Understanding the various elements that make up a specific model can significantly enhance its functionality and maintenance. This section aims to provide a detailed look into the individual components, focusing on their roles and how they interact to ensure optimal performance.

By examining the layout and arrangement of these elements, users can gain insights into the assembly and disassembly processes, making repairs and adjustments more efficient. Such knowledge empowers users to take better care of their equipment, prolonging its lifespan and ensuring reliability in operation.

Whether you are a novice or an experienced user, familiarizing yourself with the essential features and their specifications can lead to a more satisfactory experience. This exploration of the structural arrangement will serve as a valuable resource for anyone looking to deepen their understanding of this particular model.

The effective operation of any equipment relies on several crucial elements that work in harmony. Understanding these primary constituents is essential for proper maintenance and functionality, ensuring that the machine performs at its best.

- Engine: The heart of the machinery, responsible for powering the unit and driving its various functions.

- Fuel System: Comprises components that store and deliver fuel to the engine, critical for its performance.

- Pump: Facilitates the movement of liquids, essential for the machine’s primary purpose.

- Nozzle: Directs the flow of the liquid, allowing for precise application depending on the task.

- Hoses: Flexible tubes that transport the liquid from one part of the machine to another, ensuring efficiency and convenience.

Each of these elements plays a vital role, contributing to the overall effectiveness and reliability of the equipment.

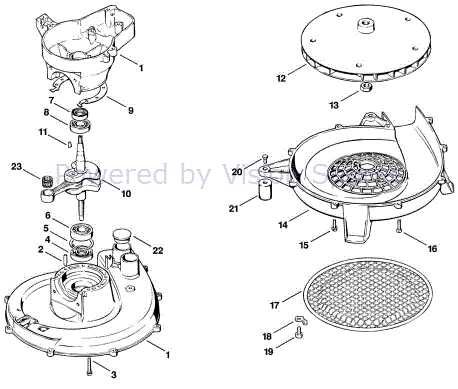

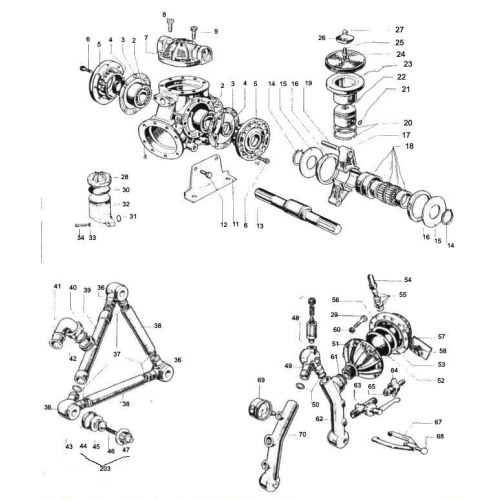

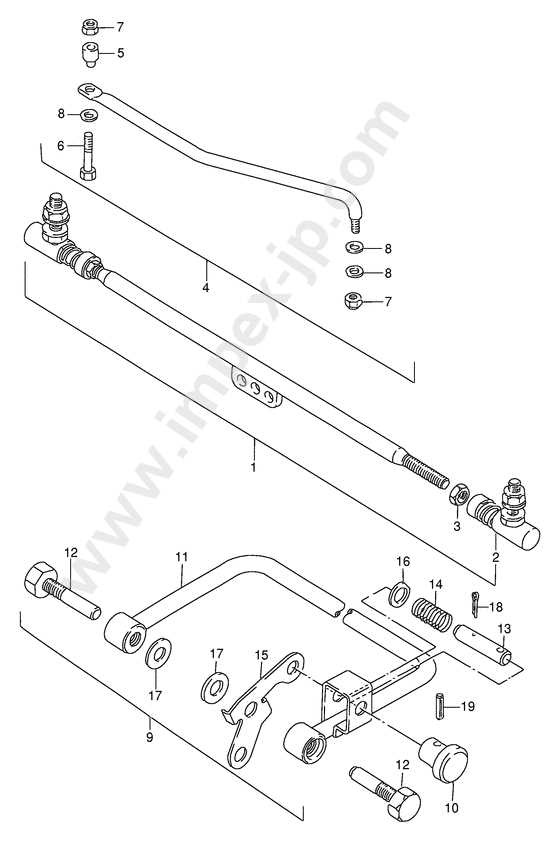

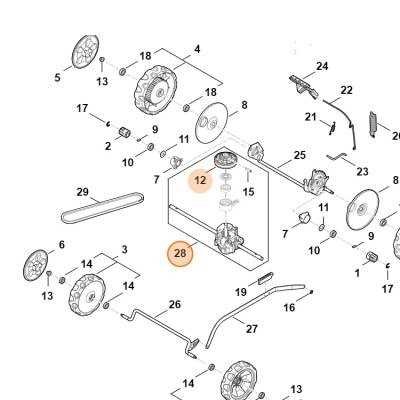

Understanding the Parts Diagram

The visual representation of components plays a crucial role in comprehending how various elements work together within a machine. By examining these illustrations, users can gain insights into the assembly and functionality of each individual piece, facilitating maintenance and repairs.

Importance of Visual Guides

Visual aids serve several significant purposes:

- They provide clarity on the relationship between different elements.

- They simplify the identification of specific components.

- They enhance understanding of assembly processes.

Key Features to Note

When analyzing these visuals, consider the following aspects:

- Each item is usually labeled with a reference number.

- Grouping of similar components can highlight functional areas.

- Color coding might be used to indicate various categories.

