Maintaining outdoor machinery requires a solid grasp of its components and their functionalities. For those invested in ensuring their tools operate smoothly, a visual representation of each part can be invaluable. This resource aims to demystify the intricate assembly of your device, allowing you to identify, replace, or repair essential elements with confidence.

From the engine to the various attachments, knowing how everything fits together is crucial for optimal performance. Each segment plays a vital role, and understanding these relationships can lead to enhanced maintenance practices. By familiarizing yourself with the structure, you can prevent common issues and extend the lifespan of your equipment.

Whether you’re a seasoned professional or a weekend warrior, having access to a detailed outline can make all the difference. It empowers you to tackle repairs head-on and provides insight into potential upgrades. Dive into this guide to explore the key features and components of your machinery, ensuring that you’re always prepared for the task at hand.

Understanding Stihl RB 400 Components

In the realm of outdoor power tools, comprehending the various elements that contribute to their functionality is crucial. Each component plays a specific role in ensuring optimal performance, reliability, and user satisfaction. By familiarizing oneself with these integral parts, users can better appreciate the engineering behind their machines and enhance their maintenance practices.

Engine: At the heart of the device lies the engine, responsible for generating the necessary power. Its design focuses on efficiency and durability, providing the force needed for effective operation.

Fuel System: The fuel system comprises components that ensure a consistent supply of energy. This system includes the tank, filters, and lines, all working together to optimize fuel delivery and reduce waste.

Air Filter: An essential element for maintaining engine health, the air filter prevents debris and contaminants from entering. Regular cleaning or replacement of this component is vital for sustained performance.

Chassis: The chassis serves as the framework of the machine, housing various parts while providing stability and support. Its design often incorporates lightweight yet robust materials for ease of use.

Controls: User interaction is facilitated through a series of controls that allow for easy operation. These components are strategically placed for accessibility, ensuring that users can operate the equipment efficiently.

Wheels and Mobility Features: Mobility components enhance maneuverability, allowing users to navigate different terrains effortlessly. The design of these elements is focused on stability and ease of transport.

Understanding the various components and their functions not only aids in troubleshooting but also fosters a greater appreciation for the technology behind these powerful tools. Proper knowledge empowers users to maintain their equipment effectively, ensuring long-lasting performance and reliability.

Overview of Parts and Functions

This section explores the various components and their roles in enhancing the performance and efficiency of the equipment. Understanding these elements is crucial for effective maintenance and operation.

Main Components

Each element serves a specific purpose, contributing to the overall functionality of the machine. Here is a brief description of the primary parts:

| Component | Function |

|---|---|

| Engine | Provides the necessary power for operation. |

| Air Filter | Prevents dirt and debris from entering the engine. |

| Fuel Tank | Stores the fuel needed for operation. |

| Blower Housing | Directs airflow for optimal performance. |

Importance of Each Element

Each component is vital for the machine’s efficiency and longevity. Regular inspection and maintenance of these parts can prevent breakdowns and enhance overall productivity.

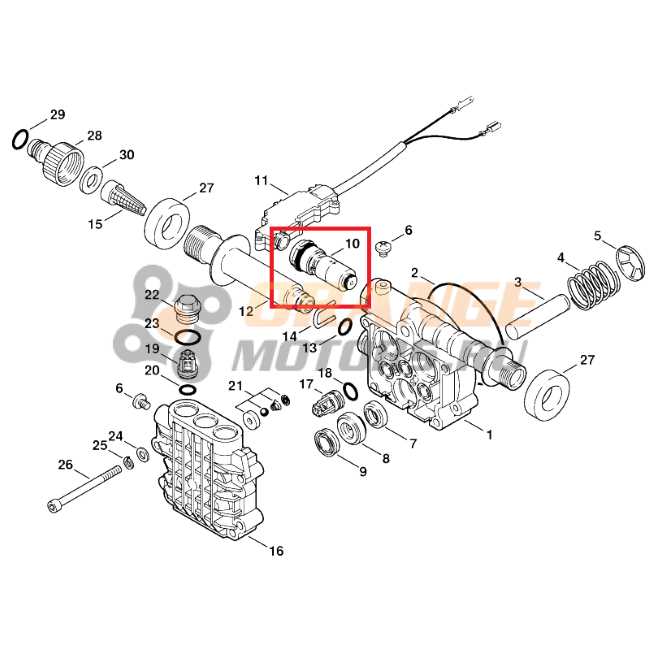

How to Read the Parts Diagram

Understanding an illustration that outlines components is essential for efficient maintenance and repair. These visuals typically use symbols and numbers to represent each element, making it easier to identify and locate specific pieces. Familiarity with this representation allows for quicker troubleshooting and enhanced assembly skills.

