When it comes to maintaining your outdoor machinery, having a comprehensive understanding of its inner workings is essential. Every tool is composed of various elements that contribute to its overall functionality. Grasping how these pieces fit together can significantly enhance your ability to troubleshoot issues and ensure optimal performance.

In this section, we will explore the intricate layout of components found in a popular model. By breaking down the assembly into its individual parts, you can gain valuable insights into how each element interacts within the system. This knowledge not only aids in repairs but also empowers users to make informed decisions regarding upgrades and replacements.

Whether you are a seasoned user or a newcomer, delving into the specifics of each component will provide you with the ultimate advantage. Understanding the arrangement and purpose of each piece is key to maximizing the efficiency and longevity of your outdoor equipment.

Understanding the Stihl KM55R Overview

This section provides a comprehensive insight into a versatile outdoor tool designed for various gardening and landscaping tasks. Known for its reliability and efficiency, this equipment serves as an essential ally for both professionals and homeowners. Its ergonomic design and powerful engine enable users to tackle a wide range of jobs, making it a preferred choice in the market.

Equipped with interchangeable attachments, this machine allows for seamless transitions between different applications, from trimming to cultivating. Users can easily customize their experience based on specific needs, enhancing overall productivity. This adaptability not only simplifies maintenance but also maximizes performance, ensuring that tasks are completed with ease.

The user-friendly features of this equipment further contribute to its popularity. With a straightforward assembly process and intuitive controls, even those new to outdoor maintenance can operate it effectively. This accessibility empowers individuals to take charge of their landscaping projects, leading to better results and satisfaction.

Key Components of the KM55R

This section explores the essential elements that contribute to the functionality and performance of a versatile garden tool. Understanding these components is crucial for effective maintenance and optimal use. Each part plays a significant role in ensuring that the device operates smoothly and efficiently, enabling users to tackle various landscaping tasks with ease.

Engine: The heart of the machine, the engine provides the necessary power for operation. Its design ensures reliable performance, making it suitable for prolonged use in diverse conditions.

Drive Shaft: This component transmits power from the engine to the working attachment. Its robust construction is vital for handling the torque generated during operation, ensuring longevity and efficiency.

Handle: The ergonomic handle offers comfort and control, allowing the user to maneuver the tool with precision. Its design helps to reduce fatigue during extended use.

Cutting Head: This attachment is responsible for executing various tasks, from trimming to clearing. Different options are available to suit specific needs, enhancing versatility in garden maintenance.

Fuel System: The fuel system ensures that the engine receives a steady supply of fuel, enabling consistent operation. Proper maintenance of this system is essential for optimal performance and efficiency.

Air Filter: This component plays a crucial role in maintaining engine performance by preventing debris and dirt from entering the combustion chamber. Regular cleaning and replacement are necessary for sustained efficiency.

Each of these parts contributes to the overall effectiveness of the tool, making understanding their functions and maintenance critical for any user. Proper care and knowledge of these elements can significantly enhance the longevity and performance of the equipment.

