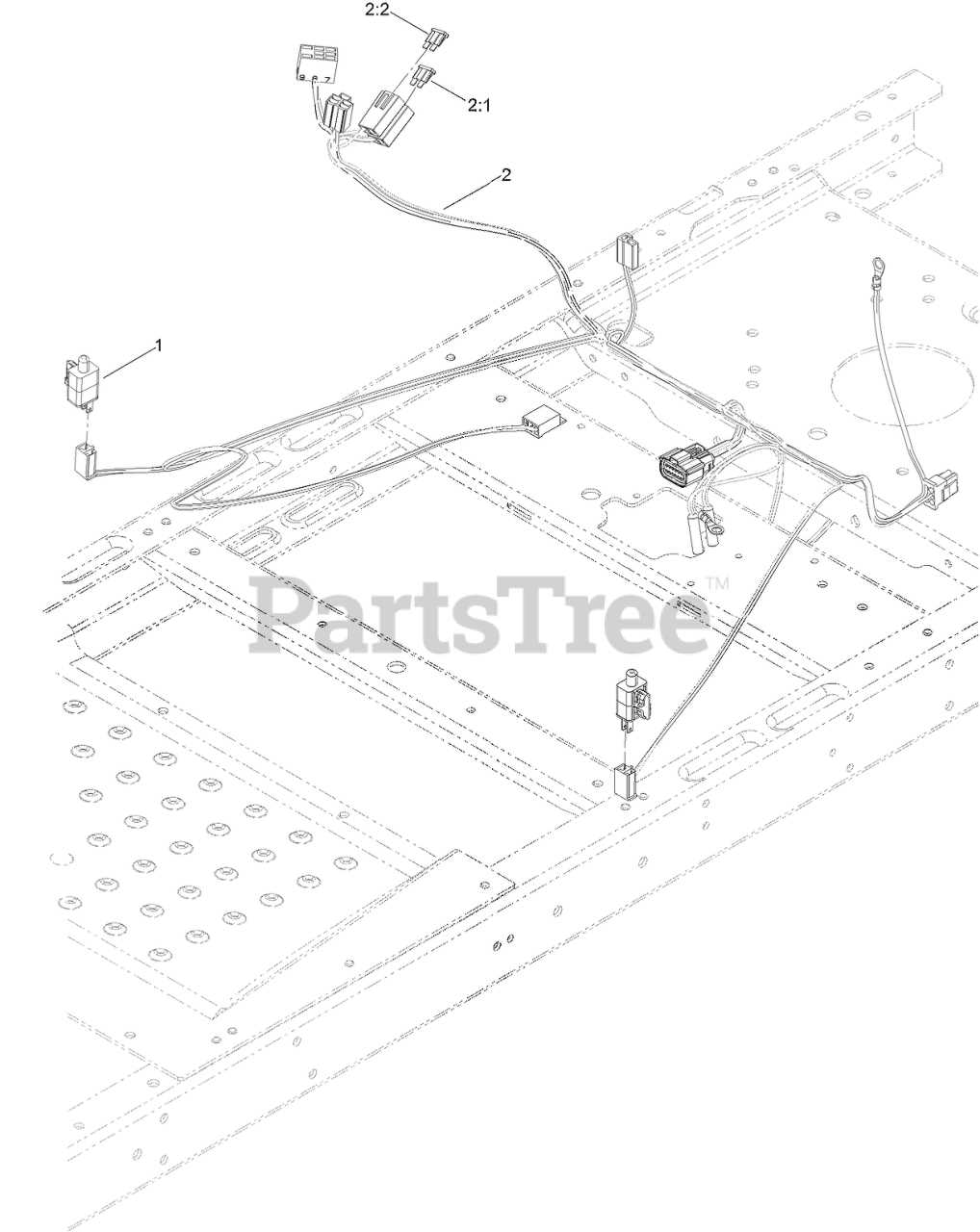

Electrical System Breakdown

The electrical framework of a lawn maintenance machine plays a critical role in its overall functionality. Understanding the components and their interactions is essential for effective troubleshooting and maintenance. This section explores the key elements that comprise the electrical setup, highlighting their functions and connections.

Main Components

- Batteries: Provide the necessary power for the machine’s operations.

- Wiring Harness: Connects various electrical parts, ensuring smooth power distribution.

- Switches: Control the flow of electricity to different functions, such as starting the engine and activating lights.

- Relays: Serve as electrically operated switches that manage high-current devices.

- Fuses: Protect the electrical system from overloads and short circuits.

