The smooth operation of any mechanical device relies on the seamless interaction of its internal components. A detailed understanding of how each element fits together is essential for maintaining the efficiency and longevity of the equipment. This section provides insights into the key mechanisms involved in the system, highlighting the crucial connections and their roles in overall functionality.

Each mechanical part serves a distinct purpose, contributing to the overall performance of the tool. Whether it’s the driving force behind the movement or the supporting elements ensuring precision, recognizing these functions is vital for anyone involved in maintenance or repairs. In this guide, we will explore the various elements that come together to create a cohesive and powerful machine.

By breaking down the system into individual components, this section aims to offer a clear and comprehensive look at the structure and workings. This knowledge is not only beneficial for professionals but also for those looking to enhance their understanding of mechanical systems and how to keep them running smoothly.

Stihl MS250 Chainsaw Overview

This versatile cutting tool is designed to handle a variety of tasks with efficiency and reliability. Engineered for both homeowners and professionals, it strikes a balance between power and ease of use. The model is ideal for tasks ranging from clearing storm debris to regular maintenance of large properties.

What sets this equipment apart is its combination of durability and user-friendly design. It features a robust motor that provides ample performance for demanding work, yet remains compact enough to ensure comfort during prolonged use. Its features also enhance safety and reduce fatigue, making it a popular choice among those who need a reliable cutting solution.

