Maintaining outdoor power equipment is crucial for ensuring optimal performance and longevity. A thorough grasp of each element within the machinery can significantly enhance the efficiency of repairs and upgrades. This guide aims to provide insights into the intricate parts that constitute a popular model, helping users navigate their maintenance tasks with ease.

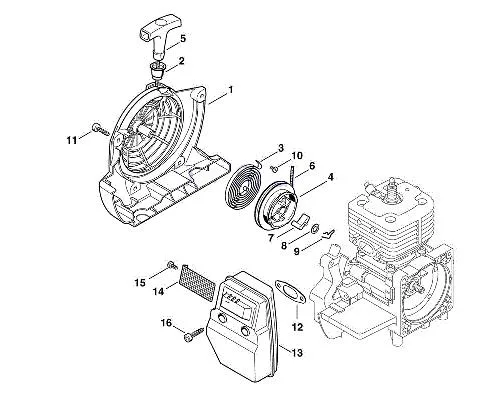

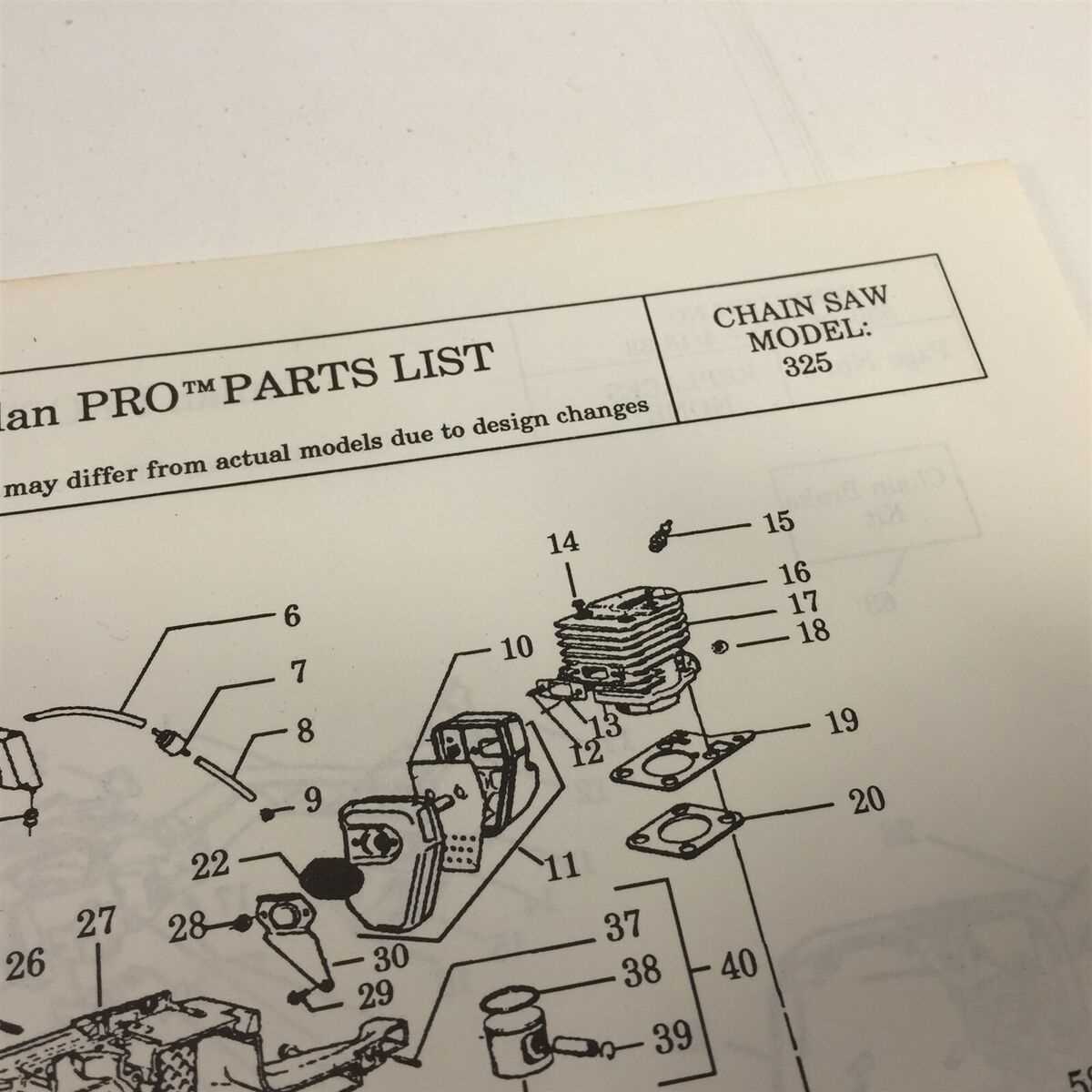

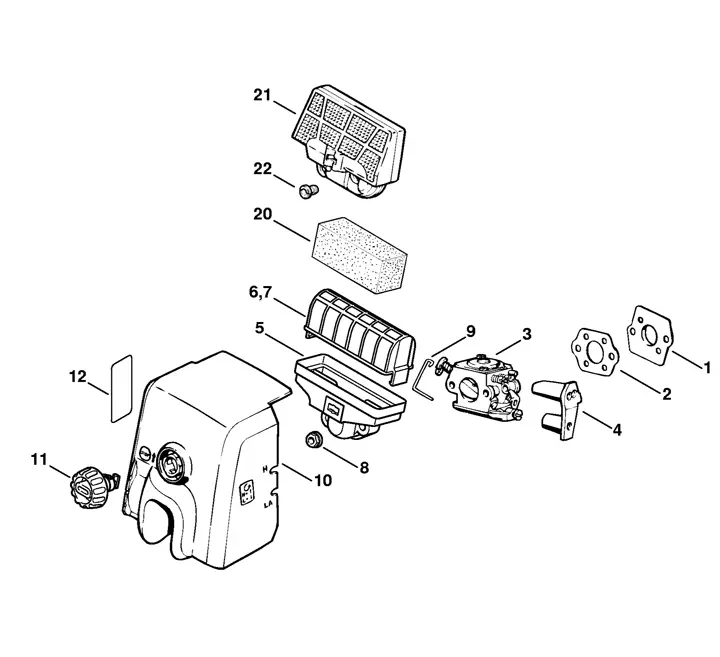

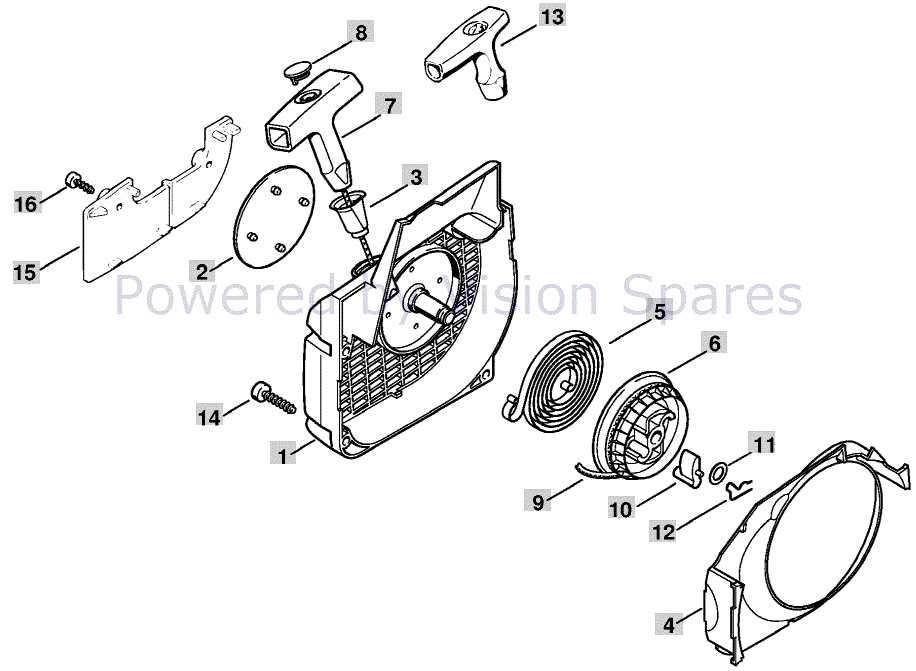

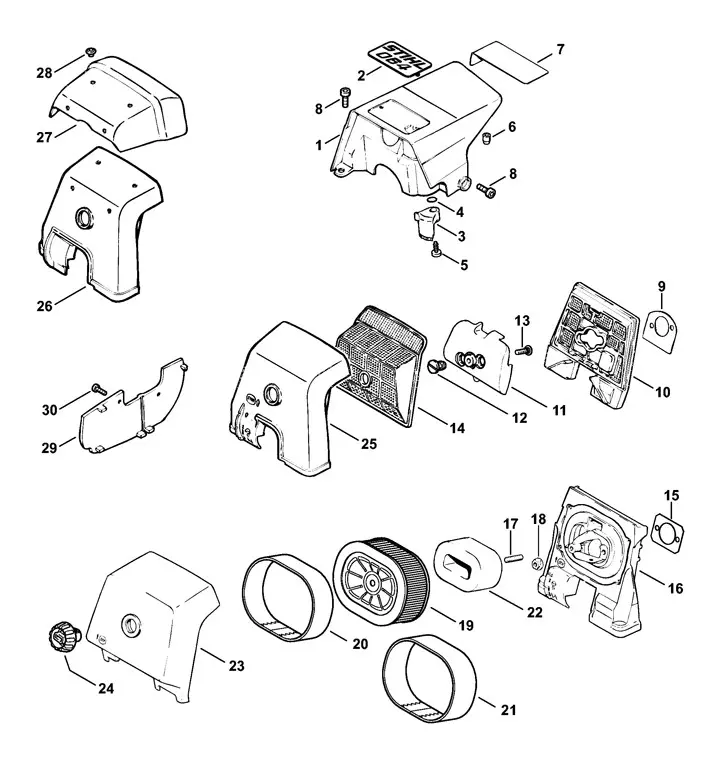

In the realm of machinery, having access to detailed illustrations can be immensely beneficial. Visual representations of components serve as invaluable references, aiding both novice and experienced users in identifying specific pieces and understanding their functions. This facilitates informed decision-making when it comes to repairs or replacements.

Furthermore, delving into the technical specifications and layout of the equipment enables users to recognize the interconnectivity of various elements. Gaining familiarity with these components not only streamlines maintenance procedures but also empowers users to tackle issues proactively, ensuring their tools remain in peak condition for years to come.

Understanding the Stihl MS250 Chainsaw