Functionality Overview

Each element of the electrical system works in harmony to ensure the machine operates efficiently. Batteries supply power, while the wiring harness directs this energy to various components. Switches allow the operator to manage power flow, and relays enhance control over larger electrical demands. Fuses act as safety measures, preventing potential damage from electrical faults.

Regular inspection and maintenance of the electrical components can prevent issues and prolong the life of the machine. Understanding this system is crucial for anyone involved in the upkeep or repair of such equipment.

Maintenance Parts and Accessories

Proper upkeep of your mowing equipment is essential for ensuring longevity and optimal performance. Utilizing the right components and supplementary items can significantly enhance the functionality of your machine. Regular maintenance not only improves efficiency but also minimizes the likelihood of breakdowns, allowing for a seamless mowing experience.

To assist in maintaining your equipment, here are some essential items and their benefits:

| Accessory | Description | Benefits |

|---|---|---|

| Oil Filter | Removes contaminants from engine oil, ensuring clean lubrication. | Extends engine life and improves efficiency. |

| Air Filter | Prevents dirt and debris from entering the engine. | Enhances air flow and engine performance. |

| Blades | Cutting components that impact grass quality. | Provides a clean cut and promotes healthy growth. |

| Battery | Supplies power for starting and operation. | Ensures reliable starting and operation efficiency. |

| Belts | Transmit power from the engine to the cutting deck. | Maintains performance and prevents slippage. |

Diagram of Steering Mechanism

The steering system is a crucial component that enables precise control of movement and direction in various machinery. Understanding its layout and functionality can enhance maintenance and troubleshooting efforts. This section aims to provide an overview of the steering apparatus, highlighting its essential parts and their interconnections.

Components of the Steering System

The steering assembly consists of several key elements that work together to ensure smooth operation. Each part has a specific role, contributing to the overall effectiveness of the steering mechanism.

| Component | Description |

|---|---|

| Steering Wheel | The primary control interface for directing movement. |

| Steering Shaft | Transfers the rotational motion from the steering wheel to the mechanism. |

| Linkage System | Connects the steering wheel to the wheels, facilitating movement. |

| Gearbox | Reduces the effort needed to turn the steering wheel and enhances responsiveness. |

Functionality Overview

Each component plays a vital role in the overall functionality of the steering mechanism. The interaction between the steering wheel, shaft, and linkage system enables effective maneuverability. Understanding this relationship is essential for optimizing performance and ensuring long-term reliability.

Wheels and Tire Specifications

This section delves into the essential characteristics of the rolling components that significantly influence performance and handling. Understanding the specifications of these elements is crucial for optimal functionality and ensuring a smooth operation.

General Dimensions

The size and configuration of the wheels and tires play a vital role in determining the overall effectiveness of the equipment. Proper measurements are necessary for compatibility and optimal performance.

| Feature | Specification |

|---|---|

| Diameter | 20 inches |

| Width | 10 inches |

| Tread Pattern | All-terrain |

| Inflation Pressure | 12 PSI |

Material Composition

The composition of the wheels and tires is critical for durability and performance. High-quality materials contribute to a longer lifespan and better resistance to wear.

Common Replacement Parts Explained

Understanding the components that may need to be replaced during regular maintenance is essential for ensuring optimal performance and longevity of your equipment. Regular wear and tear can lead to various parts requiring attention, and knowing these components can help you make informed decisions when repairs are necessary.

Frequently Replaced Components

- Blades: Sharp and efficient blades are crucial for achieving a clean cut. Over time, blades can become dull or damaged, necessitating replacement for optimal cutting performance.

- Belt: The drive belt is responsible for transferring power from the engine to the cutting deck. A worn or frayed belt can lead to reduced performance or complete failure, making timely replacement essential.

- Filters: Air and fuel filters play a vital role in maintaining engine efficiency. Clogged filters can restrict airflow or fuel flow, leading to decreased performance and potential engine damage.

- Wheels: The wheels bear the weight of the equipment and provide mobility. Regular inspection for wear can prevent issues with movement and handling.

Signs of Wear and When to Replace

- Dull Blades: If the grass is tearing rather than cutting cleanly, it may be time to replace the blades.

- Squeaking Noises: Unusual noises from the belt area can indicate wear, suggesting a need for replacement.

- Reduced Engine Performance: If the engine struggles to start or maintain power, check the filters for blockages.

- Visible Damage: Any cracks or severe wear on wheels can impact functionality and should be replaced immediately.