The design and organization of mechanical systems in agricultural machinery play a crucial role in ensuring efficiency and long-lasting performance. By examining the various components and their connections, users can better understand how each part contributes to the overall functionality. This knowledge is essential for effective maintenance and repair.

When exploring the layout of key mechanical elements, it’s important to focus on the intricate relationships between each piece. Every detail matters, and recognizing how individual sections interact can help prevent issues and ensure smoother operation. Whether you’re addressing routine upkeep or troubleshooting, a thorough understandi

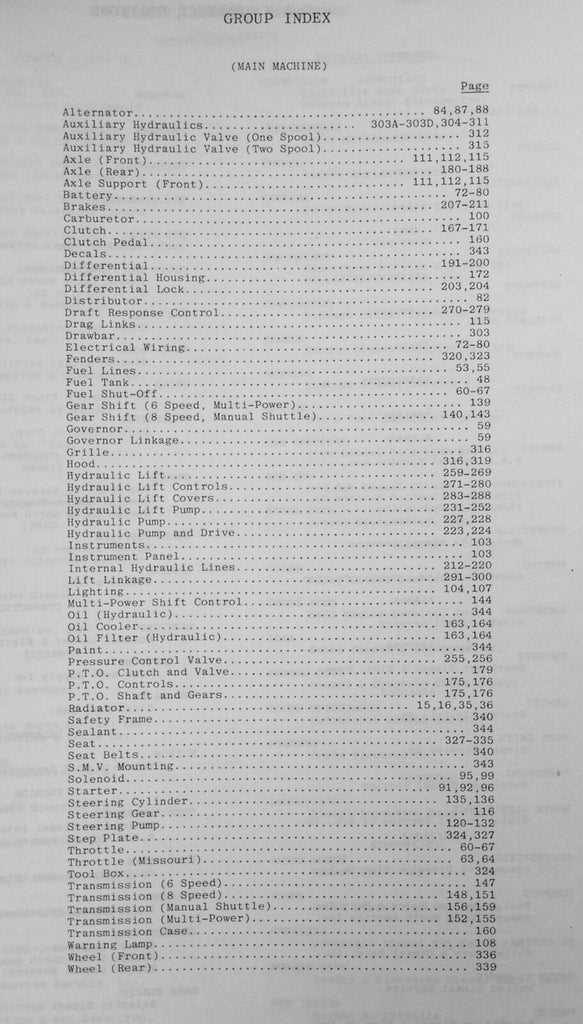

Overview of Key Components

In this section, we explore the essential elements of the machinery’s structure, which contribute to its effective operation and long-term durability. Each component plays a vital role in ensuring the system functions seamlessly, allowing the machine to handle various tasks with precision and efficiency. Understanding these parts is crucial for proper maintenance and repair.

Engine and Power System

The heart of the equipment lies in its power generation system, responsible for delivering the necessary energy to perform a wide range of tasks. This includes the fuel mechanism, cooling setup, and other interconnected elements that ensure continuous operation under different conditions.

Transmission and Drivetrain

The mechanism responsible for transferring energy from the power source to the wheels is