First, take note of the key or legend, which explains the symbols used. This can often include various lines, shapes, and numbers that correspond to particular elements. By grasping this foundation, you can better navigate the illustration.

Next, examine the layout of the components. They are usually arranged in a logical sequence that mirrors their physical arrangement in the machine. This spatial awareness can greatly assist in understanding how parts interact with one another.

Finally, when referencing this illustration for repairs, ensure you cross-reference with the accompanying manual or guidelines. This will provide context for the visual and help clarify any ambiguities. By delving into these details, you equip yourself with the ultimate knowledge for effective maintenance.

Common Issues with RB 400 Parts

Many users encounter a range of challenges related to the components of their equipment. Understanding these common problems can help in maintaining optimal performance and extending the lifespan of the machine. From minor malfunctions to more significant failures, being aware of potential issues allows for proactive measures to be taken.

One frequent concern is the wear and tear of certain elements, which can lead to reduced efficiency. Over time, seals and gaskets may degrade, resulting in leaks that compromise functionality. Additionally, connections may loosen, causing vibrations that can affect the overall operation.

Another prevalent issue involves the ignition system. Faulty spark plugs or wiring can hinder starting, leading to frustration for users. Regular inspections can help identify these problems early, ensuring smoother operation.

Furthermore, fuel delivery systems often face challenges such as clogging or contamination. Keeping fuel lines and filters clean is crucial for preventing performance issues. Neglecting these components can lead to more serious complications down the line.

Lastly, improper maintenance can exacerbate existing problems, highlighting the importance of regular check-ups and servicing. By being proactive and addressing these common issues, users can maintain their equipment in peak condition and avoid unnecessary downtime.