Understanding these aspects can significantly aid in effective troubleshooting and maintenance, ensuring optimal performance of the equipment.

Maintenance Tips for Longevity

Proper care and regular upkeep are essential for ensuring the extended lifespan of your equipment. By following a few simple guidelines, you can enhance performance and prevent premature wear and tear, keeping your machine in optimal condition.

1. Regular Cleaning: After each use, make it a habit to clean the exterior and components. Removing dirt and debris will help maintain efficiency and reduce the risk of damage.

2. Lubrication: Regularly apply suitable lubricants to moving parts to ensure smooth operation. This reduces friction and minimizes wear, contributing to a longer lifespan.

3. Inspection: Conduct periodic inspections to identify any signs of wear or damage. Addressing issues early can prevent further complications and costly repairs.

4. Proper Storage: Store your equipment in a dry, protected environment when not in use. This prevents exposure to harsh weather conditions that can lead to deterioration.

5. Follow Manufacturer Guidelines: Adhering to the recommended maintenance schedule and using appropriate replacement components will ensure your equipment operates efficiently and lasts longer.

Common Issues and Solutions

This section addresses frequent challenges encountered during the operation of outdoor equipment and offers practical solutions to enhance performance and reliability.

Frequent Problems

- Inconsistent performance leading to inefficient operation.

- Difficulty starting the device, often caused by fuel or ignition issues.

- Excessive vibration, which can indicate wear or misalignment of components.

- Leaks from fuel or fluid reservoirs, posing safety hazards.

Effective Solutions

- Ensure that the fuel is fresh and free from contaminants; consider using a fuel stabilizer.

- Check the ignition system, including spark plugs and connections, for wear or damage.

- Inspect for loose or worn parts that may contribute to vibration; tighten or replace as necessary.

- Regularly maintain seals and gaskets to prevent leaks, replacing them if they show signs of wear.

How to Identify Replacement Parts

When maintaining or repairing equipment, recognizing the correct components is crucial for optimal functionality. Understanding the various elements of your machinery will facilitate efficient identification and ensure you acquire the right replacements. This guide offers strategies to help you discern the necessary items, enhancing your overall repair experience.

Examine the User Manual

A comprehensive user manual typically contains valuable information about the equipment, including specifications and illustrations of the components. Carefully reviewing this documentation will provide insights into the necessary elements, helping you pinpoint which parts require replacement.

Utilize Online Resources

The internet is a treasure trove of information. Numerous websites offer detailed listings and visual guides that can assist in identifying specific items. By accessing these resources, you can compare your existing components with available options, ensuring accurate replacements. Remember to consider customer reviews and expert recommendations to make informed decisions.

Tools Needed for Repairs

Proper maintenance and repair require a selection of essential implements to ensure efficiency and effectiveness. Having the right tools on hand not only simplifies the repair process but also enhances the overall quality of the work performed. Whether dealing with minor adjustments or major overhauls, being equipped with the necessary equipment is crucial.

Basic Hand Tools

The foundation of any repair task begins with basic hand tools. These typically include screwdrivers, wrenches, and pliers. Each tool serves a specific function, allowing for precise manipulation of components. A set of metric and standard sockets is also advisable to accommodate various fasteners and fittings.

Specialized Equipment

In addition to basic hand tools, specialized equipment may be required for more intricate repairs. This can include torque wrenches for ensuring proper tightness, multimeters for electrical diagnostics, and cleaning supplies to maintain functionality. Investing in these tools can significantly improve the efficiency of the repair process.

Where to Buy Genuine Parts

Finding authentic components for your equipment is crucial for ensuring optimal performance and longevity. It is essential to source these items from reputable suppliers to guarantee quality and reliability. In this section, we will explore various avenues where you can obtain genuine replacements for your machinery.

Authorized Dealers

One of the most reliable options for acquiring original components is through authorized dealers. These establishments are recognized by the manufacturer and typically stock a wide range of genuine products. Purchasing from them ensures that you are receiving items that meet the specific standards set by the manufacturer, which can significantly enhance the operational efficiency of your equipment.

Online Retailers

The internet offers a convenient platform for acquiring authentic components. Numerous online retailers specialize in genuine replacements, providing detailed product descriptions and customer reviews to assist in your purchasing decision. Make sure to verify the credibility of the website and read feedback from other customers to ensure a positive buying experience.

FAQs About Stihl SG 20

This section addresses common inquiries regarding the specified equipment. It provides valuable insights to enhance understanding and facilitate effective usage. Whether you are a novice or an experienced user, these questions cover essential aspects that many find beneficial.

1. What is the primary function of this equipment?

The primary purpose of this device is to efficiently deliver liquid substances over a wide area. It is designed for various applications, including agricultural tasks and garden maintenance.

2. How do I maintain the equipment properly?

Regular maintenance is crucial for optimal performance. It involves checking the fluid levels, cleaning the nozzles, and inspecting hoses for wear and tear. Following the manufacturer’s guidelines ensures longevity.

3. What safety precautions should I take?

Safety is paramount when operating any machinery. Always wear appropriate protective gear, including gloves and goggles. Ensure you are familiar with the operating instructions and follow recommended practices to minimize risks.

4. Where can I find replacement components?

Replacement components can typically be sourced from authorized dealers or specialized retailers. It is advisable to choose genuine products to maintain compatibility and performance.

5. Can this equipment be used for different liquids?

While it is primarily designed for specific substances, some models may accommodate various liquids. Always refer to the user manual to ensure that the selected liquid is suitable for the equipment.