Exploring the functionality and components of a specific model of a power tool can enhance both its performance and user experience. This section delves into the essential features, maintenance tips, and overall design of a popular chainsaw, ensuring that users are well-equipped to handle their tasks effectively.

Key Features

- Lightweight and ergonomic design for ease of use.

- Powerful engine providing robust cutting capabilities.

- Efficient fuel consumption for longer operation times.

- Advanced safety mechanisms to protect the user during operation.

Maintenance Tips

- Regularly check and replace the chain to ensure optimal cutting efficiency.

- Keep the air filter clean to maintain engine performance.

- Inspect the spark plug periodically for signs of wear or fouling.

- Lubricate moving parts to reduce friction and prolong the tool’s lifespan.

By understanding the various aspects of this chainsaw, users can maximize their productivity and enjoy a safer cutting experience. Familiarity with the tool’s components and maintenance requirements is key to effective operation.

Key Components of the MS250

Understanding the essential elements of a power tool is crucial for optimal performance and maintenance. Each part plays a vital role in ensuring the efficiency and longevity of the equipment. Below are the primary components that contribute to its functionality.

- Engine: The heart of the machine, providing the necessary power for operation.

- Bar and Chain: These elements work together to perform cutting tasks effectively.

- Air Filter: This component ensures that clean air enters the engine, preventing damage from debris.

- Fuel System: This includes the fuel tank and lines, delivering the required fuel to the engine.

- Ignition System: Responsible for starting the engine, ensuring reliable operation.

- Clutch: Engages and disengages the chain drive, allowing for controlled cutting.

- Vibration Dampening System: Reduces operator fatigue by minimizing vibrations during use.

Each of these components is integral to the overall functionality, and understanding their roles can assist users in effective maintenance and troubleshooting.

Benefits of Using a Parts Diagram

Utilizing a visual representation of components can significantly enhance the efficiency and accuracy of maintenance and repair tasks. Such illustrations provide a clear overview of the individual elements involved, making it easier to identify, locate, and replace necessary items.

Improved Clarity

A graphical layout allows users to see the arrangement and connection of various components. This clarity helps in:

- Understanding how parts interact with each other.

- Identifying specific components without confusion.

- Reducing the chances of mistakes during assembly or disassembly.

