For anyone who relies on outdoor equipment for maintaining a pristine landscape, familiarity with the inner workings of these machines is essential. Each tool is composed of various elements that work in harmony to deliver optimal performance. Understanding these components not only aids in effective maintenance but also enhances your ability to troubleshoot and resolve potential issues.

In this section, we will explore a comprehensive overview of the individual elements that contribute to the functionality of a popular yard maintenance device. By dissecting its construction, users can gain insight into the assembly and disassembly process, making it easier to manage repairs and replacements when necessary.

Whether you are a seasoned professional or a weekend warrior, having a clear visual reference of the essential components can significantly streamline your workflow. This knowledge empowers you to tackle tasks with confidence, ensuring that your equipment remains in peak condition throughout the seasons.

Understanding Stihl FS 45 Trimmer

Grasping the workings of a grass cutting device is essential for anyone looking to maintain a tidy outdoor space. This particular model is designed for efficiency and ease of use, making it a popular choice among gardening enthusiasts and professionals alike. Familiarity with its components will enhance maintenance practices and ensure optimal performance.

Key features that define this device include:

- Lightweight construction for easy handling

- Powerful engine for effective grass cutting

- Ergonomic design for user comfort

- Versatile attachments for various gardening tasks

Understanding its inner workings involves knowing how different elements interact:

- Power System: The engine type plays a crucial role in performance and fuel efficiency.

- Cutting Mechanism: Various options for blades and strings determine the effectiveness in different environments.

- Handle and Controls: The design influences ease of operation and control during use.

Regular maintenance can prevent common issues, ensuring the device operates smoothly. This includes:

- Cleaning air filters to maintain airflow

- Checking and replacing cutting lines as needed

- Inspecting fuel quality and replacing it when stale

By comprehensively understanding this grass cutting tool, users can maximize its capabilities, ensuring a well-kept lawn throughout the season.

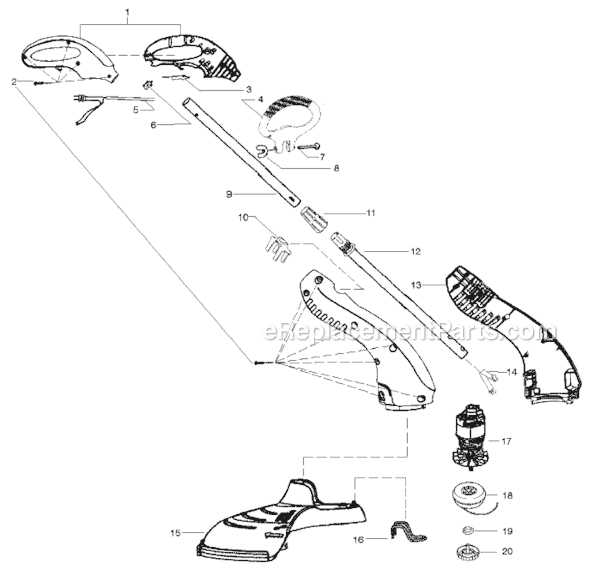

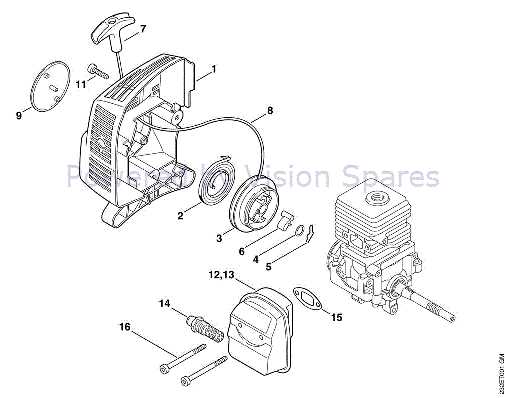

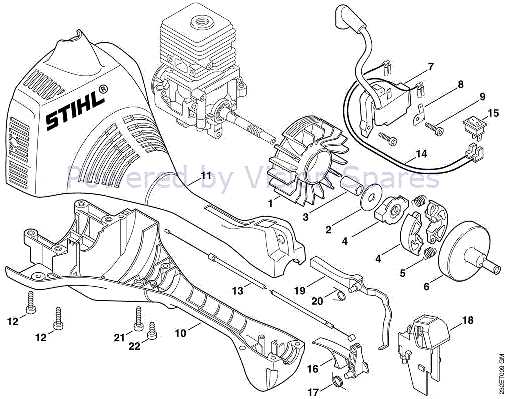

Key Components of the FS 45

The efficiency and functionality of any gardening tool rely heavily on its essential elements. Understanding the core components is vital for both performance and maintenance. This section delves into the primary features that contribute to the effectiveness of this device in managing vegetation.