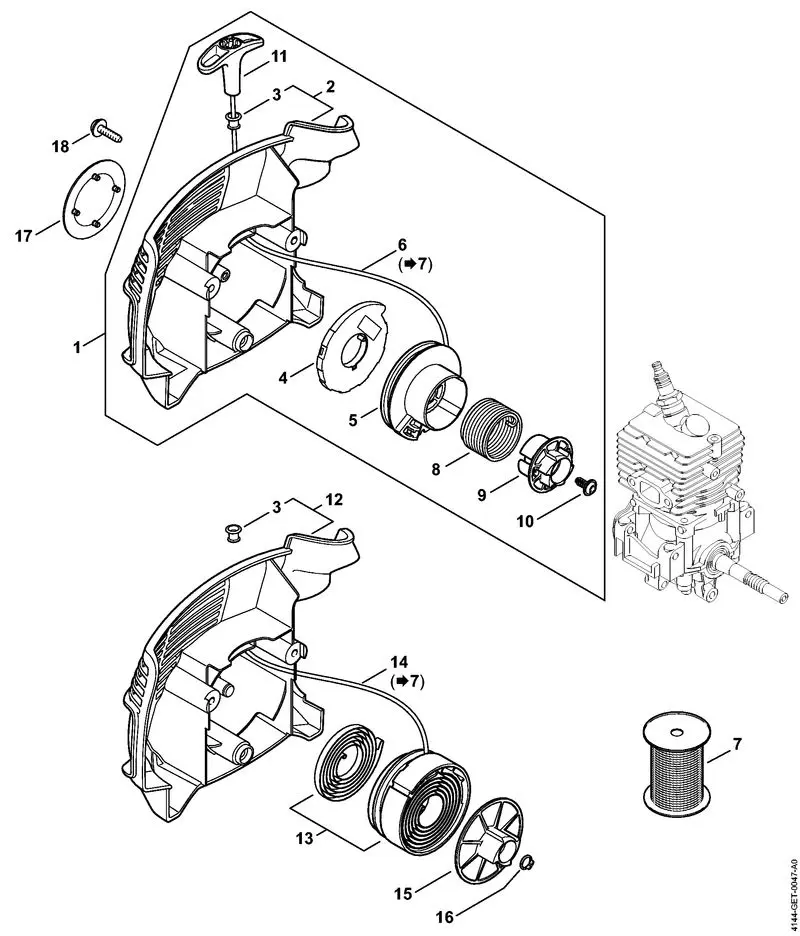

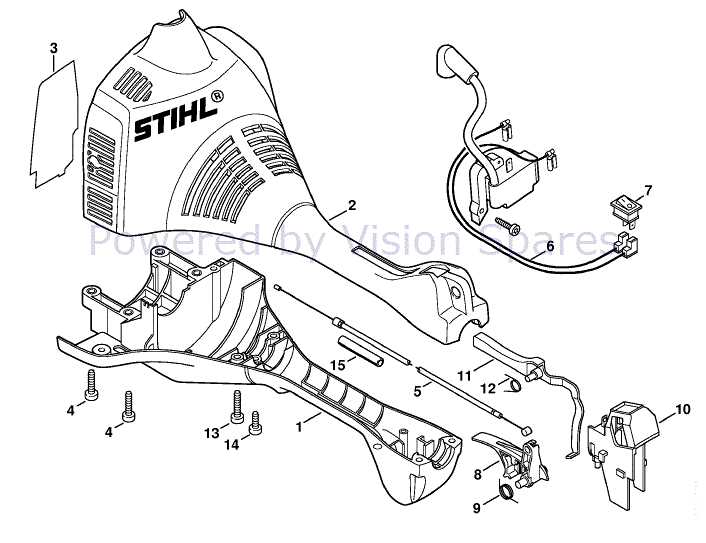

Importance of Accurate Parts Diagram

Having a precise visual representation of components is essential for effective maintenance and repair tasks. This clarity not only enhances the understanding of how different elements fit together but also streamlines the process of identifying issues. A reliable guide can significantly reduce the chances of errors during assembly or disassembly.

Utilizing an accurate schematic allows users to easily pinpoint necessary components, ensuring that replacements are made with the correct specifications. This ultimately improves the overall functionality and longevity of the equipment. Moreover, it fosters confidence in the user’s ability to perform repairs independently.

In conclusion, a detailed illustration serves as a vital tool for anyone engaged in upkeep, making the entire process more efficient and effective. Without it, the risk of miscommunication and mistakes increases, leading to potential downtime or further damage.

Common Issues and Solutions

In any mechanical equipment, users often encounter a variety of challenges that can hinder performance. Recognizing these common problems and understanding how to address them can greatly enhance the longevity and efficiency of the machine. Below are frequent issues and their respective solutions to help maintain optimal functionality.

Frequent Problems

| Issue | Solution |

|---|---|

| Engine won’t start | Check the fuel level and ensure fresh fuel is being used. Inspect the spark plug for damage and clean or replace it as needed. |

| Unusual vibrations | Examine all components for loose parts or misalignment. Tighten bolts and check for worn-out elements that may need replacement. |

| Reduced power output | Clean or replace the air filter to ensure proper airflow. Inspect the fuel lines for clogs or leaks. |

| Excessive smoke | Check the oil level and ensure it is not overfilled. Inspect the engine for any signs of damage or wear that could contribute to this issue. |

Maintenance Tips

Regular maintenance is crucial to preventing these issues. Always refer to the user manual for specific recommendations on upkeep. Keeping the equipment clean and ensuring all parts are functioning correctly can significantly minimize the likelihood of problems arising.