Time Efficiency

Having a detailed visual reference can save valuable time. This is achieved by:

- Quickly locating the needed parts.

- Minimizing the time spent searching through manuals or catalogs.

- Streamlining the repair process with step-by-step guidance.

In summary, a comprehensive illustration of components not only fosters a better understanding but also enhances productivity in maintenance activities.

Where to Find MS250 Parts PDF

Locating detailed schematics and components for your equipment can significantly enhance maintenance and repair efficiency. Various resources are available to assist in this pursuit, ensuring you have the necessary information at your fingertips.

| Resource | Description |

|---|---|

| Official Manufacturer Website | The primary source for accurate and up-to-date information. |

| Online Retailers | Many sellers provide downloadable resources with their product listings. |

| Community Forums | Enthusiast groups often share helpful documents and insights. |

| Repair Shops | Local services might offer printed materials or guides. |

Common Issues and Replacement Parts

When operating a power tool, users often encounter a variety of challenges that can affect performance. Understanding these common issues and knowing which components may require replacement is essential for maintaining efficiency and prolonging the lifespan of the equipment.

Frequent Problems

Overheating and starting difficulties are prevalent concerns. These issues can stem from clogged air filters, dull cutting blades, or improper fuel mixtures. Regular maintenance checks can help identify these problems early.

Key Components for Replacement

Essential components that may need to be swapped out include spark plugs, fuel filters, and air filters. Ensuring these parts are in good condition can significantly enhance the functionality of the tool and prevent future malfunctions.

Maintenance Tips for the MS250

Proper upkeep of your equipment is essential for ensuring optimal performance and longevity. Regular maintenance not only enhances efficiency but also prevents costly repairs in the future. Here are some valuable tips to keep your device in top shape.

Regular Cleaning

- Clean the air filter regularly to ensure proper airflow.

- Remove debris from the exterior and cooling fins to prevent overheating.

- Check and clean the spark plug to maintain ignition efficiency.

Routine Inspections

- Inspect the chain tension and sharpen the chain as needed.

- Check fuel lines for any signs of wear or damage.

- Ensure that all screws and bolts are tight and secure.

By following these maintenance practices, you can significantly extend the life of your equipment and enhance its performance.

How to Interpret Parts Diagrams

Understanding technical illustrations can greatly enhance your ability to maintain and repair machinery. These visuals provide a clear representation of components and their relationships, making it easier to identify what is needed for a project.

To effectively analyze these illustrations, consider the following elements:

| Element | Description |

|---|---|

| Labels | Identify each component with unique identifiers or names, which aids in locating specific parts. |

| Legends | Provide a key to symbols used, clarifying functions or specifications associated with each piece. |

| Groupings | Show how various elements are assembled or interact, facilitating a better understanding of the overall structure. |

By grasping these fundamentals, you can navigate technical visuals with confidence and accuracy, leading to more effective maintenance and repair endeavors.

Comparing MS250 with Other Models

When evaluating various models in the chainsaw category, it’s essential to consider key differences that can impact performance and usability. Each unit offers distinct features tailored to different user needs, making a side-by-side comparison invaluable.

Here are some critical aspects to compare:

- Power Output: Analyze engine capacity and horsepower to determine cutting efficiency.

- Weight: Lighter models can enhance maneuverability but may sacrifice power.

- Bar Length: Longer bars provide deeper cuts, while shorter bars improve precision in tight spaces.

- Fuel Efficiency: Consider how much fuel each model consumes for extended use.

- Ease of Maintenance: Check accessibility to components for routine upkeep.

By examining these factors, users can make informed choices that align with their specific cutting tasks and preferences.

DIY Repairs: Safety Precautions

Engaging in home repairs can be rewarding, but prioritizing safety is essential to prevent accidents. Taking the right precautions ensures a smooth and secure experience while working with tools and machinery.

- Wear Protective Gear: Always use safety glasses, gloves, and ear protection to shield yourself from potential hazards.

- Work in a Well-Lit Area: Adequate lighting reduces the risk of mistakes and injuries.

- Keep a Clean Workspace: Clutter can lead to slips and falls; maintain an organized area.

- Understand Your Tools: Familiarize yourself with the equipment before use to avoid improper handling.

- Follow Manufacturer Instructions: Adhere to guidelines to ensure safe and effective operation.

By implementing these safety measures, you can confidently tackle repairs while minimizing risks.