Engine Assembly

The engine serves as the powerhouse, driving the entire mechanism. A well-engineered motor ensures reliable performance and optimal power output. Key attributes include displacement, power rating, and fuel efficiency, which all play a role in determining how effectively the tool can tackle various tasks.

Cutting Mechanism

At the heart of the operation lies the cutting assembly. This crucial component is designed to deliver precise cuts while minimizing effort. Features such as blade type, line feed system, and cutting diameter are essential for adapting to different gardening needs. A sharp and well-maintained cutting mechanism enhances overall efficiency, making the job easier and quicker.

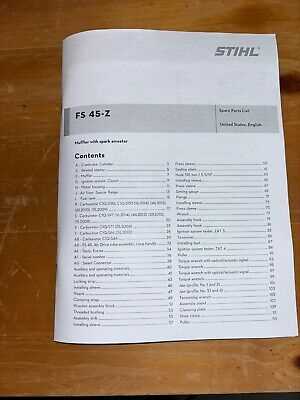

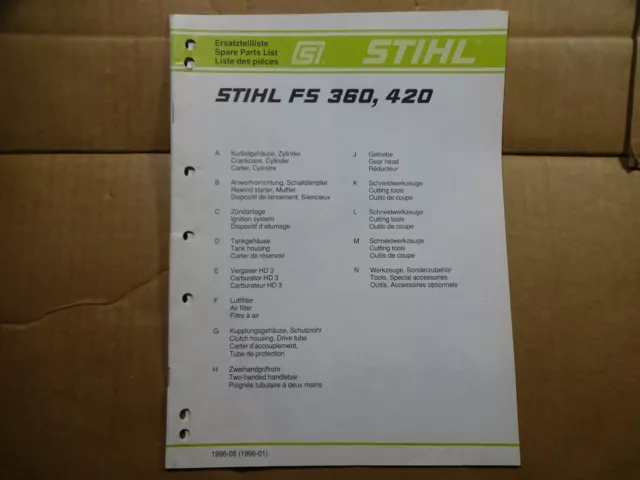

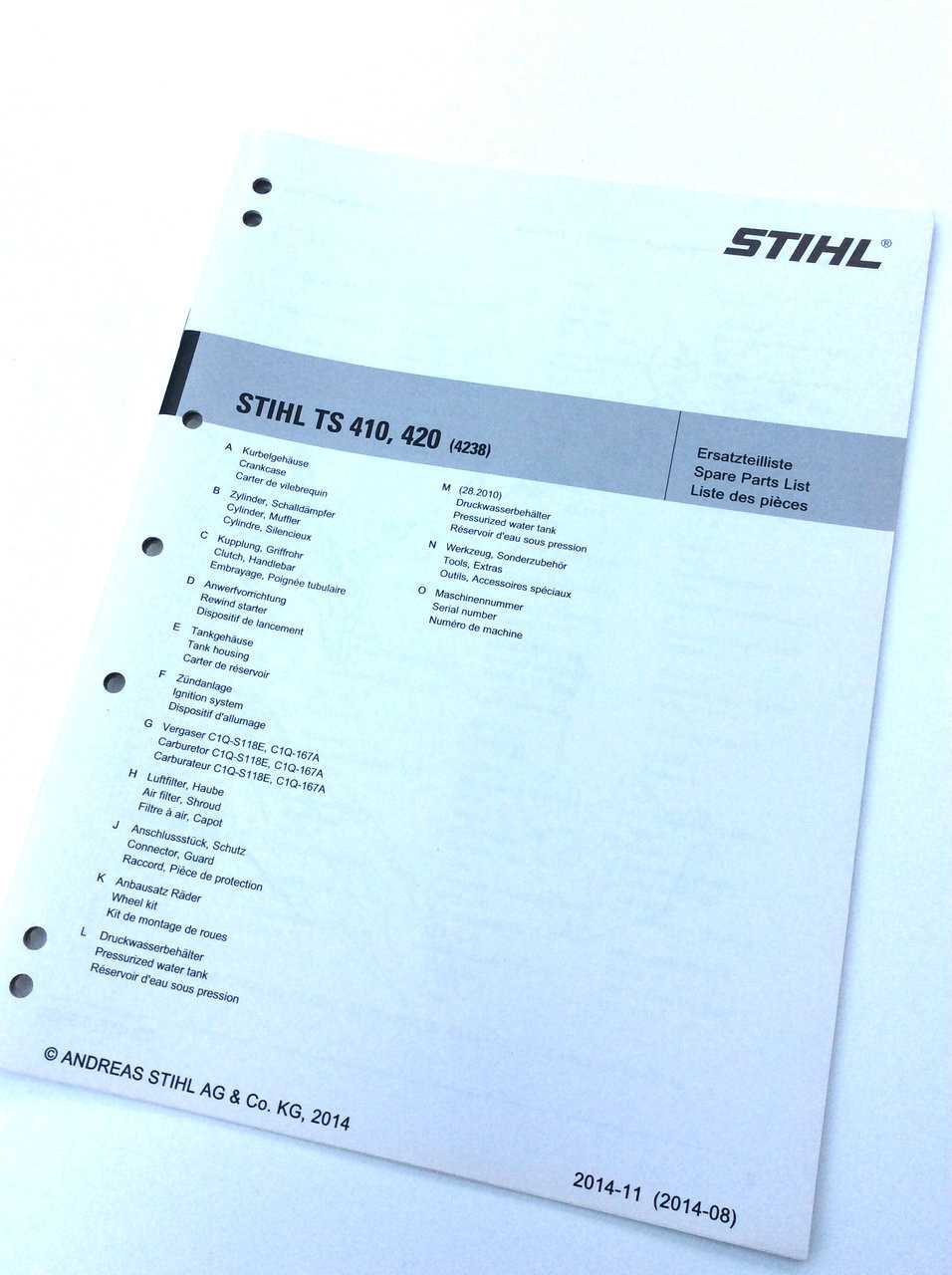

Importance of Parts Diagrams

Understanding the components of machinery is crucial for efficient maintenance and repair. Visual representations of these elements serve as essential tools for both professionals and enthusiasts. They provide clarity on how different sections interact and can significantly simplify the troubleshooting process.

Enhanced Understanding

When examining intricate machinery, having a visual guide helps users grasp the layout and functionality of various segments. This knowledge not only aids in identifying issues but also facilitates effective assembly and disassembly. Visual aids can transform complex tasks into manageable steps, ensuring that users feel more confident in their abilities.

Efficient Repairs

By referring to detailed illustrations, individuals can quickly locate specific components that may require attention. This efficiency saves both time and resources, reducing the likelihood of errors during repairs. Furthermore, a clear understanding of each part’s role can lead to informed decisions about replacements or upgrades, ultimately enhancing the overall performance of the equipment.

How to Read a Parts Diagram

Understanding an assembly illustration is essential for anyone looking to maintain or repair their equipment effectively. These visual guides offer a clear representation of various components and their relationships, simplifying the process of identification and assembly. By mastering the key elements of such illustrations, you can enhance your ability to troubleshoot and perform necessary maintenance tasks.

Identifying Components

Each element in an assembly illustration is usually labeled with a unique identifier or number. Familiarizing yourself with these labels is crucial. They often correspond to a list that provides additional information about each part, including specifications and compatibility. Pay close attention to the arrangement of these components, as it indicates how they fit together within the overall structure.

Understanding Relationships

The positioning of elements in the visual guide often reflects their functional relationships. Components that are interconnected may be shown in proximity, illustrating how they operate together. Observing these spatial arrangements can aid in comprehending the workflow and function of the entire assembly. By recognizing these connections, you can troubleshoot issues more efficiently and identify which parts may need attention or replacement.

Common Replacement Parts for FS 45

Maintaining your equipment in optimal condition often requires the replacement of key components over time. Understanding which elements are most likely to wear out can help you ensure a smoother operation and prolong the life of your machine.