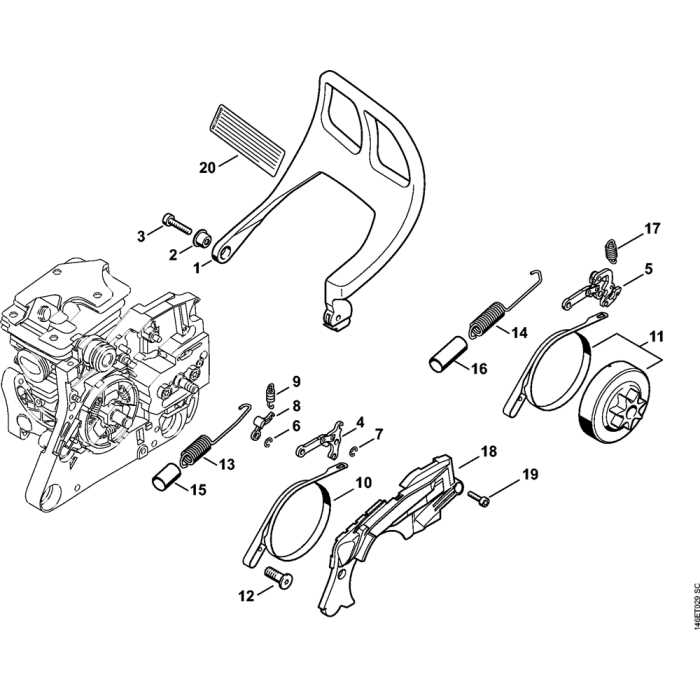

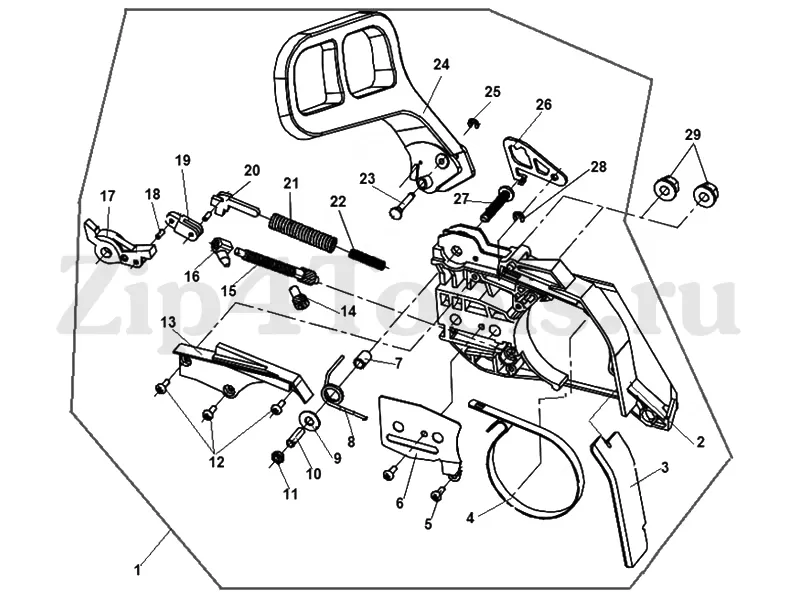

Key Components of the MS250 Chainsaw

Understanding the essential elements of this power tool helps ensure its efficient use and longevity. Each section of the device plays a crucial role in performance, from controlling the engine to guiding the cutting mechanism. Below, we will explore the main elements that contribute to the functionality and durability of this equipment.

