When it comes to maintaining a powerful and efficient lawn machine, understanding its internal systems and key elements is crucial. These machines are built with a combination of mechanical and electrical elements that work together to provide a smooth and effective cutting experience. Knowing how each part functions allows users to perform routine maintenance and make necessary repairs, ensuring a long lifespan for the equipment.

Each section of the machine serves a specific role, from the engine that powers the movement to the deck responsible for the cutting action. The arrangement of these sections ensures a balanced and coordinated operation, allowing for precise adjustments depending on the needs of the terrain. By familiarizing yourself with these systems, you can better understand how to optimize performance and maintain efficiency over time.

Regular inspections and a solid grasp of how the components interact with one another can help prevent issues before they arise. This proactive approach ensures that users can handle minor fixes and identify potential problems, keeping their equipment in top condition and avoiding costly repairs.

Toro TimeCutter Z5000 Parts Overview

This section provides a detailed look at the components that make up this efficient and reliable machine. Understanding the structure and functionality of various elements is crucial for maintaining its performance and ensuring long-lasting durability. Each element plays a role in ensuring smooth operation, from the power system to the mechanical controls.

Key features include components responsible for propulsion, steering, and cutting operations. These crucial systems are designed for high performance, providing a balanced mix of power and precision. A well-organized configuration enhances the overall user experience and ensures ease of maintenance.

The focus here is on the essential mechanisms that drive the machine’s efficiency. By familiarizing yourself with these components, you can better understand how to perform routine maintenance and troubleshooting, keeping the machine in peak condition for years to come.

Understanding the Key Components

When maintaining or repairing a machine, it’s essential to be familiar with its main elements. Each section of the equipment plays a vital role in ensuring smooth operation and long-lasting performance. By gaining a deeper knowledge of how these pieces work together, one can troubleshoot more effectively and keep everything running in optimal condition.

Engine: This is the powerhouse that drives the entire system. Regular upkeep and monitoring are crucial to prevent wear and ensure efficiency.

Blades: These sharp, durable pieces are responsible for cutting and trimming. Their condition directly impacts the quality of the job, making frequent sharpening or replacement necessary.

Transmission: The transmission controls the movement, making sure the machine can adjust speeds smoothly. Proper lubrication and timely checks are essential for this component.

Frame: The structure supports all other parts, providing stability and durability. A strong frame ensures the equipment can handle tough conditions and last over time.

By understanding these critical elements, you can maintain your machine effectively, reduce downtime, and extend its lifespan.

Engine Specifications and Maintenance Tips

Understanding the key aspects of an engine’s performance and how to maintain it properly ensures that your equipment functions efficiently over time. This section highlights essential details about the engine’s characteristics and offers practical advice for upkeep, helping you get the most out of your machine.

Key Engine Specifications

- Displacement: A crucial factor determining the power output, typically measured in cubic centimeters (cc).

- Horsepower: Defines the engine’s strength, influencing the overall performance of your equipment.

- Fuel System: The type of fuel system used, such as carburetor or fuel injection, impacts fuel efficiency and reliability.

- Cooling System: Air-cooled or liquid-cooled systems help manage heat to ensure optimal operation.

Maintenance Tips for Longevity

- Regularly check the oil level and change it as per the manufacturer’s recommendations to prevent engine wear.

- Inspect and clean the air filter to ensure proper airflow and prevent debris from entering the engine.

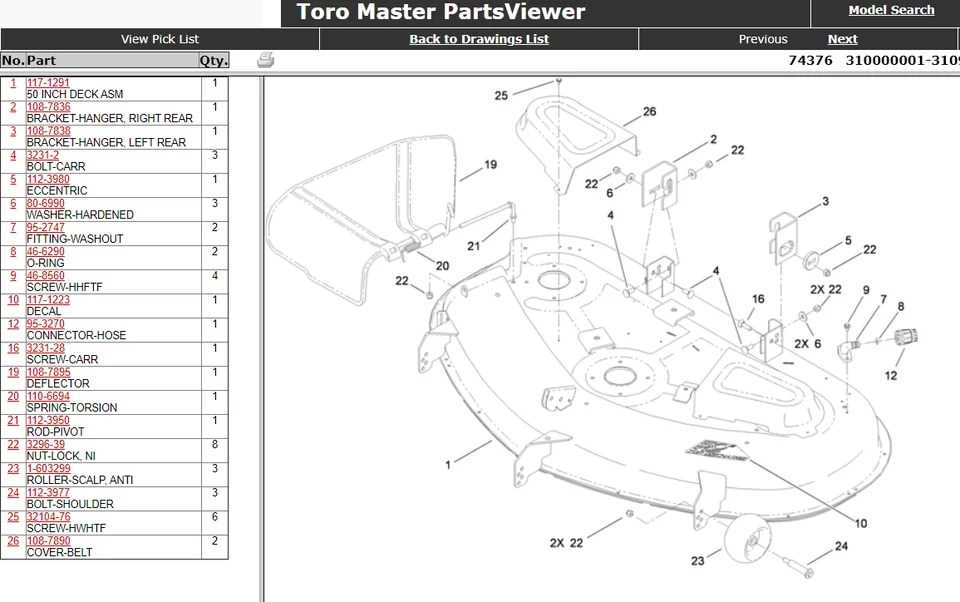

Blade System and Cutting Deck Assembly

The blade system and deck structure play a crucial role in maintaining efficient and precise grass cutting. Understanding how these elements interact is essential for ensuring optimal performance and long-lasting operation. The cutting deck not only houses the blades but also influences the overall cutting quality by regulating airflow and grass discharge.