Essential Components

One of the most frequently replaced items is the cutting line, which can become frayed or broken after extensive use. Additionally, the fuel filter should be checked regularly, as it can get clogged, affecting performance. Regularly inspecting and replacing the spark plug is crucial for ignition efficiency.

Maintenance Accessories

Another vital accessory is the air filter, which prevents debris from entering the engine. Replacing worn-out drive belts can also enhance functionality. Keeping a stock of these essential components ensures your equipment remains reliable and ready for action.

Maintenance Tips for Your Trimmer

Regular upkeep is essential for ensuring optimal performance and longevity of your garden tool. By adhering to a few simple practices, you can enhance its efficiency and reduce the likelihood of malfunctions.

Routine Cleaning

Keeping your equipment clean helps prevent dirt buildup and ensures smooth operation. Consider the following steps:

- Wipe down the exterior after each use to remove debris.

- Inspect and clear the air filter regularly to maintain airflow.

- Clean the cutting head to ensure effective cutting action.

Periodic Checks

Regular inspections can catch potential issues before they escalate. Follow these recommendations:

- Examine the cutting line for wear and replace it when necessary.

- Check fuel and oil levels before every use.

- Inspect the ignition system to ensure reliable starting.

By integrating these practices into your routine, you can keep your equipment in top condition, ready for any gardening task.

Finding Authentic Stihl Parts

Ensuring the longevity and efficiency of your equipment relies heavily on the quality of components you choose. Using genuine items not only enhances performance but also safeguards your investment. Here are some key points to consider when seeking authentic replacements.

- Authorized Dealers: Always start your search at official retailers. These sources guarantee the authenticity of their inventory.

- Online Marketplaces: If purchasing online, verify the seller’s reputation. Look for feedback from previous customers to ensure reliability.

- Part Numbers: Familiarize yourself with the specific identifiers for the components you need. This practice helps avoid compatibility issues.

Additionally, consider the following tips:

- Check for warranties or guarantees that come with the items.

- Beware of deals that seem too good to be true; they often indicate counterfeit products.

- Engage with user forums or communities for recommendations on where to find trusted supplies.

By following these guidelines, you can ensure that your machinery remains in top condition, operating effectively for years to come.

DIY Repairs Using the Diagram

Engaging in maintenance and repair tasks at home can be both rewarding and cost-effective. Understanding the layout of components can significantly enhance your ability to diagnose issues and execute repairs with confidence. By referencing a visual representation of the various elements, you can streamline your approach and tackle repairs more efficiently.

Identifying Common Issues

When you familiarize yourself with the assembly, it becomes easier to pinpoint frequent problems such as wear and tear or misalignment. Knowing where each part fits allows you to quickly assess the situation and decide on the necessary actions. Whether it’s replacing a worn-out element or adjusting a misaligned piece, a clear understanding of the configuration is invaluable.

Step-by-Step Repair Process

Once you’ve identified the issue, follow a systematic approach to the repair. Begin by gathering the required tools and components. Next, refer to the visual layout to ensure you’re working with the correct pieces. Step through the repair one phase at a time, verifying that each component is correctly reassembled before moving on. This method not only promotes accuracy but also helps in building your skills for future repairs.

When to Seek Professional Help

Understanding the intricacies of garden equipment is crucial for maintaining its longevity and performance. However, there are instances when it becomes essential to consult a specialist. Recognizing these moments can save time, resources, and prevent further complications.

Signs Indicating Professional Assistance is Needed

It’s important to be aware of specific indicators that suggest it’s time to call in an expert. Below are common signs:

| Indicator | Explanation |

|---|---|

| Persistent Issues | If problems continue despite troubleshooting, it may indicate a deeper issue. |

| Unusual Sounds | Strange noises can signal mechanical failures that require professional diagnosis. |

| Frequent Breakdowns | A high frequency of malfunctions suggests underlying problems needing expert evaluation. |

| Safety Concerns | If the equipment poses a risk to the user or surroundings, immediate professional intervention is advised. |

Benefits of Consulting a Specialist

Engaging a professional can provide numerous advantages, including:

- Expertise in diagnosing complex issues.

- Access to specialized tools and replacement components.

- Time-saving solutions that allow you to focus on other tasks.