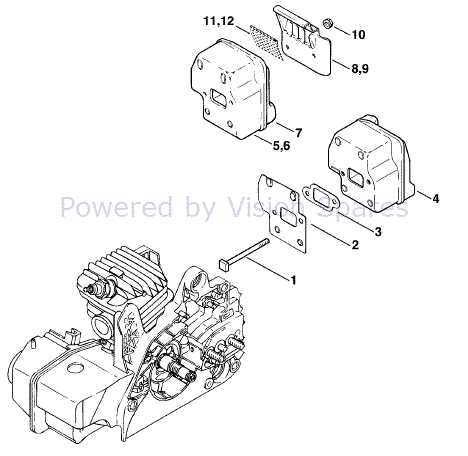

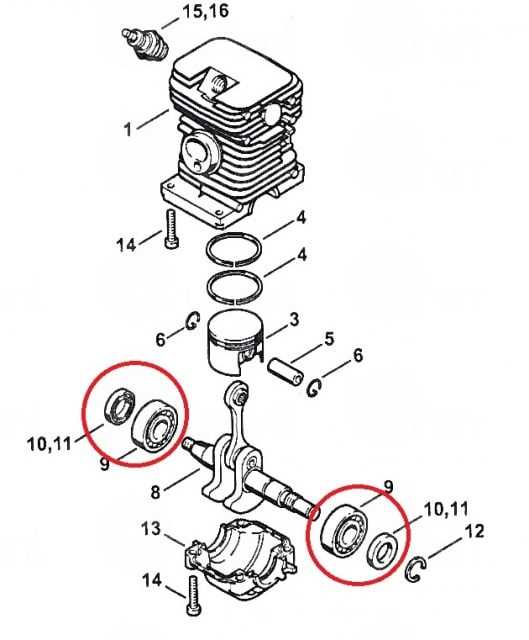

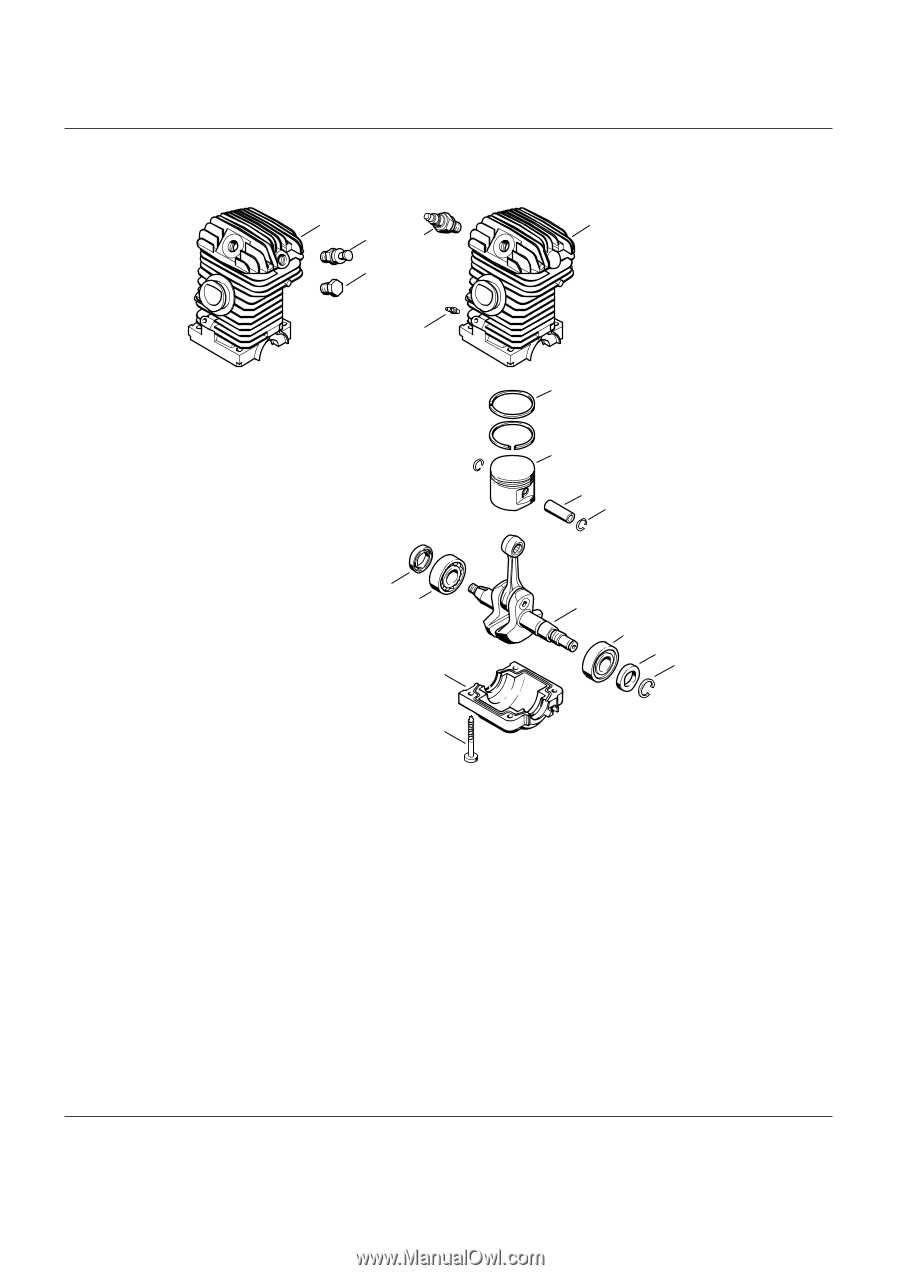

Engine Assembly

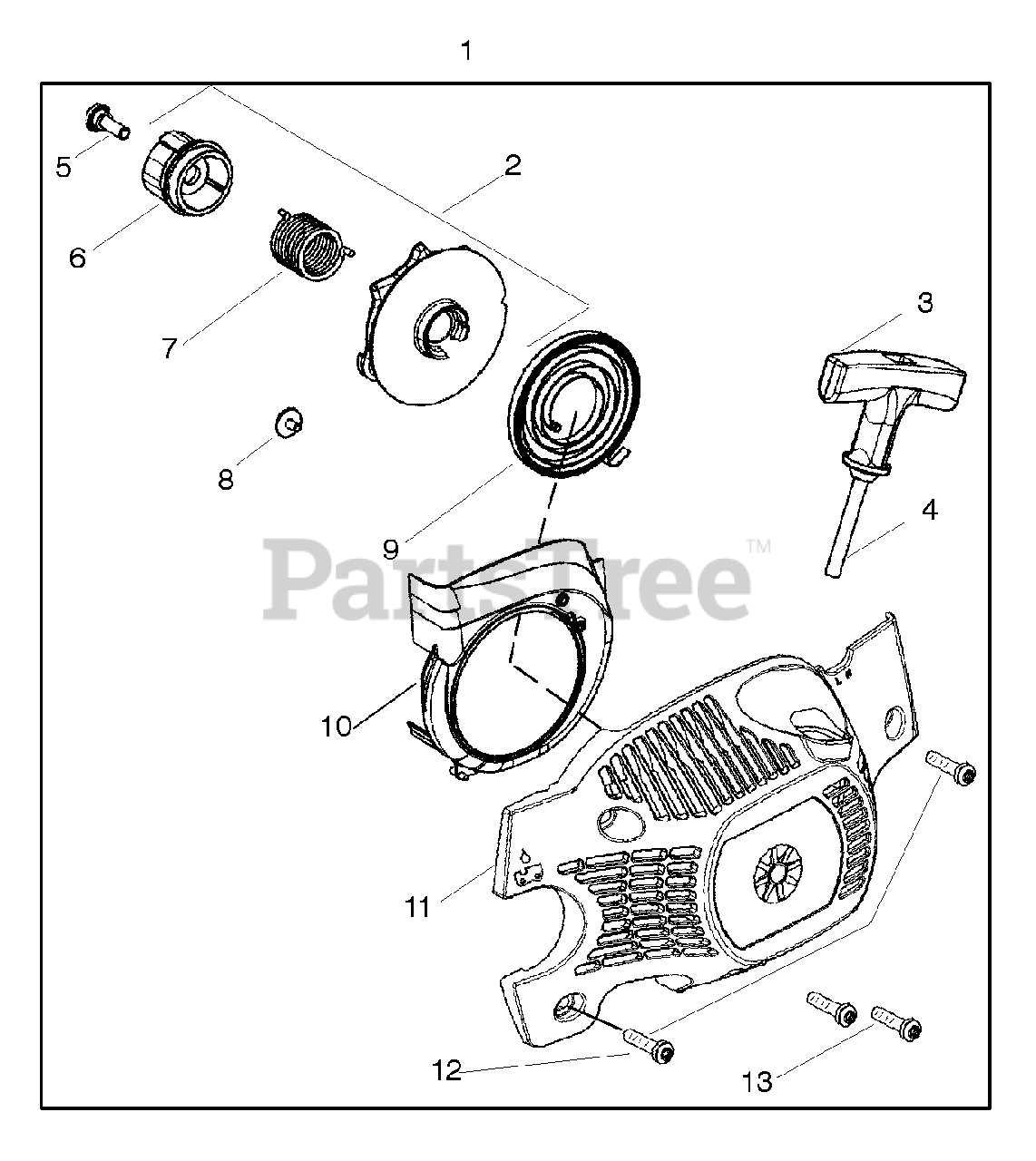

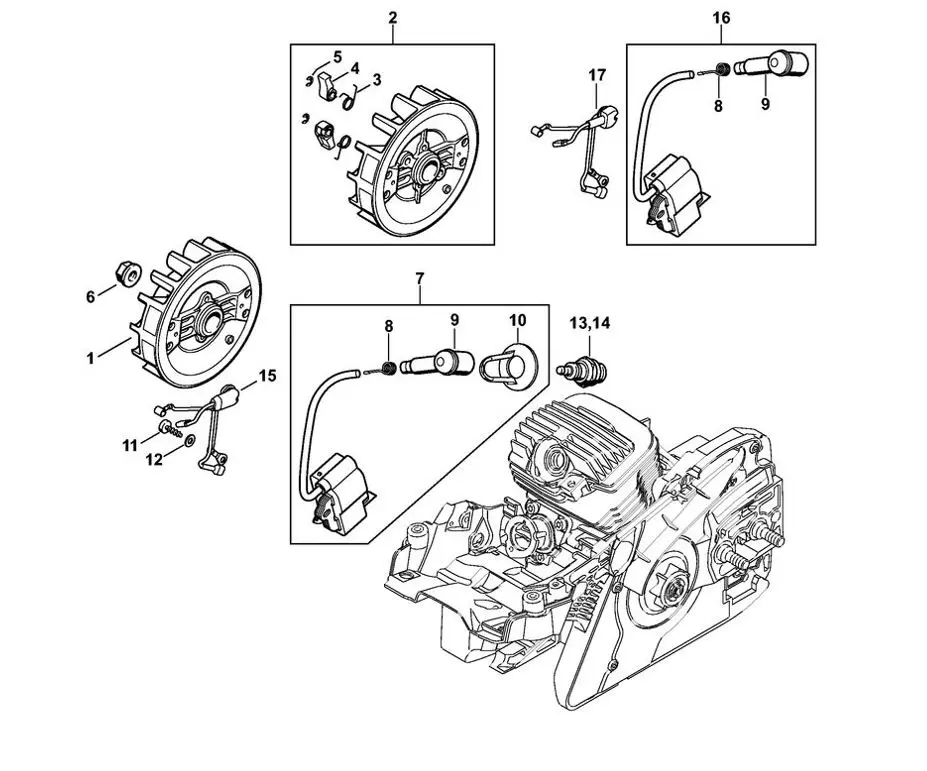

The heart of the tool is its motor. This part provides the power needed to drive the cutting motion. Proper maintenance of the motor is essential for reliable operation and minimizing wear over time.

Guide Bar and Chain

The cutting system is composed of a sturdy guide bar and a fast-moving chain. These components work together to make precise cuts through wood. The guide bar supports the chain, while the chain’s sharp teeth perform the actual cutting.