Blade Configuration and Function

The blades are designed to rotate at high speeds, providing a clean and even cut across the lawn. Proper alignment and sharpness of the blades are vital for effective grass trimming. Regular maintenance, such as sharpening and balancing, can prevent uneven cuts and reduce wear on the cutting mechanism.

Deck Maintenance and Adjustments

Maintaining the cutting deck involves inspecting for any wear or damage and ensuring that the height adjustments are set correctly. A well-maintained deck allows for smooth operation and consistent cutting results. Proper cleaning and lubrication can extend the life of the components, ensuring they remain in optimal condition.

Transmission and Drive Mechanism Details

The transmission and drive system plays a crucial role in ensuring the smooth operation of the equipment. It is responsible for transferring power from the engine to the wheels, allowing for efficient movement and control. Understanding the components of this system helps in maintaining optimal performance and longevity.

Below are the key elements that make up the transmission and drive mechanism:

- Hydrostatic Transmission: This system provides variable speed control by utilizing hydraulic fluid to transmit power, ensuring smooth acceleration and deceleration.

- Drive Belt: A durable belt that transfers power from the engine to the transmission, enabling the wheels to turn and the equipment to move.

- Axles and Wheel Assembly: These components are crucial for supporting the weight and ensuring smooth movement across various terrains.

- Control Levers: These levers allow the operator to adjust speed and direction, providing precise control over the movement.

Proper maintenance of these parts is essential for the long-term reliability of the machine. Regular inspections and timely replacements can prevent potential breakdowns and ensure smooth operation.

Electrical System Diagram and Troubleshooting

This section focuses on the intricacies of the electrical configuration and the associated troubleshooting methods. Understanding the components and their interconnections is crucial for effective maintenance and repair. An accurate grasp of the system can significantly reduce downtime and improve operational efficiency.

Key Components of the Electrical System

The electrical system consists of several vital elements that work in harmony to ensure optimal performance. Here is an overview of these components:

| Component | Description |

|---|---|

| Batteries | Provide the necessary power to start the engine and operate electrical components. |

| Switches | Control the flow of electricity to various parts of the system. |

| Relays | Act as switches that enable higher current devices to be controlled by lower current signals. |

| Fuses | Protect the electrical system from overloads and short circuits. |

Troubleshooting Common Issues

Identifying and resolving electrical problems can be straightforward with a systematic approach. Here are some common issues and their potential solutions:

| Issue | Possible Solution |

|---|---|

| Device not starting | Check battery voltage and connections. |

| Lights flickering | Inspect the wiring and replace any damaged components. |

| Blown fuses | Replace fuses and investigate the cause of the overload. |

| Unresponsive controls | Examine the switches and relays for malfunction. |

Fuel System Components and Care

The fuel system is essential for the efficient operation of any engine. It comprises several components that work together to ensure a steady supply of fuel to the engine, promoting optimal performance and longevity. Understanding these parts and how to maintain them can significantly enhance the functionality of your machinery.

Key elements of the fuel system include the fuel tank, fuel lines, fuel filter, and fuel pump. The fuel tank stores the fuel until it is needed, while the fuel lines transport it to the engine. The fuel filter plays a crucial role in removing contaminants from the fuel, protecting the engine from potential damage. The fuel pump is responsible for delivering fuel from the tank to the engine at the appropriate pressure.

Regular maintenance of these components is vital for ensuring reliable operation. Inspect fuel lines for cracks or leaks, and replace them as necessary. Change the fuel filter at recommended intervals to prevent clogs. Additionally, keep the fuel tank clean and free from debris to avoid contamination. By taking proactive steps to care for the fuel system, you can improve the overall performance and lifespan of your equipment.

Hydraulic System Parts and Functionality

The hydraulic system plays a crucial role in the operation of various machinery, utilizing fluid pressure to generate movement and power. This system consists of several components that work together seamlessly to ensure efficient performance and reliability.

Main Components of the Hydraulic System

- Hydraulic Pump: Responsible for converting mechanical energy into hydraulic energy, generating the flow of fluid necessary for system operation.

- Hydraulic Cylinder: Converts hydraulic energy back into mechanical energy, producing linear motion to drive various functions.

- Control Valves: Regulate fluid flow and direction, allowing for precise control of the system’s movements.

- Reservoir: Stores hydraulic fluid and helps maintain optimal fluid levels within the system.

- Hydraulic Hoses and Fittings: Connect various components, ensuring efficient fluid transfer and preventing leaks.

Functionality Overview

The effectiveness of a hydraulic system relies on the coordinated action of its components. The pump draws fluid from the reservoir, pushing it through the hoses to the control valves. These valves direct the flow to the hydraulic cylinder, which then moves according to the operator’s input. This process allows for various tasks to be accomplished efficiently, from lifting heavy loads to steering machinery.

Steering and Control Mechanism Breakdown

The steering and control mechanism is a crucial component in ensuring the efficient maneuverability of the machine. This system encompasses various elements that work together to provide the operator with responsive handling and precise control during operation.

Key components of this mechanism include:

- Steering Wheel: The primary interface for the operator, allowing for directional changes.

- Control Levers: These levers regulate speed and direction, enabling smooth transitions and adjustments.

- Linkage System: Connects the steering wheel and control levers to the steering mechanism, translating inputs into movement.

- Braking System: Works in conjunction with the steering mechanism to ensure safe stopping and control during operation.

Understanding the arrangement and function of these components is essential for maintaining optimal performance and addressing any issues that may arise. Proper maintenance and timely replacement of worn parts are vital for ensuring the longevity and reliability of the steering and control system.