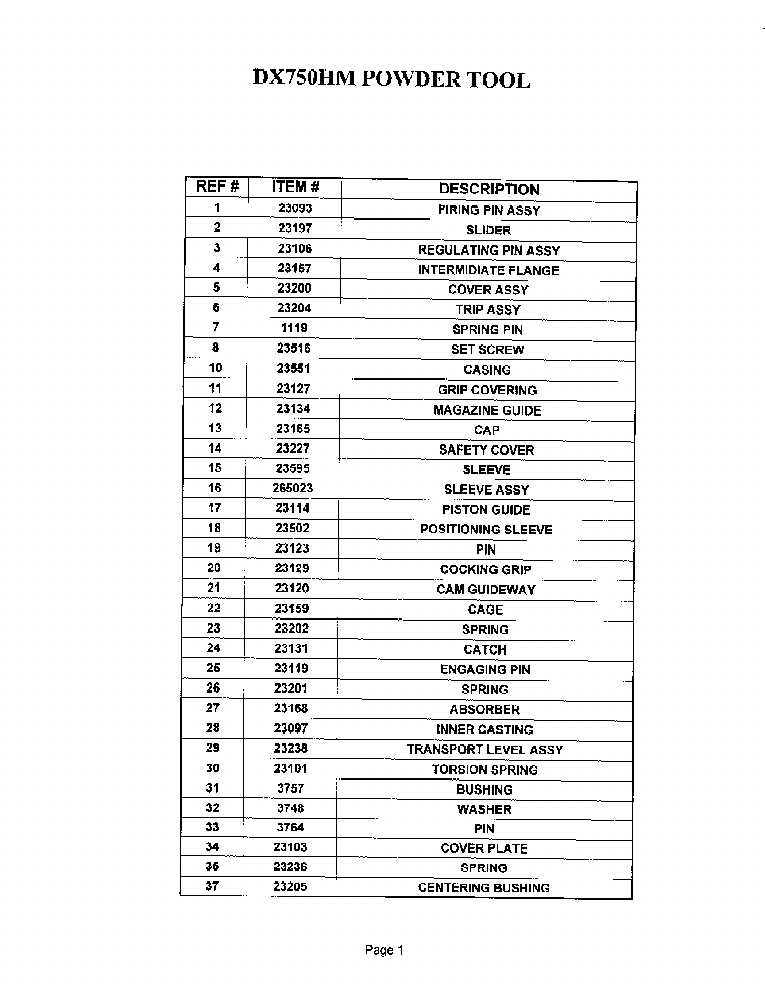

When working with specialized equipment, grasping the intricate layout of its components is crucial for both maintenance and efficient operation. A comprehensive overview of these elements not only aids in troubleshooting but also enhances overall functionality.

This guide aims to provide a visual representation of the various parts associated with a specific fastening device. By examining the configuration, users can better understand how each element interacts, ultimately leading to improved performance.

Diving deeper into the mechanics allows for a more profound appreciation of the tool’s design. Recognizing the role of each section paves the way for informed decisions during repairs and upgrades, ensuring that the tool remains reliable in demanding environments.

Understanding Hilti DX 351 Overview

This section provides a comprehensive look at a specific tool designed for fastening applications, highlighting its components and functionalities. By exploring the essential elements, users can better grasp how to operate and maintain this equipment effectively.

| Component | Function |

|---|---|

| Body | Houses the internal mechanisms and provides structural integrity. |

| Trigger | Activates the fastening process, ensuring precision and control. |

| Magazine | Holds the fasteners, facilitating quick reloading and efficiency. |

| Safety Mechanism | Prevents accidental discharge, enhancing user safety. |

| Barrel | Guides the fastener during insertion, ensuring accurate placement. |

Key Components of Hilti DX 351

This section explores the essential elements that contribute to the functionality and efficiency of a specific fastening tool. Understanding these components is crucial for maintenance and optimal operation.

| Component | Description |

|---|---|

| Power Source | Provides the necessary energy to drive fasteners effectively. |

| Trigger Mechanism | Initiates the fastening process when engaged by the user. |

| Guide Tube | Aligns fasteners for accurate placement during operation. |

| Loading Chamber | Holds and feeds fasteners into the tool for usage. |

| Safety Lock | Prevents accidental firing when not in use. |

Importance of Parts Diagram

A comprehensive visual representation of components is essential for effective maintenance and repair tasks. Such illustrations serve as valuable tools, enabling technicians and users to understand the assembly and function of intricate systems. This clarity helps in identifying individual elements, ensuring accurate replacement and efficient troubleshooting.

Facilitating Repairs

Detailed visuals significantly streamline the repair process. By providing clear references, they allow users to quickly locate and identify the necessary elements that may require attention or replacement. This efficiency reduces downtime and enhances productivity, ultimately leading to more effective service outcomes.

Enhancing User Knowledge

Visual representations also contribute to a deeper understanding of how a system operates. By familiarizing users with each component’s role, these illustrations promote informed decision-making during repairs or upgrades. Greater knowledge translates to improved confidence in handling complex machinery, fostering a culture of safety and proficiency.