| Component | Function |

|---|

| Component | Function |

|---|---|

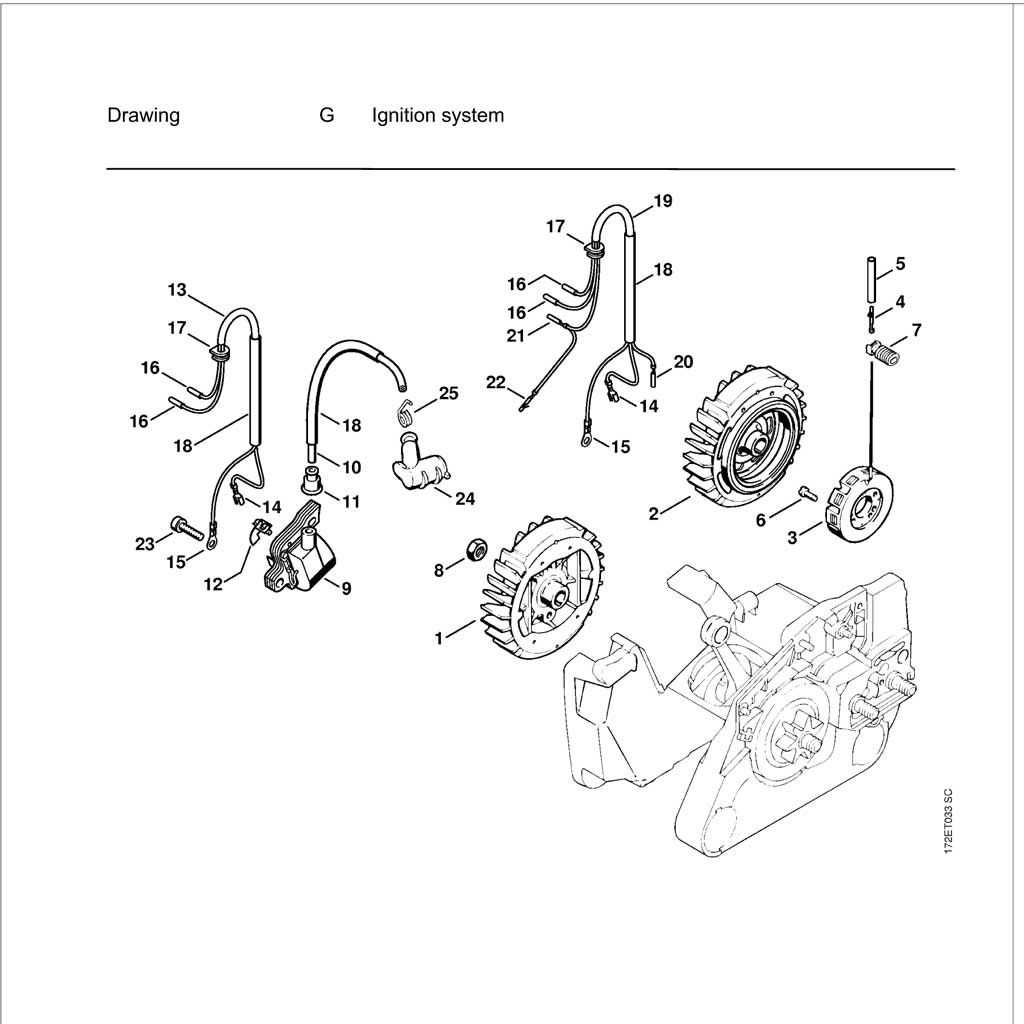

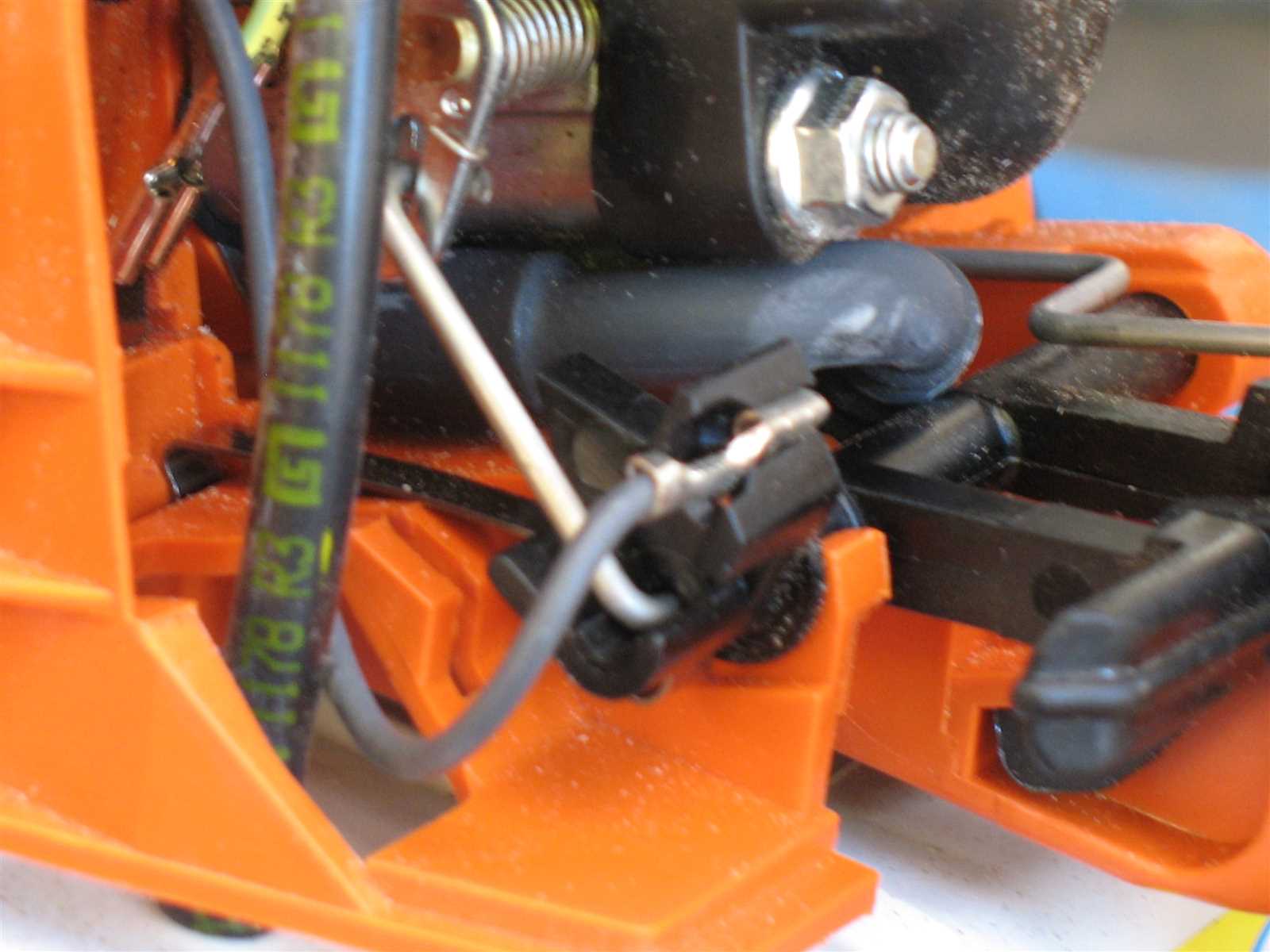

| Ignition Coil | Transforms low voltage into the high voltage needed to create the spark. |

| Spark Plug | Produces the spark necessary to ignite the fuel mixture in the combustion chamber. |

| Flywheel | Generates the initial electrical charge by interacting with the ignition coil. |