How to Use the Diagram Effectively

Utilizing a visual representation of components can greatly enhance your understanding and maintenance of equipment. By familiarizing yourself with this tool, you can streamline the identification of parts and improve the efficiency of repairs or replacements.

Here are some tips to maximize its utility:

| Step | Description |

|---|---|

| 1 | Examine the layout closely to understand the relationships between various elements. |

| 2 | Highlight or mark essential parts that require attention during your tasks. |

| 3 | Cross-reference with your equipment manual for additional specifications and guidelines. |

| 4 | Keep a copy handy while working to easily locate and manage components. |

Where to Find Replacement Parts

When it comes to maintaining your outdoor equipment, sourcing quality components is essential for optimal performance. Knowing where to look can save time and ensure you get the right items to keep your machinery running smoothly.

Authorized Dealers

Visiting certified retailers is one of the most reliable options. They typically offer genuine replacements, ensuring compatibility and durability. These establishments often have knowledgeable staff who can assist with specific inquiries.

Online Marketplaces

Another excellent avenue is exploring e-commerce platforms. Many websites specialize in outdoor machinery, providing a wide range of options. Always check reviews and seller ratings to confirm the authenticity and quality of the offerings.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your equipment involves a combination of regular upkeep and careful handling. By implementing best practices, you can enhance performance and reduce the likelihood of costly repairs. Below are essential tips to keep your tools in optimal condition.

Regular Cleaning

Maintaining cleanliness is crucial for any machinery. Dirt and debris can lead to overheating and diminished efficiency. After each use, take the time to remove any accumulated residue. Use a soft brush or cloth to wipe down surfaces and ensure all moving parts are free from obstructions.

Scheduled Inspections

Performing routine checks allows you to identify potential issues before they escalate. Inspect key components such as filters, spark plugs, and blades for wear and tear. Keeping an eye on these elements will not only prolong the life of your equipment but also enhance safety during operation.

| Maintenance Task | Frequency |

|---|---|

| Clean air filter | Every 10 hours of use |

| Check spark plug | Every 25 hours of use |

| Inspect blades | After each use |

| Change oil | Every 50 hours of use |

By adhering to these guidelines, you can maximize the performance and reliability of your equipment, ensuring it serves you well for years to come.

Comparing KM55R to Similar Models

When evaluating outdoor power equipment, it is essential to compare various models to identify the best fit for specific needs. Different devices may offer similar functionalities, but their specifications, design features, and performance capabilities can vary significantly. This section delves into a comparison of a particular model and its closest counterparts, highlighting key distinctions that can aid in decision-making.

Specifications Overview

| Model | Engine Power (cc) | Weight (lbs) | Fuel Capacity (L) | Cutting Width (in) |

|---|---|---|---|---|

| Model A | 25.4 | 10.5 | 0.55 | 16 |

| Model B | 27.2 | 11.0 | 0.60 | 18 |

| Model C | 24.5 | 9.5 | 0.50 | 15 |

| Model D | 26.0 | 10.0 | 0.65 | 17 |

Performance Analysis

Beyond mere specifications, the operational efficiency of each model is critical for users seeking reliability and effectiveness. Factors such as ease of use, vibration levels, and fuel efficiency can greatly influence user experience. A deeper investigation into user reviews and expert assessments often reveals preferences for specific models based on comfort and usability, making these aspects just as important as raw data when making a choice.

User Experiences and Reviews

This section aims to capture the insights and feedback from users regarding their encounters with a popular outdoor tool. Personal experiences can provide invaluable information, shedding light on both the strengths and weaknesses of the equipment, enabling potential buyers to make informed decisions.

Many users highlight the ease of use and versatility of the device, noting its ability to handle various tasks efficiently. Customers often appreciate how lightweight the tool is, which makes extended usage more comfortable.

However, some reviews point out certain limitations, such as occasional performance issues under heavy workloads. Users recommend regular maintenance to ensure optimal functionality, emphasizing the importance of proper care.

Overall, the feedback presents a balanced view, allowing prospective owners to delve into real-world applications and gauge whether this tool aligns with their needs.