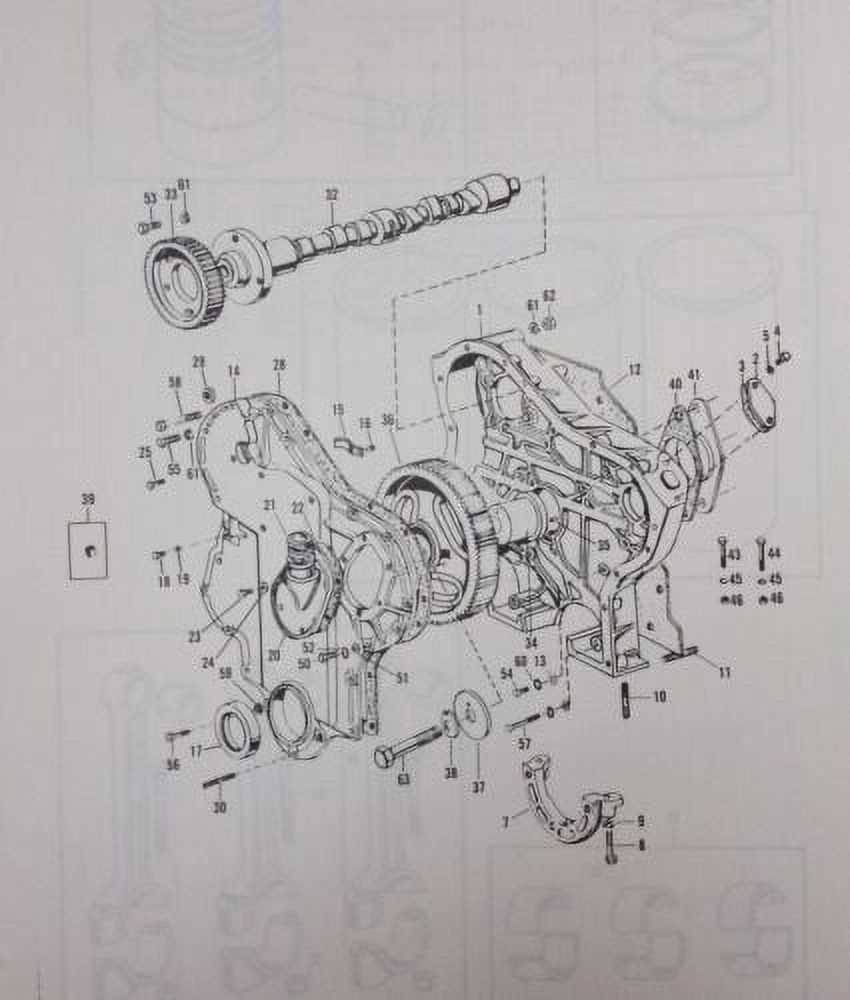

Understanding the Engine Assembly

The engine assembly is a critical component of any machinery, responsible for powering the entire system. Its structure includes various interconnected parts that work together to ensure smooth operation. A deep understanding of this assembly allows for better maintenance and performance optimization.

At the core, the engine comprises multiple sections that handle specific tasks, such as fuel combustion, air intake, and exhaust expulsion. These sections must be well-aligned and regularly inspected to prevent malfunctions or inefficiencies. Each part has a unique role, and even minor wear can impact overall functionality.

Ensuring the proper integration of these elements is essential for achieving peak efficiency. Routine checks and timely replacements of worn components can significantly extend the engine’s lifespan and maintain its reliability over time. Understanding the relationship between these parts helps in diagnosing issues early and implementing effective solutions.

Transmission System Breakdown

The transmission system plays a crucial role in ensuring smooth power transfer between the engine and the wheels. This section provides an overview of the key components involved and how they work together to maintain efficiency and performance. Understanding the individual parts of the system can help diagnose and address potential issues.