Common Issues with Hilti DX 351

When working with power fastening tools, it is essential to understand the potential challenges that may arise during operation. Over time, even the most reliable equipment can experience performance issues. For users of certain construction tools, regular use may lead to complications that affect efficiency and safety. These problems can stem from various components, including internal mechanisms, safety features, and user handling. Identifying common issues can help in troubleshooting and maintenance, ensuring that the tool operates optimally and minimizes downtime.

One frequent issue is related to misfires or jams, which can occur when the tool fails to discharge fasteners properly. This problem is often linked to an accumulation of debris or incorrect loading of the fastener magazine. Another issue involves inconsistent firing power, which can be a result of low pressure in the internal system or worn-out springs. Additionally, tool users may face difficulties with the safety lock mechanism, leading to malfunctioning or difficulty in operation. Finally, overheating and excessive wear of key components can affect the longevity of the tool, necessitating regular inspections and timely replacement of worn parts.

Addressing these concerns through routine maintenance and proper handling will not only extend the life of the tool but also enhance overall performance on the job site. Being aware of these common issues is crucial for preventing costly repairs and ensuring the tool remains in good working condition for extended periods.

Maintenance Tips for Durability

Proper maintenance is crucial to ensuring the long-term performance and reliability of your tool. Regular attention to key components and careful handling can significantly extend its lifespan and minimize the need for frequent repairs. Following a consistent maintenance routine will help to avoid downtime and maintain optimal functionality, even under challenging conditions.

Regular Cleaning

Frequent cleaning is essential for preventing dust, debris, and other contaminants from building up inside the device. Keeping the tool free from foreign particles will help to avoid unnecessary wear and tear on internal mechanisms. Use a soft brush or compressed air to clean out any areas where buildup may occur, and ensure that no dirt or moisture is trapped in sensitive parts.

Lubrication and Inspection

Regular lubrication is necessary to keep moving parts functioning smoothly. Apply high-quality lubricants to the appropriate areas as indicated by the manufacturer’s recommendations. In addition, it’s important to regularly inspect all components for signs of damage or excessive wear. Early detection of issues can prevent more serious malfunctions down the line, saving you both time and money.

Always follow the guidelines provided by the manufacturer to ensure that your tool remains in top condition. By maintaining a routine of cleaning, lubricating, and inspecting, you’ll contribute to the durability and efficiency of your equipment, making it a reliable asset for any task.

How to Replace Components

Replacing components in your equipment is essential for maintaining optimal performance and prolonging its lifespan. Whether you are dealing with worn-out pieces or upgrading certain elements, understanding the replacement process is crucial. This guide will walk you through the necessary steps to ensure a smooth transition and restore functionality.

Before you start, gather all required tools and new components. It’s important to work in a clean and organized environment to avoid losing small parts. Follow these steps to successfully replace the components:

| Step | Description |

|---|---|

| 1 | Power off the device and unplug it to ensure safety. |

| 2 | Remove any housing or coverings that may obstruct access to the components. |

| 3 | Carefully detach the old component using appropriate tools, taking care not to damage surrounding parts. |

| 4 | Inspect the area for any debris or damage before installing the new piece. |

| 5 | Install the new component, ensuring it fits securely and aligns properly with existing fixtures. |

| 6 | Reattach any housing or coverings that were removed earlier. |

| 7 | Power on the device and conduct a test to confirm that everything operates correctly. |

By following these steps, you can effectively replace components and enhance the overall performance of your equipment. Regular maintenance checks can also help identify parts that may need replacement before they fail, ensuring your tools remain in excellent condition.

Where to Find Replacement Parts

When seeking to repair or upgrade a tool, it’s essential to know where to obtain high-quality components. Locating reliable suppliers ensures that your equipment will continue to perform at its best. There are several options available for sourcing these items, ranging from official service centers to trusted online platforms.

Official Service Centers

The most straightforward option is to visit the authorized service center of the manufacturer. These centers typically offer original components designed specifically for the equipment, ensuring compatibility and optimal performance. Technicians at these centers can also provide expert advice and installation services if needed. It’s worth checking if your tool is still under warranty, as this might affect repair or replacement costs.

Online Marketplaces and Specialized Retailers

For those who prefer a more flexible approach, online marketplaces and specialized retailers present a wide range of options. Websites like Amazon, eBay, or stores focusing on construction equipment often stock components for various tools. It’s important to verify the reliability of the seller and check product reviews before purchasing. Some specialized suppliers even offer refurbished parts, which can be a more affordable alternative without sacrificing quality.

In addition to these, many third-party providers offer components that are compatible with the tool in question. Always ensure that these alternatives meet industry standards to avoid compromising the equipment’s performance.

Benefits of Using Genuine Parts

Utilizing authentic components for your tools significantly enhances their performance and longevity. By choosing original replacements, you ensure that your equipment functions at its best and meets safety standards.

- Quality Assurance: Genuine components are manufactured to stringent specifications, ensuring optimal fit and functionality.

- Increased Reliability: Using original items reduces the risk of breakdowns and enhances overall reliability.

- Warranty Protection: Many manufacturers offer warranties on their equipment, which may be voided if non-genuine items are used.

- Safety Standards: Authentic components are designed to meet safety regulations, minimizing hazards during operation.

- Performance Optimization: Genuine replacements are engineered to work seamlessly with your equipment, maximizing efficiency.

Investing in original components ultimately leads to greater satisfaction and peace of mind in your operations.