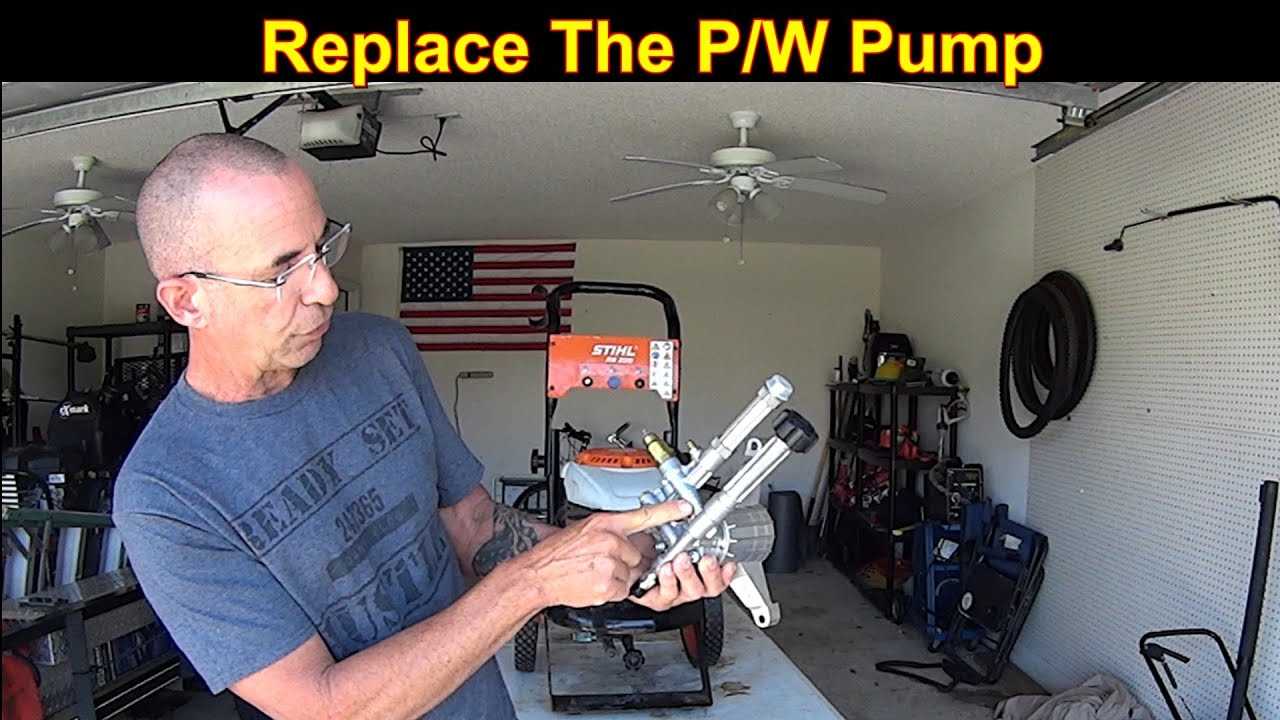

Replacing Components: A Step-by-Step Guide

Maintaining and replacing various parts of your equipment is essential for optimal performance. This guide outlines the necessary steps to effectively swap out components, ensuring longevity and efficiency.

- Gather Tools and Materials:

- Screwdrivers (flat and Phillips)

- Wrenches

- Replacement parts

- Safety gloves

- Cleaning cloths

- Power Down the Equipment:

Always ensure the machine is turned off and disconnected from any power source to prevent accidents.

- Consult the Manual:

Refer to the user manual for specific guidance on component removal and installation for your particular model.

- Remove the Old Component:

Carefully detach the existing part, taking note of how it is connected to aid in the installation of the new piece.

- Install the New Component:

Align and secure the new part in place, following the reverse order of removal.

- Test the Equipment:

Once everything is reassembled, conduct a test to ensure proper functionality before returning to regular use.

By following these steps, you can successfully replace components and maintain the performance of your machinery.

Where to Find Authentic Parts

Locating genuine components for your equipment can significantly enhance performance and longevity. It’s essential to source these elements from trusted providers to ensure compatibility and quality.

| Source | Description |

|---|---|

| Authorized Dealers | Official retailers that guarantee the authenticity of every item. |

| Online Marketplaces | Reputable platforms that offer a wide selection of genuine components with user reviews. |

| Manufacturer’s Website | The primary source for accurate information and direct purchases of original items. |

| Local Repair Shops | Experienced technicians can provide authentic components and installation services. |

Maintenance Tips for Longevity

Proper upkeep is essential for extending the lifespan of any outdoor power equipment. Regular attention to maintenance not only ensures optimal performance but also helps prevent costly repairs. Implementing a consistent care routine can significantly enhance the durability of your machinery.

Routine Cleaning

Cleaning your equipment after each use is crucial. Dirt, debris, and grass clippings can accumulate and lead to performance issues. Follow these steps for effective cleaning:

- Remove any debris from the exterior.

- Check and clean air filters regularly.

- Inspect the fuel tank for any residue.

Regular Inspections

Frequent checks can help identify wear and tear before they escalate. Focus on the following components:

- Examine the cutting blades for sharpness and damage.

- Inspect hoses and cables for signs of fraying or corrosion.

- Check fluid levels, including oil and fuel, ensuring they meet manufacturer recommendations.

By following these maintenance tips, you can ensure your equipment remains in excellent working condition for years to come.

Upgrading Parts for Better Performance

Enhancing the efficiency and effectiveness of your equipment can significantly impact its overall performance. By selecting high-quality components designed for improved functionality, you can ensure that your machinery operates at its peak. This approach not only optimizes the current capabilities but also extends the lifespan of the unit.

Choosing Superior Components is essential for achieving remarkable results. Consider investing in upgraded filters, enhanced blades, or more efficient motors. These modifications can lead to better fuel efficiency, increased power output, and smoother operation, making your tasks easier and more productive.

Regular Maintenance should accompany any upgrades to maximize their benefits. Routine checks and timely replacements help maintain optimal performance levels and prevent potential issues. Staying proactive in this regard ensures that your investments yield the best possible outcomes.

In conclusion, enhancing your machinery with upgraded components can lead to noticeable improvements in performance. By making informed choices and maintaining your equipment diligently, you will achieve remarkable efficiency and durability.

FAQs About Stihl RB 400 Parts

This section addresses common inquiries regarding components of a specific model, providing clarity and enhancing user understanding. Whether you are a novice or experienced user, these answers will assist in your maintenance and repair journey.

What are the most common issues with the equipment?

Users frequently report issues related to fuel supply, starting difficulties, and performance inconsistencies. Regular checks can prevent many of these problems.

Where can I find replacement components?

Replacement items can be sourced from authorized dealers, online marketplaces, or local retailers. Always ensure that you choose quality replacements to maintain optimal functionality.