Main Components of the Transmission

- Clutch assembly

- Gearbox

- Driveshaft

- Differential

Common Transmission Issues

- Gear slipping or difficulty in shifting

- Unusual noises during gear changes

- Fluid leaks and low fluid levels

- Overhe

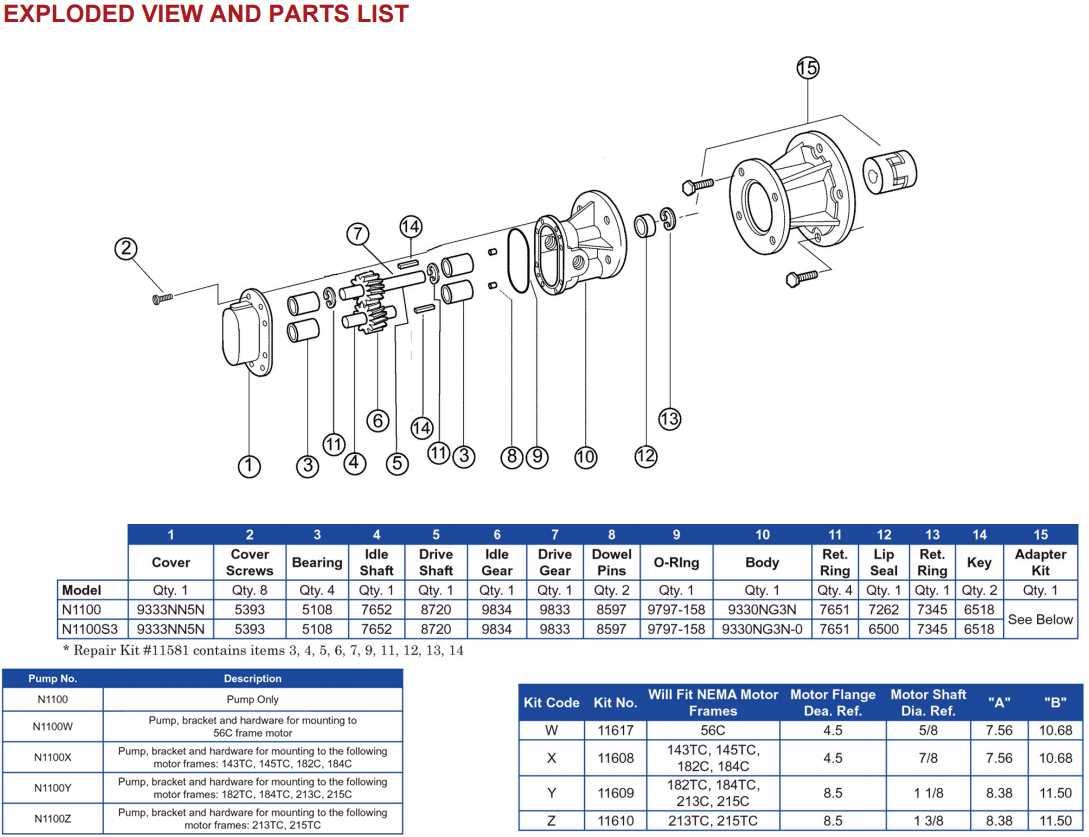

Hydraulic Mechanisms and Functions

Hydraulic systems play a crucial role in various mechanical devices, ensuring efficient operation by utilizing fluid power. These systems allow for smooth and precise control of heavy machinery, making them essential for a wide range of applications. The fluid’s pressure and flow are manipulated to perform tasks that require substantial force, such as lifting or moving heavy loads.

Key Components of these systems typically include pumps, valves, and actuators. Pumps generate the necessary pressure, while valves regulate the direction and flow of the fluid. Actuators, often in the form of cylinders, convert the hydraulic energy into mechanical motion.

The functionality of hydraulic systems ensures seamless operation, as fluid under pressure is distributed through hoses and fittings to drive mechanical parts. This setup provides the strength and control needed to handle complex tasks with minimal effort.

Exploring the Electrical Systems

The electrical framework of agricultural machinery plays a vital role in ensuring smooth operation and control of various functions. Understanding how the electrical system operates can assist in maintaining performance and identifying potential issues, without requiring specialized expertise. Key elements of this system ensure the machine’s essential tasks are powered and synchronized effectively.

Key Components of the Electrical System

From the battery to the ignition and lights, each part of the electrical system must work in harmony. These components regulate the flow of power, ensuring reliable operation during both basic and advanced tasks. Identifying potential issues early on can prevent larger problems and ensure continuous functionality in the field.

Component Function Battery Stores and supplies electrical energy Axles and Drive System Layout

The axle and drive system serves as a crucial component in agricultural machinery, facilitating power transmission and providing essential support for various implements. Understanding the arrangement and function of these elements is vital for maintaining optimal performance and ensuring smooth operation.

Typically, the drive system consists of several interconnected parts, each playing a significant role in the overall functionality:

- Axles: These structural components bear the weight of the machine and are responsible for transmitting power from the engine to the wheels.

- Transmission: This system converts the engine’s output into usable torque, allowing for various speeds and driving conditions.

- Drive Shafts: These elements transfer rotational force from the engine to the wheels, playing a critical role in mobility.

- Differentials: This mechanism enables wheels to rotate at different speeds, particularly important when navigating turns.

- Wheel Hubs: These components connect the wheels to the axles, ensuring secure attachment and facilitating rotation.

Proper maintenance of the axle and drive system is essential to prevent breakdowns and extend the lifespan of the machinery. Regular inspections and timely replacements of worn components can enhance the overall efficiency of agricultural operations.