Kill

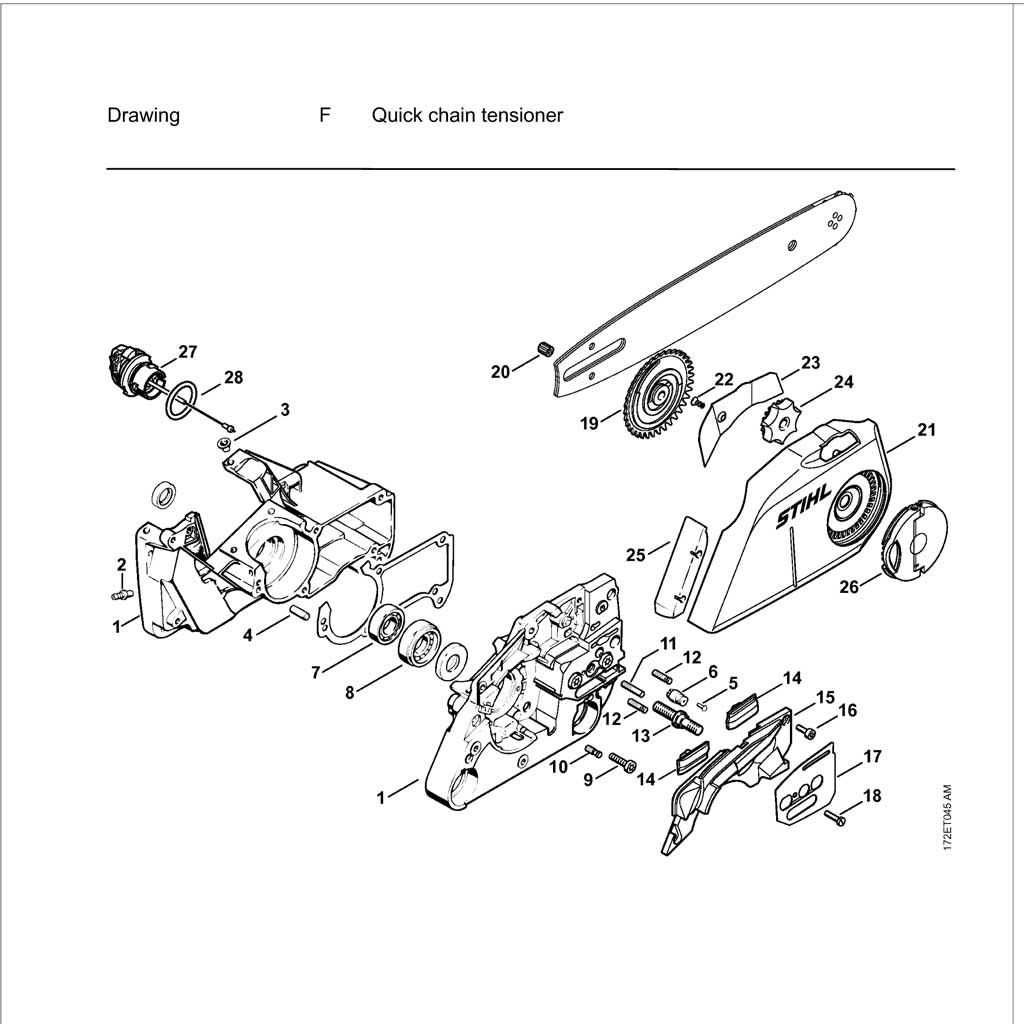

Guide Bar and Chain Mechanism

The guide bar and chain system plays a critical role in ensuring smooth and efficient cutting. This component combination allows for proper control and functionality, helping users maintain precision during operation. Understanding how these elements work together is essential for maintaining performance and safety. Key Components of the Mechanism

The guide bar supports the chain and directs it along its path. Typically made of durable metal, it must remain straight and properly aligned for accurate cutting. The chain itself consists of a series of sharp teeth that move around the bar, powered by the engine, allowing it to cut through wood or other materials. Proper tension and lubrication of the chain are vital for optimal operation. Maintenance and Safety Tips

Regular inspection of the guide bar and chain is necessary to avoid wear and damage. Sharpening the chain teeth and ensuring the bar remains in good condition will prevent accidents and improve performance Carburetor and Fuel Delivery System

The carburetor and fuel delivery mechanism play a crucial role in the overall performance and efficiency of the engine. This system is responsible for mixing air and fuel in the appropriate ratio, ensuring optimal combustion and power generation. A well-functioning carburetor not only enhances the engine’s responsiveness but also contributes to its longevity. At the core of this system, the carburetor utilizes various components, including jets, floats, and diaphragms, to regulate fuel flow. Jets control the amount of fuel entering the mixing chamber, while floats maintain the correct fuel level. The diaphragm ensures that the fuel is delivered consistently as the engine operates under different loads. Proper maintenance of this system is essential for preventing issues such as flooding or insufficient fuel supply. Regular cleaning and inspection of the carburetor components can help avoid performance problems and keep the engine running smoothly. Attention to detail in the fuel delivery system can significantly impact the overall efficiency and reliability of the engine. Maintenance Tips for MS250 Chainsaw Parts

Proper upkeep of your cutting tool is essential for ensuring optimal performance and longevity. Regular maintenance not only enhances efficiency but also minimizes the risk of unexpected breakdowns. Following a systematic approach to care can greatly improve the reliability of your equipment. Regular Cleaning

Keeping the exterior clean is crucial to prevent dirt and debris from accumulating, which can lead to potential issues. Use a soft brush or cloth to remove any residue from the housing, ensuring that air vents are clear to promote effective cooling during operation. Regular cleaning of the air filter is also important, as it prevents clogging and maintains proper airflow. Lubrication and Inspection

Consistent lubrication of moving components is vital to reduce friction and wear. Apply appropriate oils to gears and bearings according to the manufacturer’s recommendations. Additionally, conducting routine inspections of all mechanical elements helps identify wear and tear early. Check for any loose connections, cracks, or other signs of damage, as addressing these issues promptly can prevent further complications. Common Issues and Replacement Parts

Every machine can experience challenges over time, and understanding these common problems can significantly enhance its performance and longevity. Recognizing signs of wear and tear, along with knowing which components to replace, is essential for maintaining optimal functionality. Below are some frequent issues encountered with power equipment and the associated replacement components:

Addressing these common issues with the appropriate replacements can lead to improved efficiency and a longer lifespan for your equipment. |