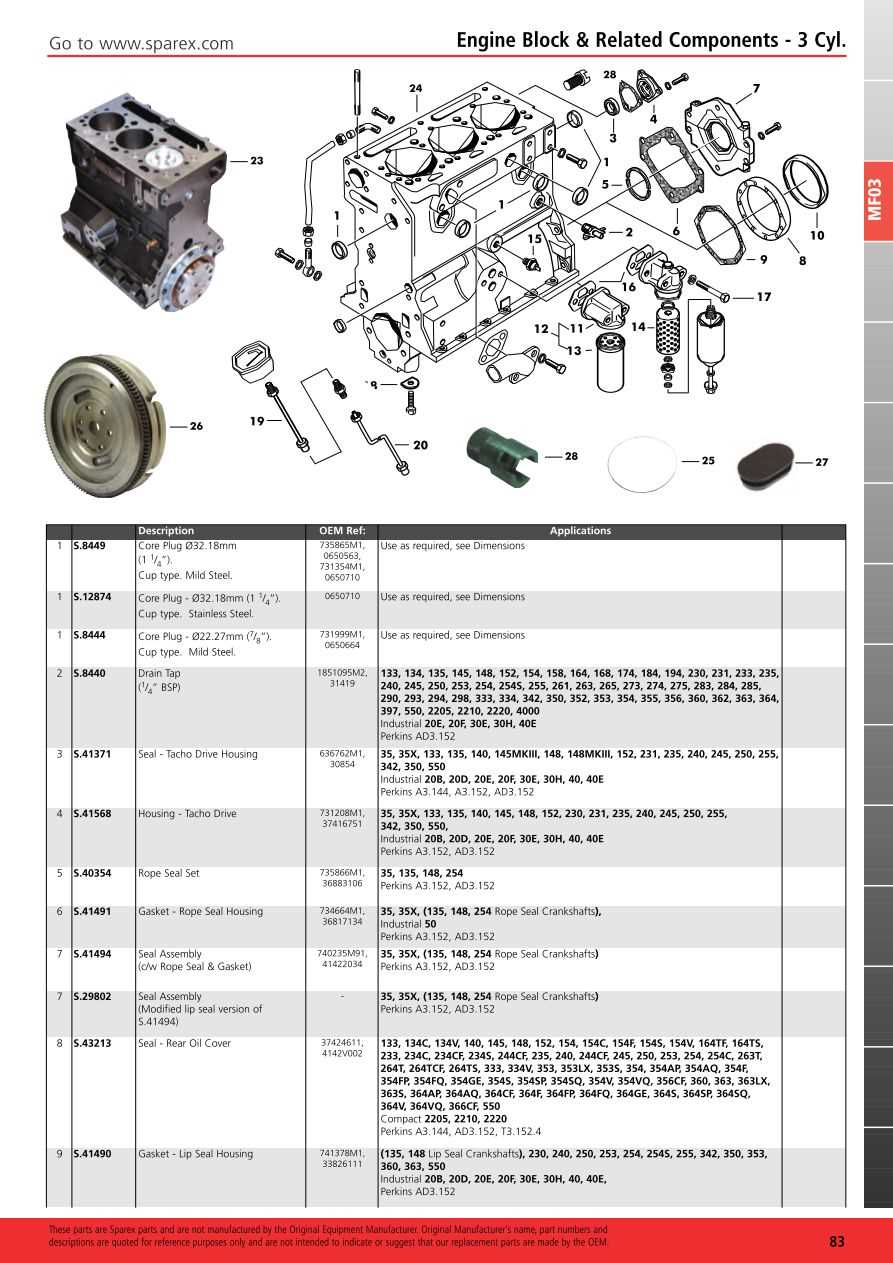

Fuel System and Related Parts

The fuel system is a crucial component of any engine, ensuring the proper delivery and management of fuel for optimal performance. This system encompasses various elements that work in harmony to facilitate fuel flow, combustion, and efficiency. Understanding these components is essential for effective maintenance and troubleshooting.

Component Description Fuel Tank The storage unit for fuel, designed to provide a steady supply while preventing contamination. Fuel Pump A device that moves fuel from the tank to the engine, ensuring adequate pressure for efficient operation. Fuel Filter Filters out impurities and debris from the fuel before it reaches the engine, protecting sensitive components. Fuel Injector Sprays the appropriate amount of fuel into the combustion chamber, contributing to optimal combustion. Fuel Lines Hoses that transport fuel between the tank, pump, filter, and engine, designed to withstand pressure and prevent leaks. Brake System and Safety Features

The braking mechanism of agricultural machinery plays a vital role in ensuring operator safety and effective machine control. It comprises various components that work together to provide reliable stopping power, especially in challenging terrain. Understanding the function and maintenance of these systems is essential for optimal performance and safety during operation.

One of the critical elements of the braking system is the hydraulic brake, which offers enhanced stopping capability by using fluid pressure. This system is designed to respond quickly to operator input, allowing for smooth deceleration. Additionally, the presence of a parking brake ensures that the machine remains stationary when not in use, preventing unintended movement.

Safety features are integrated into the braking system to protect the operator and surrounding environment. These include anti-lock brakes, which help maintain control during sudden stops by preventing wheel lock-up. Moreover, regular maintenance and inspection of brake components are crucial to avoid potential failures, ensuring that the machinery operates safely and effectively.

Maintenance and Replacement Tips

Proper upkeep and timely substitutions are crucial for ensuring the longevity and optimal performance of your agricultural machinery. Regular inspections can help identify potential issues before they escalate, allowing for efficient repairs and replacements.

Regular Checks: It is essential to routinely examine the essential components of the equipment. Look for signs of wear, such as unusual noises, leaks, or vibrations. Regular maintenance can prevent costly breakdowns and enhance operational efficiency.

Fluid Levels: Maintaining appropriate fluid levels, including oil and coolant, is vital for the smooth functioning of the machinery. Check these levels frequently and top them off as needed to avoid overheating and ensure effective lubrication.

Replacement Intervals: Adhere to recommended replacement schedules for filters, belts, and other critical components. Following the manufacturer’s guidelines helps in maintaining optimal performance and reduces the risk of unexpected failures.

Professional Assistance: When in doubt, seek help from qualified technicians who can provide expert advice and services. They can assist with complex repairs and ensure that all replacements are conducted properly, safeguarding the integrity of your equipment.